Factory Automation Market Overview, 2031

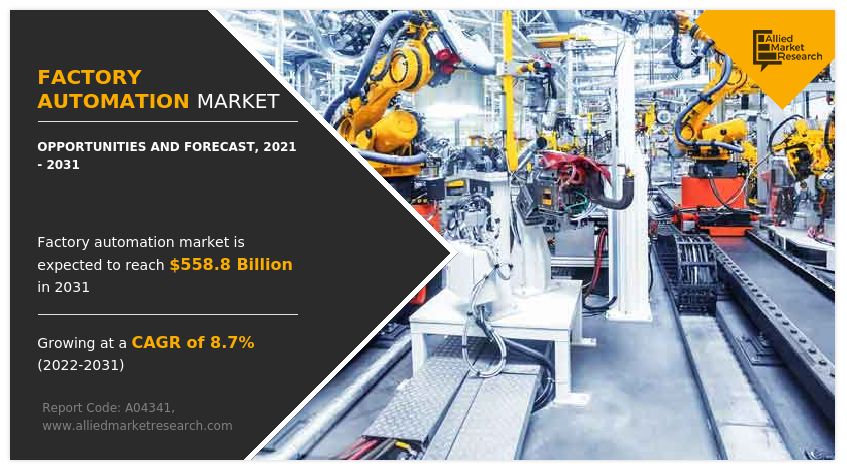

The global factory automation market was valued at $242.5 billion in 2021 and is projected to reach $558.8 billion by 2031, growing at a CAGR of 8.7% from 2022 to 2031. According to Himanshu Jangra Lead Analyst, Semiconductor and Electronics, at Allied Market Research, the factory automation market is expected to showcase remarkable growth during the forecast period of 2022-2031. The report contains a thorough examination of the market size, factory automation market trends, key market players, sales analysis, major driving factors, and key investment pockets. The report on the factory automation market provides an overview of the market as well as market definition and scope.

The ongoing technological advancements and surge in demand for control and safety systems have an impact on market growth. Furthermore, the report provides a quantitative and qualitative analysis of the factory automation market, as well as a breakdown of the pain points, value chain analysis, and key regulations. Factory automation implies to a set of technologies & automatic control devices that enhance the productivity & quality of products and simultaneously decrease the production cost. Also known as industrial automation, it minimizes human intervention in the industry and ensures superior performance as compared to humans. It comprises the use of computers, robots, control systems, and information technologies to handle industrial processes.

The development of 5G wireless technology and the adoption of industry 4.0 drive the demand for factory automation solutions in a variety of industries, including fiber & textiles, infrastructure, plastics, pharmaceuticals, and others. Digitalization, industrial IoT, and digital twin expansion are anticipated to be the key trends in the factory automation industry. The Internet of Things (IoT) is essential to automation technology as it facilitates the development of efficient, cost-efficient, and responsive system architectures. Solutions for the industrial internet of things (IIoT) help connect industrial assets, rapidly & simply generate transparency, and boost efficiency. The full lifecycle of device management and shop floor software is made simpler by IIoT and edge computing solutions. In order to automate the manufacturing process and improve the customer experience, businesses implement IIoT technologies. IIoT solutions are anticipated to be adopted so quickly across industries, which would help the market grow during the forecast period.

Industrial IoT solutions such as factory robotics and automated manufacturing equipment use sophisticated analytics, edge computing, cloud computing, artificial intelligence (AI), and machine learning to evaluate machine data and gain insightful knowledge that can be used to maximize asset availability and productivity. For instance, IndustrialEdge, MindSphere, and Mendix from Siemens are industrial IoT solutions that deliver insights from industrial data using cutting-edge technologies such as AI, edge computing, cloud, and advanced analytics. Schmalz, a manufacturer of vacuum automation and ergonomic handling solutions makes use of Siemens Industrial IoT's capabilities to improve its extended analytics and customer maintenance offerings. Therefore, this continued growth of Industrial IoT across industries is expected to drive factory automation market expansion during the forecast period..

The global factory automation market is expected to witness notable growth during the forecast period, owing to an increase in demand for automation for qualitative and reliable manufacturing. Moreover, the industry players are focusing on increasing the efficiency of the manufacturing process to achieve low-cost and high-quality production results, which majorly drives the factory automation market. Furthermore, an increase in the adoption of industry 4.0 revolutions is projected to shape the future of manufacturing industries by standardizing the processes.

However, the limited availability of professionals and awareness regarding security, and the high costs for implementation of factory automation systems are one of the prime factors that restrain the factory automation market growth. An increase in demand for automation in Asian countries such as China and Japan is projected to provide a lucrative opportunity to expand the factory automation market during the forecast period.

Segment Overview

The factory automation market is segmented into Components, Control and Safety Systems, and Industry Verticals,

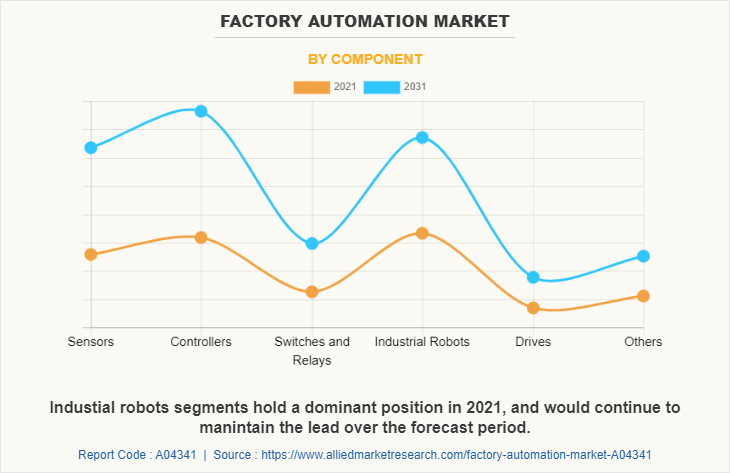

On the basis of components, the factory automation market is divided into sensors, controllers, switches & relays, industrial robots, drives, and others. In 2021, the industrial robots segment dominated the market in terms of revenue and is expected to follow the same trend during the forecast period.

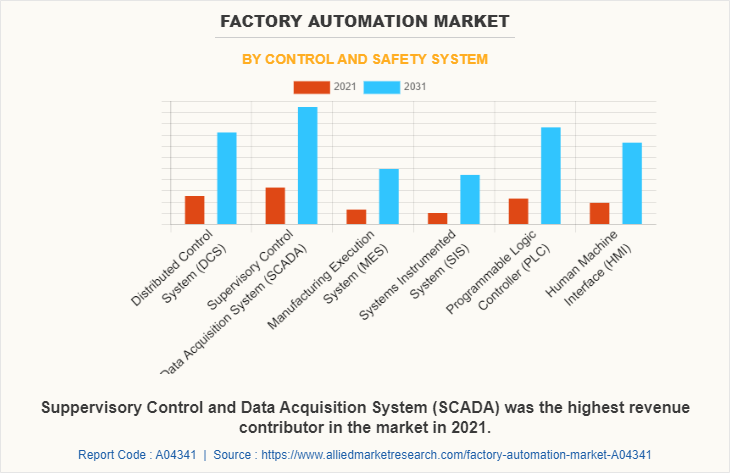

By control and safety systems, the market is classified into Distributed Control System (DCS), Supervisory Control and Data Acquisition System (SCADA), Manufacturing Execution System (MES), Systems Instrumented Systems (SIS), Programmable Logic Controller (PLC), and Human Machine Interface (HMI). The Supervisory Control and Data Acquisition System (SCADA) segment dominated the factory automation industry in 2021 in terms of revenue and is expected to dominate the market during the forecast period.

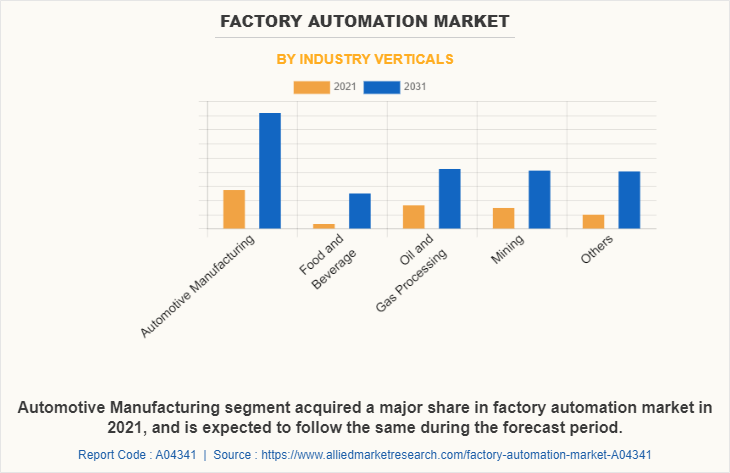

On the basis of industry vertical, the factory automation market is divided into automotive manufacturing, food & beverage, oil & gas processing, mining, and others. In 2021, the automotive manufacturing segment dominated the market in terms of revenue and is expected to follow the same trend during the forecast period.

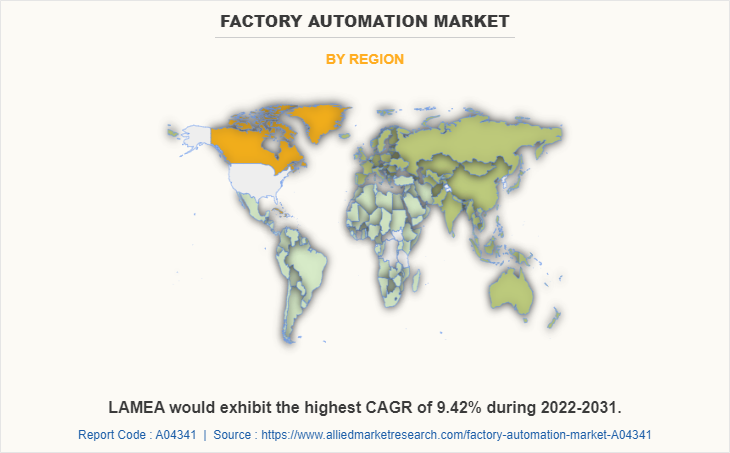

Region-wise, the factory automation market trends are analyzed across North America (the U.S., Canada, and Mexico), Europe (UK, France, Germany, and Rest of Europe), Asia-Pacific (China, India, Japan, South Korea, and Rest of Asia-Pacific), and LAMEA (Latin America, Middle East, and Africa). Europe remains a significant participant in the factory automation market forecast. Major organizations and government institutions in the country are intensely putting resources into technology.

Competitive Analysis

Competitive analysis and profiles of the major global Factory automation market players that have been provided in the report include, ABB Ltd, Danaher Industrial Ltd, Emerson Electric Co., General Electric, Honeywell International Inc., Mitsubishi, Electric Corporation, OMRON Corporation, Rockwell Automation Inc., Schneider Electric, Siemens AG and Yokogawa Electric Corporation.

Country Analysis

Country-wise, the U.S. acquired a prime share in the factory automation market overview in the North American region and is expected to grow at a high CAGR of 8.01% during the forecast period of 2022-2031. The U.S. holds a dominant position in the factory automation market, owing to the rise in investment by prime vendors to boost automation solutions.

In Europe, Germany dominated the factory automation market in terms of revenue in 2021 and is expected to follow the same trend during the forecast period. Furthermore, Germany is expected to emerge as the fastest-growing country in Europe's factory automation with a CAGR of 6.39%, owing to a significant development in Industrial IoT, in the country.

In Asia-Pacific, Japan is expected to emerge as a significant market for factory automation, owing to a significant rise in investment by prime players in next-generation automation solutions to boost the factory automation market.

In LAMEA, Latin America garnered a significant factory automation market share in 2021 owing to the presence of prime vendors such as ABB Ltd, Middle East Builders Mechanical Group, and others that are significantly investing in factory automation in Latin America. Moreover, the Middle East region is expected to grow at a high CAGR of 9.79% from 2022 to 2031.

Top Impacting Factors

Due to the rising demand for automation for high-quality and dependable production, the factory automation market is anticipated to expand significantly over the course of the forecast period. Additionally, industry participants are concentrating on enhancing the manufacturing process efficiency to achieve low-cost and high-quality production outputs, which significantly fuel the factory automation market size. The future of manufacturing industries is also expected to be influenced by the increased use of industry 4.0 revolutions, which will standardize operations. One of the main constraints limiting the growth of the factory automation market is the lack of professionals, lack of security awareness, and high implementation costs for factory automation systems. The rise in automation demand in Asian nations like China and Japan will present lucrative opportunities for prime vendors operating in this region.

Historical Data & Information

The factory automation market is highly competitive, owing to the strong presence of existing vendors. Vendors of factory automation machines with extensive technical and financial resources are expected to gain a competitive advantage over their competitors because they can cater to market demands. The competitive environment in this market is expected to increase as technological innovations, product extensions, and different strategies adopted by key vendors increase.

Key Developments/ Strategies

ABB Ltd, Rockwell Automation Inc., Siemens AG, Emerson Electric Co., and Mitsubishi Electric Corporation are the top 5 companies holding a prime share in the factory automation market. Top market players have adopted various strategies, such as product launch, partnerships, innovation, and product development, to expand their foothold in the factory automation market.

- In November 2020, Rockwell automation launched a new version in asset management software i.e Factory Talk Asset Centre Software. The newly developed software helps to ease the workflow and manage and development of the new devices.

- In February 2021, ABB introduced cobots portfolio in GoFa and SWIFTI cobots. Cobots allow the high capacity and help the robots with their movements.

- In June 2021, Rockwell Automation Inc. acquired Plex Systems, a smart manufacturing solution provider, for USD 2.22 billion. The acquisition aims to expand industrial cloud offerings with Plex Systems’ cloud-native smart manufacturing platform

- In July 2021, Rockwell Automation Inc. collaborated with a cloud-based product digitalization and traceability platform, Kezzler AS. The partnership aims to enable manufacturers to capture their product's end-to-end journey from raw material sources to the point of sale or beyond by using cloud-based chain solutions.

- In July 2021, Siemens AG expanded its partnership with SAP SE to deliver a new solution for services and asset lifecycle management. The partnership aims to connect plant floor operations, product development through digital twins, and remote condition monitoring with original equipment manufacturers (OEMs) to facilitate collaboration across the asset lifecycle.

- In May 2022, Emerson announced the release of its PACSystems RSTi-EP CPE 200 programmable automation controllers (PAC). The new family of compact PACs helps OEMs successfully meet customer requirements by minimizing the need for specialized software engineering talent.

- In June 2022, Mitsubishi Electric Corporation announced that it would invest around INR 2.2 billion in its subsidiary Mitsubishi Electric India Pvt. Ltd. to establish a new factory in India. The company is expected to start factory operations in December 2023, with the factory manufacturing inverters and other factory automation (FA) control system products, expanding the company's capabilities to meet the growing demand in India

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the factory automation market analysis from 2021 to 2031 to identify the prevailing factory automation market opportunities.

- Market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights buyers' and suppliers' potency to enable stakeholders to make profit-oriented business decisions and strengthen their supplier-buyer network.

- An in-depth analysis of the factory automation market segmentation assists in determining the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes an analysis of regional and global factory automation market trends, key players, market segments, application areas, and market growth strategies.

Factory Automation Market Report Highlights

| Aspects | Details |

| Market Size By 2031 | USD 558.8 billion |

| Growth Rate | CAGR of 8.7% |

| Forecast period | 2021 - 2031 |

| Report Pages | 328 |

| By Industry Verticals |

|

| By Component |

|

| By Control and Safety System |

|

| By Region |

|

| Key Market Players | Rockwell Automation Inc., General Electric, Yokogawa Electric Corporation, Schneider Electric, Danaher, Siemens AG, Mitsubishi Electric Corporation, Honeywell International Inc., Emerson Electric Co., OMRON Corporation, ABB Ltd |

Analyst Review

Factory automation enhances the efficiency of the industrial and manufacturing process by ensuring superior quality consistent products while decreasing human intervention. Nowadays, increasing adoption of the industry 4.0 trend and enabling technologies among companies have augmented the demand for factory automation. Moreover, the rise in demand for mass production with reduced operational costs acts as the major driver of the factory automation market. However, the limited availability of industry professionals and the higher investment associated with the implementation of factory automation systems are a major hindrance to this market.

The leading players in this market have adopted various strategies to sustain the market competition. Some have innovative new technologies and systems to expand the portfolio of factory automation systems and have witnessed significant market growth. In LAMEA, some major players acquired small businesses and expanded their offering, for instance, ABB acquired Bernecker & Rainer Industrie-Electronik (B&R), a provider of open architecture solutions and software for machine and factory automation, to counteract Siemens AG’s prowess in the industry. Industrial control systems are interconnected to monitor control and perform various industrial tasks and automate processes. Asia-Pacific is expected to witness higher growth during the forecast period due to the proliferating of manufacturing industries in this region. The key players in the global factory automation market include ABB Ltd, Danaher Industrial Ltd, Emerson Electric Co., General Electric, Honeywell International Inc., Mitsubishi, Electric Corporation, OMRON Corporation, Rockwell Automation Inc., Schneider Electric, Siemens AG, and Yokogawa Electric Corporation. Market players have implemented product launch and acquisition answer key development strategies to keep pace with the demands of end users. This enables companies to develop efficient products in multiplying their sales across different geographies

Asia-Pacific is the largest regional market for Factory Automation.

In 2021, the automotive manufacturing segment dominated the market in terms of revenue and is expected to follow the same trend during the forecast period,

The global factory automation market was valued at $242.5 billion in 2021 and is projected to reach $558.8 billion by 2031, registering a CAGR of 8.67% from 2022 to 2031.

The future of manufacturing industries is also expected to be influenced by the increased use of industry 4.0 revolutions, which will standardize operations. One of the main constraints limiting the growth of the factory automation market is the lack of professionals, lack of security awareness, and high implementation costs for factory automation systems.

ABB Ltd, Danaher Industrial Ltd, Emerson Electric Co., General Electric, Honeywell International Inc., Mitsubishi, and Electric Corporation are the top companies to hold the market share in Factory Automation.

Loading Table Of Content...