Graphite Packing Market Research, 2031

The global graphite packing market was valued at $396.2 million in 2021 and is projected to reach $661.0 million by 2031, growing at a CAGR of 5.3% from 2022 to 2031.

Report Key Highlighters:

- Validated insights verified through primary interviews with raw materials suppliers, wholesalers, and manufacturers of graphite packing to understand the market trends, growth factors, pricing and key players competitive strategies.

- 20 countries are covered in the graphite packing market report. The segment analysis of each country in both value ($million) and volume (kilotons) during the forecast period 2021-2031 is covered in the report.

- Historical data and regulations are also covered in the report.

- Over 3,700 product literatures, annual reports, industry releases, and other such documents of major industry participants have been reviewed in order to obtain a better understanding of the market.

Graphite packing is a highly resistant sealant used in systems with valves, faucets, and stuffing boxes, as well as other machines with watertight mechanical parts. It can be applied either to static valve stems or to moving joints. Graphite packing offers high chemical resistance, great lubricity, and excellent thermal conductivity. It is the choice of many industries because it is a reliable, cost-effective, and easy-to-install sealant. Most graphite packing strings are produced from several graphite filaments that have been twisted together. A yarn is a name given to the resulting graphite packing thread. The tensile strength and endurance of these yarns are then increased through braiding. Manufacturers treat the strands with substances like PTFE after braiding to further boost their chemical resistance. The braided packing is then treated with blocking agents to improve the packing's capacity to seal overall and successfully seal the filaments.

The usage of graphite packing is common in industries that treat acids and oils because of its renowned resilience to chemicals and extremely high temperatures. Because of its durability, it is the ideal sealer for the gas, chemical, and fuel sectors. Because graphite packing may last forever and is proven to offer superior valve protection, refineries are able to considerably reduce their maintenance expenses. It is the go-to packing choice for anyone who wants to get the best seals and protection for their valves because it is self-lubricating and virtually 100% non-abrasive. When temperatures are above 250°C (482°F), pure graphite is often used, especially for applications requiring self-lubrication. In high-temperature and pressure conditions, such as those found in refineries, paper, and pulp mills, petrochemical plants, power plants, and wastewater treatment facilities, graphite packing is frequently employed. Control and block valves, LP steam turbine valves, condensate line valves, manually operated valves, and power recovery valves are all excellent candidates for graphite packing. blowers for soot, agitators and mixers, pumps for boiler feed and condensate, pumps for hot water circulation, and pumps for heater drain.

Increased demand for graphite packing from high temperature applications

Graphite packing is widely used in high temperature & pressure environments such as refineries, paper, and pulp mills, petrochemical plants, power plants, and wastewater treatment facilities. To withstand extremely high temperatures and high pressures for static application, braided graphite packing produced from exfoliated graphite yarn with corrosion inhibitor properties and a unique lubricant is reinforced with stainless steel or inconel wire. It has high thermal conductivity and a low coefficient of friction. Expanded graphite is used to create a range of flat gaskets, including spiral wound gaskets, serrated gaskets, and graphite gaskets with strengthened steel inserts, as well as die-pressed rings to seal the stems of various types of valves. The refining, petrochemical, chemical, and thermal power sectors are the principal application areas for these graphite-based seals. These industries feature a mix of essential operating conditions, such as high temperatures, pressure, flammability, risk of explosion, and media toxicity. For both seal providers and operators, the longevity and dependability of seals are of the utmost importance in such circumstances. Users want independent performance verification because the effectiveness of the graphite utilized is largely dependent on its quality.

Increased demand for graphite packing in valve and pump packing

Valves and pumps are used in various industries including water and wastewater treatment, chemical, oil & gas, power industry among others. Valve packing is a component in a valve that forms pressure seal between the inside of the valve and the outside of the valve, keeping the process fluid from leaking out. The packing in pumps is often made to allow some leakage between the sleeve/shaft and packing to offer lubrication and heat evacuation owing to the revolving sleeve. With process temperature changes or simply seasonal ambient temperatures, the packing will eventually deteriorate, relax, or become loose and start to leak. In addition, any process fluid that spills out of a valve can be expensive, untidy, and potentially dangerous to human health and the environment.

Reinforced graphite packing can be used in valves, pumps, expansion joints, mixers and agitators in high-pressure and temperature. It offers an economic solution for applications above the temperature limit of PTFE packings. It fills the gap between the medium temperature packings for up to 280°C and the more expensive high temperature packings made from pure carbon or graphite. Reinforced graphite packing can be used for steam and other valves in many different industries. It is also suitable for static applications. It is not suitable for concentrated acids, oleum, fuming nitic acid, aqua regia, fluorine. These factors are projected to drive the demand for reinforced graphite packings.

The most common soft sealing material utilized in high-temperature applications is expanded graphite, and this trend is likely to continue. Despite worries about oxidation, which starts at about 400°C, graphite is now frequently used in industrial applications at temperatures much higher than this. This is made feasible by the expanded graphite material's ongoing development, which includes improvements in purity, ash content regulation, and oxidation inhibitor quality. New housing, packing, and gasket constructions are being developed concurrently. New designs that lower the temperature at the seal face (such as an extended stuffing box with cooling fins) provide barriers that restrict airflow to the seal. Today, there are specialized gaskets and joints that contain the graphite or, in some situations, can make up for aging with Live Load spring systems and other mechanisms. All of these concepts indicate that applications with a working temperature of up to 650 °C can use high-quality expanded graphite seals.

Generating a tight seal using expanded graphite material is difficult and needs to take into account the many features of expanded graphite, the application including the construction of the joint to be sealed, operating parameters, surrounding environmental features, existing stresses, and system-generated stresses or movements acting against seal during plant operation. The increased export duty on graphite in China is hindering the market's growth by limiting the availability outside the country to promote domestic demand.

Graphite packing material is produced using flake graphite. High purity and processing must be applied to the graphite that will be utilized in the graphite packing. The purification level of graphite must be reached. Because the purifying process is highly expensive, spherical graphite costs about two to three times as much as flake graphite. In addition, there are a lot of waste byproducts from the process that need to be carefully controlled to prevent pollution. Increased export duty om graphite in China to promote domestic demand will hinder the graphite packing market growth. Environmental issues can result from the mining and production of graphite. While the dust released during graphite mining contains dangerous air pollutants, the hazardous chemicals employed during its processing might pollute the environment when released into the nearby land and water. In order to stop this waste, the government agencies have established a few rules.

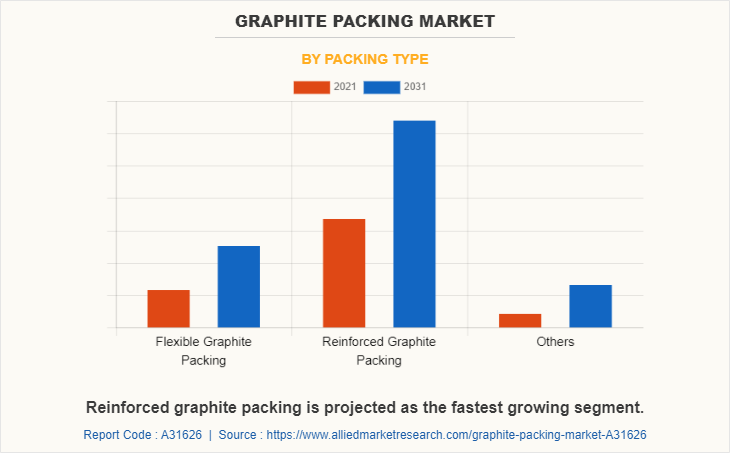

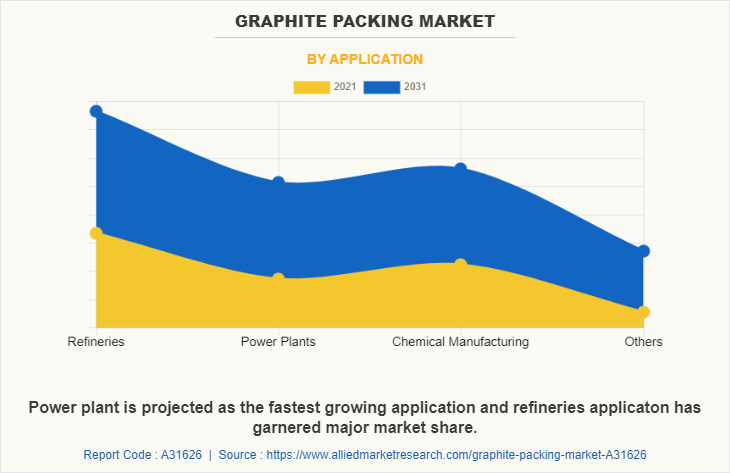

The graphite packing market is segmented on the basis of type, application, and region. On the basis of type, the market is categorized into flexible graphite packing, reinforced graphite packing, and others. On the basis of application, it is categorized into refineries, power plants, chemical manufacturing, and others. Region-wise, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

Major players operating in the global graphite packing market include Garlock Sealing Technologies, Sunwell Seals, Phelps Industrial Products, Klinger Limited, Sealmax, Mineral Seal Corporation, W. L. Gore and Associates, Cixi Xinsheng Seal Factory, Marshall packing and Insulation Industrie and Hysesaling.

Reinforced graphite packing has garnered 54.8% of the market share and is projected to grow at 5.5% CAGR during the forecasted period. Graphite packing reinforced with wire is braided from expanded graphite yarns, reinforced with metal wire, and normally reinforced with Inconel wire. It retains all the inherent benefits of flexible graphite packing. Packing from exfoliated pure graphite reinforced with a thin Inconel wire. Reinforced graphite packing can be used in valves, pumps, expansion joints, mixers, and agitators in high pressure and temperature. It offers an economic solution for applications above the temperature limit of PTFE packings. Flexible graphite packing is projected to grow at 5.0% during the forecasted period.

The power plant segment is projected as the fastest-growing segment at a CAGR of 5.6% during the forecasted period. The power generation industry currently uses graphite packing, which is the most adaptable and common packing material. It is produced using yarns made of extremely pure and high-strength graphite. High-temperature graphite dispersion provides lubrication and braid blocking. Because graphite packing is so efficient, there is no need to put wire, which could harm the stem. It has exceptionally low frictional qualities and good sealing capacities. The refineries segment has garnered a 31.9% market share.

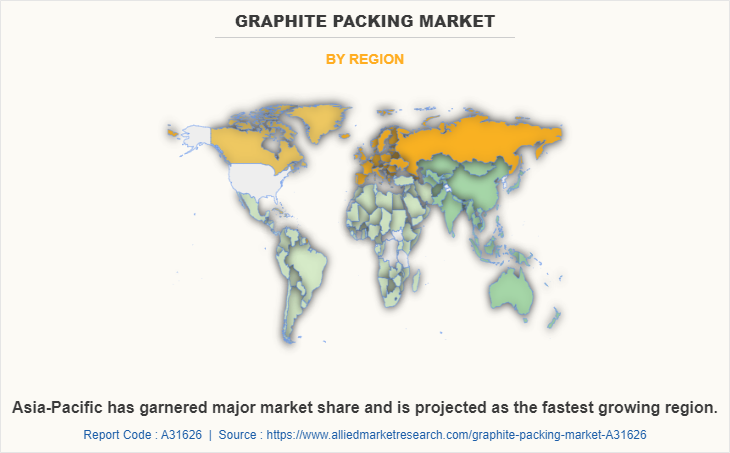

Asia-Pacific has garnered a 57.3% market share and is projected as the fastest-growing region at a CAGR of 5.6% during the forecasted period. Several global firms are looking to expand their presence and market share in the Asia-Pacific region by expanding their operations in emerging economies, such as China, India, and several Southeast Asian countries. Asia-Pacific accounts for more than half of global energy consumption, with 85% of that regional consumption coming from fossil fuels. Demand for energy is rising owing to rapid urbanization and industrialization. These factors are driving the demand for graphite packing in the Asia-pacific region.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the graphite packing market analysis from 2021 to 2031 to identify the prevailing graphite packing market opportunities.

- Market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders to make profit-oriented business decisions and strengthen their supplier-buyer network.

- An in-depth analysis of the graphite packing market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes an analysis of the regional as well as global graphite packing market trends, key players, market segments, application areas, and market growth strategies.

Graphite Packing Market Report Highlights

| Aspects | Details |

| Market Size By 2031 | USD 661 million |

| Growth Rate | CAGR of 5.3% |

| Forecast period | 2021 - 2031 |

| Report Pages | 284 |

| By Packing Type |

|

| By Application |

|

| By Region |

|

| Key Market Players | Shri Rangaa Asbestos Company, Marshall packing and Insulation Industries, Cixi Xinsheng Seal Factory, Phelps Industrial Products, Sunwell Seals, W. L. Gore & Associates, Inc., klinger limited, Garlock Sealing Technologies, Sealmax, Mineral Seal Corporation |

Analyst Review

According to perspective of CXOs of leading companies, increasing demand from refineries, power plants and chemical manufacturing industry is driving the demand for graphite packing. Graphite packing is mainly woven by various reinforced graphite fibers, metal wires like copper, steel, nickel, glass yarn and other reinforced graphite wires. Suitable for dynamic sealing under high temperature and high-pressure conditions. Natural flake graphite has a wide usage in many industries, like refractories, batteries, steel making, brake pads and brake linings, foundry facings and lubricants. Pure expanded graphite wire that has been reinforced with glass fiber, stainless steel, nickel, Inconel, and other components makes up reinforced graphite packing. It possesses a variety of extended graphite properties, including high strength, great adaptability, and exceptional flexibility. It is the most efficient sealing element to address the high temperature and high pressure sealing issues when combined with standard braided packing.

Increasing demand from the chemical manufacturing industry is the upcoming trend in Graphite Packing Market around the world.

Refineries are the leading application of the Graphite Packing Market.

Asia-Pacific is the largest regional market for Graphite Packing.

The graphite packing market was valued at $396.2 million in 2021 and is projected to reach $661.0 million by 2031, growing at a CAGR of 5.3% from 2022 to 2031.

Garlock Sealing Technologies, Sunwell Seals, Phelps Industrial Products, Klinger Limited, Sealmax, and Mineral Seal Corporation are the top companies to hold the market share in Graphite Packing.

The graphite packing market is segmented on the basis of type, application, and region. On the basis of type, flexible graphite packing, reinforced graphite packing, and others..On the basis of application, the market is categorized into refineries, power plants, chemical manufacturing, and others.

COVID-19 had a negative impact on the graphite packing market owing to a decrease in demand from various end-use industries like chemicals, refineries, and power plants.

Loading Table Of Content...