Hopper dryers Market Overview:

The global hopper dryer market size was $421.3 million in 2017, and is projected to reach $576.2 million in 2025, growing at a CAGR of 3.9%. Hopper dryers are installed on injection molding machine, extrusion machine, and blow molding machine to eliminate moisture from the surface of pellets of plastic materials prior to melting them. Hopper dryers of different capacities, which include less than 100 KG, 100 KG to 500 KG, and more than 500 KG, are available in the market.

Factors such as increase in demand for plastics processing machinery due to increase in demand for plastic products globally is expected to drive the adoption of hopper dryers, thereby boosting the growth of the hopper dryer industry. In addition, these dryers are cost effective drying method for plastics and other thermoplastic granules. Increased emphasis on use of energy efficient machines is expected to propel the growth of the global hopper dryer industry. Moreover, development in the extrusion machine and upsurge in demand for injection molding machines are estimated to fuel the growth of the hopper dryer market over the coming years.

Rise in awareness about energy saving propel the growth of the hopper dryer industry. Hopper dryer uses less energy to dry resins and polymers in comparison to conventional dryers. Manufacturers of the hopper dryers have amalgamated energy saving methods for every design phase of the product improvement to decrease power consumption and increase operational efficiency without compromising on the quality and performance of the dryers. For instance, Yann Bang offers HD, IHD, and DHD-G series of energy-efficient hopper dryers that saves over 30% energy and extends life of the equipment. There is a rapid rise of temperature inside the hopper for better drying and lessens more than 30% of drying time.

Hopper dryer manufacturers have adopted various strategies, such as acquisitions, product launches, business expansions, and others, to promote their businesses and improve their product offerings in the global hopper dryer market; for instance, in 2016, Novatec Inc., opened a 35,000-square-foot manufacturing facility in Brookhaven. Through this move, Novatec expanded its business of dryers in North America, thereby leading the market growth. Similarly, in March 2017, Dri-Air Industries launched mini dryers for small rate drying. One type of dryer launched was a mini portable off the press dryer and the other one was mini floor mounted dryer with press mounted hopper.

Hot air is blown through hopper dryers to dry resins and other thermoplastics right at the throat of the machine. Drying temperatures required to dry plastic materials are as high as 225°-300° F. Hence, material required to produce hopper dryers must be able to withstand high temperature as well as must be robust in nature. This is one of the reasons of them being expensive in nature. Hence, high initial cost of hopper dryer is expected to hamper the growth of the market. On the contrary, technologies such as regeneration optimization and adaptive control of heating helps to cut energy costs for processing of polymers and resins. Hence, advanced technological and design developments by prominent players create lucrative opportunities for the hopper dryer market.

Segment Overview

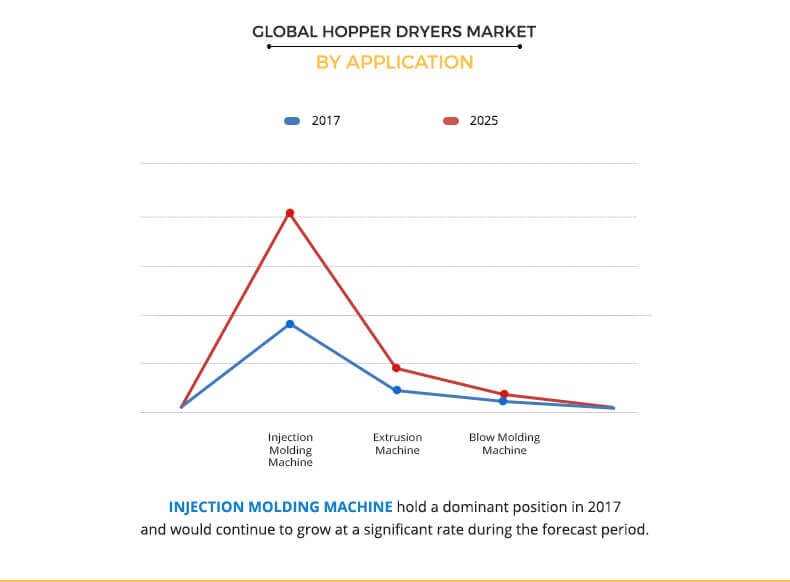

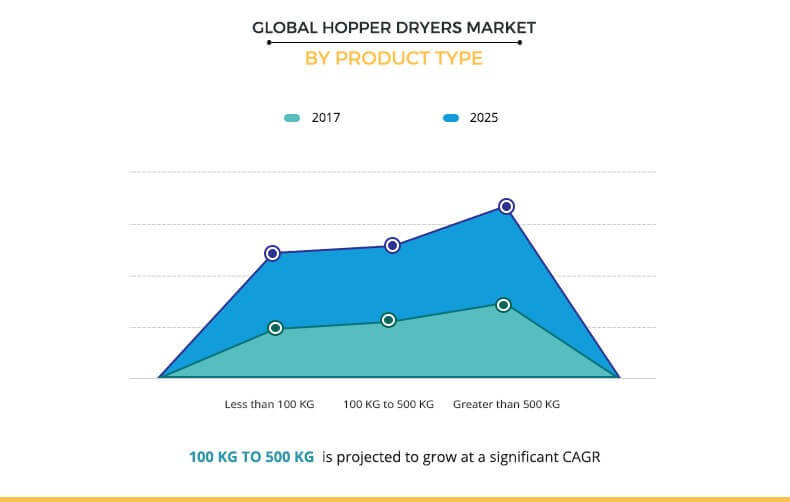

The global hopper dryer market is segmented based on product type, application, and region. Based on product type, the market is fragmented into less than 100 KG, 100 KG to 500 KG, and more than 500 KG. The more than 500 KG segment is anticipated to dominate the global hopper dryer market throughout the study period. The applications covered in the study include injection molding machine, extrusion machine, and blow molding machine. The injection molding machine segment is projected to dominate the global hopper dryer market in the near future.

By Product Type

By product type, the market is segmented into less than 100 KG, 100 KG to 500 KG, and more than 500 KG. Among these, the more than 500 KG segment holds a dominant position and is expected to grow at a significant growth rate during the hopper dryer market forecast period, owing to increase in deployment of more than 500 KG capacity hopper dryers in injection molding machine and extrusion machine.

By Region

The market is analyzed across North America, Europe, Asia-Pacific, and LAMEA. Among these, Asia-Pacific holds a significant share in the global hopper dryer market, and is projected to grow at a substantial CAGR, owing to many small and mid-level players operating in countries such as China, Hong Kong, and India. In addition, the growth in demand for automobiles in economies such as India and China, fuels the demand for plastics for applications such as packaging as well as automotive component manufacturing. The automobile industry in India experienced an increase in sales of around 10% from 2017 to 2018. Moreover, China is one of the large markets for the plastic industry, which in turn, fuels the hopper dryer market growth.

Key Benefits for Hopper dryers Market:

- The study provides an in-depth of global hopper dryers market analysis along with the current trends and future estimations to elucidate the imminent investment pockets.

- Information about the key drivers, restraints, and opportunities and their impact analyses on the market is included in the study.

- Porter’s five forces analysis illustrates the potency of the buyers and suppliers operating in the industry.

- The quantitative analysis of the global hopper dryer market from 2017 to 2025 is provided to determine the market potential.

Hopper Dryers Market Report Highlights

| Aspects | Details |

| By PRODUCT TYPE |

|

| By APPLICATION |

|

| By Region |

|

| Key Market Players | BRY-AIR (ASIA) PVT. LTD., MOTAN HOLDING GMBH, CONAIR, SHINI PLASTICS TECHNOLOGIES, INC., SUMMIT SYSTEMS, DRI-AIR INDUSTRIES INC, KENPLAS INDUSTRY LIMITED, ACS GROUP, NOVATEC INC, YANN BANG ELECTRICAL MACHINERY CO., LTD. |

Analyst Review

Hopper dryer uses less energy to dry resins and polymers in comparison to conventional dryers. Manufacturers of the hopper dryers have amalgamated energy saving methods for every design phase of the product improvement so as to lessen power consumption and increase operational efficiency without compromising on the quality and performance of the dryers. For instance, Yann Bang offers HD, IHD, and DHD-G series of energy-efficient hopper dryers that saves energy over 30% and lengthens life time of equipment. There is a rapid rise of temperature inside the hopper for better drying and lessens more than 30% of drying time. In addition, hopper dryers have gained increase in popularity in the recent years, owing to its features of drying plastic materials in less amount of time by removing moisture from them as compared to conventional drying methods.

Escalating demand for processed food & beverages and subsequent requisite for plastic processing machinery, which in turn is expected to boost the growth of the hopper dryers market. Moreover, upsurge in installation of hopper dryers on injection molding machines boosts the growth of the hopper dryer market. Furthermore, emerging economies such as China, Japan, and India have experienced significant rise in the demand for hopper dryer with increase in applications in injection molding and extrusion machine.

Loading Table Of Content...