Ceramic Foam Market Overview:

The global ceramic foam market size was valued at $419.4 million in 2021, and is projected to reach $797.6 million by 2031, growing at a CAGR of 6.7% from 2022 to 2031.

Ceramic foam is durable, tough foam, with three-dimensional mesh like network. It is categorized into two types which is open hole ceramics and closed hole ceramics. It is primarily made up from the oxide and non-oxide ceramics which includes, titanium oxide, silicone oxide, zirconia, alumina oxide, and others. It adopts several manufacturing techniques named replication methods, direct foaming, starch consolidation, gel casting foam, and impregnation. Ceramic foams are widely employed in high temperature application due to which it is one of the most preferred foams in metal casting industry. Furthermore, it has micro structure, thermal conductivity, and has a high porosity due to which it is widely used in the industrial application, in electronics, automotive, and other end-use sectors.

Surge in population coupled with rapid urbanization has increased the growth of the construction sector in both developed and developing economies, where closed cell type of ceramic foams is popularly used in construction industry as a thermal and acoustic insulation material. Closed cell type of ceramic foams are resistant to corrosion and does not create pollution, owing to which it is the most preferred ceramic foam in the construction industry. This is expected to boost the demand for ceramic foam in the growing building & construction sector. In addition, strong economic growth has surged the establishments of industries where ceramic foam is used in metal casting industry. This is projected to propel the growth of the ceramic foam market.

However, high cost of raw materials leads to increase in the price of ceramic foams over the past few years. Furthermore, high technological cost and complicated manufacturing process may hinder the growth of ceramic foams. These factors may hamper the growth of the ceramic foam market during the forecast period. Furthermore, a wide range of alternative substitute available over ceramic foam. For instance, foam glass ceramics with different composition such as, soda lime silica, glass bottles, clamshell, and others.

On the contrary, increase in usage of ceramics in diversified industry is projected to create new opportunities for the market. In addition, rise in use of ceramic foams in the pollution control applications has positively impacted the growth of the market; thus offering most lucrative opportunities for the market.

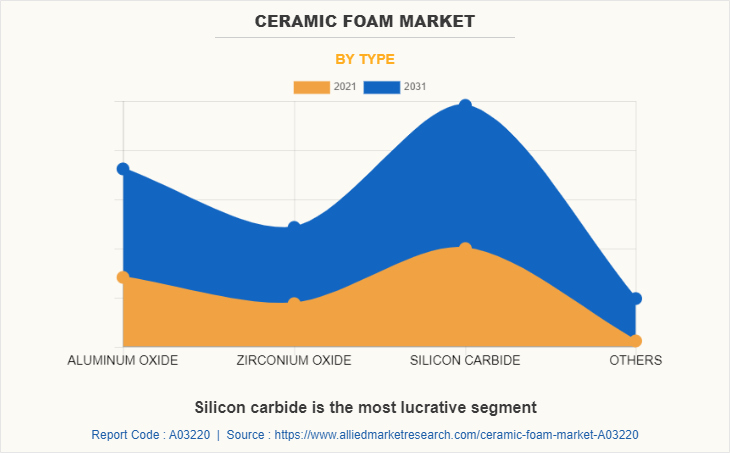

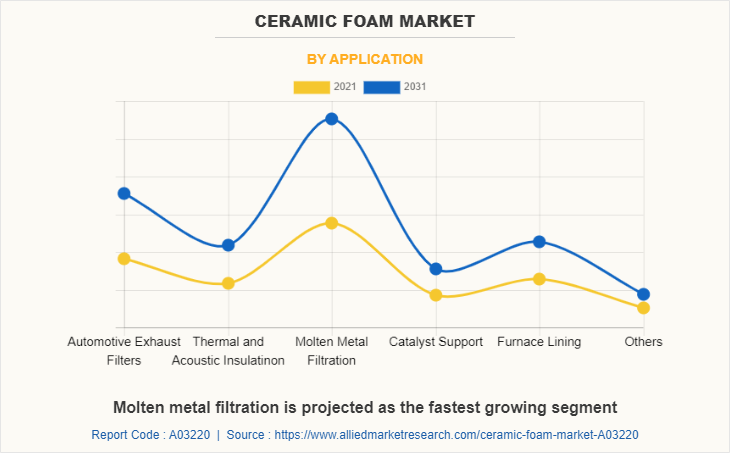

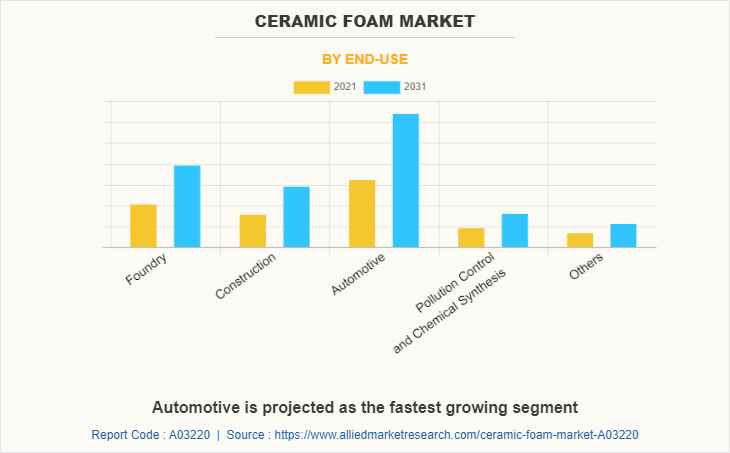

The ceramic foam market is segmented into type, application and end-use, and region. On the basis of type, the market is categorized into aluminum oxide, zirconium oxide, silicon carbide, and other. On the basis of application, it is divided into automotive exhaust filter, thermal and acoustic insulation, molten metal filtration, catalyst support, furnace lining, and other. On the basis of end-use, the market is classified into foundry, construction, automotive, pollution control and chemical synthesis, and other. Region-wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

The global ceramic foam market profiles leading players that include AdTech Metallurgical Materials Co., Ltd., Advanced Ceramic Materials, Altech Alloys India Pvt. Ltd., Drache Umwelttechnik GmbH, ERG Aerospace Corporation, FCRI Ceramics Testing & Technology Service Co., LTD, Galaxy Enterprise, LANIK s.r.o., Patronage, Pyrotek, Saint Gobain, SELEE Corporation, Tec Ceramic Solutions, Ultramet, and Wunder-Mold, Inc. The global ceramic foam market report provides in-depth competitive analysis as well as profiles of these major players.

In 2021, the silicon carbide segment was the largest revenue generator, and is anticipated to grow at a CAGR of 7.1% during the forecast period. Surge in demand for consumer goods has increased the establishments of chemical manufacturing units in both developed and developing economies where silicon carbide-ceramic foams are widely employed as protective coating in various industrial equipment and furnaces for enhancing the combustion process. Moreover, it finds application in automotive industry as automotive exhaust flirtation applications, in foam packaging industry, and catalyst carrier in metal casting sectors. These factors are anticipated to increase the sales of silicon carbide based ceramic foams; thus creating remunerative opportunities for the market.

By application, the molten metal filtration segment dominated the global market in 2021, and is anticipated to grow at a CAGR of 7.3% during forecast period. Molten metal filtration is a technique which is used to remove entertained solids from molten aluminum or any metal alloys before casting. Ceramic foams are used in molten metal filters to efficiently filter out tiny inclusions from the metals. Furthermore, rise in population across the globe, rapid establishment of industrial, chemical, and manufacturing units in both developed and developing economies have enhanced the demand for ceramic foams where silicon carbide based ceramic foams are widely employed as protective and insulating material in various industrial equipment and furnaces for enhancing the metal quality. These factors are anticipated to increase the sales of ceramic foams in molten metal filtration industry; thus creating remunerative opportunities for the market.

The ceramic foam market is expected to recover rapidly post-COVID-19 situation due to its increased dependency over automotive, pollution control and chemical synthesis sectors. For instance, according to an article published by Financial Express, the Indian automotive industry registered a growth of 15% in 2021, and is expected to grow at an average annual growth rate of 18.6% by 2025. This is expected to enhance the performance of the ceramic foam market post- COVID-19 scenario.

In 2021, the automotive segment was the largest revenue generator, and is anticipated to grow at a CAGR of 7.1% during the forecast period. Increase in the transportation and logistics activities has led to growth of the automotive sector where ceramic foams are widely used for enhancing the efficiency of exhaust gas conversion. In addition, ceramic foams offer high durability, strength, abrasion resistant, and waterproof property due to which it is most preferred ceramic foam in the automotive sector. This is projected to drive the growth of the ceramic foam in the rise in automotive sector. Moreover, rise in middle class income and young population has led to increase in trend for personal vehicles, and government support in the automotive industry has escalated the demand for ceramic foams.

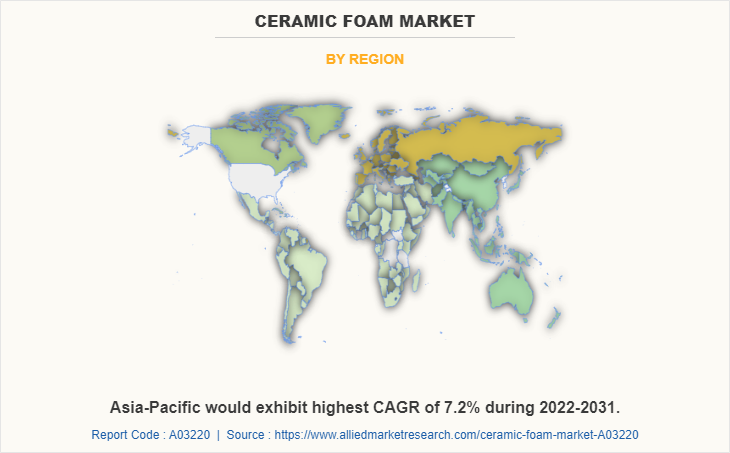

The Asia-Pacific ceramic foams market size is projected to grow at the highest CAGR of 7.2% during the forecast period and accounted for 46% of the ceramic foams market share in 2021. This is attributed to the proliferating demand for iron & steel from various end-use sectors such as industrial, construction infrastructure, automotive and others have led the iron & steel manufacturers to increase their production capacities where ceramic foams are widely used for temperature stability purposes and molten metal filtration purposes. For instance, according to a report published by India Brands Equity Foundation, India’s finished steel consumption is anticipated to increase to 230 metric ton (MT) by 2030-31 from 93.43 metric ton (MT) in 2020-21.

In addition, China's consumer electronics sector is increasing rapidly, which in turn has enhanced the performance of the ceramic foam market in the region. Ceramic foams are thermally stable and possess mesh like micro structure owing to which it is used in the manufacturing process of batteries, scaffolds, electrodes, and also used as coolant. According to a report published by the United Nations Statistics Division, China witnessed around 28.7% of the global manufacturing output for consumer electronic products in 2019. Also, countries such as India and Australia are witnessing a rapid increase in automotive sectors where ceramic foam is employed in automotive exhaust filtration.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the ceramic foam market analysis from 2021 to 2031 to identify the prevailing ceramic foam market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the ceramic foam market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global ceramic foam market trends, key players, market segments, application areas, and market growth strategies.

Ceramic Foam Market Report Highlights

| Aspects | Details |

| Market Size By 2031 | USD 797.6 million |

| Growth Rate | CAGR of 6.7% |

| Forecast period | 2021 - 2031 |

| Report Pages | 358 |

| By Type |

|

| By Application |

|

| By End-use |

|

| By Region |

|

| Key Market Players | ERG AEROSPACE CORPORATION, Patronage Filtex India Pvt.Ltd., Advanced Ceramic Materials, Ultramet, Wunder-Mold, Inc., Drache Umwelttechnik GmbH, Tec Ceramic Solutions, AdTech Metallurgical Materials Co., Ltd., FCRI Ceramics Testing & Technology Service Co., LTD, LANIK s.r.o., Galaxy Enterprise, SELEE Corporation, Altech Alloys India Pvt. Ltd., Saint Gobain, Pyrotek Inc. |

Analyst Review

According to CXOs of leading companies, the global ceramic foam market is expected to exhibit high growth potential. Ceramic foams are used in automotive exhaust filters, pollution control and chemical synthesis, metal filtration, acoustic and thermal insulation, and corrosion resistance purposes in a variety of end-use sectors such as building & construction, electronics, biomedical, industrial, and others. Industrial equipment requires high strength, corrosion protection, and abrasion resistant properties and it can be accomplished with the use of advanced ceramic foams.

In addition, ceramic foam possesses excellent significant properties such as high mechanical strength, acoustic and thermal insulation, chemical resistance, and corrosion resistance that makes it best suited for automotive exhaust filters applications. It serves as a protective and coolant material in under hood parts and engine components owing to its scratch resistance property. Furthermore, factors such as biocompatibility, bioactivity, and high strength makes it best suited component in dental industry for restoration, crowns, prostheses, and other. CXOs further added that sustained economic growth and development of the automotive and construction sector have increased the popularity of ceramic foam.

Closed cell type of ceramic foams are resistant to corrosion and does not create pollution, owing to which it is the most preferred ceramic foam in the construction industry.

The molten metal filtration segment dominated the global market in 2021 and is anticipated to grow at a CAGR of 7.3% during the forecast period.

The Asia-Pacific ceramic foams market accounted for largest share of more than 40% of across the globe in 2021.

The global ceramic foam market is projected to reach $797.6 million by 2031, growing at a CAGR of 6.7% from 2022 to 2031.

The global ceramic foam market profiles leading players that include AdTech Metallurgical Materials Co., Ltd., Advanced Ceramic Materials, Altech Alloys India Pvt. Ltd., Drache Umwelttechnik GmbH, ERG Aerospace Corporation, FCRI Ceramics Testing & Technology Service Co., LTD, Galaxy Enterprise, LANIK s.r.o., Patronage, Pyrotek, Saint Gobain, SELEE Corporation, Tec Ceramic Solutions, Ultramet, and Wunder-Mold, Inc.

Loading Table Of Content...