Forklift Battery Market Overview

The global forklift battery market was valued at USD 5.9 billion in 2022, and is projected to reach USD 11.2 billion by 2032, growing at a CAGR of 6.5% from 2023 to 2032.

Electric forklifts and other electric material handling equipment are powered by forklift batteries, which is a specific kind of battery. The electric forklift equipment runs on batteries, while internal combustion engine (ICE) forklifts run on gasoline or diesel. The electrical energy required to run the forklift's electric motor, which powers the vehicle's lifting and propulsion systems, is supplied by the forklift batteries.

Key Report Highlighters:

- The report outlines the current forklift battery market trends and future scenario of the market from 2023 to 2032 to understand the prevailing opportunities and potential investment pockets.

- The global forklift battery market has been analyzed in terms of value ($ billion). The analysis in the report is provided for 4 major regions and more than 15 countries.

- The forklift battery market is fragmented in nature with few players such as Iberdrola S.A., Amara Raja Batteries Ltd., EnerSys, East Penn Manufacturing Company, Inc., Exide Industries Ltd. which hold a significant share of the market.

- The report provides strategy planning and industry dynamics to enhance decision making for existing market players and new entrants entering the forklift battery market.

Forklift batteries come in various voltage ratings, such as 24V, 36V, and 48V, depending on the forklift's power requirements. Their capacity is measured in ampere-hours (Ah) and represents the amount of energy a battery can store. Higher capacity batteries can generally provide longer operating times. The charging time varies between battery types. Lithium-ion batteries typically offer faster charging times compared to lead-acid batteries. Lead-acid batteries require regular maintenance, including watering and cleaning. Lithium-ion batteries generally have lower maintenance requirements. The cycle life represents the number of charge-discharge cycles a battery can undergo before its capacity significantly degrades

Key Components of Forklift Batteries

Cells: Forklift batteries are composed of individual cells connected in series. Each cell contributes a specific voltage to the overall battery pack.

Electrolyte: Sulfuric acid solution serves as the electrolyte in lead-acid batteries. It is a lithium salt solution used in lithium-ion batteries. During charging and discharging, the electrolyte helps ions move between the positive and negative electrodes of the battery.

Positive and Negative Plates: Lead dioxide and sponge lead are used to make the positive and negative plates of lead-acid batteries, respectively. Lithium cobalt oxide, lithium manganese oxide, or other lithium compounds are commonly used as the positive electrode in lithium-ion batteries.

Battery Management System (BMS): To monitor and control a number of characteristics, including voltage, temperature, and state of charge, modern forklift batteries frequently come with a battery management system. The BMS helps optimize battery performance and safety.

The primary application of forklift batteries is in material handling and warehousing equipment, where electric forklifts are used to lift, transport, and stack materials in a variety of industrial settings. Forklifts with batteries are commonly used in manufacturing facilities for tasks such as moving raw materials, transporting finished goods, and facilitating efficient logistics within the production area. Distribution centers rely on forklifts powered by batteries to manage the movement and organization of goods, ensuring timely and accurate order fulfillment. Electric forklifts equipped with batteries are used in retail environments for tasks like stocking shelves, moving inventory within stores, and managing storage areas. Forklifts with batteries are used at ports and shipping yards for the loading and unloading of cargo containers, contributing to efficient logistics and material handling in these areas.

Electric forklifts powered by batteries produce zero emissions during operation, making them environment-friendly and suitable for indoor use. Electric forklifts with batteries often have lower operating costs compared to internal combustion engine (ICE) forklifts. They require less maintenance, and electricity can be a more cost-effective energy source. Forklifts powered by batteries operate more quietly than their ICE counterparts, making them suitable for noise-sensitive environments such as warehouses and retail spaces. Electric forklifts generally produce less vibration than their internal combustion counterparts, contributing to operator comfort and potentially reducing wear and tear on equipment. Modern forklift batteries, especially lithium-ion batteries, are known for their energy efficiency. They provide longer operating time and require less time for recharging compared to traditional lead-acid batteries.

The initial investment in electric forklifts and their associated batteries are higher than acquiring traditional internal combustion forklifts, particularly when opting for advanced battery technologies. Establishing adequate charging infrastructure is essential for electric forklifts, and the upfront costs of installing charging stations pose to be a challenge. Electric forklifts have a limited operating range on a single charge compared to the continuous operation possible with traditional ICE forklifts. While lithium-ion batteries have longer lifespans compared to lead-acid batteries, their replacement costs are substantially higher. Proper battery management is crucial to maximize their lifespan. The need for recharging introduces downtime, and the availability of charging infrastructure impacts the operational efficiency.

Ongoing advancements in battery technologies, especially lithium-ion batteries, present opportunities for improved performance, longer lifespans, and faster charging times. Hydrogen fuel cell technology is emerging as an alternative power source for forklifts, offering opportunities for longer operating hours and faster refueling. The growing emphasis on sustainability provides opportunities for businesses to showcase their commitment toward environment-friendly practices by adopting electric forklifts. Incentives and subsidies from governments encouraging the adoption of electric vehicles and cleaner technologies provide opportunities for businesses to offset initial investment costs. The integration of forklifts with battery management systems and telematics contributes to opportunities for data-driven insights, predictive maintenance, and improved overall efficiency in logistics and material handling operations. .

Market Dynamics

Economic advantages coupled with government benefits

Electric forklifts powered by efficient batteries often have lower operating costs compared to their internal combustion engine counterparts. Moreover, lithium-ion forklift batteries are 40% more energy efficient than lead acid batteries. Lithium-ion batteries are experiencing growth in demand owing to greater efficiency and thus are beneficial for forklift equipment and lifting truck users. In addition, incentives, subsidies, and government support for the adoption of electric vehicles, including electric forklifts, encourage businesses to invest in cleaner energy alternatives. Stringent environmental regulations and a growing emphasis on sustainability also drives the adoption of electric forklifts with cleaner battery technologies, as they produce zero emissions during operation.

Increased energy efficiency and technological advancements

Reducing carbon emissions and emphasizing energy efficiency promotes the use of cutting-edge battery technologies, such lithium-ion batteries, which have a high energy density. The market is growing because to ongoing breakthroughs in battery technology, which include improvements in energy density, charging speed, and overall performance. Businesses are looking for more sophisticated and efficient solutions. Electric forklifts with advanced batteries contribute to operational efficiency through reduced downtime, lower maintenance requirements, and quieter, smoother operation.

High upfront costs and battery replacement costs

The initial investment in electric forklifts and advanced battery technologies can be a significant barrier for businesses, especially for small and medium-sized enterprises. This high investment discourages the growth for forklift batteries. Moreover, after a certain time period and multiple charging, replacing batteries, especially lead acid batteries, also incurs higher costs which again is costly for small and medium size business owners. The need for proper charging infrastructure can be a restraint, as businesses need to invest in charging stations and ensure convenient access for their fleets.

Advancements in charging technology and development in hydrogen infrastructure

Charging times can be reduced and overall operational efficiency can be increased with the development of faster and more efficient charging technologies. This offers lucrative opportunity for the forklift battery industry growth. The growth of hydrogen infrastructure presents opportunities for the adoption of hydrogen fuel cell-powered forklifts, especially in applications requiring extended operating hours. This advanced technology also offers immense potential for industry growth.

Integration with renewable energy and expanding e-commerce

Integrating forklift batteries with renewable energy sources, such as solar or wind, provides opportunities for sustainable and off-grid operations. The market offers great potential for companies that are offering customizable battery solutions which are tailored to specific industry requirements, providing flexibility and optimization. In addition, the global expansion of e-commerce drives the demand for efficient material handling solutions, creating opportunities for the adoption of electric forklifts and advanced battery technologies.

Segment Overview

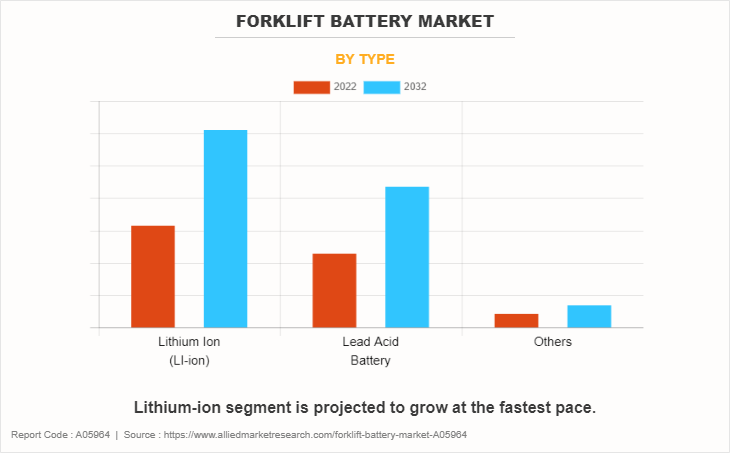

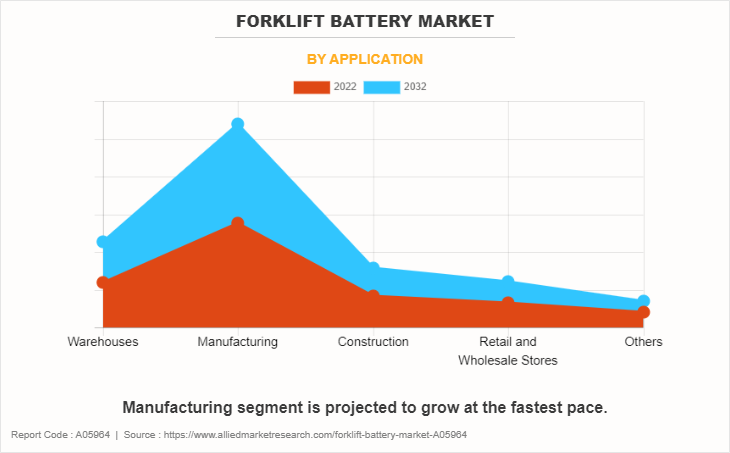

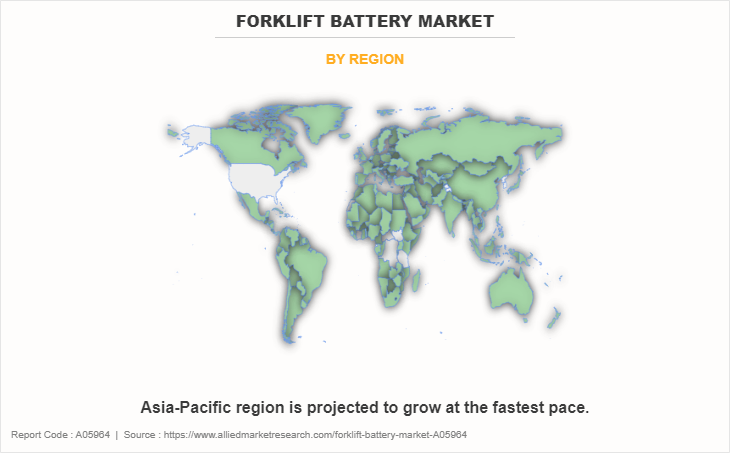

The forklift battery market size is segmented on the basis of type, application, and region. Depending on the type, the market is categorized into lithium ion (Li-ion), lead acid battery, and others. Based on application, the market is divided into warehouses, manufacturing, construction, retail & wholesale stores, and others. By region, the forklift battery market analysis is done across North America, Europe, Asia-Pacific, and LAMEA (Latin America, the Middle East, and Africa).

Global Market By Type

Depending on the type, the market is categorized into lithium ion (Li-ion), lead acid battery, and others. The lithium ion battery dominated the forklift battery market share in 2022. Lithium ions are the main ingredient in the electrochemical process that powers lithium-ion (Li-ion) batteries, a class of rechargeable battery. Because of their high energy density, comparatively low self-discharge rate, and multiple rechargeability, they have emerged as one of the most widely used types of rechargeable batteries for a variety of applications.

Li-ion batteries are essential for energy storage applications such grid stabilization, renewable energy integration, and energy storage systems for homes and businesses. The trend towards renewable energy sources fuels the demand for efficient energy storage solutions. Li-ion batteries continue to dominate the market for consumer electronics, including smartphones, laptops, tablets, and wearable devices. Trends in compactness, longer battery life, and faster-charging capabilities drive innovation in this sector.

Global Market By Application

Based on application, the market is divided into warehouses, manufacturing, construction, retail & wholesale stores, and others. The manufacturing segment dominated the market in 2022, and is projected to grow at a highest CAGR during the forklift battery market forecast period. Manufacturing is the process of using different physical, chemical, or mechanical processes to transform raw materials, components, or parts into finished things. It entails converting raw materials or components into finished goods on a big scale with the aid of personnel, equipment, machinery, and a planned production procedure. The sector is undergoing a transition as a result of the incorporation of digital technologies like automation, machine learning, IoT, and AI into industrial processes.

Predictive maintenance, data-driven decision-making, and smart factories are a few examples of this, which boost production and efficiency. The growing emphasis on sustainability is fostering the development of green manufacturing practices. Companies are investing in renewable energy sources, eco-friendly materials, and resource-efficient processes to reduce environmental impact, which has become a significant driver for the market growth.

Global Market By Region

By region, the forklift battery market analysis is done across North America, Europe, Asia-Pacific, and LAMEA (Latin America, the Middle East, and Africa). Asia-Pacific dominated the Forklift Battery Market Growth. Advanced battery technologies are becoming more and more popular as a result of the emphasis on energy efficiency and cutting operating expenses. Businesses are being encouraged to invest in electric forklifts by government subsidies and other forms of support. The industry is being shaped by ongoing developments in battery technology, such as enhanced energy density and infrastructure for charging.

China has been experiencing a trend toward the electrification of material handling equipment, including forklifts. This shift is driven by environmental concerns, regulatory changes, and a focus on sustainability. There is a growth in the adoption of lithium-ion batteries for forklifts in China. Lithium-ion batteries offer advantages such as longer lifespan, faster charging, and lower maintenance requirements compared to traditional lead-acid batteries.

Competitve Landscape

The major players operating in the forklift battery industry are Iberdrola S.A., Amara Raja Batteries Ltd., EnerSys, East Penn Manufacturing Company, Inc., EXIDE INDUSTRIES LTD., Trojan Battery Company, LLC., GS Yuasa International Ltd., Flux Power, Zhejiang Narada Power Source Co., Ltd., and Electrovaya. The companies adopted key strategies such as collaboration and expansion to increase their market share.

Key Benefits For Stakeholders

This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the forklift battery market analysis from 2022 to 2032 to identify the prevailing forklift battery market opportunities.

The market research is offered along with information related to key drivers, restraints, and opportunities.

Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

In-depth analysis of the forklift battery market segmentation assists to determine the prevailing market opportunities.

Major countries in each region are mapped according to their revenue contribution to the global market.

Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

The report includes the analysis of the regional as well as global forklift battery market trends, key players, market segments, application areas, and market growth strategies.

Forklift Battery Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 11.2 billion |

| Growth Rate | CAGR of 6.5% |

| Forecast period | 2022 - 2032 |

| Report Pages | 250 |

| By Application |

|

| By Type |

|

| By Region |

|

| Key Market Players | Flux Power, GS Yuasa International Ltd., EXIDE INDUSTRIES LTD., Trojan Battery Company, LLC., Amara Raja Batteries Ltd., Electrovaya, Iberdrola S.A., EnerSys, Zhejiang Narada Power Source Co., Ltd, East Penn Manufacturing Company, Inc. |

Analyst Review

According to the insights from the CXOs, there is an increase in the demand for forklift batteries due to the growing use of electric forklifts, which is being driven by cost reductions, environmental concerns, and government incentives. Furthermore, the business is growing because of improved energy efficiency and advancements in battery technologies. The market for forklift batteries is witnessing a shift toward lithium-ion batteries owing to greater energy density, longer lifespan, and quicker charging times offered by these batteries. Forklift battery telematics and Internet of Things (IoT) integration is growing, offering real-time data on battery health, usage trends, and maintenance requirements for more effective fleet management. Hydrogen fuel cell technology is gaining popularity as a substitute power source for forklifts because it allows for longer operation hours and quicker refueling.

Some companies are seeking to lease battery models, which provide them access to the newest battery technology without the need for heavy investment of purchasing a new equipment all together which in turn proves to be economic for the company. Energy storage solutions with forklift batteries are gaining popularity.

Economic advantages coupled with government benefits and increased energy efficiency and technological advancements are the upcoming trends of Forklift Battery Market in the world.

Asia-Pacific is the largest regional market for Forklift Battery.

Manufacturing is the leading application of Forklift Battery Market.

$11.2 is the estimated industry size of Forklift Battery by 2032.

Iberdrola S.A., Amara Raja Batteries Ltd., EnerSys, East Penn Manufacturing Company, Inc., EXIDE INDUSTRIES LTD., Trojan Battery Company, LLC., GS Yuasa International Ltd., Flux Power, Zhejiang Narada Power Source Co., Ltd., and Electrovaya are the top companies to hold the market share in Forklift Battery.

Loading Table Of Content...

Loading Research Methodology...