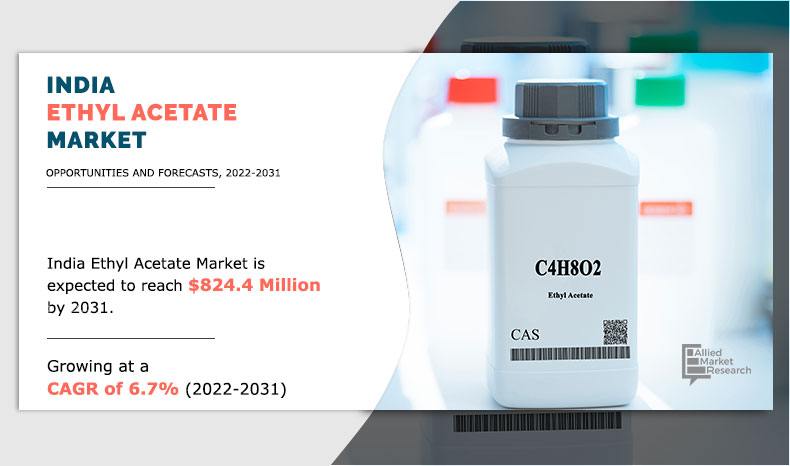

The India ethyl acetate market size was valued at $432.0 million in 2021, and is projected to reach $824.4 million by 2031, growing at a CAGR of 6.7% from 2022 to 2031.

Ethyl acetate is a colorless, volatile, and flammable liquid with a fruity odor. It is commonly used as a solvent in various industries in India, including pharmaceuticals, paints and coatings, printing inks, adhesives, and food flavorings.

One of the primary uses of ethyl acetate in India is in the pharmaceutical industry. Ethyl acetate is used as a solvent in drug manufacturing processes, particularly for the extraction of active pharmaceutical ingredients (APIs) from plants. India is a significant producer of generic drugs, and the demand for ethyl acetate as a solvent is expected to continue to grow as the Indian pharmaceutical industry expands.

In the paints and coatings industry, ethyl acetate is used as a solvent for nitrocellulose lacquers, acrylic lacquers, and other coating systems. The growth of the Indian construction industry has led to an increase in demand for paints and coatings, which in turn has boosted the demand for ethyl acetate as a solvent. The printing industry in India also uses ethyl acetate as a solvent for inks. Ethyl acetate-based inks are fast-drying and produce high-quality prints, making them ideal for printing on a variety of surfaces, including paper, plastic, and metal

Historical Trends of Ethyl Acetate in India:

- In the early 2000s, the demand for ethyl acetate in India was relatively low, and the market was dominated by a few major players. However, as the Indian economy began to grow and industrialization increased, the demand for ethyl acetate started to rise rapidly.

- From 2010 to 2015, the demand for ethyl acetate in India continued to rise, at a slower pace of around 6% per annum. During this period, the pharmaceutical industry emerged as a significant consumer of ethyl acetate, as it is widely used as a solvent for manufacturing drugs.

The India ethyl acetate market is driven owing to increase in demand for ethyl acetate across construction industry.

Ethyl acetate is a widely used solvent in the construction industry for various applications such as coatings, adhesives, and paints. With the growth of the construction industry in India, there has been an increase in the demand for ethyl acetate. The construction industry in India has been experiencing significant growth in recent years, driven by the government's infrastructure development initiatives, rise in urbanization, and increase in foreign investment in the sector. This growth has led to an increase in the consumption of various construction-related materials, including ethyl acetate. GDP from Construction in India increased to $36.84 billion in the fourth quarter of 2022 from $33.02 billion in the third quarter of 2022. The government has been promoting infrastructure development, including building highways, airports, railways, and affordable housing, which has led to significant growth in the construction sector. In addition, ethyl acetate is also used in coatings, adhesives, and paints in the construction industry as a cleaning agent for equipment and tools. It helps to remove dirt, grime, and other contaminants from surfaces and equipment, ensuring that they are clean and ready for use.

However, availability of substitute products is anticipated to hamper the market growth. Methyl ethyl ketone (MEK) is a solvent that can be used as a substitute for ethyl acetate in some applications in India. It has a similar solvency power and can be used in some coatings, adhesives, and paints. It helps to dissolve the resins and improve their flow properties, resulting in a smooth and uniform coating. MEK is used as a solvent for various synthetic polymers in adhesives in India, including vinyl acetate, polyvinyl alcohol, and acrylics.

Lack of technological advancement in India is the major challenge for growth of ethyl acetate market in India. India is still using conventional manufacturing processes for ethyl acetate production, which can lead to high production costs and limited production capacity. The lack of advanced technology also means that the quality of the product may not be as good as it could be. The conventional manufacturing processes used in India for the production of ethyl acetate are not optimized for energy efficiency or process sustainability. This can lead to higher production costs as well as negative environmental impacts.

Separation technology is an important aspect of ethyl acetate production, as it determines the quality and purity of the final product. However, most of the separation processes used in India are based on distillation, which can be energy-intensive and expensive. There is a need for more advanced separation technologies, such as membrane separation and reactive distillation, which can reduce energy consumption and improve the quality of the product

Ethyl acetate is widely used in the adhesive industry in India, primarily as a solvent for various synthetic polymers. It is used to dissolve the polymers and improve their flow properties, resulting in a strong and durable bond. Ethyl acetate is used in the manufacturing of various adhesives used in the packaging industry. It is used as a solvent for various synthetic polymers, including polyethylene, polypropylene, and polyester. In March 2022, TCPL packaging limited doubled its flexible packaging plant capacity, which has gone into commercial production in India. The company also expanded offset capacity by adding a new printing line at the Goa plant. Ethyl acetate is used in the manufacturing of various adhesives used in the automotive industry in India. It is used as a solvent for various synthetic polymers, including polyurethane and epoxy. These adhesives are used to bond various materials such as metal, plastic, and rubber, providing a strong and durable bond.

Ethyl acetate is also used as a solvent in the manufacturing of various woodworking adhesives. It is used to dissolve various polymers such as phenol-formaldehyde resins and melamine-formaldehyde resins, which are used to bond wood products. These adhesives are commonly used in the production of furniture, cabinetry, and flooring. As a result, increasing demand from the adhesive industry is expected to provide sufficient development prospects for the India ethyl acetate market trend in the future.

The India ethyl acetate is segmented into application, and end-use industry. On the basis of application, the market is classified into pigments, paints and coatings, process solvents, adhesives and sealants and others. On the basis of end-use industry, the market is divided into artificial leather, packaging, automotive, food and beverages, pharmaceutical, and others.

Key players engaged in development and production of ethyl acetate in India include Celanese Corporation, Dhanlaxmi Organics & Chemical, HELM AG, IOL Chemicals and Pharmaceuticals Limited, Jubilant Ingrevia Limited, Maharashtra Aldehydes & Chemicals Ltd, Merck KGaA, Saanvi Corp., Solvay S.A., and Vizag Chemical International.

By Application

Paints and coatings application is projected as the most lucrative segment.

India Ethyl Acetate Market, By Application

On the basis of application, the process solvents segment dominated the India ethyl acetate market in 2021. In the manufacturing of pharmaceutical and cosmetic goods, ethyl acetate is used as a process solvent. It is especially helpful when removing natural goods like essential oils from plant-based materials. The creation of flavors and aromas involves the use of process solvents. When decaffeinated coffee and tea are made, it is also employed as a solvent for the separation of caffeine. Ethyl acetate is used as a process solvent in the production of pharmaceutical and cosmetic products.

It is particularly useful for extracting natural products, such as essential oils, from plant materials. Process solvent is used in the production of flavors and fragrances. Ethyl acetate is becoming increasingly popular as a process solvent for adhesives used in a variety of sectors, including automotive, construction, and woodworking. Ethyl acetate is a commonly used solvent for extracting flavors and fragrances from natural sources like fruits, flowers, and spices. Ethyl acetate is considered safe for use in food applications as it is non-toxic and has a low odor & taste.

As per the Careerizma, the food processing business accounts for around $130 billion from overall Indian food and beverage industry. It contributes 10% of agricultural GDP and 12% of manufacturing GDP. Thus, the increasing demand for process solvents is expected to boost the India ethyl acetate market during the forecast period.

By End-use Industry

Automotive end-use industry is projected as the most lucrative segment.

India Ethyl Acetate Market, By End-Use Industry

By end-use industry, the pharmaceuticals segment dominated the India ethyl acetate market in terms of revenue in 2021. The pharmaceutical industry frequently uses the versatile solvent ethyl acetate to produce a range of medications, including antibiotics, analgesics, and anti-inflammatory drugs. Active pharmaceutical ingredients and other substances that are insoluble in water can be dissolved with special success using this method. In order to extract natural substances from plant materials for use in pharmaceutical goods, ethyl acetate is also employed. It is frequently used to remove alkaloids, essential oils, and other active substances from medicinal plants.

Ethyl acetate is used as a purification solvent in the pharmaceutical industry to remove impurities and contaminants from pharmaceutical compounds. It is a mild solvent that can dissolve many types of impurities without affecting the purity of the active ingredient. Ethyl acetate is also growing in popularity as a coating material for tablets and capsules to improve their appearance, taste, and stability. It is used as a solvent for various pharmaceutical formulations, including injectables and oral suspensions.

Key Benefits For Stakeholders

- The report provides in-depth analysis of the India ethyl acetate market forecast along with the current trends and future estimations.

- This report highlights the key drivers, opportunities, and restraints of the market along with the impact analysis during the forecast period.

- Porter’s five forces analysis helps to analyze the potential of the buyers & suppliers and the competitive scenario of the India ethyl acetate market for strategy building.

- A comprehensive market analysis covers the factors that drive and restrain the India ethyl acetate market growth.

- The qualitative data about market dynamics, trends, and developments is provided in the report.

India Ethyl Acetate Market Report Highlights

| Aspects | Details |

| By Application |

|

| By End-Use Industry |

|

| Key Market Players | Maharashtra Aldehydes & Chemicals Ltd., Dhanlaxmi Organics & Chemical, IOL Chemicals and Pharmaceuticals Limited, Saanvi Corp., Vizag Chemical International, Celanese Corporation, Merck KGaA, HELM AG, Solvay S.A., Jubilant Ingrevia Limited |

Analyst Review

According to the opinions of various CXOs of leading companies, the India ethyl acetate market is driven by the use of ethyl acetate in the production of paints and coating in India. Ethyl acetate is commonly used in the production of paints and coatings in India as a solvent and co-solvent. It is used in the formulation of solvent-based coatings, such as nitrocellulose, cellulose acetate butyrate, and acrylics, and as a coalescing agent in waterborne coatings. It helps to dissolve the resins and improve their flow properties, resulting in a smooth and uniform coating.

However, the availability of substitutes is expected to restrain industry expansion. Methyl ethyl ketone (MEK) is a substitute for ethyl acetate in some applications, helping to dissolve resins and improve flow properties, resulting in a smooth and uniform coating. Acetone is also used as a cleaning agent in various industries to remove contaminants and ensure clean surfaces and equipment.

Increase in demand for ethyl acetate across construction and paints & coatings end-user are the key factors boosting the India ethyl acetate market growth .

The India ethyl acetate market was valued at $432.0 million in 2021, and is projected to reach $824.4 million by 2031, registering a CAGR of 6.7% from 2022 to 2031

IOL Chemicals and Pharmaceuticals Limited, Dhanlaxmi Organics & Chemical, Vizag Chemical International, and Maharashtra Aldehydes & Chemicals Ltd. Are the most established players of the India ethyl acetate.

Pharmaceutical industry is projected to increase the demand for India ethyl actetate.

The India ethyl acetate is segmented into application, and end-use industry. On the basis of application, the market is classified into pigments, paints and coatings, process solvents, adhesives and sealants and others. On the basis of end-use industry, the market is divided into artificial leather, packaging, automotive, food and beverages, pharmaceutical, and others.

Ethyl acetate is a chemical compound that is commonly used as a solvent in various industries, including pharmaceuticals, food and beverage, and paint manufacturing in India. It is also used as a flavoring agent in some food products, such as confectioneries and baked goods. In India, ethyl acetate is widely used in the production of pharmaceuticals, as it is a common solvent for several drugs and is also used as a flavoring agent in food products.

Loading Table Of Content...