Composite Resin Market Outlook - 2032

The global composite resin market size was valued at $25.4 billion in 2022, and is projected to reach $49.4 billion by 2032, growing at a CAGR of 7% from 2023 to 2032.

Report Key Highlighters:

- The composite resin market has been analyzed in both value and volume. The value of the composite resin market is analyzed in millions while the volume is analyzed in kilo tons.

- Global Composite resin market is fragmented in nature with many players such as Hexion Inc., SABIC, Celanese Corporation, Huntsman International LLC, Dow, Evonik Industries AG, Scott Bader Company Ltd., DSM, Allnex GmbH, and Sumitomo Bakelite Co., Ltd. Corp. Also tracked key strategies such as product launches, acquisitions, mergers, expansion etc. of various manufacturers of Composite resin.

- Included more than 20 countries in the report which covers market volume as well as market value for all the countries of composite resin market.

- Covered the detailed list of manufacturers by application of composite resin market. It covers the product information, application, and geographical presence of the companies.

- Conducted primary interviews with raw material suppliers, wholesalers, suppliers, and manufacturers of composite resin market to understand the market trends, growth factors, pricing, and key players competitive strategies.

Resins work as a glue to hold the fibers together and protect the fibers from mechanical and environmental damage. There are two major groups of resins. These include thermosets and thermoplastics which are made of polymers (large molecules made up of long chains of smaller molecules). Polyester, epoxy, vinyl ester, and polyurethane are examples of common thermosets resins. Acrylonitrile butadiene styrene, polyethylene, polystyrene, and polycarbonate are typical thermoplastics resins.

In the context of composite materials, resins are an important component that serve as the matrix material to hold together the reinforcing fibers or particles. The resin used in composites can be made from a variety of materials, such as epoxies, polyesters, vinyl esters, and thermoplastics. The resin is typically chosen based on its properties and compatibility with the reinforcing material. For example, epoxy resins are often used with carbon or glass fibers, while polyester resins are commonly used with fiberglass.

The resin in a composite plays an important role in determining the overall performance of the material. It provides strength and stiffness, as well as resistance to impact, heat, and moisture. The resin also affects the processing of the composite material, such as its curing time and temperature. One of the challenges in using resins in composites is achieving a good bond between the resin and the reinforcing material. This can be improved by surface treatment of the reinforcing material or by using coupling agents that enhance the adhesion between the two materials. Overall, the choice of resin is an important consideration in the design and production of composite materials and can greatly impact their performance and properties.

The global composite resins market is driven by a surge in demand for composite resins in the aerospace sector as composite resins have many applications in the aerospace industry due to their high strength-to-weight ratio, excellent durability, and resistance to heat and corrosion. One of the major drivers of market expansion is the rise in the use of composite resin in the building and construction industry, as well as in aerospace and military applications.

Another element driving the composite resin market growth is the demand for lightweight materials in the transportation sector, which in turn increases fuel efficiency. Furthermore, the rise in demand for thermoplastic resins is imposing a positive outlook on the growth of the market. On the other hand, the high cost associated with manufacturing and the challenges in recycling limits the growth of the market.

Increase in Demand for Composite Resins in Several Industries

Composite resins are gaining popularity in several industries due to their unique properties and versatility. These materials are made by combining two or more different materials to create a stronger and more durable product. Here are some industries where composite resins are in high demand:

Automotive industry: Composite resins are used to make lightweight and strong parts for cars, such as body panels and engine components. They are also used in the production of aircraft and other transportation vehicles.

Construction industry: Composite resins are used in the construction of buildings, bridges, and other structures. They are used to reinforce concrete, to create lightweight panels for walls and ceilings, and to make composite decking.

Marine industry: Composite resins are used to make boats, ships, and other watercraft. They are highly resistant to corrosion, water damage, and UV radiation, making them ideal for use in marine environments.

Sports equipment industry: Composite resins are used to make lightweight and durable sporting goods such as tennis rackets, golf clubs, and skis. They offer excellent strength and stiffness properties, as well as resistance to impact and vibration.

Medical industry: Composite resins are used in the production of dental fillings, implants, and prosthetics. They are biocompatible, which means they do not react with the human body, and can withstand the harsh conditions inside the mouth.

Thus, composite resins are gaining popularity in various industries due to their unique properties such as strength, durability, and lightweight. The market is expected to witness innovative applications in the future with the growing demand for these materials.

The composite resin market is segmented on the basis of resin type, manufacturing process, application and region. By resin type, the market is bifurcated into thermosets and thermoplastics. By resin type, the market is categorized into layup, filament, winding, injection molding, pultrusion, compression molding, and resin transfer molding. By application, the market is fragmented into construction & infrastructure, transportation, electricals & electronics, pipes & tanks, wind energy, marine, aerospace & defense and others. By region, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

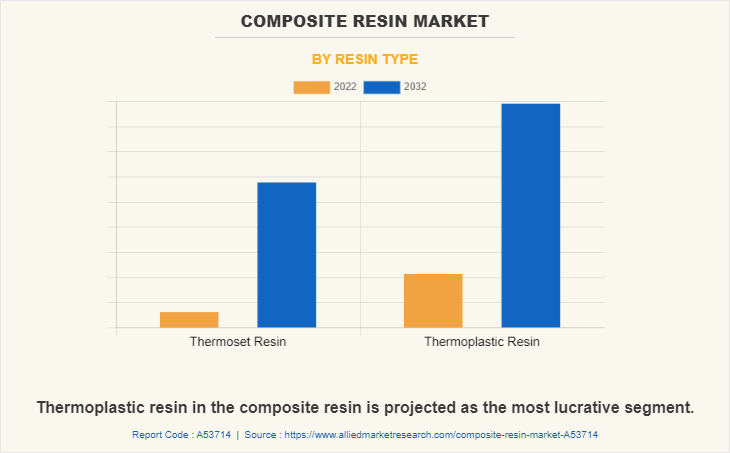

Composite Resin Market By Resin Type

Based on resin type, the thermoplastic resin segment dominated the largest market share in 2022 as thermoplastic resins are a group of materials that can be melted and re-molded when heated, making them useful in a wide range of industrial and commercial applications.

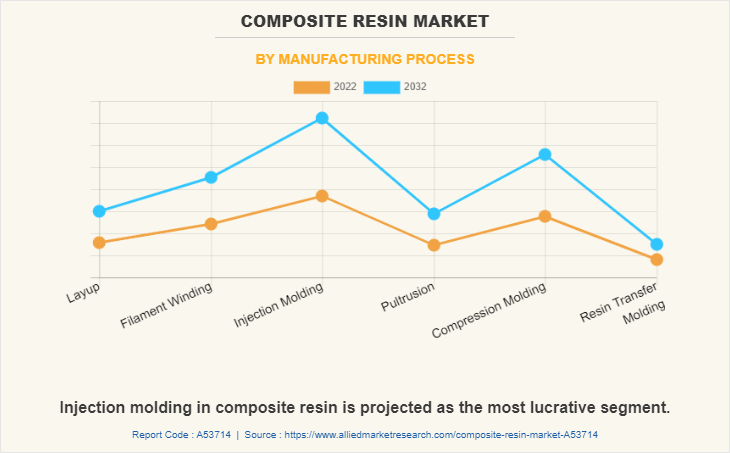

Composite Resin Market By Manufacturing Process

Based on the manufacturing process, the injection molding segment dominated the largest market share in 2022 as injection molding is a highly automated process, which can reduce labor costs and increase efficiency in manufacturing composite resin products.

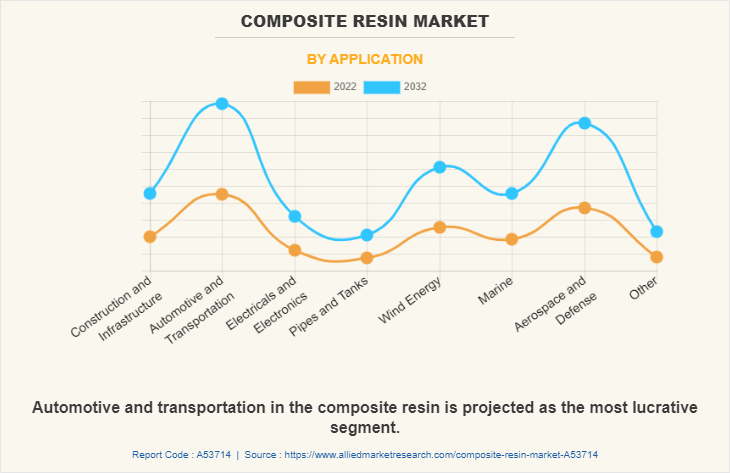

Composite Resin Market By Application

Based on application, the automotive and transportation segment dominated the largest market share in 2022 owing to composite resins are widely used in the automotive and transportation sector because they offer several advantages over traditional materials, such as metals and plastics.

Composite Resin Market By Region

Based on region, the Asia-Pacific region dominated the highest market share in 2022 due to the highly developed automotive and transportation sector in China and the continuous investments are done in the region through the years to advance the automotive and transportation.

The major players operating in the industry include Hexion Inc., SABIC, Celanese Corporation, Huntsman International LLC, Dow, Evonik Industries AG, Scott Bader Company Ltd., DSM, Allnex GmbH, and Sumitomo Bakelite Co., Ltd. Corp. These players have adopted product launch as their key strategy to increase their market shares.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the composite resin market analysis from 2022 to 2032 to identify the prevailing composite resin market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the composite resin market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global composite resin market trends, key players, market segments, application areas, and market growth strategies.

Composite Resin Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 49.4 billion |

| Growth Rate | CAGR of 7% |

| Forecast period | 2022 - 2032 |

| Report Pages | 350 |

| By Resin Type |

|

| By Manufacturing Process |

|

| By Application |

|

| By Region |

|

| Key Market Players | Celanese Corporation, Sumitomo Bakelite Co., Ltd., Scott Bader Company Ltd., SABIC, Hexion Inc., Evonik Industries AG, Allnex GmbH, Dow, Huntsman International LLC, DSM |

Analyst Review

The composite resins market is consolidated in nature. There is an increase in demand for composite resins in different industries including construction, wind energy, aerospace, consumer goods, and healthcare. An increase in the number of applications of composite resins as these are temperature and weather resistant, this factor is projected to boost the market growth during the forecast period.

The industry is characterized by a high number of new market entrants that are seeking to tap lucrative opportunities in the global market while existing players are entering into strategic collaborations to increase capacities & expand their reach into emerging markets. The joint venture, merger, and acquisition activities in the industry have increased significantly over the past decade. Companies constantly seek to establish long-term contract agreements with trusted partners for sustainable business operations globally.

Automotive and transportation is the leading application of Composite Resin Market.

Asia-Pacific is the largest regional market for Composite Resin

The Composite Resin Market valued for $25.4 billion in 2022 and is estimated to reach $49.4 billion by 2032, exhibiting a CAGR of 7% from 2023 to 2032.

The major players operating in the industry include Hexion Inc., SABIC, Celanese Corporation, Huntsman International LLC, Dow, Evonik Industries AG, Scott Bader Company Ltd., DSM, Allnex GmbH, and Sumitomo Bakelite Co., Ltd. Corp.

Rise in Use of Composite Resins in the Medical Sector

Loading Table Of Content...

Loading Research Methodology...