Aircraft Manufacturers Market - 2031:

The global aircraft manufacturing market size was valued at $296.6 billion in 2021, and is projected to reach $476.4 billion by 2031, growing at a CAGR of 5% from 2022 to 2031.

Aircraft manufacturing refers to the process of designing, building, and assembling various types of aircraft, including commercial airliners, military aircraft, and general aviation planes. The process involves a wide range of activities, including engineering design, materials selection, fabrication of components, assembly, and testing. The manufacturing of aircraft typically involves the use of advanced materials as well as complex systems and electronics to ensure safety, reliability, and performance. The manufacturing process can be highly complex and may involve the collaboration of multiple companies and suppliers working together to produce a single aircraft. Aircraft manufacturing is a crucial industry as it supports not only the aviation industry however, also the broader economy. It generates jobs, drives innovation, and contributes to technological advancements in fields such as materials science, robotics, and artificial intelligence (AI).

Aircraft manufacturing is a labor-intensive industry that generates significant employment opportunities in fields such as engineering, manufacturing, and materials science It contributes significantly to the overall economy by generating income, creating demand for goods & services, and stimulating innovation & technological advancement. Furthermore, aircraft manufacturing involves the use of advanced materials, systems, and technologies, which often lead to technological advancements in other industries, such as automotive, aerospace, and defense. It is a significant contributor to global trade, as aircraft and their components are exported to countries around the world, promoting global economic growth and development. The aircraft manufacturing industry is crucial to national security, as it provides military aircraft and defense systems to support national defense and security. The aviation industry has made significant strides in improving fuel efficiency and reducing emissions, which have resulted in lower carbon footprints and reduced environmental impact.

he factors such as favorable government initiatives, surge in demand for air travel, and technological advancement in aircraft manufacturing supplement the growth of the market. However, high manufacturing cost and environment regulations are the factors expected to hamper the growth of the aircraft manufacturing market. In addition, rise in demand for cargo services coupled with the increase in trade among nations and emergence of LCC (low-cost carriers) creates market opportunities for the key players operating in the market.

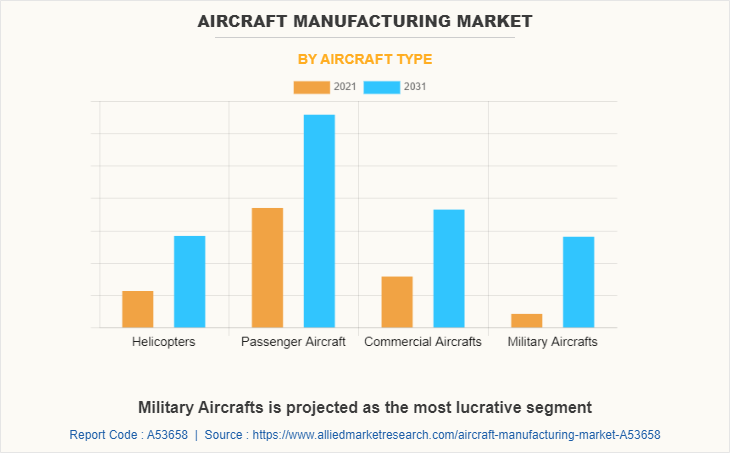

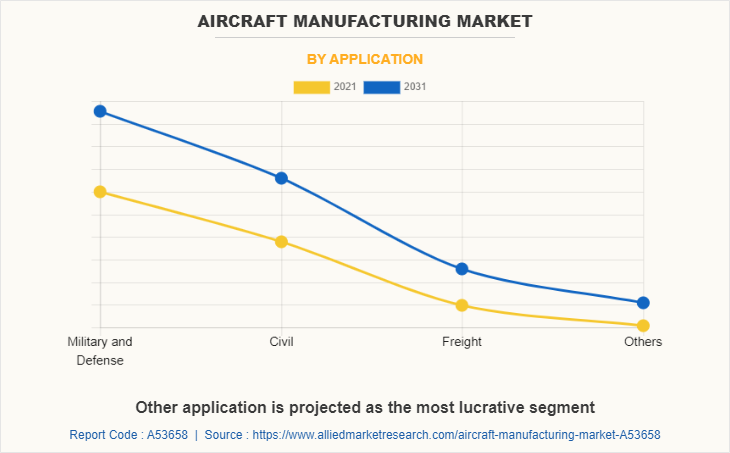

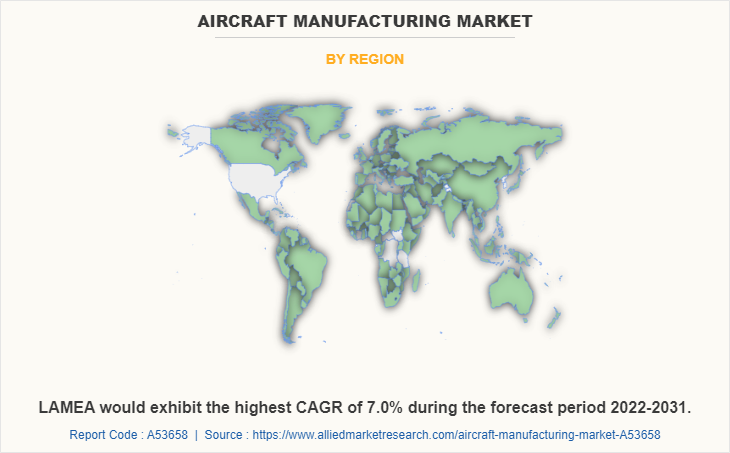

The aircraft manufacturing market is segmented on the basis of type, application, and region. By type, the market is divided into helicopters, passenger aircraft, commercial aircrafts, and military aircrafts. By application, it is classified into military & defense, civil, freight, and others. By region, it is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

The leading players operating in the market are Lockheed Martin Corporation, Raytheon Technologies Corporation, Textron Inc., Boeing, Airbus, Commercial Aircraft Corporation of China, Ltd., Dassault Aviation, Embraer, General Dynamics Corporation, and Leonardo S.p.A. which have been operating in the industry & have opted numerous developmental strategies, which supplement the growth of the market across the globe.

Various government initiative to fuel market growth

The industry is a critical sector that requires substantial investment on R&D, skilled labor, and state-of-the-art manufacturing facilities. Owing to the high cost of developing and producing aircraft, governments around the world provide financial support to this industry to ensure its sustainability and growth. The government support for aircraft manufacturing market, including subsidies to aircraft manufacturers to support their development and production of new aircraft creates a wider scope for the growth of the market across the globe. These subsidies can take various forms, such as direct grants, low-interest loans, and tax breaks. Subsidies enable aircraft manufacturers to reduce their costs and remain competitive in the global market. For instance, the U.S. government provides subsidies to Boeing, the largest aircraft manufacturer in the country, through the Export-Import Bank (Ex-Im Bank). The Ex-Im Bank provides loans and guarantees to foreign buyers of Boeing aircraft, which helps the company to compete with its European rival, Airbus.

Moreover, various governments offer tax incentives to aircraft manufacturers to support their R&D efforts. Tax incentives can include tax credits, tax exemptions, and accelerated depreciation. These incentives reduce the cost of R&D for aircraft manufacturers, which help them to develop new technologies and products. For instance, the UK government offers tax incentives to aircraft manufacturers through the Aerospace Technology Institute (ATI). The ATI provides funding for R&D projects and offers tax credits to companies that invest in R&D in the aerospace sector. Governments invest in infrastructure to support the development and production of aircraft. This infrastructure can include airports, research centers, and manufacturing facilities. Infrastructure investment can reduce the cost of doing business for aircraft manufacturers and make it easier for them to develop and produce new aircraft. The Chinese government invested heavily in infrastructure to support its aircraft manufacturing industry. China has built new airports, research centers, and manufacturing facilities to support the development and production of new aircraft. China is also developing a new airport in Beijing that is expected to be one of the largest in the world, which is anticipated to provide significant opportunities for the country's aircraft manufacturers.

Technological advancement in aircraft

The technological advancements in the market have led to increased demand for more advanced and efficient aircraft. The aircraft industry is constantly developing new technologies to improve safety, efficiency, and reduce costs, which in turn increases demand for aircraft. One of the major technological advancements in the market is the development of more fuel-efficient engines. The use of advanced materials, such as carbon fiber composites, has helped reduce the weight of aircraft, which in turn reduces fuel consumption and emissions. In addition, the use of digital technology and data analytics has led to improvements in aircraft design and performance. For instance, Boeing's 787 Dreamliner uses lightweight composite materials, advanced engines, and advanced avionics, which make it more fuel-efficient and environmentally friendlier than traditional aircraft.

Moreover, the development of new technologies in avionics and communication systems has also led to improvements in aircraft safety and efficiency. For instance, the use of advanced navigation and communication systems, such as satellite-based GPS, has made air travel safer and more efficient. The demand for more advanced and efficient aircraft has also led to increased competition in the aircraft manufacturing market. New players are entering the market with innovative technologies, challenging established players and driving innovation.

High manufacturing cost

Aircraft manufacturing requires high investments in R&D, manufacturing facilities, and materials. This can lead to high costs, which can be a significant restraint for the growth of the market. Developing and producing new aircraft can be a capital-intensive process that requires significant investment in R&D, manufacturing, and certification. For instance, development and production of the Boeing 787 Dreamliner reportedly cost over $32 billion, which is significantly higher than the cost of developing traditional aircraft. The high cost of developing new aircraft can limit the number of companies that can enter the market, which can reduce competition and innovation. This can result in a market dominated by a few major players, such as Boeing and Airbus, which can regulate consumer choice and innovation. In addition to the high cost of development, there are high costs associated with manufacturing and certification. The manufacturing process for aircraft is complex and requires specialized equipment, materials, and skilled labor. Certification is a lengthy and expensive process, requiring aircraft to undergo rigorous testing and meet strict safety standards.

The high cost of developing and producing new aircraft can also limit the ability of airlines to purchase new planes. Airlines must carefully manage their costs and prioritize their investments, which can result in a slower rate of aircraft purchases. Furthermore, high costs can impact the profitability of aircraft manufacturers. High costs can reduce profit margins, making it more challenging for companies to invest in R&D and compete in the global market. However, there are efforts to reduce the high costs associated with aircraft manufacturing. For instance, governments around the world provide subsidies, tax incentives, and R&D funding to support the industry. These measures enable aircraft manufacturers to reduce their costs, develop new technologies, and compete in the global market. In addition, advancements in technology have also led to more efficient and cost-effective manufacturing processes. For instance, the use of automation and 3D printing in manufacturing has reduced labor costs and increased efficiency.

Rise in demand for cargo services coupled with increase in trade among nations

Rise in demand for cargo services coupled with increase in trade among nations is expected to create a significant opportunity for the aircraft manufacturing market. The global freight industry is projected to grow significantly in the coming years, driven by the expansion of e-commerce, the growth of the global middle class, and the increasing trade among nations. As the demand for air cargo services continues to rise, it is expected to create an increased demand for freighter aircraft. These are aircraft that are specifically designed for carrying cargo, with a large cargo door and a reinforced floor to handle heavy loads. The production of freighter aircraft represents a significant opportunity for aircraft manufacturers. In addition to freighter aircraft, manufacturers can also develop new aircraft technologies to improve cargo services. For instance, companies such as Boeing and Airbus have developed new technologies that allow passenger aircraft to carry cargo in the passenger cabin, known as freighter aircraft. This technology allows airlines to maximize their cargo capacity, without sacrificing passenger capacity.

Moreover, the increase in trade among nations is expected to drive demand for wide-body aircraft that can carry large amounts of cargo over long distances. These aircraft are well-suited for international trade and can carry high-value goods such as electronics, pharmaceuticals, and luxury goods.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the aircraft manufacturing market analysis from 2021 to 2031 to identify the prevailing aircraft manufacturing market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the aircraft manufacturing market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global aircraft manufacturing market trends, key players, market segments, application areas, and market growth strategies.

Aircraft Manufacturing Market Report Highlights

| Aspects | Details |

| Market Size By 2031 | USD 476.4 billion |

| Growth Rate | CAGR of 5% |

| Forecast period | 2021 - 2031 |

| Report Pages | 300 |

| By Aircraft Type |

|

| By Application |

|

| By Region |

|

| Key Market Players | Embraer, Commercial Aircraft Corporation of China,Ltd., Raytheon Technologies Corporation, Airbus, Textron Inc., Dassault Aviation, Boeing, Lockheed Martin Corporation, Leonardo S.P.A., General Dynamics Corporation |

Analyst Review

The aircraft manufacturing market report presents both challenges and opportunities. The industry is highly competitive and dynamic, which requires a significant investment in R&D to stay ahead of competitors and meet the changing demands of customers. One of the main challenges being faced in the aircraft manufacturing market is the high cost of development and production. Aircraft manufacturing is a capital-intensive business that requires significant investments in technology, engineering, and manufacturing capabilities. In addition, the industry is subject to a high degree of regulation, which adds to the cost and complexity of bringing new products to market. As a result, managing costs and maintaining profitability is a key concern for the industry.

The demand for new aircraft is subject to fluctuations on the basis of a range of factors, including economic conditions, geopolitical risks, and changing customer preferences. This can create uncertainty for manufacturers and make it difficult to predict future demand and revenue. The increase in air travel and transportation, particularly in emerging markets creates a wider scope for the growth of the market across the globe. As more people travel by air for business, leisure, and other purposes, the demand for new aircraft and related products is expected to grow. Development of innovative technologies and innovations can improve the safety, efficiency, and performance of aircraft. Investing on R&D to develop new products and technologies can provide a competitive advantage and help to meet the evolving needs of customers.

The market growth is supplemented by factors such as favorable government initiatives, rise in demand for air travel, and technological advancement in aircraft manufacturing. However, high manufacturing cost and environment regulation are the factors expected to hamper the growth of the aircraft manufacturing market. In addition, rise in demand for cargo services coupled with the increase in trade among nations and emergence of LCC (low-cost carriers) creates developmental opportunities for the key players operating in the aircraft manufacturing market

Increased usage in civil aviation are the upcoming trends of aircraft manufacturing market in the world

Commercial Aircrafts used for civil aviation are the leading application of aircraft manufacturing market

North America is the largest regional market for aircraft manufacturing

The global aircraft manufacturing market was valued at $296.57 billion in 2021, and is projected to reach $476.43 billion by 2031, registering a CAGR of 5.0% from 2022 to 2031

The key players operating in the aircraft manufacturing market are Lockheed Martin Corporation, Raytheon Technologies Corporation, Textron Inc., Boeing, Airbus, Commercial Aircraft Corporation of China, Ltd., Dassault Aviation, Embraer, General Dynamics Corporation, and Leonardo S.p.A. which have been operating in the industry & have opted numerous developmental strategies, which supplement the growth of the market across the globe.

Loading Table Of Content...

Loading Research Methodology...