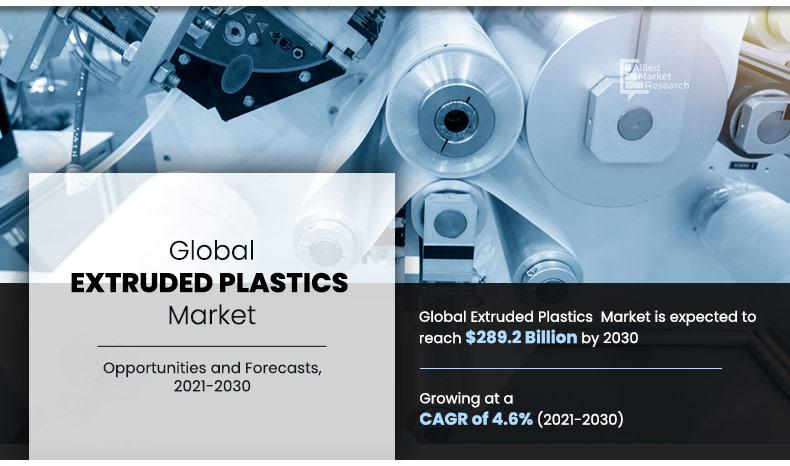

Extruded Plastics Market Outlook - 2021–2030

The global extruded plastics market was valued at $185.6 billion in 2020, and is projected to reach $289.2 billion by 2030, growing at a CAGR of 4.6% from 2021 to 2030.

Extruded plastics are materials manufactured by melting and forming of high volume polymeric material in a continuous process. They are used to generate a wide range of plastic-based products, parts and forms such as pipes, tubes, films, wraps, sheets, and other custom products. They find application in a variety of industries such as building & construction, packaging, automotive, and others, owing to their availability in almost all shapes and sizes.

Increase in population has increased demand for various consumer goods, which has led the packaging sector to witness a significant growth where extruded plastics are widely used for manufacturing films & wraps. For instance, according to a report published by the National Investment Promotion and Facilitation Agency, the packaging industry was worth over $917 billion in 2019, and is expected to reach $1.05 trillion by 2024, growing at a CAGR of 2.8%. This acts as one of the key drivers responsible for growth of the extruded plastics market during the forecast period. In addition, the building & construction sector is growing rapidly in both developed and developing economies, owing to increasing demand for commercial space such as offices, hotels, malls, industrial corridors, and others. Furthermore, increasing investments in building infrastructure in countries such as the U.S., China, Japan, Mexico, India, and others have led the building & construction sector to witness a significant growth. For instance, according to a report published by Invest India, the Indian government has an investment budget of $1.4 trillion on infrastructure in which 16% of the amount is contributed towards the development of urban infrastructure. Extruded plastics offer limitless possibilities in design achieved by bending, molding, and extrusion. They are low conductors of heat and electricity; thus are widely used as insulating materials, cladding panels, and pipes in offices, malls, residential facilities, and other construction sites. These are the major extruded plastics market growth factors.

However, several countries such as Taiwan, Bangladesh, the UK, China, and others have made efforts to ban the use of various extruded plastic-based products. This has set back the key manufacturers from producing extruded plastics. Furthermore, the manufacturing process of extruded plastics involves the release of several toxic chemical constituents that damages the immune system of humans. Also, long term exposure to extruded plastics may cause health-related problems such as irritation in eye, vision failure, respiratory problems, dizziness, genotoxic, cardiovascular, and gastrointestinal problems. This factor hampers the market growth.

On the contrary, extruded plastics are widely employed as a substitute over metals for manufacturing long pipes & tubes used for irrigation in agriculture, manufacturing fishing rods for sports & leisure activities, and others. Also, they are highly resistance to corrosion that makes the customers become more linear towards purchasing extruded plastics-based products. In addition, factors such as growing concentration of manufacturers, availability of feedstock at reduced prices, and arrival of local players has led the manufacturers to offer extruded plastics at low prices. It is a key factor that is anticipated to offer new opportunity in the global extruded plastics material market.

The extruded plastics market is segmented on the basis of material type, application, end use, and region. On the basis of material type, the market is categorized into polyethylene, polypropylene, polyvinyl chloride, polystyrene, and others. On the basis of application, it is divided into pipes & tubing, wire insulation, windows & door profiles, films, and others. By end use, it is classified into building & construction, packaging, automotive, industrial, and others. Region-wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

The global extruded plastics market profiles leading players that include Atlantis Plastics, Inc., China Plastic Extrusion Ltd., Crescent Plastics Incorporated, GSH Industries, Keller Plastics Inc., Lakeland Plastics, Inc., Nenplas Limited, Petro Packaging Company, Inc., Pexco LLC, and Saint Gobain.

Extruded Plastics market, by region

The Asia-Pacific extruded plastics market size is projected to grow at the highest CAGR of 5.4% during the forecast period and accounted for 40.2% of extruded plastics market share in 2020. This is attributed to the proliferating demand for consumer electronic products where extruded plastics are used as a prime insulating material. For instance, according to a report published by the United Nations Statistics Division, china witnessed around 28.7% of the global manufacturing output for consumer electronic products in 2019. In addition to this, countries such as India and Australia are witnessing a rapid increase in automotive sectors where extruded plastics are widely used in sealing systems to enhance the aerodynamics of vehicle. For instance, according to a report published by India Brands Equity Foundation, the number of passenger vehicles stood at 279,745 units in March 2021, registering a growth of 28.39% as compared to 217,879 units in March 2020.

By Region

Asia-Pacific would exhibit highest CAGR of 5.4% during 2021-2030.

Extruded Plastics market, by material type

In 2020, the polyethylene segment was the largest revenue generator, and is anticipated to grow at a CAGR of 4.8% during the forecast period. Polyethylene-based extruded plastics are versatile and low cost extruded plastics generally available in high density polyethylene (HDPE), medium polyethylene, and low density polyethylene (LDPE) grades. The polyethylene extrusion are tough, translucent, have low coefficient of friction, and offers good chemical resistance as compared to other types of extruded plastics. This factor is escalating the growth of this segment in the global market.

By Material Type

Polypropylene is the most lucrative segment

Extruded Plastics market, by application

By application, the films segment dominated the global market in 2020, and is anticipated to grow at a CAGR of 4.8% during forecast period. This is attributed to the fact that extruded plastics-based films are widely used for packaging application in food & beverage, pharmaceutical, agriculture, and other end use sectors. In addition, the increasing awareness for health and hygiene-related activities has surged the demand for packed consumer goods where extruded plastic-based films are widely used for packaging applications. These factors are augmenting the growth of the films segment in the global extruded plastics market.

By Application

Windows and door profile is projected as the fastest growing segment

Extruded Plastics market, by end use

By end-use, the packaging end use segment dominated the global market in 2020, and is anticipated to grow at a CAGR of 4.9% during the forecast period. This is attributed to the increase in global trade that has rationalized tariffs and lowered trade barriers which in turn have given rise to international trade in packaging machinery and materials where extruded plastics-based films are widely used for packaging applications.

By End-use

Building & Construction end-use is projected as the fastest growing segment

Key benefits for stakeholders

- Porter’s five forces analysis helps analyze the potential of buyers & suppliers and the competitive scenario of the industry for strategy building.

- It outlines the current extruded plastics market trends and future estimations from 2020 to 2030 to understand the prevailing opportunities and potential investment pockets.

- The major countries in the region have been mapped according to their individual revenue contribution to the regional market.

- The key drivers, restraints, and opportunities and their detailed impact analysis are explained in the study.

- The profiles of key players and their key strategic developments are enlisted in the report.

Impact Of Covid-19 On The Global Extruded Plastics Market

- The novel coronavirus is an incomparable global pandemic that has spread to over 180 countries and caused huge losses of lives and the economy around the globe.

- The major end-users of extruded plastics such as building & construction, packaging, automotive, industrial, and electrical & electronics have been negatively impacted due to the ongoing pandemic outbreak.

- The ongoing health crisis has increased the supply-demand gap, hampering the global extruded plastics supply chain. According to an article published by The Economic Times, the exports of electronic products such as wires and cables, semiconductors, and others have dipped due to supply chain issues.

- Also, several electronics companies have either shut down or shrank their operations due to the risk of infections among the workforce where extruded plastics are widely used as an insulating material in various consumer electronics products.

- Moreover, more than 100 countries have locked their international borders for transportation and non-essential trade activities which in turn have reduced the consumption of extruded plastics among several end-use sectors.

- In addition, the falling income of has led to a contraction of the demand for extruded plastics among the building & construction sector. For instance, according to a report published by International Labour Organization, the impact on construction enterprises has been significant, with many facing liquidity problems.

- In 2020, extruded plastics prices are expected to be higher in Asia. The price rise is due to continued regional demand trends and tight product availability. Firm downstream demand for extruded plastics and stronger upstream costs are expected to sustain the price gain.

Extruded Plastics Market Report Highlights

| Aspects | Details |

| By Material |

|

| By Application |

|

| By End-use |

|

| By Region |

|

| By Key Market Players |

|

Analyst Review

According to CXOs of leading companies, the global extruded plastics market is expected to exhibit high growth potential. Extruded plastics are used to produce a wide range of plastic-based products, parts and forms such as pipes, tubes, films, wraps, sheets, and other custom products in a variety of end use sectors such as building & construction, automotive, packaging, industrial, and others. High volume plastic materials that require efficient electrical insulation, high tensile strength, flexibility, and ease of machining can be accomplished with the use of extruded plastics.

In addition, extruded plastics are employed as substitute over metals, owing to its corrosion resistance properties that make customers more linear toward purchasing extruded plastics-based products. In addition, factors such as reduced raw material price, easy availability, and arrival of local players enhance performance of extruded plastics in several end use industries.

CXOs further added that sustained economic growth and development of the packaging sector have increased the popularity of extruded plastics.

Escalating demand from packaging sector and increase in demand from building & construction sector are the other major growth factors in the extruded plastics market.

The global extruded plastics market was valued at $185.6 billion in 2020, and is projected to reach $289.2 billion by 2030, growing at a CAGR of 4.6% from 2021 to 2030.

Atlantis Plastics, Inc., China Plastic Extrusion Ltd., Crescent Plastics Incorporated, GSH Industries, Keller Plastics Inc., Lakeland Plastics, Inc., Nenplas Limited, Petro Packaging Company, Inc., Pexco LLC, and Saint Gobain are the most established players in the global extruded plastics market.

Packaging industry is projected to increase the demand of extruded plastics market

The extruded plastics market is segmented on the basis of material type, application, end use, and region. On the basis of material type, the market is categorized into polyethylene, polypropylene, polyvinyl chloride, polystyrene, and others. On the basis of application, it is divided into pipes and & tubing, wire insulation, windows and & door profiles, films, and others. By end use, it is classified into building & construction, packaging, automotive, industrial, and others. Region-wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

Increase in awareness regarding hygienic goods, safe food, and pharmaceuticals boost the demand for extruded plastics in the growing packaging industry. In addition, factors such as reduced raw material costs associated with manufacture and procurement of extruded plastic-based films has made key manufacturers become more linear toward using extruded plastics for film production. Moreover, extruded plastics offer limitless possibilities in design achieved by bending, molding, and extrusion. They are low conductors of heat and electricity; thus, are widely used as insulating materials, cladding panels, and pipes in offices, malls, residential facilities, and other construction sites.

Pipes & tubing, wire insulation, windows and door profiles, films, and others application are expected to drive the adoption of extruded plastics.

Loading Table Of Content...