Enclosed Conveyor Belts Market Research, 2032

The global enclosed conveyor belts market size was valued at $646.8 million in 2023, and is projected to reach $1,029.6 million by 2032, growing at a CAGR of 5.4% from 2024 to 2032.The risk of injuries and mishaps at work decreases with enclosed conveyor belts as they surround moving parts and materials in a protective shell. This design contributes to the preservation of product integrity by eliminating contamination from dust, debris, or other environmental pollutants. Furthermore, enclosed conveyor belts have the option to incorporate features such as dust extraction systems and spillage control mechanisms to further enhance efficiency and safety.

Report Key Highlighters

• The enclosed conveyor belts market has been analyzed across more than 16 countries. The analysis includes a country-by-country breakdown analysis in terms of value ($million) available from 2022 to 2032.

• The research combined high-quality data, professional opinion, and research, with significant independent opinion. The research methodology aims to provide a balanced view of the global enclosed conveyor belts market, and help stakeholders make educated decisions to achieve ambitious growth objectives.

• The research reviewed more than 3,700 product catalogs, annual reports, industry descriptions, and other comparable resources from leading industry players to gain a better understanding of the enclosed conveyor belts market.

• The enclosed conveyor belts market share is marginally fragmented, with players such as Fenner Dunlop, Continental AG, Bridgestone Corporation, Flexco, Buhler, Intralox, Rexnord Corporation, Habasit AG, Fluent Conveyors, and KWS Manufacturing Company Ltd. Major strategies such as product launch, partnerships, expansion, and other strategies of players operating in the market are tracked and monitored.

Market Dynamics

Growth in the enclosed conveyor belts market is anticipated to be driven by an increase in the need for effective material transportation across a range of sectors. As they handle bulk products, grains, or powders with efficiency and dependability, enclosed conveyors belts are highly valued in a variety of industries, including manufacturing, logistics, mining, and agriculture. These conveyors provide a number of benefits, such as the ability to handle goods with gentleness, great capacity, and versatility in moving a variety of products.

Enclosed conveyors belts are essential for maintaining a steady and uninterrupted flow of materials during the manufacturing process in sectors such as mining and agriculture where bulk material handling is a fundamental component of operations. They make it easier for goods to travel between locations, such storage facilities and processing units, or from production lines to distribution centers, with minimal manual intervention and maximum efficiency.

In addition, enclosed conveyor belts provide consistent performance even in the most challenging circumstances as they are built to withstand harsh weather, high temperatures, and abrasive substances. As long as companies maintain their emphasis on productivity, cost-effectiveness, and efficiency in their material handling operations, there will likely be a strong market for enclosed belt conveyors, which will propel enclosed conveyor belts market expansion in the near future.

Enclosed conveyor belts are manufactured using various hazardous chemicals. These components include primary amine-based sulfenamides, such as N-cyclo-hexyl-2-benzothiazole sulfenamide, and thiazoles, such as 2-mercaptobenzothiazole. These ’substances of very high concern’ (SVHC’s) have a negative effect on humans and the environment. Workers who regularly work with them as part of their job role, such as conveyor maintenance staff and belt splicers for example, are potentially at greatest risk and therefore most in need of safeguards. Thus, governments have implemented various regulations that safeguard the interests of the workers. For example, the EU REACH Regulation applies to businesses that import, make, sell, or distribute chemicals in region, whether as raw materials or in their finished state. Such factors are anticipated to have negative impacts on the enclosed conveyor belts market.

Moreover, technological developments, especially in the areas of digitization, automation, and conveyor design, are expected to drive enclosed conveyor belts market growth. Technological developments have the capacity to improve enclosed conveyor belt systems' performance, dependability, and sustainability, which propels market expansion. Manufacturers create next-generation conveyor solutions with better performance and lower costs by utilizing cutting-edge technology including lightweight materials, energy-efficient components, and sophisticated control systems.

The fusion of intelligent sensors with IoT (Internet of Things) connectivity, for instance, permits predictive maintenance, energy usage management, and real-time conveyor operation monitoring. Further streamlining conveyor operation and minimizing manual intervention are automation technologies, which include automatic belt tracking, tensioning systems, and material flow management that benefit end users by lowering labor costs and increasing productivity. In addition, advances in conveyor design allow increased flexibility and scalability to accommodate a variety of application requirements and site constraints. Examples of these innovations include modular construction, changeable frame configurations, and configurable features. Such factors are expected to drive the growth pf enclosed conveyor belts market

Digitalization enables the implementation of artificial intelligence (AI), machine learning algorithms, and advanced data analytics to enhance decision-making processes, pinpoint operational inefficiencies, and optimize conveyor performance. Enclosed conveyor belts market participants have established a unique identity, generated fresh revenue streams, and seized new prospects in sectors such as manufacturing, logistics, mining, and agriculture by adopting cutting-edge technology. These elements should present profitable growth prospects for the enclosed conveyor belts industry.

Segmental Overview

The enclosed conveyor belts market forecast is segmented on the basis of enclosure type, installation type, application, and region. By enclosure type, the market is divided into fully enclosed belt conveyors, and partial enclosed belt conveyors. By installation type, the market is bifurcated into overhead and floor. By application, the market is classified into mining, construction, manufacturing, others. Region-wise, it is analyzed across North America (the U.S., Canada, and Mexico), Europe (the UK, France, Germany, Italy, and rest of Europe), Asia-Pacific (China, Japan, India, South Korea, and rest of Asia-Pacific), Latin America, and Middle East & Africa.

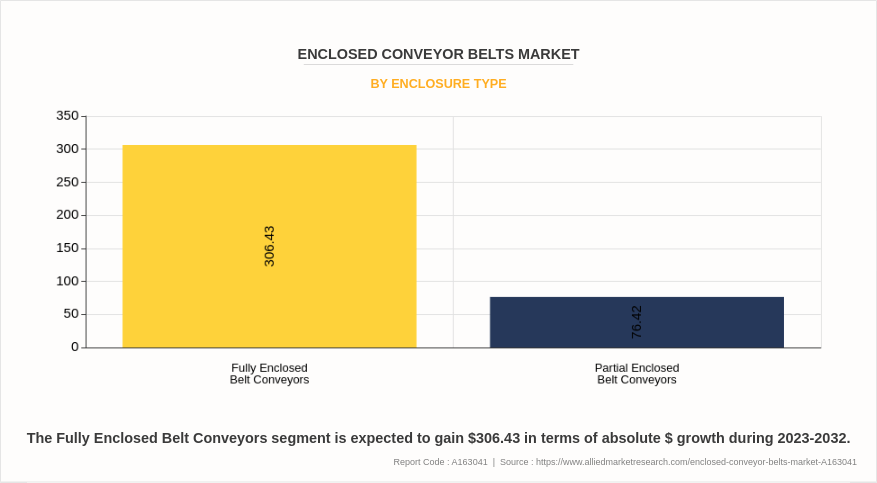

By type, the enclosed conveyor belts market overview is divided into fully enclosed belt conveyors, and partial enclosed belt conveyors. In 2022, the fully enclosed belt conveyors segment dominated the enclosed conveyor belts market, in terms of revenue, and the partial enclosed belt conveyors segment is expected to grow with a higher CAGR during the forecast period.

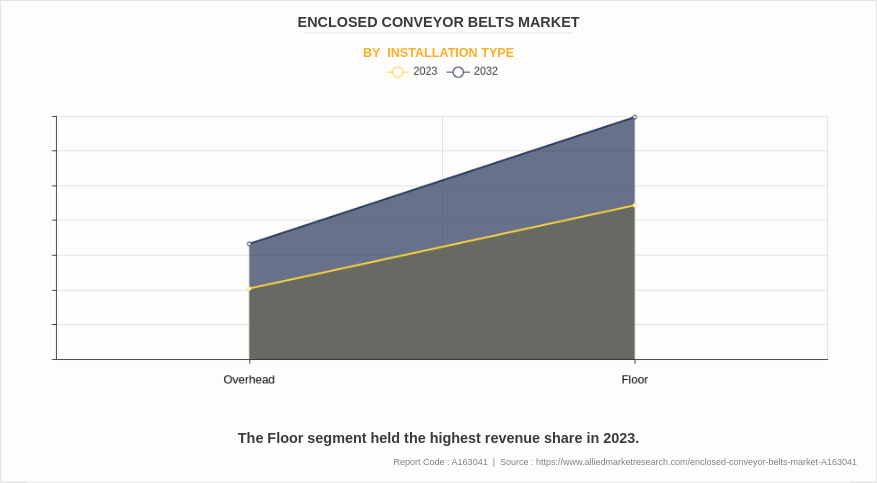

By installation type, the enclosed conveyor belts market is divided into overhead, and floor. In 2022, the floor segment dominated the enclosed conveyor belts market, in terms of revenue, and overhead segment is expected to witness growth at a higher CAGR during the forecast period.

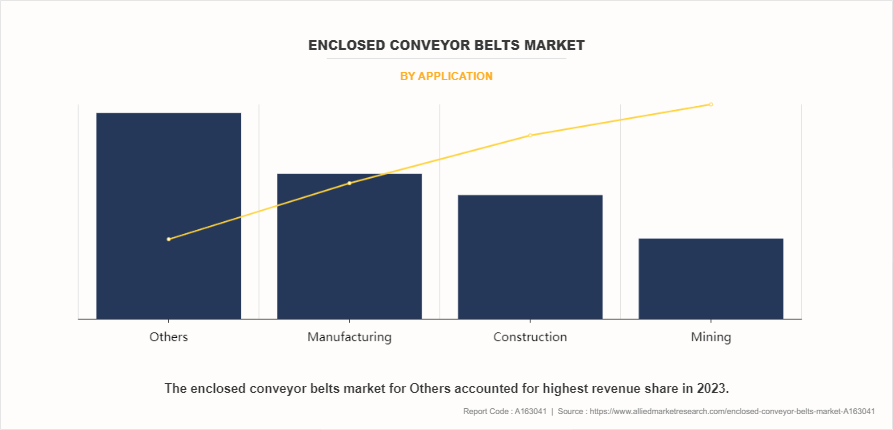

By application, the enclosed conveyor belts market is divided into mining, construction, manufacturing, others. In 2022, the others segment dominated the enclosed conveyor belts market, in terms of revenue, and the mining segment is expected to witness growth at a higher CAGR during the forecast period.

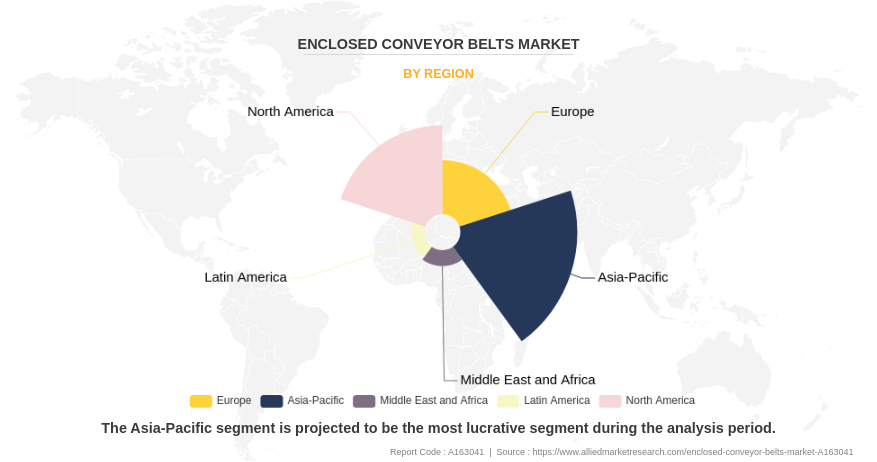

Region-wise, the enclosed conveyor belts market is studied across North America (the U.S., Canada, and Mexico), Europe (the UK, France, Germany, Italy, and rest of Europe), Asia-Pacific (China, Japan, India, South Korea, and rest of Asia-Pacific), and Latin America, and Middle East & Africa. Asia-Pacific accounted for the highest market share in 2022 and Middle East & Africa region is expected to grow with the highest CAGR during the forecast period.

Competition Analysis

Key companies profiled in the enclosed conveyor belts market report include Fenner Dunlop, Continental AG, Bridgestone Corporation, Flexco, Buhler, Intralox, Rexnord Corporation, Habasit AG, Fluent Conveyors, and KWS Manufacturing Company Ltd.

The major players that operate in the global market have adopted key strategies such as acquisition, business expansion, product launch, and other strategies to strengthen their market outreach and sustain the stiff competition in the market.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the enclosed conveyor belts market analysis from 2023 to 2032 to identify the prevailing enclosed conveyor belts market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the enclosed conveyor belts market outlook and segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global enclosed conveyor belts market trends, key players, market segments, application areas, and market growth strategies.

Enclosed Conveyor Belts Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 1 billion |

| Growth Rate | CAGR of 5.4% |

| Forecast period | 2023 - 2032 |

| Report Pages | 220 |

| By Enclosure Type |

|

| By Installation Type |

|

| By Application |

|

| By Region |

|

Analyst Review

The rising implementation of automation in material handling operations across various sectors is fueling the need for enclosed conveyor belts. Automated conveyor setups provide advantages in efficiency, cost reduction related to labor, and enhanced safety by minimizing manual tasks and optimizing material movement within manufacturing, distribution, and logistical settings. In addition, strict regulations that monitor the containment of dust and materials in industries such as mining, agriculture, and construction contribute to the demand for enclosed conveyor belts.

However, a significant challenge in the enclosed conveyor belts market stems from the substantial initial investment required for procuring and installing conveyor systems. Yet, advancements in enclosed conveyor belts design and manufacturing technology offer avenues for improvement. Innovations such as the utilization of lightweight materials, energy-efficient components, and sophisticated control systems have the potential to boost conveyor performance, trim operational expenses, and elevate overall efficiency, thus fostering market expansion.

The global enclosed conveyor belts market was valued at $646.8 million in 2023, and is projected to reach $1,029.6 million by 2032, registering a CAGR of 5.4% from 2024 to 2032.

The forecast period considered for the global enclosed belt conveyor is 2023 to 2032, wherein, 2023 is the base year, 2024 is the estimated year, and 2032 is the forecast year.

The latest version of global enclosed belt conveyor report can be obtained on demand from the website.

The base year considered in the global enclosed belt conveyor report is 2023.

The major players profiled in the enclosed belt conveyor include Fenner Dunlop, Continental AG, Bridgestone Corporation, Flexco, Buhler, Intralox, Rexnord Corporation, Habasit AG, Fluent Conveyors, and KWS Manufacturing Company Ltd.

The top ten market players are selected based on two key attributes - competitive strength and market positioning.

The report contains an exclusive company profile section, where leading companies in the market are profiled. These profiles typically cover company overview, geographical presence, market dominance (in terms of revenue and volume sales), various strategies, and recent developments.

Based on installation type, the floor segment was the largest revenue generator in 2023.

Loading Table Of Content...

Loading Research Methodology...