Joint Sealants Market Research, 2031

The global joint sealants market size was valued at $1.0 billion in 2021, and is projected to reach $1.6 billion by 2031, growing at a CAGR of 4.7% from 2022 to 2031.

Report Key Highlighters:

- Other 6,700 product literatures, annual reports, industry releases, and other such documents of major industry participants along with authentic industry journals, trade associations' releases, and government websites have been reviewed for generating high-value industry insights.

- The study covers approximately 20 countries. The segment analysis of each country in terms of value and volume during the forecast period 2021-2031 is covered in the joint sealants market report.

- The joint sealants market is highly fragmented, with several players including 3M, American Sealants, Inc., Hodgson Sealants, ITW Performance Polymer, MAPEI S.p.A., NANPAO RESINS CHEMICAL GROUP, Pidilite Industries Limited, RPM International Inc., Sika AG and Wacker Chemie AG.

Joint sealants are materials used to seal joints and openings (gaps) between two or more substrates and are an essential part of building design and construction. These are primarily used to stop air, water, and other environmental components from entering or leaving a building while allowing for some movement of the substrates. These are intended to prevent corrosion at joint edges in clay and concrete tiles. Some of the characteristics necessary to enhance the joint sealant's performance are UV resistance, non-chalking, non-staining, self-cleaning, resists abrasion and penetration, flexibility when exposed to weather and aging, and excellent resistance to physical and chemical reactions.

Growing demand from various end-use industries is driving the joint sealants market growth.

Joint sealants are used in various industries, including building and construction, transportation, automobile, aerospace and defense, electronics, electricals, and others. Joint sealants are extensively used in the building and construction sector due to their desirable properties such as insolubility, corrosion resistance, and adhesion. These are utilized on pavements and roads to extend their service life. Joint seals reduce the quantity of surface water that enters the pavement system, minimizing the danger of pumping, erosion, D-cracking, or any other type of damage brought on by moisture intrusion.

According to a recent Texas A and M University study, if joint seals are installed, they can be highly effective in preventing moisture infiltration and thus performance issues related to erosion damage. Joint seals prevent incompressible particles (such dirt, boulders, and other debris) from entering the joint and becoming trapped inside. Preformed compression sealants and silicone sealants function better than asphalt-based sealants for roadway pavements, but they are frequently proportionately more expensive. In the case of highways, the joints must be strengthened and sealed to guard against heavy traffic damage. Joint sealants are ideal as they prevent water, particles, and gases from entering.

Many key players are providing their joint sealant products which are used in the construction of highways, bridges, and roads. For instance, Dow offers silicone pavement sealants that are excellent for sealing a variety of applications, such as expansion joints, transverse joints, longitudinal joints, construction joints, crack-control joints, and parapet walls, among other projects of a similar nature.

Moreover, Durabuild provides pavement sealants such as D900 POLYSULPHIDE SEALANT PPS and DURASIL TPU (thermoplastic polyurethanes) which seal runway, road, bridge joints and can withstand extreme horizontal/vertical joint movements due to dynamic loads as well as temperature variations. Growing investments in the construction industry have also stimulated the demand for joint sealants.

For example, on 1 May 2021, Durabuild, a manufacturer of high-quality building and construction care products, recently signed contracts with two major corporations, GR Infra and PNC, indicating a clear shift in their focus to providing their extensive selection of construction chemicals, which includes admixtures, curing compounds, sealants, and others, to large highway projects. Owing to the excellent advantages of joint sealants, they are used immensely in the building and construction sector leading to the expansion of the joint sealant market.

The utilization of joint sealants in the aerospace sector drives the joint sealants industry. Materials used in the construction of aircraft must adhere to strict guidelines and be able to endure the strains of harsh and fluctuating environments. Joint sealants can be used to seal surfaces, joints, and openings in an aircraft's fuel tanks, access doors, windscreens, and other components to stop fluids from passing through. The runways, aprons, restrooms, and places for loading and unloading aircraft all experience heavy traffic, continuous use, and heavy loads. Joint sealants are thus necessary to keep the spaces between the fields impermeable.

Joint sealants help eliminate vibration and lower aircraft maintenance costs, extending the life of the product. Due to several properties, polysulfides are ideal for use in the manufacturing of aircraft. They are superior fuel sealants because they easily handle jet and other fuels. They are suitable for potting or sealing electronic components inside of tanks since they are also effective as a dielectric.

The aircraft sector receives joint sealant products from numerous manufacturers, including PPG Industries, Inc., 3M, and others. For instance, PR-1422 and Pro-Seal 890 from PPG Industries, Inc. are lighter in weight, withstand higher temperatures, cure faster, and are easier to apply. Therefore, there is an increase in the demand for joint sealants in the aerospace sector.

The strict regulations on the use of solvents in joint sealants restrain the growth of the joint sealants market. Joint sealants contain solvents as their key component. Volatile organic compounds (VOCs) or toxic substances are released into the atmosphere by solvents. During a product's service life, volatile compounds like formaldehyde may continue to be released. When semi-volatile substances like phthalate plasticizers are released, they stick to the dust and can be inhaled or eaten.

Short-term side effects of breathing in VOCs, according to the Environmental Protection Agency (EPA), include nausea, eye, nose, and throat irritation, loss of coordination, weariness, disorientation, headache, allergic skin reaction, and other problems. Depending on the type of solvent being used, there are long-term dangers such as cancer, genetic changes, and harm to the developing and reproductive systems. Government regulations and VOC-removal green construction initiatives have made the issue more widely known.

Several organizations and governmental bodies, including Leadership in Energy and Environmental Design (LEED), Registration, Evaluation, Authorization and Restriction of Chemicals (REACH), and different regional regulatory authorities, have directed that manufacturers provide eco-friendly joint sealants with low VOC emission. Different government regulations are put to their use because of the health hazards related to joint sealants, hampering market expansion. Nevertheless, surge in infrastructural development is projected to generate extraordinary growth opportunities.

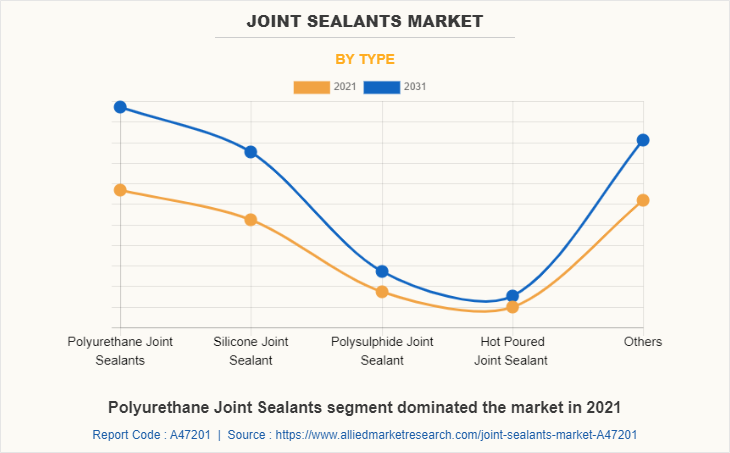

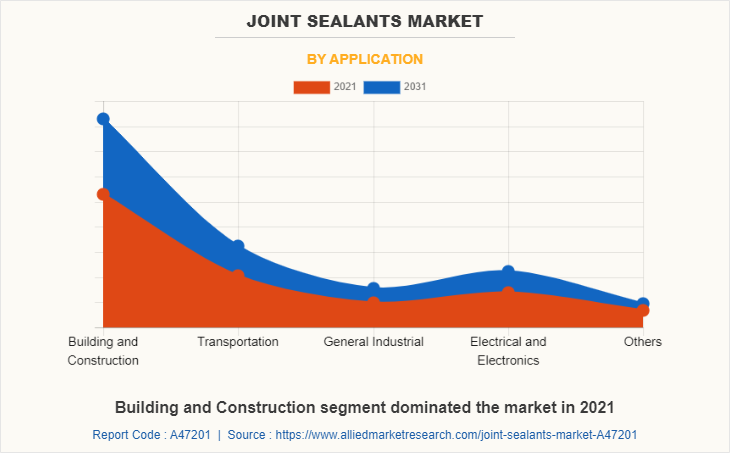

The joint sealants market is segmented into type, end-use industry, and region. By type, the market is divided into polyurethane joint sealants, silicone joint sealant, polysulphide joint sealant, hot poured joint sealant and others (acrylic, epoxy, PTFE). The end-use industry segment is categorized into building and construction, transportation, general industrial, electrical and electronics and others. Region wise, the joint sealants market share is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

Region wise, Asia-Pacific dominated the market due to rise in demand for joint sealants in the construction and residential sectors. Moreover, the increase in investments in the transportation sector have increased the usage of joint sealants in this region. Rise in population and industrialization boosts the the need for joint sealants in Asia-Pacific .

By type, the polyurethane joint sealants segment leads the market, as it is majorly used in the the automobile and residential sectors. It is used in the manufacture of vehicles, repairing auto glass, making, and installing air conditioning in HVAC systems, and manufacturing and sealing metal structures like trucks and containers. It is used to reduce vibration and provide sealing in metal sheet joints. It is also utilized in gutter joints, pipelines used to collect rainwater from roofs, and edges between prefabricated building materials.

The building and construction segment dominated the global market, because of the growing demand for joint sealants in the construction of roads, bridges, highways, buildings, and others. It is employed to join and connect the various parts and materials to the primary framework and to one another. They assist in sealing up gaps between the structure's parts and surfaces, keeping water and other substances from penetrating between surfaces and mechanical joints.

Key Players and Strategies:

The key players operating in the joint sealants market are 3M, American Sealants, Inc., Hodgson Sealants, ITW Performance Polymer, MAPEI S.p.A., NANPAO RESINS CHEMICAL GROUP, Pidilite Industries Limited, RPM International Inc., Sika AG and Wacker Chemie AG. The key players adopted various strategies such as acquisition, new product launches, business expansion and partnership to sustain the market competition.

In December 2021, Sika AG expanded its business by establishing an innovative technology center and manufacturing factory for high-quality adhesives and sealants in Pune, India. The company primarily manufactures products for the transportation and construction industries through its three new production lines. This expansion will increase the demand for joint sealants across the globe.

In December 2020, Wacker Chemie AG launched renewables-based silicone sealants ELASTOSIL, an eco-brand in Europe. The new brand is based on the REDcert2 standard which confirms the traceability of renewable raw materials across WACKER’s entire production process – from the initial upstream process to the ready-to-use silicone sealant.

In September 2019, Sika AG acquired Crevo-Hengxin, a Chinese manufacturer of silicone sealants and adhesives used in both industry and construction applications. With this acquisition, Sika AG is expanding its target markets industry and sealing and bonding presence in China and the Asia-Pacific region and is gaining additional silicone technology plus a production footprint.

Key Market Trends:

Joint sealants are widely used in the medical sector. These are intended to be used to stop caries from developing in vulnerable pits and fissures of posterior teeth in children and adolescents. However, sealants have grown more common today over time and are now frequently used for patients of all ages, not only to stop the development of new carious lesions but also to stop the advancement of caries in places where there are shallow incipient carious lesions.

Manufacturers of joint sealants depend significantly on research and development to remain one step ahead of environmental regulations and consumer needs. As a result of persistent and fruitful research and development over the past few years, numerous companies have developed a wide range of joint sealants which are utilized for different purposes.

Nanocomposite joint sealants are the future of the industry as use of renewable resources has been gaining interest due to their high economic benefits. For instance, Eco-Nanoseal, a sealant developed by using a composite of graphene-oxide and chitosan, an aquaculture waste-derived material for healing micro-cracks in concrete. In the concrete environment, the nanofibrous film-forming composite rapidly solidifies without the help of an external polymerizing agent. Concrete microcrack repair may be achieved using Eco-Nanoseal due to its efficient ability to build a firm plug and strong bonding with the concrete surface.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the joint sealants market analysis from 2021 to 2031 to identify the prevailing joint sealants market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the joint sealants market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global joint sealants market trends, key players, market segments, application areas, and market growth strategies.

Joint Sealants Market Report Highlights

| Aspects | Details |

| Market Size By 2031 | USD 1.6 billion |

| Growth Rate | CAGR of 4.7% |

| Forecast period | 2021 - 2031 |

| Report Pages | 300 |

| By Type |

|

| By Application |

|

| By Region |

|

| Key Market Players | MAPEI S.p.A., Wacker Chemie AG, American Sealants, Inc., Sika AG, Pidilite Industries Limited, NANPAO RESINS CHEMICAL GROUP, RPM International Inc., 3M, ITW Performance Polymer, Hodgson Sealants |

Analyst Review

According to the opinions of various CXOs of leading companies, the joint sealants market is driven by the surge in demand for residential and commercial buildings. Joint sealants play a significant role in the safety of modern commercial establishments against water damage to the structures and their contents. These are used to close open joints to avoid the passage of water and air (both inside and outside), to improve the aesthetic and cleanability of interior surfaces when water resistance is not a concern, and to reduce the amount of sound that can travel through cracks (usually interior and internal to composite assemblies).

Joint sealants are widely used in the automotive industry for a broad range of tasks, including the repair of upholstery, acoustic insulation, door panel cladding, and insulating matting. Joint sealant is applied to the fractures and openings of the trunk lid, bonnet, doors, and steel plate to prevent corrosion caused by waterlogging.

The solvents used in the manufacturing process of joint sealants cause severe side effects on human health and the environment. They release poisonous substances or volatile organic compounds (VOCs) into the atmosphere. These substances when inhaled cause nausea, eye, nose, and throat irritation, lack of coordination, disorientation, headache, allergic skin reaction, and other issues. Therefore, various regulatory bodies and government agencies have imposed restrictions on the use of solvents which restrains the market growth. However, the surge in infrastructural development due to foreign investments, rise in economies and other factors have led to excellent growth opportunities for many manufacturers across the globe.

Currently, polyurethane joint sealants are majorly used joint sealants; however, silicone joint sealants are expected to grow in terms of revenue. Similarly, the Asia-Pacific region is expected to grow at a significant rate during the forecast period.

The global joint sealants market was valued at $1.0 billion in 2021, and is projected to reach $1.6 billion by 2031, growing at a CAGR of 4.7% from 2022 to 2031.

The joint sealants market is driven by an increase in demand for these joint sealants in various end use industries including transportation, electronics, healthcare, automobile, and others.

Building and Construction is the leading application of Joint Sealants Market.

Asia-Pacific is the largest regional market for Joint Sealants.

The key players operating in the joint sealants market are 3M, American Sealants, Inc., Hodgson Sealants, ITW Performance Polymer, MAPEI S.p.A., NANPAO RESINS CHEMICAL GROUP, Pidilite Industries Limited, RPM International Inc., Sika AG, and Wacker Chemie AG.

Loading Table Of Content...