Cast Resin Dry Type Transformer Market Overview

The global cast resin dry type transformer market size was valued at USD 4.6 billion in 2024, and is projected to reach USD 8.7 billion by 2034, growing at a CAGR of 6.7% from 2025 to 2034. Rising investments in power distribution networks and grid modernization are boosting demand for cast resin dry type transformers. Their low maintenance, eco-friendly design, and suitability for harsh and densely populated environments further drive market growth.

Key Market Trend & Insights

- Type: Olefins segment dominated the market in 2023 and is projected to grow at the fastest CAGR of 5.2% during the forecast period.

- Product Type: Ethylene segment led the market in 2023, while propylene is anticipated to register the highest CAGR of 5.5%.

- Application: Packaging segment held the largest share in 2023, whereas aerospace is expected to grow at the fastest CAGR of 6.1%.

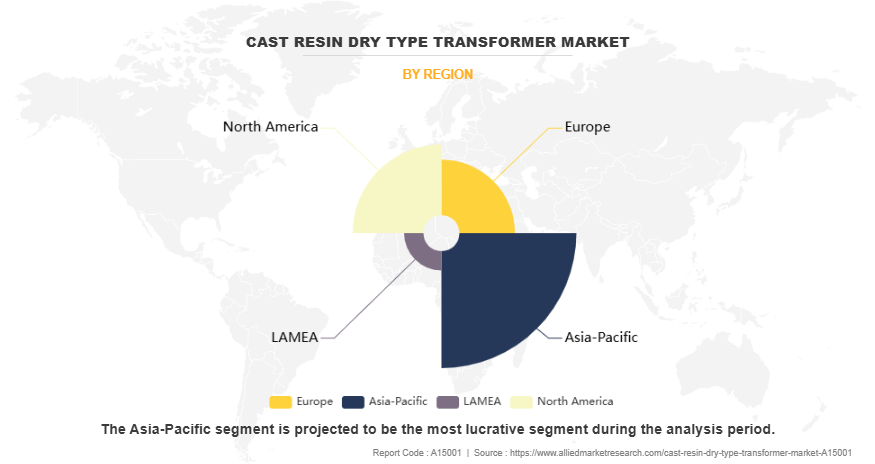

- Region: Asia-Pacific accounted for half of the market share in 2024 and is expected to maintain its dominance.

Market Size & Forecast

- 2034 Projected Market Size: USD 8.7 billion

- 2024 Market Size: USD 4.6 billion

- Compound Annual Growth Rate (CAGR) (2025-2024): 6.7%

Introduction

Cast resin dry type transformers (CRDTs) are vital in power distribution infrastructure known for their enhanced safety, environmental friendliness, and superior insulation properties. These transformers, unlike conventional oil-filled transformers, use epoxy resin to encapsulate the windings, offering a clean, fire-resistant, and moisture-proof solution. A cast resin dry type transformer is an electrical device that transforms voltage levels using magnetic induction, similar to conventional transformers, but without using oil as a cooling or insulating medium.

The working principle of cast resin dry type transformer is similar to conventional transformers. They operate based on the principle of electromagnetic induction. When alternating current (AC) flows through the primary winding, it generates a magnetic field that induces a voltage in the secondary winding. The key difference lies in the insulation medium. In cast resin dry type transformers, the windings are embedded in epoxy resin, which acts both as insulation and as a barrier to environmental contaminants. The cast resin dry type transformer industry is witnessing steady growth due to increasing demand for safe, eco-friendly, and low-maintenance power distribution solutions. Smart grid integration enables efficient communication between energy producers and consumers, optimizing electricity distribution and usage. Improving grid reliability helps prevent power outages and supports the seamless integration of renewable energy sources.

Key Takeaways

- The global cast resin dry type transformer market has been analyzed in terms of value ($million). The analysis in the report is provided on the type, cooling type, phase, voltage, end-use, and class, 4 major regions, and more than 15 countries.

- The global cast resin dry type transformer market report includes a detailed study covering underlying factors influencing the industry opportunities and trends.

- The Key players in the cast resin dry type transformer market include Shneider Electric, Siemens Energy, Eaton Corporation, Hitachi Ltd, Toshiba Corporation, Fuji Electric Co., Ltd, CG Power & Industrial Solutions Ltd, Kirloskar Electric Company, Bharat Heavy Electricals Limited, Hammond Power Solutions.

- The report facilitates strategy planning and industry dynamics to enhance decision making for existing market players and new entrants entering the alternators industry.

- Countries such as China, the U.S., Canada, Germany, and Brazil hold a significant share in the global cast resin dry type transformer market.

Market Dynamics

Power generation capacity has grown exponentially, and the transmission infrastructure has evolved accordingly. CRDTs are used in power plants, substations, and distribution networks where space constraints, safety, and minimal maintenance are critical. They are particularly suited for renewable energy installations such as wind and solar power plants, where remote, rugged environments necessitate robust solutions. CRDTs are widely used in infrastructure projects for efficient power distribution with the rapid development of smart cities and metro rail projects. They ensure safe power supply with reduced fire risks and lower operational noise in high-rise buildings, commercial complexes, malls, and hospitals. Manufacturing industries, those involved in pharmaceuticals, automotive, steel, and electronics, require uninterrupted power supply and secure energy systems. CRDTs meet these needs through high efficiency, lower failure rates, and improved temperature tolerance. They can also withstand overload conditions for short durations without failure. The need for high-efficiency, fireproof, and low-noise power transformers in data centers and IT parks has surged as India becomes a global IT and data hub. CRDTs are ideal for such applications due to their silent operation and low maintenance needs, which are vital for uninterrupted data processing and storage.

Increase in urbanization and industrialization is expected to drive the growth of the cast resin dry type transformer market. Urban expansion is driving demand for advanced power distribution solutions, particularly in smart cities, high-rise buildings, commercial centers, and transportation hubs. Cast resin dry-type transformers, known for their oil-free design, mitigate fire risks and environmental concerns, making them ideal for indoor installations in densely populated areas like malls, hospitals, and offices. Their compact design and low maintenance make them perfect fit for urban applications. In November 2024, the Indian government extended the Atal Innovation Mission (AIM) until.

March 2028, with approximately ($320.65 million) ₹2,750 crore budget, supporting over 3,500 startups and initiatives like Atal Tinkering Labs and Incubation Centers to foster innovation. On the industrial front, India's "Make in India" and National Infrastructure Pipeline (NIP) initiatives have boosted sectors such as automotive, pharmaceuticals, and textiles, all of which require reliable power supply. Cast resin dry-type transformers provide high efficiency and durability required in environments with challenging conditions like moisture or dust, making them ideal for these industries. All these factors are expected to drive the demand for the cast resin dry type transformer market during the forecast period.

However, limited capacity range of cast resin dry type transformer is expected to hamper the growth of the cast resin dry type transformer market. Cast resin dry type transformers have a limited capacity range, making them more suitable for low-to-medium voltage applications (up to 12.5 MVA and 33 kV). These transformers are ideal for commercial, residential, and industrial settings with moderate power demands. Designed to offer robust protection, they use epoxy resin to encapsulate windings, preventing moisture ingress and eliminating the need for insulating oils. This construction makes them pollution-free, fire-safe, and low-maintenance, making them well-suited for environments like high-rise buildings, hospitals, underground substations, and eco-sensitive areas. Cast resin transformers are often preferred in spaces where space and environmental considerations are paramount due to their compact design and reliable performance in moderate power scenarios.

Segments Overview

The cast resin dry type transformer market is segmented into type, cooling type, phase, voltage, end-use, class and region. On the basis of type, the market is divided into dry type converter transformer, and dry type rectifier transformer. As per cooling type, the market is classified into natural air cooling, and forced air cooling. On the basis of phase, the market is categorized into single phase and three phase. Depending on voltage, the market is bifurcated into low and medium. On the basis of end-use, the market is divided into industrial, commercial and others. On the basis of class, the market is divided into class F and class H. Based on region, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

By Type

On the basis of type, the dry type converter transformer dominated the cast resin dry type transformers market accounting for 59% of the market share in 2024. This dominance is attributed to their widespread application in power electronics and industrial drives, offering enhanced thermal performance, improved safety, and reduced maintenance requirements compared to traditional transformer types.

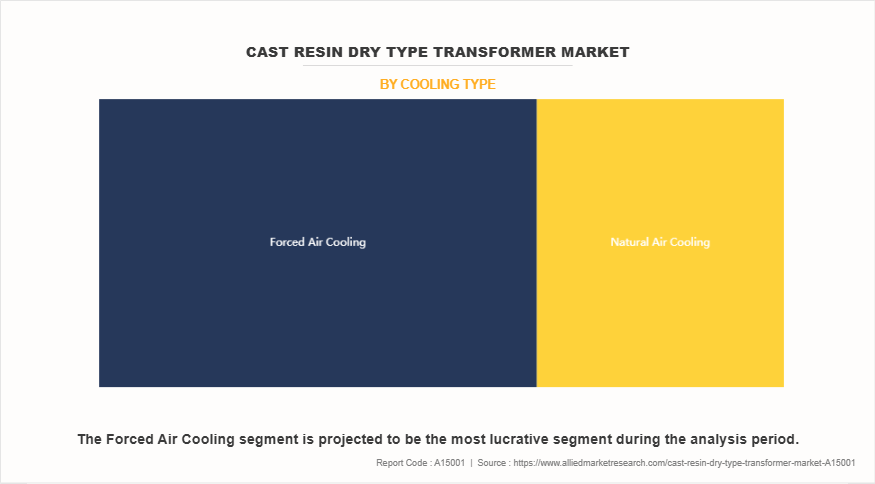

By Cooling

On the basis of cooling type, the forced air cooling dominated the cast resin dry type transformers market accounting for 63% of the market share in 2024. This is primarily due to its superior efficiency in dissipating heat, which enhances transformer performance, extends service life, and supports higher load capacities in compact installations.

By Phase

On the basis of phase, the single phase segment dominated the cast resin dry type transformers market accounting for 88% of the market share in 2024. Their dominance is driven by widespread usage in residential, commercial, and light industrial applications where lower power demand and simpler installation requirements are prevalent.

By Voltage

On the basis of voltage, the low segment dominated the cast resin dry type transformers market accounting for 71% of the market share in 2024. This strong presence is attributed to their extensive use in commercial buildings, residential complexes, and small-scale industrial setups where voltage requirements are moderate, making them cost-effective and easier to install and maintain.

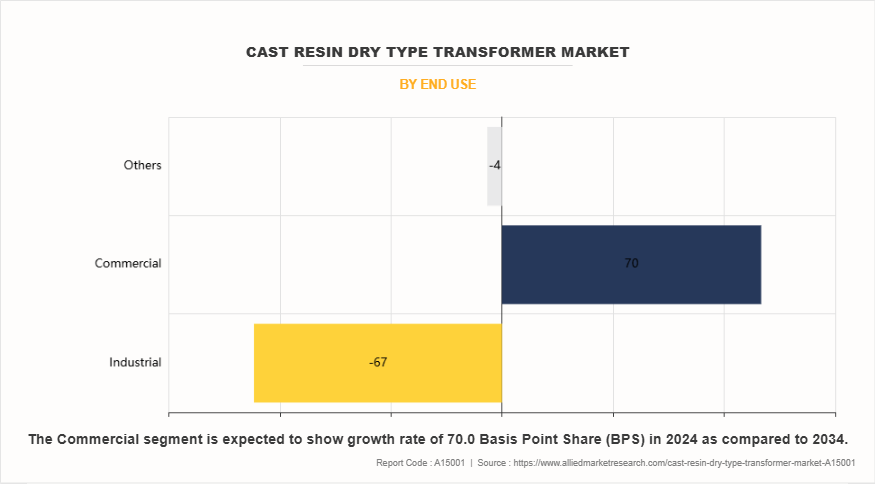

By End-Use

On the basis of end-use, the industrial segment dominated the cast resin dry type transformers market growing with the CAGR of 50% during the forecast period. This significant growth is driven by rising industrial automation, expansion of manufacturing facilities, and increasing demand for reliable and safe power distribution in harsh environments where cast resin dry type transformers offer enhanced fire resistance and low maintenance.

By Class

On the basis of class, the class F segment dominated the cast resin dry type transformers market accounting for 76% of the market share in 2024. This dominance is due to its ability to withstand higher operating temperatures (up to 155°C), making it ideal for applications requiring enhanced thermal endurance, long service life, and performance stability under varying load conditions.

By Region

Region wise, Asia-Pacific dominated the cast resin dry type transformers market, representing the CAGR of 44% during the forecast period due to rapid urbanization, robust industrialization, and increase in investments in energy infrastructure across emerging economies such as China, India, and Southeast Asian nations. The region's growing demand for electricity, fueled by expanding residential and commercial sectors, has led to the widespread deployment of efficient and safe transformer technologies such as cast resin dry type transformers. Furthermore, government initiatives promoting renewable energy integration and smart grid development have accelerated the adoption of these transformers, particularly in renewable power generation projects and urban substations where fire safety, compact design, and low maintenance are essential.

Which are the Top Cast Resin Dry Type Transformers companies

The following are the leading companies in the market. These players have adopted various strategies to increase their market penetration and strengthen their position in the cast resin dry type transformers industry.

- Schneider Electric

- Siemens Energy

- Eaton

- Hitachi Ltd

- Toshiba Corporation

- Fuji Electric Co., Ltd.

- CG Power & Industrial Solutions Ltd

- Kirloskar Electric Company

- Bharat Heavy Electricals Limited

- Hammond Power Solutions

What are the Recent Developments in the Cast Resin Dry Type Transformers Market

In August 2024, Hammond Power Solutions Inc is a leading manufacturer of dry-type, cast resin transformers, and related magnetics, announced its intention to increase its planned capital program by approximately $20 million over two years.

In September 2024, Hitachi Ltd. announced an investment exceeding $200 million to expand its operations in Brazil, marking a significant step in its global $1.5 billion plan to boost transformer manufacturing capacity. This investment, revealed during the celebration of the company's 70th anniversary in Brazil, represents Hitachi Energy's largest single investment in the country to date.

Key Benefits for Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the cast resin dry type transformer market analysis from 2024 to 2034 to identify the prevailing cast resin dry type transformer market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the cast resin dry type transformer market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global cast resin dry type transformer market growth forecast.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global cast resin dry type transformer market trends, key players, market segments, application areas, and market growth strategies.

Cast Resin Dry Type Transformer Market Report Highlights

| Aspects | Details |

| Market Size By 2034 | USD 8.7 billion |

| Growth Rate | CAGR of 6.7% |

| Forecast period | 2024 - 2034 |

| Report Pages | 427 |

| By Type |

|

| By Cooling Type |

|

| By Phase |

|

| By Voltage |

|

| By End Use |

|

| By Class |

|

| By Region |

|

| Key Market Players | CG Power & Industrial Solutions Ltd., Siemens Energy, Bharat Heavy Electricals Limited, Schneider Electric, Hammond Power Solutions Inc., Kirloskar Electric Company, Fuji Electric Co., Ltd., Eaton Corporation, Hitachi Ltd., TOSHIBA CORPORATION |

Analyst Review

According to the opinions of various CXOs of leading companies, the growing preference for safer, low maintenance, and environmentally sustainable solutions is expected to drive the growth of the cast resin dry type transformer market. As compared to traditional oil-immersed transformers, cast resin dry type transformers use solid epoxy resin for insulation, eliminating the need for flammable insulating liquids. This design significantly reduces fire hazards, making them ideal for installation in populated and sensitive environments such as commercial buildings, underground substations, hospitals, and high-rise structures. Their compact design, resistance to moisture, and minimal maintenance requirements enhance reliability and operational efficiency, particularly in urban and decentralized grid infrastructures. In addition, increasing investments in renewable energy and smart grids further support cast resin transformer market growth, as these transformers are well-suited for integration with solar and wind systems, offering improved safety and lower environmental impact. However, high initial costs and limited power rating capacity are expected to hamper the growth of the cast resin dry type transformer market. Compared to oil-immersed transformers, cast resin transformers typically involve higher manufacturing and installation costs due to advanced materials and specialized production processes such as vacuum casting. Furthermore, they are generally restricted to medium-voltage applications and may not be suitable for large-scale or high-voltage power distribution, limiting their use in heavy industrial or utility-scale projects. The cooling mechanisms of cast resin transformers, which often rely on natural or forced air, can also be less efficient under high load conditions. These constraints can deter utilities and developers with cost-sensitive or large-capacity requirements from adopting this technology, especially in regions with limited financial resources.

Growing demand for renewable energy integration and compact design and installation flexibility are the upcoming trends of cast resin dry type transformer market in the global.

Industrial is the leading application of cast resin dry type transformer market.

Asia-Pacific is the largest regional market for Cast Resin Dry Type Transformer.

The cast resin dry type transformer market was valued at $4.5 billion in 2024 and is estimated to reach $8.6 billion by 2034, exhibiting a CAGR of 6.7% from 2025 to 2034.

Schneider Electric, Siemens Energy, Eaton, Hitachi Ltd, TOSHIBA CORPORATION, Fuji Electric Co., Ltd, CG Power & Industrial Solutions Ltd, Kirloskar Electric Company, Bharat Heavy Electricals Limited, Hammond Power Solutions are the top companies to hold the market share in Cast Resin Dry Type Transformer.

Loading Table Of Content...

Loading Research Methodology...