Aerospace Torque Sensor Market Research, 2034

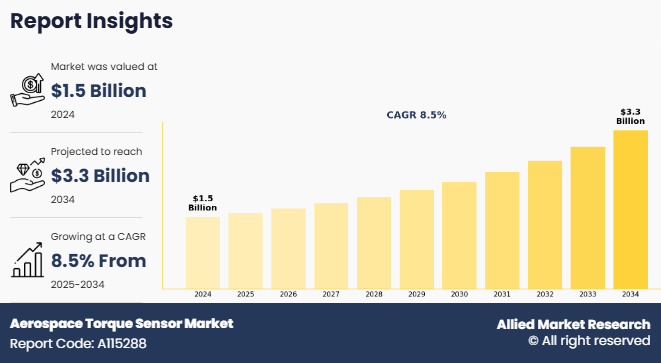

The global aerospace torque sensor market size was valued at $1.5 billion in 2024, and is projected to reach $3.3 billion by 2034, growing at a CAGR of 8.5% from 2025 to 2034.

aerospace torque sensor industry are precision measurement devices designed to quantify torque — the rotational force applied to a shaft or component — in aerospace systems. These sensors are critical for monitoring and validating the performance of engines, gearboxes, rotor systems, actuation mechanisms, and other drivetrain components across civil, military, and emerging aircraft platforms. Aerospace torque sensors can be contact-based, such as strain gauge and rotary sensors, or non-contact, including surface acoustic wave, optical, and magnetoelastic technologies, depending on the application and environmental requirements.

Key Takeaways

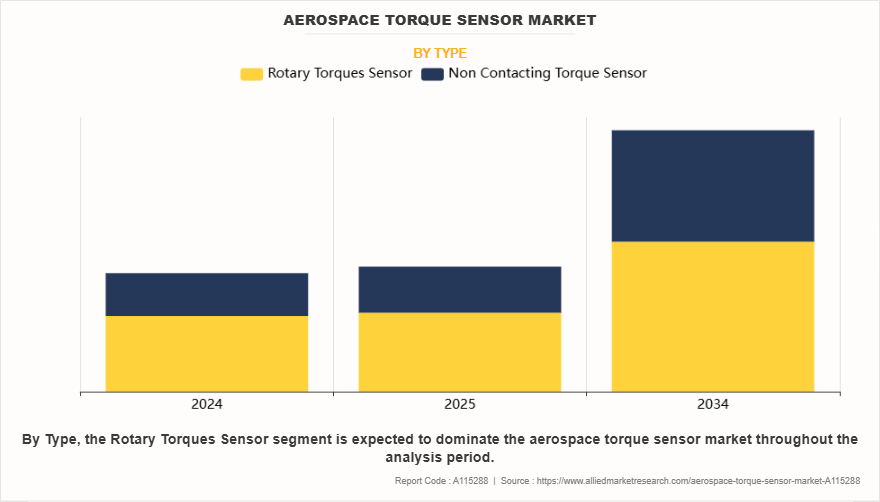

- Based on type, the rotary torque segment held the largest share in the aerospace torque sensor market in 2024.

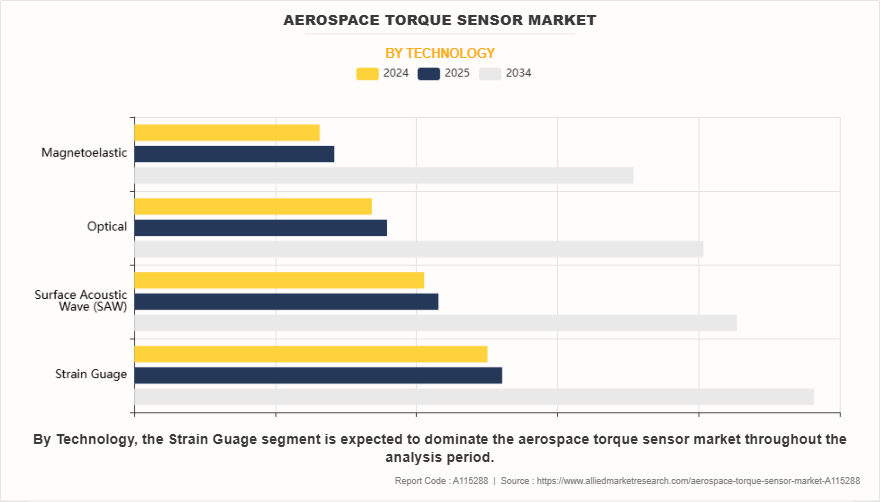

- By technology, the strain guage segment was the major shareholder in 2024.

- Based on application, the airliner segment dominated the market, in terms of share, in 2024.

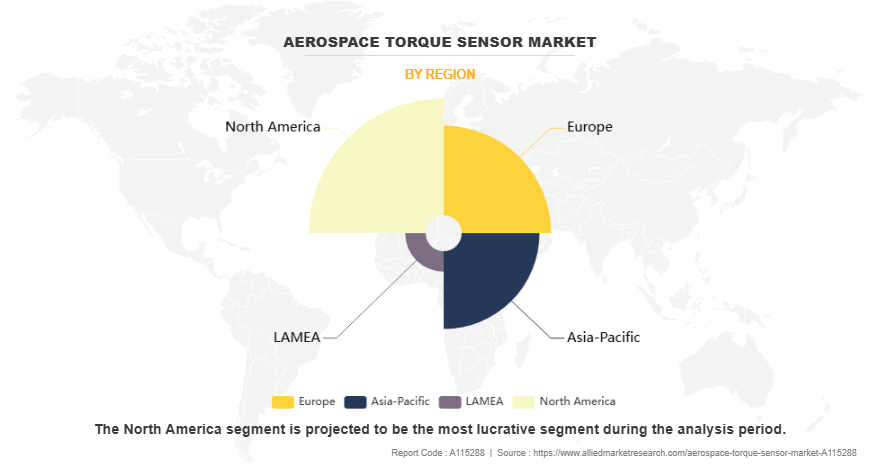

- Region-wise, the North America region held the largest aerospace torque sensor market share in 2024.

It provide real-time, high-accuracy data for both static and dynamic torque loads, enabling engineers to ensure safety, reliability, and efficiency in aircraft operations. These sensors are extensively used in design, development, testing, certification, and in-service monitoring, supporting predictive maintenance, digital twin integration, and performance optimization. With the rise of electric propulsion, UAVs, and eVTOL aircraft, aerospace torque sensors are becoming increasingly vital in modern, high-tech aviation systems.

For instance, in February 2025, McLaren Applied, a specialist in electronics, has supplied its next-generation surface acoustic wave torque sensor to an undisclosed motorsport client for use across all participants in the race series. The sensor is a compact, lightweight, and robust non-contact device, delivering precise wireless torque measurements. Moreover, In September 2023, ABB introduced two new variants of its GoFa collaborative robot, GoFa 10 and GoFa 12, leveraging advanced cobot automation for improved efficiency. Equipped with intelligent torque sensors and motion control technologies, these robots enable precise control and smooth movements, making them suitable for high-accuracy applications such as aerospace component assembly, surface finishing, fastening, and testing tasks.

The growing adoption of predictive maintenance in aerospace is driving demand for aerospace torque sensor market demand, as they provide real-time monitoring of engines, gearboxes, and rotor systems, enabling early fault detection, reducing downtime, and enhancing operational efficiency and safety. Furthermore, advancements in sensor technology, and integration with digital twins and IoT platforms have driven the demand for aerospace torque sensor . However, the high cost of advanced torque sensors, including optical and surface acoustic wave technologies, is limiting adoption in the aerospace sector, especially among cost-sensitive segments, thereby hampering market growth despite their precision and performance advantages. Moreover, complex calibration and certification requirements are major factors that hamper the growth of the aerospace torque sensor market. On the contrary, the rapid expansion of UAVs and eVTOL aircraft is creating significant opportunities for the aerospace torque sensor market size, as these platforms require compact, lightweight, and high-precision sensors for propulsion, rotor, and drivetrain monitoring, ensuring efficiency, safety, and reliability.

Segment Review

The aerospace torque sensor market segmentation on the basis of type, technology, application, and region. On the basis of type, the market is divided into rotary torque sensors, and non-contacting torque sensor. By technology, it is segmented into strain acoustic wave (SAW), optical, magnetoelastic. On the basis of application, it is categorized into airliner, general aviation, business aircraft, and others. Region wise, it is studied across North America, Europe, Asia-Pacific, and LAMEA.

By Type

On the basis of type, the rotary torque sensors segment has attained the highest market share. These sensors are widely used due to their reliability, accuracy, and compatibility with a broad range of aerospace applications, including engine testing, rotor monitoring, and drivetrain validation. Their ability to measure both static and dynamic torque loads in rotating shafts makes them essential for airliners, business jets, and military aircraft. While non-contacting torque sensors are gaining traction for specialized applications, rotary torque sensors continue to dominate the market due to their proven performance, cost-effectiveness, and widespread adoption across commercial, general aviation, and defense platforms.

By Technology

On the basis of technology, the strain guage segment acquired the highest aerospace torque sensor market share in 2024 in the Aerospace Torque Sensor market. This is primarily due to their proven accuracy, reliability, and versatility across various aerospace applications, including engine testing, rotor monitoring, and drivetrain analysis. Their ability to measure both static and dynamic torque loads with high precision makes them indispensable for airliners, business jets, and military aircraft. While advanced technologies such as surface acoustic wave, optical, and magnetoelastic sensors are gaining adoption for specialized and non-contact applications, strain gauge sensors continue to dominate owing to their cost-effectiveness, ease of integration, and long-standing industry acceptance.

By Region

Region wise, North America emerged as the leading region in the Aerospace Torque Sensor market in 2024, securing the highest market share due to its well-established aerospace and defense industry, presence of major aircraft OEMs, and advanced R&D infrastructure. The region’s focus on innovation, precision engineering, and adoption of predictive maintenance strategies has increased the demand for high-accuracy torque sensors in airliners, business jets, rotorcraft, and UAVs. Additionally, growing investments in urban air mobility, electrification of aircraft systems, and integration of digital twins and IoT-enabled monitoring platforms have further strengthened North America’s dominance in the aerospace torque sensor market.

However, Asia-Pacific is projected to grow at the fastest rate in the aerospace torque sensor market during the forecast period, driven by the region’s expanding aerospace manufacturing, rising commercial aircraft production, and growing defense modernization programs. Increasing investments in unmanned aerial vehicles (UAVs), eVTOL aircraft, and regional air mobility initiatives are boosting the demand for high-precision torque sensors. Rapid urbanization, infrastructure development, and the emergence of domestic aircraft OEMs in countries such as China and India are fueling market growth. Technological adoption, coupled with supportive government policies and rising demand for predictive maintenance, further strengthens the region’s growth trajectory.

The report focuses on growth prospects, restraints, and trends of the Aerospace Torque Sensor market analysis. The study provides Porter’s five forces analysis to understand the impact of numerous factors, such as bargaining power of suppliers, competitive intensity of competitors, threat of new entrants, threat of substitutes, and bargaining power of buyers, on the Aerospace Torque Sensor market.

Competitive Analysis

The report analyses the profiles of key players operating in the Aerospace Torque Sensor market such as Honeywell International Inc., TE Connectivity Ltd., Kistler Instrumente AG (Kistler Group), FUTEK Advanced Sensor Technology Inc., HBM Test and Measurement, Applied Measurements Ltd., Sensor Technology Ltd., Crane Electronics Ltd., ABB Ltd., PCB Piezotronics, Inc. These players have adopted various strategies to increase their market penetration and strengthen their position in the Aerospace Torque Sensor market.

Rise in Demand for Predictive Maintenance

The rise in demand for predictive maintenance is significantly driving growth in the aerospace torque sensor market growth. Aerospace operators, including commercial airlines, defense agencies, and aircraft OEMs, are increasingly shifting from traditional time-based maintenance to condition-based and predictive strategies. Predictive maintenance relies on continuous monitoring of critical components, enabling early detection of wear, fatigue, or potential failure before it escalates into costly downtime or safety hazards. Torque sensors play a pivotal role in this transition by providing precise, real-time measurements of rotational forces in engines, gearboxes, rotor systems, and actuation mechanisms. Integration of torque sensors with digital twin platforms, IoT-enabled systems, and predictive analytics allows for enhanced operational efficiency, optimized maintenance schedules, and extended component lifespan. In addition, the growing emphasis on safety, compliance, and cost-efficiency in aerospace operations further boosts the adoption of torque sensors as essential tools for enabling predictive maintenance, making them indispensable in modern aircraft fleets.

Advancements in Sensor Technology

Advancements in sensor technology are significantly increasing the demand for aerospace torque sensors across commercial, general aviation, and defense sectors. Modern aerospace applications require highly accurate, reliable, and durable sensors capable of operating in extreme conditions such as high temperatures, vibrations, and electromagnetic interference. Innovations in non-contact technologies like surface acoustic wave (SAW), optical, and magnetoelastic sensors, along with improvements in traditional strain gauge systems, are enhancing measurement precision and reducing maintenance needs. Miniaturization and lightweight designs allow integration into compact components, including UAVs, eVTOL aircraft, and more-electric aircraft systems. In addition, the integration of torque sensors with IoT platforms, digital twins, and predictive maintenance systems is enabling real-time monitoring, performance optimization, and early fault detection. These technological developments not only improve operational efficiency and safety but also expand applications across emerging aerospace platforms, thereby driving market growth and creating new opportunities for sensor manufacturers.

Integration with Digital Twins and IoT Platforms

The integration of aerospace torque sensor industry with digital twins and IoT platforms is significantly boosting market demand. Digital twin technology enables real-time simulation and monitoring of aircraft systems, including engines, gearboxes, rotor systems, and actuators, by creating virtual replicas of physical components. Torque sensors provide accurate, continuous data on rotational forces, which is essential for these digital models to predict performance, detect anomalies, and optimize maintenance schedules. Coupled with IoT platforms, torque sensors enable remote monitoring, data analytics, and predictive maintenance, allowing operators to reduce downtime, enhance safety, and extend component lifespan. This integration is particularly important for more-electric aircraft, UAVs, and eVTOL platforms, where precise torque measurement ensures efficiency, reliability, and compliance with regulatory standards. As aerospace manufacturers and operators increasingly adopt smart, connected aircraft systems, the demand for advanced torque sensors compatible with digital ecosystems is expected to grow substantially.

High Cost of Advanced Sensors

The high cost of advanced aerospace torque sensors is acting as a significant restraint on market growth. Cutting-edge technologies, such as surface acoustic wave (SAW), optical, and magnetoelastic sensors, offer high precision, reliability, and non-contact measurement capabilities but come with substantial development, manufacturing, and integration costs. These expenses make them less accessible for cost-sensitive segments, including general aviation, small UAVs, and emerging aircraft manufacturers, limiting widespread adoption. In addition, the integration of advanced sensors into aircraft systems often requires specialized calibration, testing, and compliance with stringent aviation regulations, further increasing total costs. While these sensors provide critical benefits such as real-time monitoring, predictive maintenance support, and performance optimization, many operators and OEMs continue to rely on more affordable alternatives like strain gauge sensors. Consequently, the high investment requirement for advanced torque sensors is slowing their penetration, especially in emerging markets, thereby restraining overall growth in the aerospace torque sensor market growth.

Complex Calibration and Certification Requirements

The complex calibration and certification requirements in the aerospace industry are hampering the growth of the aerospace torque sensor market. Aerospace torque sensors must comply with stringent international standards and regulatory norms to ensure accuracy, reliability, and safety in critical applications such as engine testing, rotor monitoring, and drivetrain validation. Achieving these certifications involves rigorous testing, precise calibration, and extensive documentation, which can be time-consuming and costly for manufacturers and operators. In addition, sensors often need to perform reliably under extreme conditions, including high temperatures, vibrations, and electromagnetic interference, further complicating the calibration process. These challenges limit the adoption of advanced torque sensors, particularly in cost-sensitive segments like general aviation, small UAVs, and emerging aircraft platforms. While advanced sensors provide real-time monitoring, predictive maintenance capabilities, and improved operational efficiency, the time, cost, and technical expertise required for calibration and certification create significant barriers, restraining market growth despite the increasing demand for precision torque measurement.

Expansion of UAVs and eVTOL Aircraft

The rapid expansion of unmanned aerial vehicles (UAVs) and electric vertical take-off and landing (eVTOL) aircraft presents a highly lucrative opportunity for the aerospace torque sensor market. These emerging platforms require compact, lightweight, and high-precision torque sensors to monitor propulsion systems, rotor assemblies, gearboxes, and drivetrain components, ensuring operational efficiency, reliability, and safety. UAVs are increasingly used in defense, agriculture, logistics, and surveillance applications, driving demand for torque sensors capable of performing under varying loads and environmental conditions. Similarly, the growth of urban air mobility and eVTOL aircraft is accelerating the need for distributed electric propulsion monitoring, where precise torque measurement is essential for balancing and redundancy. As manufacturers focus on electrification, automation, and smart monitoring systems, torque sensors integrated with digital twins and IoT-enabled predictive maintenance platforms become indispensable. Consequently, the expansion of UAVs and eVTOL aircraft is expected to significantly boost market adoption and create new revenue opportunities for sensor suppliers globally.

Integration with Smart Aircraft Systems

The integration of aerospace torque sensors with smart aircraft systems represents a highly lucrative opportunity for market growth. Modern aircraft are increasingly equipped with advanced monitoring, predictive maintenance, and autonomous control systems that rely on accurate real-time torque measurements from engines, gearboxes, rotor assemblies, and actuation mechanisms. Torque sensors provide critical data that enable health and usage monitoring systems (HUMS), digital twins, and IoT platforms to optimize performance, predict component failures, and reduce operational downtime. This is particularly important for more-electric aircraft, UAVs, and eVTOL platforms, where precision torque measurement ensures system reliability, efficiency, and safety. As aerospace manufacturers focus on digitalization, electrification, and automation, the demand for torque sensors compatible with integrated smart systems is rising rapidly. By enabling seamless connectivity and real-time analytics, these sensors are becoming essential components of next-generation aircraft, presenting significant opportunities for growth and innovation in the aerospace torque sensor market.

Key Benefits for Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the aerospace torque sensor market analysis from 2024 to 2034 to identify the prevailing aerospace torque sensor market forecast.

- Market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders to make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the aerospace torque sensor market segmentation assists in determining the prevailing aerospace torque sensor market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global aerospace torque sensor market trends, key players, market segments, application areas, and market growth strategies.

Aerospace Torque Sensor Market Report Highlights

| Aspects | Details |

| Market Size By 2034 | USD 3.3 billion |

| Growth Rate | CAGR of 8.5% |

| Forecast period | 2024 - 2034 |

| Report Pages | 310 |

| By Type |

|

| By Technology |

|

| By Application |

|

| By Region |

|

| Key Market Players | ABB, Crane Electronics Ltd., Hottinger Bruel & Kjaer, TE Connectivity, FUTEK Advanced Sensor Technology, Inc., Kistler Group, PCB Piezotronics, Inc., Sensor Technology Ltd., Applied Measurements Ltd., Honeywell International Inc. |

Upcoming trends in the global aerospace torque sensor market include adoption of non-contact sensing technologies, integration with IoT and AI for real-time monitoring, miniaturization, and growing use in UAVs and space applications.

Airliner is the leading application of Aerospace Torque Sensor Market

Asia-Pacific is the largest regional market for Aerospace Torque Sensor

The aerospace torque sensor market was valued at $1,511.2 million in 2024 and is estimated to reach $3,332.8 million by 2034, exhibiting a CAGR of 8.5% from 2025 to 2034.

s Honeywell International Inc., TE Connectivity Ltd., Kistler Instrumente AG (Kistler Group), FUTEK Advanced Sensor Technology Inc., HBM Test and Measurement, Applied Measurements Ltd., Sensor Technology Ltd., Crane Electronics Ltd., ABB Ltd., PCB Piezotronics, Inc.

Loading Table Of Content...

Loading Research Methodology...