Aluminum Foam Market Overview

The global aluminum foam market was valued at USD 41.3 million in 2022, and is projected to reach USD 60.5 million by 2032, growing at a CAGR of 4.1% from 2023 to 2032.

Introduction

Aluminum foam is created by injecting a gas, such as nitrogen or argon, into molten aluminum. This gas reacts with the metal and creates small bubbles that form the foam. The size and distribution of the bubbles can be controlled by varying the gas pressure and flow rate as well as the temperature of the molten aluminum. Once the foam is created, it can be cast into various shapes and sizes, depending on the application.

One of the key properties of aluminum foam is its high strength-to-weight ratio, which makes it an ideal material for aerospace and automotive applications. In addition, the foam is resistant to impact and vibration, which makes it suitable for use in high-impact environments, such as in the construction of crash barriers and other safety equipment.

Furthermore, the porous structure of the foam can effectively absorb sound waves, making it apt for noise reduction in various applications. This makes aluminum foam valuable in the construction of buildings, where it can help to reduce noise pollution and improve acoustic comfort. In addition, aluminum foam exhibits high impact resistance; thus, its ability to absorb energy on impact makes it a valuable material for use in impact protection applications, such as in automotive and aerospace industries. This can help to improve the safety of passengers and reduce the risk of damage to components in the event of an impact.

Aluminum foam possesses high thermal conductivity, which makes it an ideal material for use in heat sinks and other cooling applications. The foam can be used in insulation applications, as it has a low thermal conductivity in comparison to other metals.

Furthermore, aluminum foam is used in the construction of crash barriers, which are designed to absorb impact energy in the event of a collision. It further finds its application in construction of lightweight automotive components, such as floor pans and seat frames, which help to reduce the overall weight of the vehicle and improve fuel efficiency.

Report Key Highlighters:

- The aluminum foam market study covers 20 countries. The research includes a segment analysis of each country in terms of both value ($million) and volume (kilotons) for the projected period 2022-2032.

- The study integrated high-quality data, professional opinions and analysis, and critical independent perspectives. The research approach is intended to provide a balanced view of global markets and to assist stakeholders in making educated decisions in order to achieve their most ambitious growth objectives.

- Over 3,700 product literatures, annual reports, industry statements, and other comparable materials from major industry participants were reviewed to gain a better understanding of the market.

Rise in use of aluminum foam in energy absorption drives the growth of aluminum foam market.

Aluminum foam is a lightweight material with a high strength-to-weight ratio and superior energy absorption capabilities, making it an ideal material for use in energy absorption applications. Thus, surge in demand for aluminum foam in applications that require energy absorption acts as the key driving force of the global aluminum foam market.

Moreover, aluminum foam finds its major application in the automotive industry, where it absorbs impact energy during collisions, thereby reducing the force of the blow and preserving the lives of the occupants. In addition, it is used in the construction industry for seismic protection, and in the defense industry for armor systems to provide protection against ballistic impacts. Moreover, it is used in vehicle armor systems to protect military vehicles from landmine explosions and other threats. Thus, increase in applications of aluminum foam across various industries drives the growth of the global aluminum foam market.

However, corrosion susceptibility of aluminum foam hinders the market growth of market. Aluminum foam is less susceptible to corrosion than traditional aluminum alloys due to its open-cell structure. The exposure to corrosive agents such as saltwater, acids, and alkaline solutions can cause the aluminum to break down and corrode. Another factor that can contribute to the corrosion of aluminum foam is the presence of galvanic cells.

Galvanic corrosion occurs when two different metals come into contact in the presence of an electrolyte, such as saltwater, and an electric current flows between them. This can result in the corrosion of one or both of the metals. To prevent this, it is important to avoid using dissimilar metals in contact with the aluminum foam.

Segments Overview

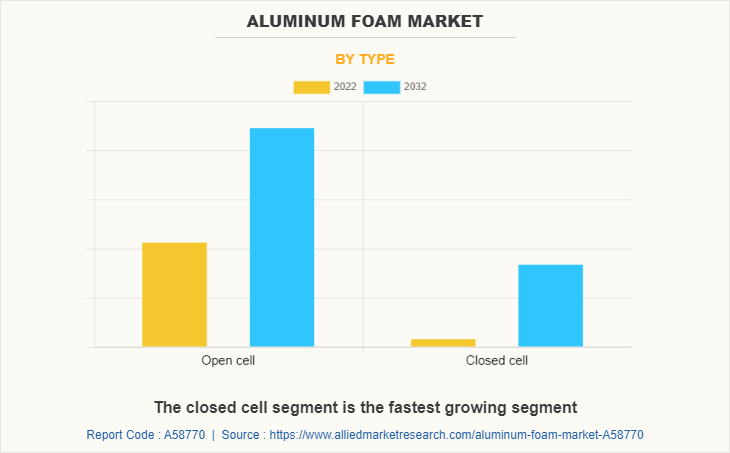

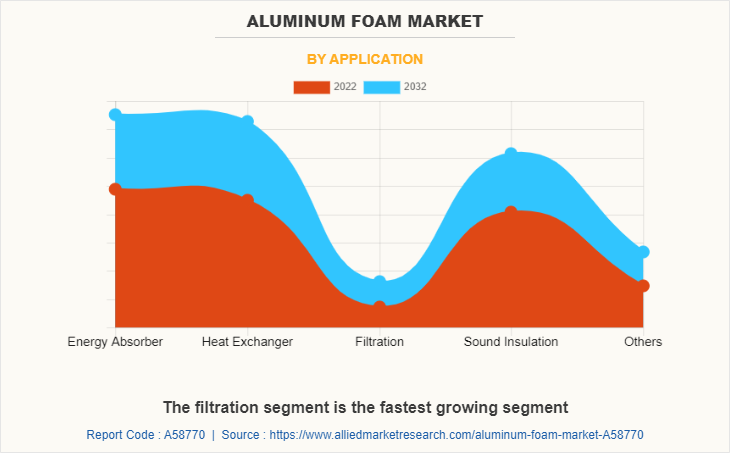

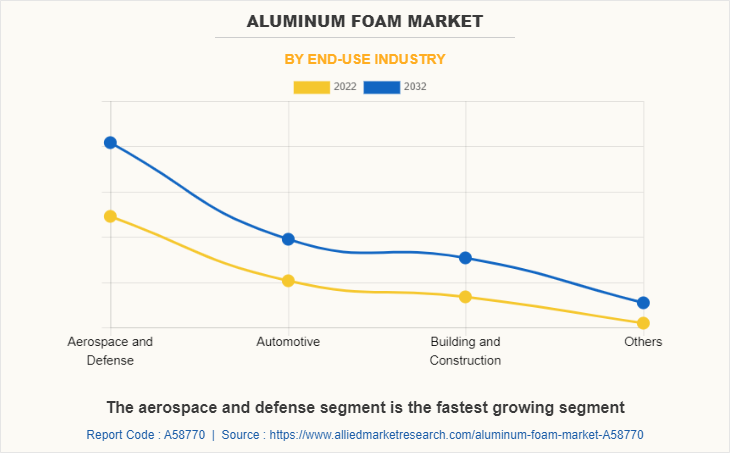

The aluminum foam industry is segmented into type, application, end-use industry, and region. On the basis of type, the market is categorized into open cell and closed cell. By application, it is divided into energy absorber, heat exchanger, filtration, sound insulation, and others. Depending on end-use industry, it is categorized into aerospace & defense, automotive, building & construction, and others. Region wise, it is studied across North America, Europe, Asia-Pacific, and LAMEA.

Closed cell aluminum foam has a variety of potential uses due to its unique properties, such as its high strength-to-weight ratio, thermal insulation, and impact resistance. Closed cell aluminum foam can also be used as a sound-absorbing material in construction, automotive, and other applications. It can help reduce noise levels and improve acoustics in enclosed spaces.

Aluminum foam can be used as a filtration medium in various applications due to its unique properties. Aluminum foam can be used as a filter medium in water treatment plants. The foam's porous structure allows water to flow through while trapping impurities and contaminants, such as sediment, bacteria, and viruses. It can also be used to remove heavy metals, such as lead and arsenic, from drinking water.

Aluminum foam can be used to absorb impacts in the event of a crash or other impact-related incidents in buildings. Its ability to dissipate energy makes it an ideal material for this purpose. It can be used as a structural material for building facades, roofs, and walls, as well as for insulation, fire protection, and soundproofing.

Aluminum foam is being used in various applications in the Asia-Pacific region. In the aerospace industry, it is used for structural components and as a core material for sandwich structures. In the construction industry, it is used for insulation, soundproofing, and fire-resistant applications as a building material. Additionally, it is used as the core material in composite panels.

Competitive Analysis

Major players operating in the global aluminum foam market include American Elements, BEIHAI Composite Materials Co., Ltd., ERG Aerospace Corporation, Foamtech Global, Havel Metal Foam, NANOCHEMAZONE, Nanoshel LLC, VIM Technology Ltd, Xiamen TJ Metal Material Co., Ltd., and Xiamen Tmax Battery Equipments Limited.

Historical Trends

In 1957, Researchers at the National Bureau of Standards (now NIST) discovered that aluminum could be made into a foam by adding calcium carbonate to molten aluminum and allowing it to solidify.

In 1983, Researchers at the Massachusetts Institute of Technology (MIT) developed a new process for producing aluminum foam using a powder metallurgy technique.

In 2000, The European Space Agency (ESA) used aluminum foam in a successful test of a new launch vehicle that required a lightweight, yet strong, heat shield. The is Atmospheric Reentry Demonstrator (ARD), which required a lightweight, yet strong, heat shield. The aluminum foam heat shield was able to withstand temperatures of up to 1,700°C (3,092°F) and successfully protected the spacecraft during its reentry into the Earth's atmosphere.

In 2010, researchers at the Fraunhofer Institute for Manufacturing Technology and Advanced Materials in Germany developed a new type of aluminum foam that is stronger and more heat-resistant than previous versions. The new aluminum foam had other advantages over previous versions, such as improved acoustic damping and increased energy absorption capacity. These properties make it an attractive material for use in crash-resistant components in the automotive industry as well as in noise reduction applications in the construction industry.

Key Benefits For Stakeholders

This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the aluminum foam market analysis from 2022 to 2032 to identify the prevailing aluminum foam market opportunities.

The aluminum foam market research is offered along with information related to key drivers, restraints, and opportunities.

Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

In-depth analysis of the aluminum foam market segmentation assists to determine the prevailing market opportunities.

Major countries in each region are mapped according to their revenue contribution to the global market.

Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

The report includes the analysis of the regional as well as global aluminum foam market trends, key players, market segments, application areas, and market growth strategies.

Aluminum Foam Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 60.5 million |

| Growth Rate | CAGR of 4.1% |

| Forecast period | 2022 - 2032 |

| Report Pages | 350 |

| By Type |

|

| By Application |

|

| By End-Use Industry |

|

| By Region |

|

| Key Market Players | Havel Metal Foam, Xiamen Tmax Battery Equipments Limited., BEIHAI Composite Materials Co., Ltd., Xiamen TJ Metal Material Co., Ltd., Nanoshel LLC, NANOCHEMAZONE, FOAMTECH GLOBAL, VIM Technology Ltd, AMERICAN ELEMENTS, ERG Aerospace Corporation |

Analyst Review

According to the opinions of various CXOs of leading companies, aluminum foam is gaining high traction in the global market due to increase in its adoption for construction and interior decoration. Aluminum foam is an ideal material for use in construction due to its lightweight, high strength-to-weight ratio, and energy absorption capabilities; thus, it finds its application in interior decoration, insulation, and structural elements.

The CXOs further added that aluminum foam manufacturers are continually developing new manufacturing techniques for aluminum foam, such as additive manufacturing and powder metallurgy. These techniques allow for the production of complex geometries and custom-designed structures. Aluminum foam has also been noticed as an innovative cellular material for absorbing energy and reducing load due to its strong load resistance and low density.

The Asia-Pacific region is projected to register robust growth during the forecast period. According to Jindal Aluminum, high-speed trains in China are manufactured using aluminum foam due to its ability to reduce weight and increase speed, resulting in improved fuel efficiency and reduced operating costs. As a result, the demand for aluminum foam in the aerospace construction industry is anticipated to rise during the forecast period.

American Elements, BEIHAI Composite Materials Co., Ltd., ERG Aerospace Corporation, Foamtech Global, Havel Metal Foam, NANOCHEMAZONE, Nanoshel LLC, VIM Technology Ltd, Xiamen TJ Metal Material Co., Ltd., and Xiamen Tmax Battery Equipments Limited. are the op companies to hold the market share in Aluminum Foam Market.

Rise in use of aluminum foam in energy absorption and increase in adoption of aluminum foams for construction and interior decoration are the driving factor of Aluminum Foam Market.

The leading application of Aluminum Foam Market includes energy absorber, heat exchanger, filtration, sound insulation, and others.

The leading end-use industry of the Aluminum Foam Market includes aerospace & defense, automotive, building & construction, and others.

Asia-Pacific is the largest region of Aluminum Foam Market.

Recyclability of aluminum foam are the upcoming trends of Aluminum Foam Market in the world.

Poor quality of aluminum foam production is one of the challenge in the Aluminum Foam Market.

Loading Table Of Content...

Loading Research Methodology...