Co-Polymer Sealants Market Research, 2031

The global co-polymer sealants market was valued at $412.5 million in 2021, and is projected to reach $768.5 million by 2031, growing at a CAGR of 6.4% from 2022 to 2031.

Co-polymers are derived from different types of monomers that re linked with similar polymer chain. High strength, resilience, modulus to weight ratio, resistance to corrosion, lack of conductivity, and low production cost make co-polymer ideal for production of sealants. Co-polymer sealants offer durability and conformability, making them ideal to be used for preventing drafts and heat loss.

The growth of the global co-polymer sealants market is driven by increase in use of acrylic co-polymer-based sealants. Acrylic co-polymers, also known as emulsion polymers are versatile products, used for formulation of co-polymer sealants. Acrylic co-polymer based sealants are low cost, environment-friendly, and sustainable sealants, available in the market. Modified styrene acrylic co-polymer is another versatile polymer that is used for production of sealants. This type of co-polymer sealant offers high adhesion property with diverse substrate products.

Modified styrene acrylic co-polymer-based sealants are gaining importance across wet lamination and adhesion application, which drives the growth of the global market. Moreover, styrene/acrylic co-polymer emulsion containing UV-curable additive are used for production of sealants. This type of co-polymer sealants are used for sealing and adhesion application in Crack Bridging (CB) systems. Styrene/acrylic co-polymer based sealants pose beneficial characteristics such as resistance to water & alkalis, minimal dirt pick-up, and improved adhesion performance under dynamic and static crack.

In addition, styrene/acrylic co-polymer-based sealants offer improved elongation and tensile strength under subfreezing temperature condition. All these factors collectively drive the growth of the global co-polymer sealants market. Acrylic-styrene co-polymers are also gaining importance in the sealant industry. Acrylic-styrene co-polymer sealants offer high adhesion strength at low operating temperature, mechanical stability, and high drying efficiency, making them viable to be used for high application speed. Key-players in the co-polymer industry are using and testing different co-polymers for improving the adhesion property of sealants and expanding the product application across other industrial sectors.

Styrene-acrylic co-polymer is widely used for sealant production, which is used in the building and construction industry. For instance, VAE emulsion is used as an alternative over styrene-acrylic co-polymer for sealant production. Moreover, combination of VAE emulsion and styrene-acrylic co-polymer with inorganic fillers can be used for production of cement composite joint sealant. Leveling test, pour consistency test, constant elongation test, tensile test and shear test were conducted to test the efficiency of cement composite joint sealant. All these factors have escalated the growth of the co-polymer sealant market.

However, cyanoacrylate-based co-polymer sealants tend to increase the risk of infection, cytotoxicity, and tissue necrosis. Thus, hampering the demand for synthetic co-polymer sealants in the medical industry. To overcome this problem, the demand for synthetic glues based on other polymer materials such as poly(ethylene glycol) (PEG), polyurethanes, and polyesters is gaining importance in the medical use. This factor has negatively hampered the growth of co-polymer sealants in the medical industry as there are better alternatives available in the market.

Conversely, hydrogenated block co-polymers sealants are anticipated to offer new growth opportunities during the forecast period. Hydrogenated styrenic block co-polymers (HSBCs) consist of hard block of styrene and soft block of hydrogenated diene. HSBCs are compatible and used for formulation of sealants as HSBC-based sealants are durable and offer conformability. However, the demand for HSBC-based co-polymer sealants is limited but the demand is anticipated to rise in the future owing to high cohesive strength and ability to crosslink without a chemical vulcanization process.

These factors cut down the production cost of co-polymer sealants and high cohesive strength make co-polymer sealants a promising product to be used in the medical industry. High adhesive strength with water repellant property is utmost important during considering the use of sealants. Several R&D activities are carried out to study the molecular characteristics of alternating co-polymers of styrene derivatives, such as styrene, vinyl phenol (VP), and vinyl catechol (VC) for their intended use in sealants. Radical copolymerization of these styrene derivatives produces sealants that offer enhanced adhesion characteristic with improved water repellant property.

In addition, styrene butadiene block co-polymers (SBCs)-based sealants are gaining importance in the global market. SBCs are useful base materials, used for formulation of sealants as SBC-based co-polymer sealants offer unique combination of strength and elastomeric properties. All these factors are anticipated to drive the growth of the global market.

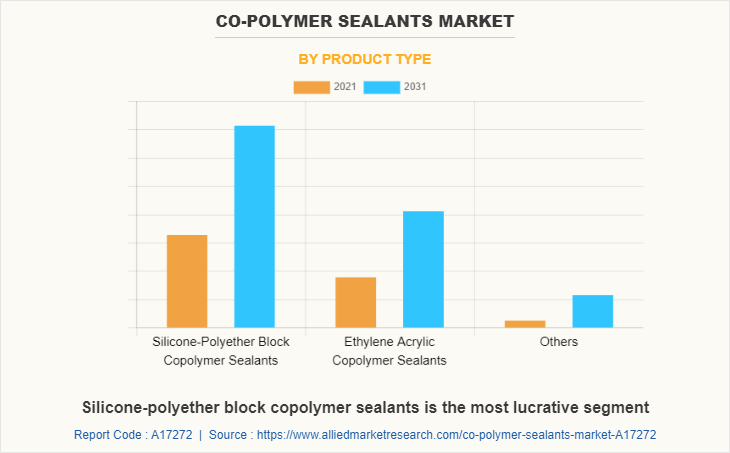

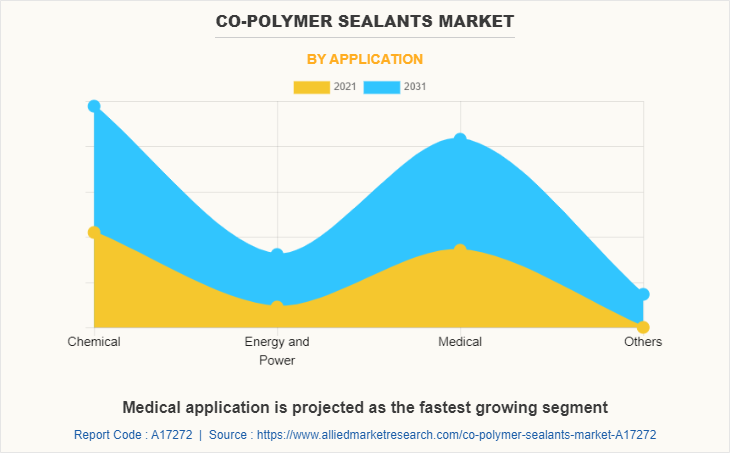

The co-polymer sealants market is segmented on the basis of product type, application, and region. On the basis of product type, the market is categorized into silicone-polyether block co-polymer sealants, ethylene acrylic co-polymer sealants, and others. The applications covered in the report includes chemical, energy & power, medical, and others. Region-wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

The global co-polymer sealants market profiles leading players that include, Allfasteners USA LLC, Ashland, BASF SE, Bostik, Chemtron, Inc., Dow, Evonik Industries, Henkel AG & Co. KGaA, Kraton Corporation, 3M Company, MAPEI, Momentive, Premier Building Solutions, SEKISUI Fuller, and Selleys.

The global co-polymer sealants market report provides in-depth competitive analysis as well as profiles of these major players. Key-players in the co-polymer sealants market are filing large number of patents to gain high market share and sustain competitive scenarios in the global market. For instance, Shanghai Baolijia New Material Co., Ltd. filed patent on use of styrene-acrylic co-polymer emulsion for building sealant. The patent was registered in 2018 and after several experimental test on the efficiency and versatility of the co-polymer sealant, the patent was approved in 2020.

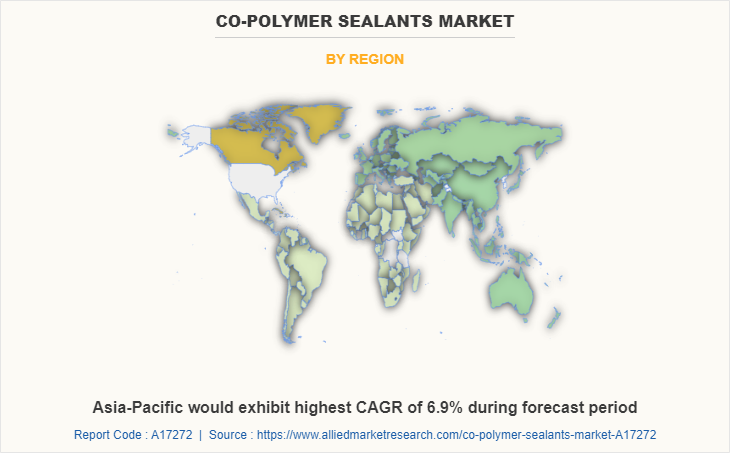

The Asia-Pacific co-polymer sealants market size is projected to grow at the highest CAGR during the forecast period, and accounted for a major market share in 2021 with 42% share in the global market. The rise in infrastructural activities in countries such as India and China surges the demand for construction chemicals which consequently increases the requirement of co-polymer sealants. In addition, the rise in demand for low volatile organic compound (VOCs) content co-polymer sealants from countries such as China, Japan, and India increases the demand for water based co-polymer sealants. This is a key market trend in the co-polymer sealants market. Silicone, acrylic, and epoxies based co-polymer sealants are dominantly used in the electronics industry. Electronic sector in India has experienced rapid growth owing to surge in sales of consumer electronic goods such as flat panel televisions, laptops, smart phones, and others. This is a key factor driving the growth of the co-polymer sealants market in the Asia-Pacific region.

In 2021, the silicon-polyether block co-polymer sealants was the largest revenue generator, and is anticipated to grow at a CAGR of 6.7% during the forecast period. High adhesion and performance of silicone-polyether block-based co-polymer sealants make them an ideal choice for adhesion of roofing substrates, tile, concrete, clay, slate, and pre-painted metals. Co-polymer sealants based on silicone-polyether are durable sealants used mainly for application that are exposed to high wind conditions as these sealants are capable withstanding wear & tear and crack formation.

In addition, silicone-polyether based co-polymer sealants tend to cure quick and offer smooth and paintable surface. All these factors have escalated the demand for silicone-polyether block co-polymer sealants. Silicone-polyether block co-polymer sealant are widely used for adhesion of damp, non-porous surfaces such as metals, glass, and glazed tiles owing to its versatility and formulation chemistry. The demand for silicone-polyether based co-polymer sealants is growing in the building and construction industry as they tend to minimize tile chattering, shifting, and offer enhanced adhesion as compared with other types of co-polymer sealants.

In 2021, the chemical application was the largest revenue generator and is anticipated to grow at a CAGR of 6.6% during the forecast period. Co-polymer sealants are vital in the chemical industry as these tend to fill gaps, cracks, joints, and other opening in the machineries and other reaction tanks & vessels. Presence of cracks and joints in industrial equipment might increase the risk of seepage of liquids, gas or other unwanted matter. Larger diameter vessels and tanks are generally fabricated in pieces and then joined together with mechanical equipment, such as nuts and industrial bolts. However, managing the risk of cracks at the equipment joints is inevitable. Moreover, vibrational effects and other mechanical factors tend to form invisible cracks near the equipment joints, thereby increasing the risk of equipment failure and product degradation. Co-polymer sealants are considered as vital adhesive products as compared to other industrial sealants. Co-polymer sealants used in the chemical industry are mainly based on polyester, polyamide, polysulfide, vinyl, and polyurethane sealants.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the co-polymer sealants market analysis from 2021 to 2031 to identify the prevailing co-polymer sealants market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the co-polymer sealants market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global co-polymer sealants market trends, key players, market segments, application areas, and market growth strategies.

Co-Polymer Sealants Market Report Highlights

| Aspects | Details |

| Market Size By 2031 | USD 768.5 million |

| Growth Rate | CAGR of 6.4% |

| Forecast period | 2021 - 2031 |

| Report Pages | 260 |

| By Product Type |

|

| By Application |

|

| By Region |

|

| Key Market Players | Allfasteners USA LLC, Bostik, Momentive, Ashland Global Holdings Inc., Selleys, Kraton Corporation, Dow, Evonik Industries AG., Henkel AG and Co. KgaA, MAPEI, BASF SE, SEKISUI FULLER, Chemtron Inc., Premier Building Solutions, 3M Company |

Analyst Review

The global co-polymer sealants market is expected to exhibit high growth owing to its use in medical and solar panel application. Solar modules are gaining importance owing to the growing renewable energy sector. Solar module is made up of 6 major components, such as tempered glass, EVA film, back sheet, aluminum alloy frame, junction box, and sealant. Solar panels working condition depend on type of sealant used for adhesion of components as the panels tend to sustain harsh and changing environmental conditions. Silicone-polyether block co-polymer sealant are mostly widely used sealants for in solar panels.

Co-polymer sealants are versatile choice in the medical industry as they tend minimize the risk of seepage of body fluids. There are several other substitute sealants that are used in the medical industry. However, toxicity and high production cost have escalated the demand for biodegradable and low cost surgical sealants. Several liquid-based co-polymer sealants based on PEG4-PLGA-NHS and PEG4-NH2 co-polymer are gaining importance, owing to their environment-friendly characteristic and low cost is anticipated to offer new growth opportunities. Mechanical, rheological, and cross-linking property of liquid-based co-polymer sealants, make them versatile and widely adopted sealants in the medical industry during production of precision surgical instruments.

In addition, packaging of medical surgical, implants, and other miniature tools is crucial as improper packaging leads to risk associated, such as purity and potency. Thus, there is need for proper packaging material and use of sealants that are capable of offering required barrier and adsorption characteristic. Co-polymer sealants are gaining importance across medical packaging of implants and other sensitive devices as this type of sealants meet all the required regulatory guidelines and offer high adhesion property

Surgical sealants play a crucial role that help to prevent seepage of fluids and liquids, which in turn help to minimize hemostasis and close incisions. Co-polymer sealants are a versatile choice in the medical industry as they tend minimize the risk of seepage of body fluids. There are several other substitute sealants that are used in the medical industry. However, toxicity and high production cost have escalated the demand for biodegradable and low cost surgical sealants. Several liquid-based co-polymer sealants based on PEG4-PLGA-NHS, and PEG4-NH2 co-polymer are gaining importance, owing to their environment-friendly characteristic and low cost. These are the upcoming trends of co-polymer sealants market in the world

Asia-Pacific is the largest regional market for co-polymer sealants

Chemical application is the leading application of co-polymer sealants market

The global co-polymer sealants market forecast was valued at $412.5 million in 2021, and is projected to reach $768.5 million by 2031, growing at a CAGR of 6.4% from 2022 to 2031.

Allfasteners USA LLC, Ashland, BASF SE, and Bostik are the top companies to hold the market share in co-polymer sealants

Loading Table Of Content...