Hydraulic Power Unit Market Research, 2032

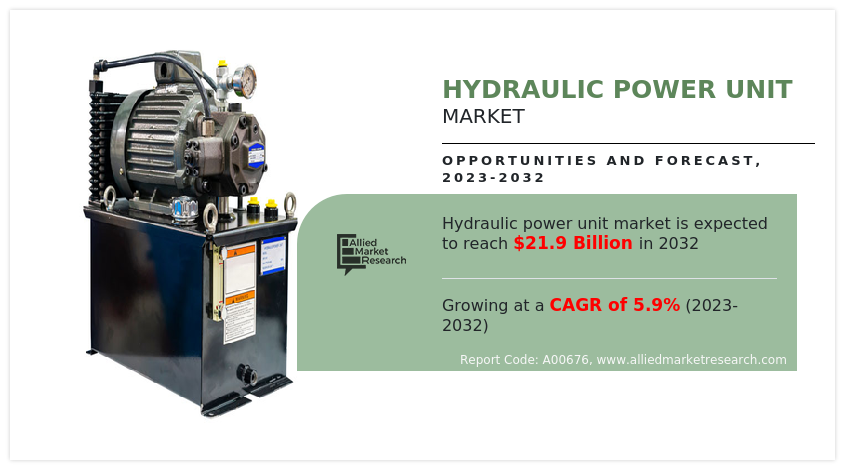

The global hydraulic power unit market was valued at $12.4 billion in 2022, and is projected to reach $21.9 billion by 2032, growing at a CAGR of 5.9% from 2023 to 2032.

Key Report Highlighters:

- The report outlines the current hydraulic power unit market statistics, trends, and future scenario of the market from 2023 to 2032 to understand the prevailing opportunities and potential investment pockets.

- The global hydraulic power unit market has been analyzed in terms of value ($ billion). The analysis in the report is provided for 4 major regions and more than 15 countries.

- The hydraulic power unit market is fragmented in nature with few players such as Brevini Fluid Power S.p.A, Bailey International LLC, Hydac International GmbH, Weber Hydraulik GmbH which hold a significant share of the market.

- The report provides strategy planning and industry dynamics to enhance decision making for existing market players and new entrants entering the hydraulic power unit market.

Hydraulic power units (HPUs) are primarily used for production, regulation and for providing hydraulic power to machinery and equipment. HPUs consist of various components which include hydraulic actuators, tools, and motors. It is the source of power for the whole system. Industries such as manufacturing, agriculture, construction, and aerospace have major applications of HPUs. HPUs are powered by electric motors or internal combustion engines. HPUs with electric motors are used commonly in industrial applications. While HPUs with internal combustion engines are used in mobile or remote applications. Since the HPUs are responsible for the flow of liquid/fluid within the hydraulic systems, the pump component pressurizes the fluid and creates a stable or desired flow.

The fluid or liquid, majorly oil, is stored in the reservoir. The pump gets a stable and sufficient supply of oil/liquid from the reservoir. It aids in heat dissipation which is usually produced during the operation of HPUs. The HPUs also consist of hydraulic fluids which lubricate the parts and also act as a conduit for the transmission of energy. There are two types of valves in the HPUs namely control valves and directional valves. HPUs also consist of control valves which are used to control the direction and pressure of the fluid.

The presence of accumulator in the HPUs ensures the stable pressure in system by storing the hydraulic energy. Accumulators aid during the need for rapid responses, during peak hours, and when there is need for temporary power sources. There are filtration systems that eliminate impurities for smooth and durable run of HPUs. The HPUs also consist of cooling systems which include a heat exchanger and/or fan. The role of heat exchanger is to control the hydraulic fluids temperature and prevent overheating. The HPUs also consist of pressure relief valves that return the extra fluid to the reservoir which helps prevent the system from overpressure. The system also has operators that receive performance data regarding monitoring instruments & control, flow meters, temperature sensors, and pressure gauges.

HPUs offer high power density, meaning they can transmit a large amount of power in a relatively small and lightweight package. Hydraulic systems provide precise control over the speed, force, and direction of motion, making them suitable for applications that require accurate and responsive control. These systems are well-suited for applications that require high torque at low speeds, making them effective for heavy-duty machinery and equipment. Hydraulic systems can be designed with overload protection features, such as pressure relief valves, to prevent damage to components in the event of excessive force. Hydraulic power units are versatile and can be adapted to various applications, including industrial machinery, construction equipment, and material handling systems.

Hydraulic power units can deliver substantial power in a compact design, allowing for easier integration into different types of machinery and equipment. Hydraulic components are designed to withstand harsh operating conditions, making hydraulic systems durable and reliable in demanding environments.

The increasing adoption of industrial automation in manufacturing and processing industries drives the demand for hydraulic power units to provide the necessary power and control for automated systems. Growth in construction and mining activities worldwide contributes to the demand for heavy-duty machinery, such as excavators and bulldozers, which often use hydraulic power units for efficient operation. The growth of renewable energy projects, including hydropower and wind energy, creates opportunities for hydraulic systems used in power generation, energy storage, and control systems.

The agriculture sector relies on hydraulic systems for various applications, including tractors, harvesters, and irrigation equipment, contributing to the demand for hydraulic power units. As industries focus on energy efficiency and sustainability, hydraulic systems are chosen for their ability to provide power with high efficiency, contributing to market growth. The expansion of the manufacturing sector, especially in emerging economies, fuels the demand for hydraulic power units used in a wide range of industrial machinery. Investments in infrastructure development, including roads, bridges, and other construction projects, lead to increased demand for hydraulic equipment and power units.

Despite the many benefits that hydraulic power units provide, there are also drawbacks and limitations to their application. Understanding these limitations is important for a comprehensive assessment of their suitability in various applications. Hydraulic systems are susceptible to fluid leaks, which can result in environmental concerns and require additional maintenance. The potential for oil spills can be a significant drawback, especially in sensitive or clean environments. Hydraulic systems often require regular maintenance to ensure proper functioning. The maintenance of hydraulic fluid, filters, seals, and other components is essential to prevent issues such as contamination and

Hydraulic systems can be complex, involving numerous components such as pumps, valves, hoses, and actuators. The complexity can lead to challenges in troubleshooting and repairs, requiring skilled personnel. Hydraulic components, especially large pumps and reservoirs can be heavy and take up significant space. This may limit their application in situations where weight and space constraints are critical. Hydraulic systems typically use oil-based hydraulic fluids, and the disposal or leakage of hydraulic fluid can have environmental consequences. Efforts to address environmental impact include the use of environmentally friendly fluids and improved containment systems.

Market Dynamics

Rising Automation In Industrial And Machinery

The use of hydraulic power units in industrial automation and machinery is diverse, spanning various sectors such as manufacturing, metalworking, plastics processing, and more. Their ability to deliver high force, precise control, and reliable performance makes them an essential component in many industrial applications. Advances in hydraulic technology continue to enhance efficiency, control, and energy conservation in industrial automation processes.

Hydraulic power units are extensively used in hydraulic presses for tasks such as metal forming, stamping, forging, and molding. They provide the force needed for shaping and manipulating materials. Hydraulic systems power machine tools such as hydraulic brakes, shears, and bending machines. The precise control offered by hydraulic power units is essential for accurate machining and forming operations. Hydraulic power units are integral to injection molding machines used in the plastics industry. They provide the force required to inject molten plastic into molds, shaping the final product. Such applications of HPUs drive the hydraulic power unit market growth.

Technological Advancements And Industry 4.0

Technological advancements and the principles of Industry 4.0 have significantly influenced the design, functionality, and integration of hydraulic power units (HPUs) in industrial settings. Advanced sensors and the Internet of Things (IoT) technology have been integrated into hydraulic systems. Smart sensors monitor parameters such as pressure, temperature, and fluid condition, providing real-time data for condition monitoring and predictive maintenance. IoT-enabled sensors in hydraulic power units allow for continuous monitoring of system health. Data analytics and machine learning algorithms can analyze this data to predict potential issues, enabling proactive maintenance and reducing downtime.

Industry 4.0 concepts enable remote monitoring and control of hydraulic systems. Through secure cloud-based platforms, operators can monitor HPU performance, receive alerts, and even adjust system parameters remotely, improving operational efficiency and responsiveness. The concept of digital twins involves creating a virtual replica of a physical hydraulic system. This virtual model allows for simulations, testing, and optimization, providing insights into system behavior and performance before changes are implemented in the physical system.

Cost Challenges

The cost challenges associated with hydraulic power units (HPUs) can vary depending on factors such as the application, system complexity, customization requirements, and market conditions. The upfront or initial capital cost of acquiring hydraulic power units can be significant, especially for large or customized systems. This includes the cost of components such as pumps, motors, valves, reservoirs, and control systems. Customized hydraulic power units tailored to specific applications often involve additional engineering and design costs. Customization may be required to meet unique specifications, resulting in higher upfront expenses. Hydraulic systems require regular maintenance to ensure optimal performance and reliability. Maintenance costs can include expenses for fluid changes, filter replacements, seal replacements, and addressing wear and tear on components.

Industry 4.0 And Rise Of Electric And Hybrid Applications

The integration of Industry 4.0 principles provides opportunities for smart hydraulic power units with IoT connectivity, data analytics, and remote monitoring capabilities. Smart HPUs can offer real-time insights, predictive maintenance, and enhanced operational efficiency. Growing emphasis on energy efficiency presents opportunities for hydraulic power units that incorporate variable speed drives, load-sensing technology, and other energy-efficient features. Manufacturers can capitalize on the demand for environmentally friendly and sustainable hydraulic systems.

Tailoring hydraulic power units to meet the specific requirements of diverse applications, such as aerospace, marine, and industrial machinery, offers significant opportunities. Customization allows for optimal performance and efficiency in specialized use cases. Opportunities exist for hydraulic power units that are part of electric-hydraulic and hybrid systems. Such systems leverage the advantages of both hydraulic and electric technologies, catering to applications where efficiency and flexibility are paramount.

The hydraulic power unit market size is segmented on the basis of operating pressure rating, application, and region.

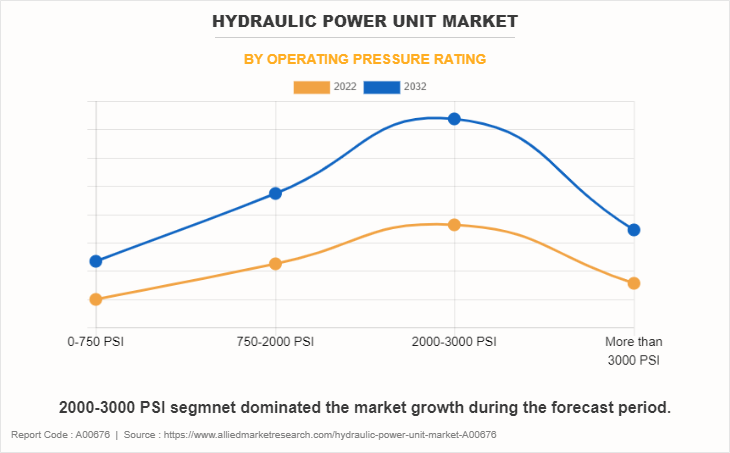

By operating pressure rating, the market is classified into 0-750 PSI, 750-2000 PSI, 2000-3000 PSI, and more than 3000 PSI. The 2000-3000 PSI segment accounted for 37.2% share in 2022 and is expected to maintain its dominance during the hydraulic power unit market forecast period. A hydraulic power unit (HPU) operating in the pressure range of 2000 to 3000 psi (pounds per square inch) is suited for applications that require higher pressure levels. The increased pressure allows for the generation of greater force and precision in various industrial processes. Hydraulic power units in this pressure range are commonly used in machine tools such as milling machines, lathes, and machining centers. The high pressure allows for precise control of cutting tools and the efficient operation of hydraulic actuators.

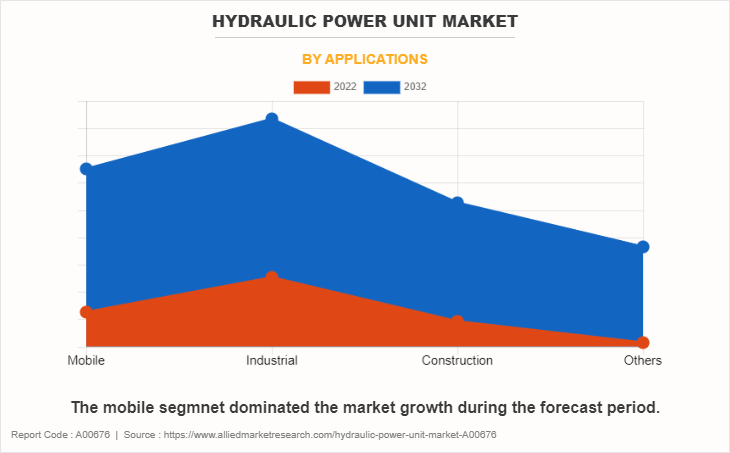

By application, the market is segmented into mobile, industrial, construction, and others. The mobile segment accounted for 25.2% hydraulic power unit market share in 2022 and is projected to grow at fastest pace during the forecast period. Mobile hydraulic power units play a crucial role in a variety of applications where on-the-go hydraulic power is required. These mobile units are designed for versatility, compactness, and ease of transport. Mobile hydraulic power units are extensively used in construction applications for powering hydraulic systems in equipment such as excavators, loaders, cranes, and compactors. These units provide the necessary power for lifting, digging, and other construction tasks.

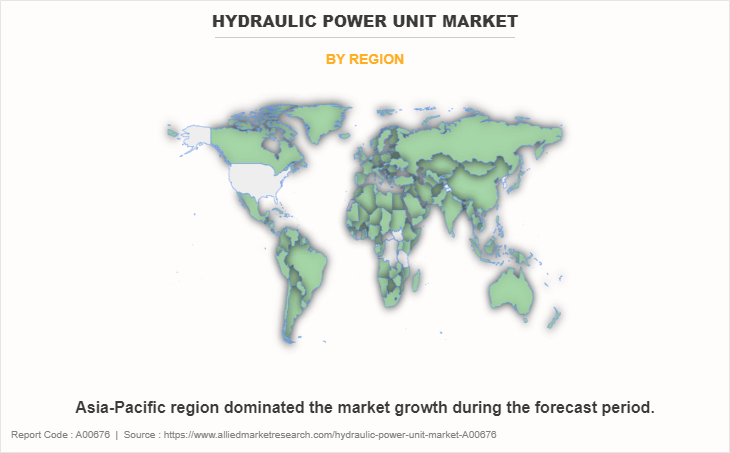

Region-wise, the hydraulic power unit market analysis is done across North America, Europe, Asia-Pacific, and LAMEA. On the basis of region, Asia-Pacific accounted for 41% hydraulic power unit market share in 2022 and is expected to maintain its dominance during the forecast period. The Asia-Pacific region has been a significant contributor to the global hydraulic power unit market, driven by rapid industrialization and infrastructure development. Economic growth, urbanization, and increased industrial activities have been key drivers for the hydraulic power unit market in the Asia-Pacific region. Hydraulic power units find extensive use in various industrial applications across the region, including manufacturing, construction, mining, and agriculture.

Key players operating in the hydraulic power unit industry include Brevini Fluid Power S.p.A, Bailey International LLC, Hydac International GmbH, Weber Hydraulik GmbH, Nachi-Fujikoshi Corporation (Nachi Robotic Systems, Inc.), Hydro-Tek Co Ltd., Bosch Rexroth AG, Parker Hannifin Corporation, Eaton, and Dana Incorporated.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the hydraulic power unit market analysis from 2022 to 2032 to identify the prevailing hydraulic power unit market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the hydraulic power unit market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global hydraulic power unit market trends, key players, market segments, application areas, and market growth strategies.

Hydraulic Power Unit Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 21.9 billion |

| Growth Rate | CAGR of 5.9% |

| Forecast period | 2022 - 2032 |

| Report Pages | 250 |

| By Operating Pressure Rating |

|

| By Applications |

|

| By Region |

|

| Key Market Players | Holstein Hydraulik GmbH, Hydac International GmbH, Hydro-tek Co Ltd., Weber Hydraulik GmbH, Bailey International LLC, Dana Limited, NACHI-FUJIKOSHI CORPORATION (NACHI ROBOTIC SYSTEMS, INC.), Parker Hannifin Corporation, Eaton Corporation plc, Bosch Rexroth AG |

Analyst Review

Hydraulic power units are versatile and can be customized based on the specific requirements of the hydraulic system and the machinery they serve. They are used in various applications, including hydraulic presses, industrial machinery, construction equipment, material handling systems, and more. The design and specifications of hydraulic power units can vary based on factors such as the required power output, system pressure, flow rate, and environmental conditions. They play a critical role in providing efficient and reliable power for hydraulic systems, contributing to the operation of a wide range of mechanical and industrial processes.

While hydraulic power units offer numerous advantages, there are also certain disadvantages and restraining factors associated with their use. Hydraulic power units can be expensive to manufacture and maintain. Initial costs may include the purchase of specialized components, and ongoing costs are associated with maintenance, fluid replacement, and repairs. While hydraulic systems provide precise control in many applications, they may not offer the same level of precision as certain electronic or electromechanical systems in some situations.

Rising automation in industrial & machinery sector and technological advancements & industry 4.0 are the recent trends of Hydraulic Power Unit Market in the world.

The mobile application is the leading application of Hydraulic Power Unit Market.

Brevini Fluid Power S.p.A, Bailey International LLC, Hydac International GmbH, Weber Hydraulik GmbH, Nachi-Fujikoshi Corporation (Nachi Robotic Systems, Inc.), Hydro-Tek Co Ltd., Bosch Rexroth AG, Parker Hannifin Corporation, Eaton, and Dana Incorporated are the top companies to hold the market share in Hydraulic Power Unit.

Asia-Pacific is the largest regional market for Hydraulic Power Unit.

$21.9 billion is the estimated industry size of Hydraulic Power Unit by 2032

Loading Table Of Content...

Loading Research Methodology...