Fiberglass Cutting Robots Market Research, 2032

The Global Fiberglass Cutting Robots Market Size was valued at $19 million in 2022, and is projected to reach $40.8 million by 2032, growing at a CAGR of 8.1% from 2023 to 2032. Fiberglass cutting robots are advanced machines built to work in manufacturing industries, carrying out tasks that might be basic or complicated. These robots can independently carry out tasks such as cutting, trimming, and others owing to the combination of mechanical parts, electronic controls, and software programming used in their construction.

Market Dynamics

Fiberglass cutting robots are reprogrammable, and the program can be changed many times depending on the usage and industrial requirements. For automation applications, fiberglass cutting robots help to increase productivity by reducing costs and producing high-quality products. Most fiberglass cutting robots consist of a drive, end-effector, robotic manipulator, sensors, and controllers. The robotic controller is the brain of the robot that helps to give instructions. Robot sensors consist of microphones and cameras that keep the robot aware of the industrial environment. The robotic manipulator is generally the arm of the robot that helps the robot in moving and positioning, while the end effectors help the robot to interact with the workpieces. Varies types of robots are used in industries, including articulated, SCARA, and others. The type of robot selected depends upon the degree of freedom of movement, size required, and payload capacities. Fiberglass cutting robots help in optimizing manufacturing for healthy and efficient processes.

Labor charges across the UK grow by more than 12% every year, thus resulting in shortage of workers. To overcome such problems, market players are investing in fiberglass cutting robots. For instance, in January 2022, Rishi Sunak, the chancellor of the Exchequer invested in robotics to help the UK population and the economy to tackle the crisis of inflation caused due to labor shortage. In addition, it is estimated that the labor cost will increase by more than 20% in the U.S. Hence, this leads to increase in initiatives taken by industries to use robots to compensate with the labor charge and shortage, which drives the fiberglass cutting robots market. In addition, as per the data from the factories and industries of North America, manufacturers and industrial users ordered more than 35%, or more than 25,000 robots, in 2021 as compared to 2019. High imports of robots are attributable to their use in the automotive, aerospace and marine industry. Hence, the growth in microelectronic industry requiring larger number of robots is expected to drive the fiberglass cutting robots market.

This significant upfront financial commitment restricts the broader utilization of fiberglass cutting robots. The adoption of these robots is hindered by the high initial investment and ongoing maintenance costs, attributed to the amalgamation of top-tier hardware substantial installation expenses, the demand for advanced integration capabilities, and sophisticated software control systems. Such factors restrain the fiberglass cutting robots market growth.

Nowadays, the use of fiberglass cutting robots has increased in the pipe and tank, wind energy and manufacturing industries; however, industries such as marine, automotive, and others have deployed fiberglass cutting robots. Increase in demand for precision cutting of products from the wind energy and marine sectors is creating the demand for fiberglass cutting robots. In the future, adoption of robotics technology is expected to increase further, leading to the market growth.

Ongoing advancements in robotics technology, including improved precision, faster cutting speeds, and enhanced software capabilities, offer opportunities for the development of more efficient and versatile fiberglass cutting robots. Innovations such as AI-driven automation, machine learning, and advanced sensors open avenues for enhanced performance and expanded applications.

By Product Type:

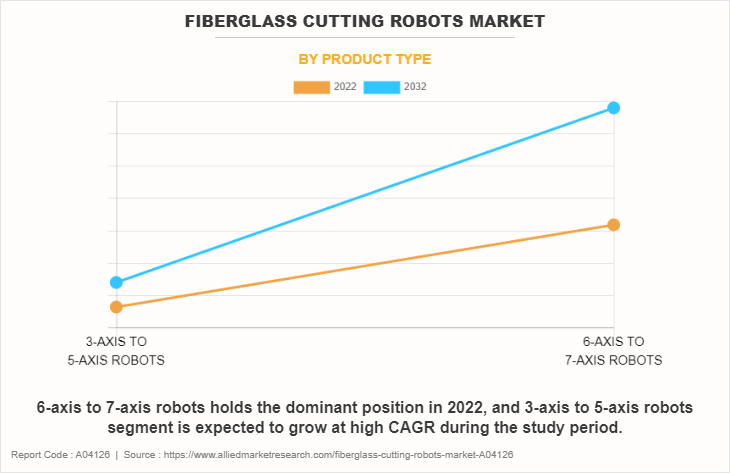

The fiberglass cutting robots market is divided into 3-axis to 5-axis robots, and 6-axis to 7-axis robots. Fiberglass cutting robots range from 3-axis to 5-axis configurations, differing in their degrees of movement. 3-axis robots like Cartesian and gantry types enable movement in X, Y, Z directions. 4-axis SCARA robots and certain articulated ones add rotational axes, aiding in tasks like cutting. 5-axis robots, including specialized machining arms and some articulated models, offer even greater flexibility with additional rotational axes. The 6-axis robots feature six degrees of freedom, typically comprising articulated arms with rotational joints in X, Y, Z axes and additional wrist rotations. They are apt for fiberglass cutting due to their adaptability in multiple angles and precise cutting paths. 7-axis robots further enhance this capability by adding an additional axis, enabling more intricate and optimized cutting movements, enhancing efficiency and accuracy in fiberglass cutting applications.

The 6-axis to 7-axis robots segment is expected to exhibit the largest revenue contributor during the forecast period. The 3-axis to 5-axis robots segment is expected to exhibit the highest CAGR share in the product type segment in the fiberglass cutting robots market during the forecast period.

By Application:

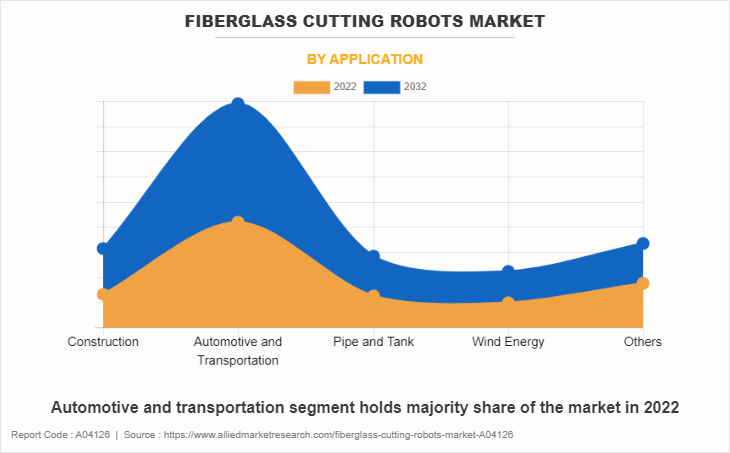

The fiberglass cutting robots market is divided into construction, automotive and transportation, pipe and tank, wind energy, and other. Fiberglass cutting robots aid in constructing composite structures, shaping panels, and cutting custom components. In automotive and transportation segment, fiberglass cutting robots contribute to manufacturing vehicle components, cutting fiberglass for automotive bodies, ensuring accuracy and consistency in aerodynamic parts, enhancing vehicle performance and durability. Within the wind energy sector, fiberglass cutting robots are instrumental in manufacturing wind turbine blades. These robots precisely cut and shape fiberglass composite materials, ensuring uniformity and structural integrity in blade construction. The other end-user industries include textile, marine, and electrical.

The automotive and transportation segment is expected to be the largest revenue contributor during the forecast period, and the construction segment is expected to exhibit the highest CAGR share in the application segment in the fiberglass cutting robots industry during the forecast period.

By Payload:

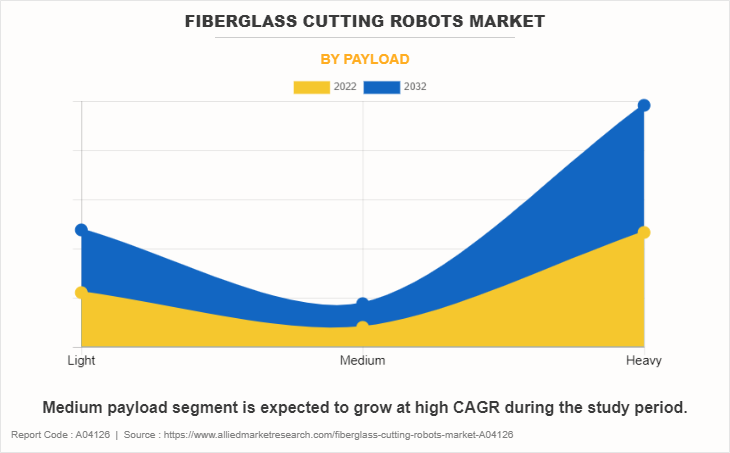

The fiberglass cutting robots market is divided into light, medium, and heavy. In light segment, payload capacity up to 50kg is considered. Majority of mini robots, SCARA robots or 3 and 4 axis motion robots are considered in the segment as per payload capacity. Medium segment payload capacity, more than 50kg to 100 kg is considered. In heavy segment payload capacity, more than 100 kg is considered. Majority of articulated robots with 6 and 7 axis motion robots are considered in the segment as per payload capacity.

The heavy segment is expected to be the largest revenue contributor during the forecast period, and the light segment is expected to exhibit the highest CAGR share in the payload segment in the fiberglass cutting robots market during the forecast period.

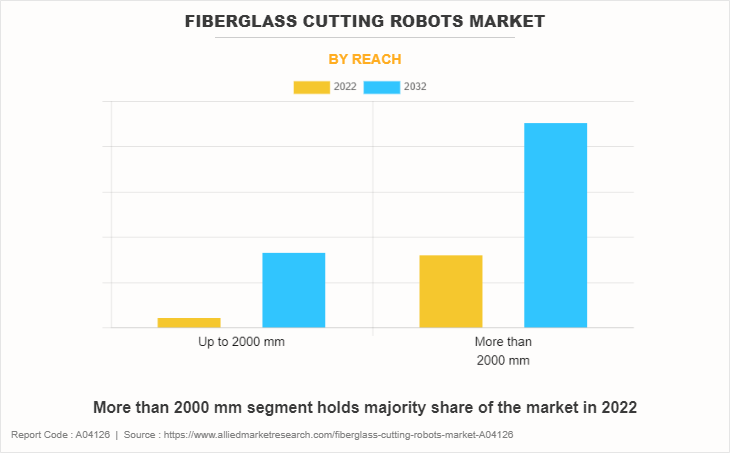

By Reach:

The fiberglass cutting robots market share is divided into up to 2000 mm, and more than 2000 mm. The more than 2000 mm segment is expected to be the largest revenue contributor during the forecast period, and the up to 2000 mm segment is expected to exhibit the highest CAGR share in the reach segment in the fiberglass cutting robots market during the forecast period.

Segmental Overview

The fiberglass cutting robots market overview is segmented on the basis of product type, application, payload, reach, and region. By product type, the market is classified into 3-axis to 5-axis robots, and 6-axis to 7-axis robots. By application, the market is divided into construction, automotive and transportation, pipe and tank, wind energy, and other. By payload, the market is divided into light, medium, and heavy. By reach, the market is divided into up to 2000 mm, and more than 2000 mm.

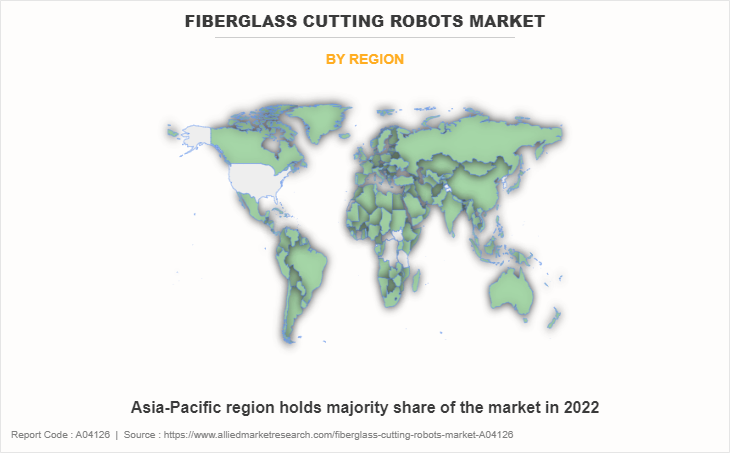

Region-wise, the market is analyzed across North America (the U.S., Canada, and Mexico), Europe (Germany, the UK, France, Italy, and rest of Europe), Asia-Pacific (China, India, Japan, South Korea, and rest of Asia-Pacific), and LAMEA (Latin America, Middle East, and Africa).

Competition Analysis

The major players profiled in the fiberglass cutting robots market ABB, Comau, Daihen Corporation Co., Ltd., Denso Corporation, Fanuc Corporation, Seiko Epson Corporation, Kawasaki Heavy Industries, Ltd., KUKA AG, Universal Robots A/S, and Yaskawa Electric Corporation.

Major companies in the market have adopted product launch, business expansion, and other strategies as their key developmental strategies to offer better products and services to customers in the fiberglass cutting robots market.

Some examples of expansion and product launch on the market.

In June 2023, ABB Robotic announced expansion of the GoFa cobot family, with new variants such as GoFa 10 and GoFa 12. These cobots are equipped with enhanced efficiency, higher payload capacity, and other features.

In July 2022, Fanuc Corporation announced the expansion of the U.S. manufacturing plant in Michigan. The expansion is nearly two million square feet, which includes a 655,000 square-foot state-of-the-art facility to house manufacturing, engineering, and R&D projects.

In January 2022, Fanuc Corporation launched a new robot M-1000iA for applications such as handling heavy loads for construction material, automotive components, and electric vehicle material handling sectors.

In April 2022, Kawasaki Heavy Industries, Ltd. inaugurated a new innovation hub for robotics development called “Future Lab HANEDA” based near Haneda Airport, Tokyo, Japan.

In February 2023, Mitsubishi Electric Corporation announced an investment of approximately $223 million to build a new factory in India.

In October 2022, Yaskawa Electric Corporation opened a new Robotics Technology Centre based in Turkey.

In February 2022, Yaskawa Electric Corporation launched HC10DTP and HC20DTP two new collaborative robots for industrial applications. These robots are specialized in material handling, assembly, dispensing, packaging, machine tending, and welding applications.

In July 2022, NACHI-FUJIKOSHI CORPORATION launched brand new two robots with high efficiency, high speed MZ07F and MZ07LF. These robots will increase the productivity and precision of miniature electronic and electrical components.

In April 2021, NACHI-FUJIKOSHI CORPORATION launched “EC06” and “MZ12H” compact fiberglass cutting robots to expand its product portfolio in lineup robots.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the fiberglass cutting robots market analysis from 2022 to 2032 to identify the prevailing fiberglass cutting robots market opportunity.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the fiberglass cutting robots market forecast, and segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global fiberglass cutting robots market trends, key players, market segments, application areas, and market growth strategies.

Fiberglass Cutting Robots Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 40.8 million |

| Growth Rate | CAGR of 8.1% |

| Forecast period | 2022 - 2032 |

| Report Pages | 220 |

| By Payload |

|

| By Reach |

|

| By Product Type |

|

| By Application |

|

| By Region |

|

| Key Market Players | DENSO CORPORATION, Kawasaki Heavy Industries, Ltd., KUKA AG, Seiko Epson Corporation., Yaskawa Electric Corporation, FANUC Corporation, ABB, DAIHEN Corporation, Universal Robots A/S, Comau S.p.A. |

Analyst Review

Rise in demand for automation has revolutionized the adoption of robotics technology. The fiberglass cutting robots market is expected to witness growth, owing to the advent of technologies such as modular robotics. Modular robots have the ability to adapt to the environment they operate in and consist of robotic modules that automatically and dynamically change their geometrical construction as per the requirement. However, further innovation of these technologies and potential in emerging economies are expected to provide significant opportunities for growth and expansion. Major players are developing affordable, compact, and energy-efficient robotics solutions to reach out to a wider customer base. The construction and automotive sectors dominate the fiberglass cutting robots industry and are estimated to maintain their dominance throughout the forecast period.

However, the demand from industries, including aerospace, marine, and construction is increasing, and newer applications are being explored with customized robotics solutions. Application of fiberglass cutting robots in marine and sustainable energy sector is expected to be lucrative areas for investments. Vendors are developing specialized solutions for small- and medium-sized businesses to meet their specific business requirements.

The market is expected to be driven by rise in demand for automation and the scarcity of skilled labor. Leading players aim to explore new technologies and applications to meet the growing demands from customers.

The global fiberglass cutting robots market was valued at $18,976.1 thousand in 2022, and is projected to reach $40,800.8 thousand by 2032, registering a CAGR of 8.1% from 2023 to 2032.

The forecast period considered for the global fiberglass cutting robots market is 2022 to 2032, wherein, 2022 is the base year, 2023 is the estimated year, and 2032 is the forecast year.

The latest version of global fiberglass cutting robots market report can be obtained on demand from the website.

The base year considered in the global fiberglass cutting robots market report is 2022.

The major players profiled in the fiberglass cutting robots market include ABB, Comau, Daihen Corporation Co., Ltd., Denso Corporation, Fanuc Corporation, Seiko Epson Corporation, Kawasaki Heavy Industries, Ltd., KUKA AG, Universal Robots A/S, and Yaskawa Electric Corporation.

The top ten market players are selected based on two key attributes - competitive strength and market positioning.

The report contains an exclusive company profile section, where leading companies in the market are profiled. These profiles typically cover company overview, geographical presence, market dominance (in terms of revenue and volume sales), various strategies, and recent developments.

Based on product type, the 6-axis to 7-axis robots segment was the largest revenue generator in 2022.

Loading Table Of Content...

Loading Research Methodology...