Metal Abrasives Market Outlook - 2032

The global metal abrasives market size was valued at $6.2 billion in 2022, and is projected to reach $9.6 billion by 2032, growing at a CAGR of 4.6% from 2023 to 2032.

Report Key Highlighters:

- The metal abrasives market study covers 20 countries. The research includes a segment analysis of each country in terms of both value ($million) and volume (kilotons) for the projected period 2023-2032.

- The study integrated high-quality data, professional opinions and analysis, and critical independent perspectives. The research approach is intended to provide a balanced view of global markets and to assist stakeholders in making educated decisions in order to achieve their most ambitious growth objectives.

- Over 3,700 product literatures, annual reports, industry statements, and other comparable materials from major industry participants were reviewed to gain a better understanding of the market.

- The metal abrasives market is highly fragmented, with several players including 3M Company, AirBlast-Abrasives B.V., Camel Grinding Wheels Works Sarid Ltd., Ervin Industries, Finishing Systems, Inc., KLINGSPOR Abrasives, Inc., Metaltec Steel Abrasive Co., Noritake Co., Ltd., Saint-Gobain, and W Abrasives. Also tracked key strategies such as acquisitions, product launches, mergers, expansion etc. of the players operating in metal abrasives market.

Metal abrasives are hard and sharp materials that are used to shape, finish, and clean metal surfaces. They are widely used in various industries, including automotive, aerospace, construction, and manufacturing. Abrasives are available in various forms such as grains, powders, pastes, and slurries. Metal abrasives are made from various materials such as aluminum oxide, silicon carbide, diamond, and cubic boron nitride. The use of metal abrasives can improve the quality and durability of metal products. The use of abrasives in the production of gears can improve their wear resistance, reduce noise, and increase their lifespan. Metal abrasives can also be used to create a variety of surface finishes, from matte to highly polished.

Metal Abrasives is a versatile abrasive that can be used on a wide range of metals, while diamond is an extremely hard abrasive that is ideal for cutting and shaping hard materials. Silicon carbide is a popular abrasive for grinding and polishing, while cubic boron nitride is used for cutting and shaping hard metals such as titanium and hardened steels.

The size and shape of the abrasive particles also play a role in the final surface finish. Fine-grit abrasives are used for finishing and polishing, while coarse-grit abrasives are used for rough shaping and removal of material. The shape of the abrasive particles can also impact the final finish, with irregular shapes creating a more random finish and uniform shapes creating a more consistent finish. The advantage of metal abrasives is their ability to produce a consistent finish. Metal abrasives are available in a wide range of sizes and shapes, allowing them to be used for a variety of applications. They are particularly useful for removing burrs and other imperfections from metal surfaces.

Iron oxide is a versatile metal abrasive that has many applications beyond just cleaning and removing rust from surfaces. One of its most common uses is in the production of pigments. Iron oxide pigments are used in a wide range of products, from paint and coatings to plastics, ceramics, and paper. Iron oxide pigments come in a variety of colors, including red, yellow, brown, and black. The color of the pigment is determined by the size and shape of the iron oxide particles. For instance, smaller particles produce a more intense color, while larger particles produce a more muted color.

Steel shot is a type of metal abrasive that is made from high-carbon steel. It is used for cleaning and peening surfaces, as well as for shot blasting. Steel shot is also used in wheel blasting and air blasting applications. In shot blasting, steel shot is propelled at high speeds onto the surface being treated, which removes rust, scale, and other contaminants. The force of the steel shot also creates a surface texture that improves adhesion for subsequent treatments.

Steel grit is commonly used for cutting and grinding surfaces, particularly in applications where a more aggressive abrasive material is required. Its sharp edges allow it to remove surface materials more effectively than rounded abrasives like steel shot. One advantage of steel grit over other types of abrasives is its ability to be recycled and reused multiple times, which can help reduce costs and environmental impact. However, it is important to properly dispose of used steel grit to avoid environmental damage.

Metal abrasives can be hazardous if not handled correctly. They can cause eye and respiratory irritation, as well as skin irritation if they come into contact with the skin. It is important to wear appropriate protective equipment, such as gloves, eye protection, and a respirator, when using metal abrasives.

Increase in demand for aerospace industry drives the growth of the metal abrasives market during the forecast period.

The aerospace industry is relying heavily on precision manufacturing and high-quality materials to produce aircraft components that meet strict safety and performance standards. Metal abrasives are used for grinding, polishing, and shaping metal surfaces to ensure their performance and longevity. Boeing forecasts that there will be a demand for more than 43,500 new airplanes valued at $7.2 trillion by 2040, where metal abrasives are gaining popularity in glass beads, silicon carbide, and garnet. Metal components in the aerospace industry often have sharp edges or burrs that need to be removed to ensure the smooth functioning of the parts. Metal abrasives such as ceramic beads, aluminum oxide, and diamond powder are commonly used for deburring in the aerospace industry.

However, health hazards with respect to metal abrasives are expected to hinder the growth of the metal abrasives market during the forecast period. Metal abrasives, such as steel shot and grit, can pose several health hazards if not used properly. Metal particles can be inhaled by workers, causing respiratory problems such as asthma, lung damage, and metal fume fever. Skin irritation can occur through direct contact with the abrasive particles or through contact with contaminated clothing or equipment. Metal abrasives can also pose fire and explosion hazards, especially if they are used near flammable materials or in areas where there is a risk of sparks or ignition. Workers should wear protective clothing and gloves made from materials that are resistant to abrasion and avoid rubbing or scratching their skin while working with metal abrasives.

The metal abrasives market is segmented into material, type, end-use industry, and region. On the basis of materials type, the market is bifurcated into steel and others. As per type, the market is divided into coated abrasives, bonded abrasives, and super abrasives. Depending on end-use industry, the market is categorized into automotive, metalworking, building and constructions, machinery and equipment, and others. Region-wise the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

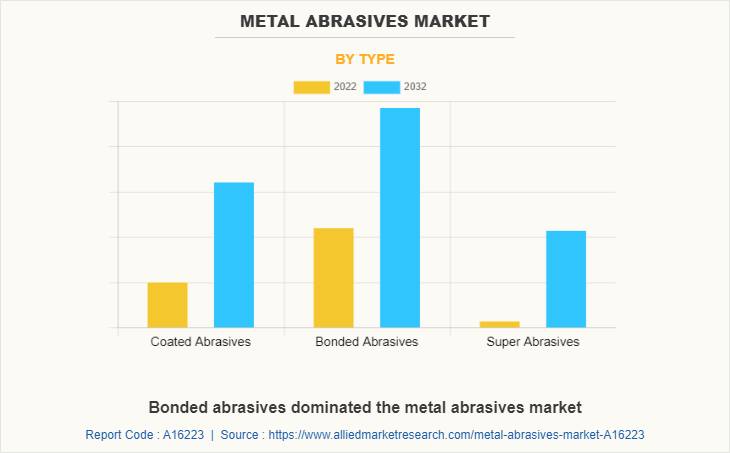

Metal Abrasives Market By Type

Bonded abrasives are commonly used in metal abrasives applications for grinding and finishing purposes. The bonding material in bonded abrasives plays a crucial role in holding the abrasive grain particles together, allowing them to effectively remove stock from the metal surface.

Vitrified wheels, which fall under the category of bonded abrasives, are specifically designed for precision grinding in the tool and die. These wheels excel in maintaining their shape and form even during demanding grinding operations. They are known for their exceptional ability to remove stock efficiently while minimizing wheel wear. This makes vitrified wheels highly effective for grinding and finishing hard materials such as metal and ceramic alloys.

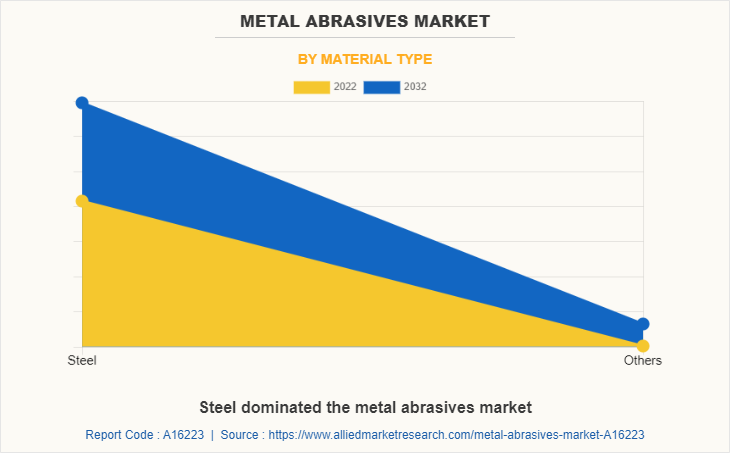

Metal Abrasives Market By Material Type

Metal abrasives are frequently employed in steel manufacturing for tasks like surface preparation, cleaning, deburring, polishing, and finishing. Their utilization in steel is mainly motivated by their remarkable hardness, toughness, and capacity to effectively work on challenging materials. They are particularly useful for polishing and finishing steel, such as stainless steel, to enhance its visual appeal and resistance to corrosion. Polishing wheels and abrasive belts are commonly employed to achieve a smooth and reflective surface on stainless steel products.

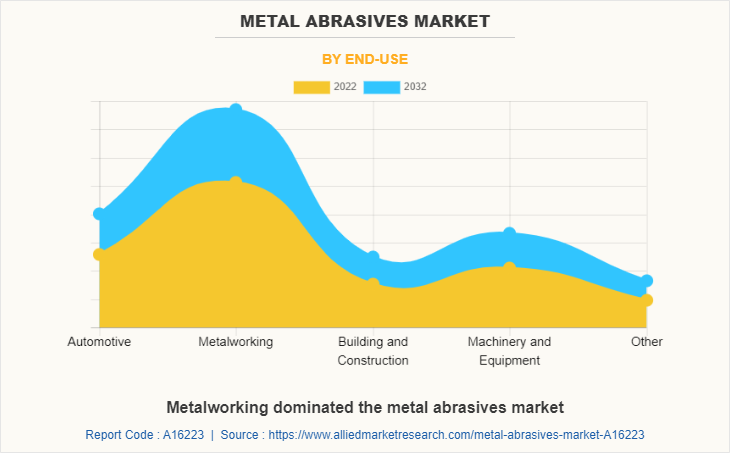

Metal Abrasives Market By End Use industry

Metal abrasives play a important role in metalworking by shaping, cutting, polishing, and refining metal surfaces. The specific application of metal abrasives depends on the type of abrasive and the desired outcome. Additionally, metal abrasives are utilized to generate a compressive stress layer on metal parts, enhancing their fatigue life and resistance to stress corrosion cracking.

Metal Abrasives Market By Region

Metal abrasives are utilized in Asia-Pacific countries to clean surfaces of various materials like concrete and steel, eliminating dirt, grime, and other contaminants. This cleaning process is essential for maintaining the cleanliness and appearance of buildings and infrastructure. Furthermore, metal abrasives are employed to achieve a consistent, appealing, and long-lasting finish on the surfaces of concrete, steel, and other materials. This contributes to enhancing the visual aesthetics and overall performance of buildings and infrastructure.

The major players operating in the metal abrasives market include 3M Company, AirBlast-Abrasives B.V., Camel Grinding Wheels Works Sarid Ltd., Ervin Industries, Finishing Systems, Inc., KLINGSPOR Abrasives, Inc., Metaltec Steel Abrasive Co., Noritake Co., Ltd., Saint-Gobain, and W Abrasives.

Historical Trends of Metal Abrasives:

- In 1910s, the first abrasive wheels for use in metalworking are invented. These wheels were made of abrasive materials such as silicon carbide or aluminum oxide, and were used for grinding, cutting, and finishing metal surfaces. They were initially used in hand-held grinders and later in larger industrial machines. These wheels revolutionized the metalworking industry, increasing efficiency and speed in shaping and polishing metal parts.

- In 1940s, shot blasting, a process for cleaning and preparing metal surfaces using small metal particles, becomes popular in the manufacturing industry. The process was developed in the 1930s but became more popular in the 1940s, particularly in the manufacturing industry. It is used to improve the fatigue life and surface hardness of metal parts by inducing compressive stresses in the surface layer.

- Abrasive blasting, also known as sandblasting, was recognized as a hazardous process in the 1980s due to the release of toxic dust particles such as silica into the air. This led to the development of safer abrasive blasting methods that use alternative blasting media, such as garnet or crushed glass, which do not release as many toxic dust particles.

- In 2010s, the use of robotic automation in abrasive processes becomes increasingly common in the manufacturing industry, improving efficiency and consistency.

- In 2015, the development of high-performance abrasive materials, such as zirconia alumina and ceramic grain, enables faster and more effective metal removal, reducing processing times and improving productivity.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the metal abrasives market analysis from 2022 to 2032 to identify the prevailing metal abrasives market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the metal abrasives market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global metal abrasives market trends, key players, market segments, application areas, and market growth strategies.

Metal Abrasives Market, by Type Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 9.6 billion |

| Growth Rate | CAGR of 4.6% |

| Forecast period | 2022 - 2032 |

| Report Pages | 350 |

| By End-Use |

|

| By Type |

|

| By Material Type |

|

| By Region |

|

| Key Market Players | Finishing Systems, Inc., Metaltec Steel Abrasive Co., Noritake Co., Ltd., 3M Company, W Abrasives, Air Blast-Abrasives B.V., Camel Grinding Wheels Works Sarid Ltd, Saint Gobain, KLINGSPOR Abrasives, Inc., Ervin Industries |

Analyst Review

According to the opinions of various CXOs of leading companies, the metal abrasives market is driven by rise in demand from steel industry. Steel abrasives offer several advantages such as high hardness, toughness, and durability, which make them effective for various applications. Steel shot and steel grit are two common types of metal abrasives made from steel.

The growing demand of metal abrasives for energy-efficient and lightweight materials drive the growth of metal abrasives market. Metal abrasives are used in aerospace, automotive, construction, and manufacturing to produce energy-efficient and lightweight materials. They are used for surface preparation, cleaning, and finishing of metallic components, which are key processes in the production of lightweight and energy-efficient materials.

However, the environmental impact of metal abrasives is expected to restrain industry expansion. Metal abrasives are typically made from steel, which is a non-renewable resource and can generate waste and pollutants. Manufacturers use recycled scrap metal as a raw material, reducing the need for new extraction of iron ore.

The Asia-Pacific region is projected to register robust growth during the forecast period. Metal abrasives are extensively utilized in industries including construction, automotive, marine, and manufacturing in Asia-Pacific countries. The construction sector, in particular, is a prominent user of metal abrasives in the region, employing them for surface preparation, cleaning, and finishing purposes in diverse building and infrastructure projects.

Increase in usage of metal abrasives in 3D printing and other advanced manufacturing technologies upcoming trends of Metal Abrasives Market in the world.

Increase in demand for aerospace industry, The growing demand for metal abrasives for energy-efficient and lightweight materials, and rise in demand for metal abrasives in the construction industry are the driving factor of Metal Abrasives Market.

Region-wise the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

Asia-Pacific is the largest region of Metal Abrasives Market.

The global metal abrasives market was valued at $6.2 billion in 2022, and is projected to reach $9.6 billion by 2032, growing at a CAGR of 4.6% from 2023 to 2032.

The leading end-use industry of Metal Abrasives Market includes automotive, metalworking, building and constructions, machinery and equipment, and others.

3M Company, AirBlast-Abrasives B.V., Camel Grinding Wheels Works Sarid Ltd., Ervin Industries, Finishing Systems, Inc., KLINGSPOR Abrasives, Inc., Metaltec Steel Abrasive Co., Noritake Co., Ltd., Saint-Gobain, and W Abrasives are the top companies to hold the market share in Metal Abrasives.

Loading Table Of Content...

Loading Research Methodology...