The LAMEA Polyurea Coatings Market is expected to reach a value of $127 million by 2032.

Polyurea coatings are a class of protective coating materials that are produced when amines and isocyanates are combined. This chemical method creates an elastomeric coating that is multifunctional and durable. These coatings have distinctive characteristics that include superior abrasion resistance, quick cure times, flexibility, resilience to chemicals and environmental conditions, and high tensile strength. These coatings are frequently used for waterproofing, corrosion protection, industrial flooring, and other protective coating needs in a wide range of industries, including construction, transportation, oil & gas, and automotive applications.

The lucrative use of polyurea coatings in the oil & gas industry is poised to drive significant expansion in the LAMEA polyurea coatings market.

Wide usage of polyurea coatings in the oil & gas industry drives the market growth in LAMEA. These coatings are essential as they offer robust and efficient protection for a range of assets and infrastructure. Polyurea coatings are an ideal choice for effective defense against the extreme and caustic environments seen in the oil & gas industry. Protection of pipelines, tanks, and other equipment from corrosion due to adverse conditions is a major use for polyurea coatings.

Many manufacturers are offering their products that are used in the oil & gas sector. For instance, PolyZilla, a manufacturer of polyurethane, polyurea and hybrid spray-applied elastomer coatings, based in South Africa, offers polyurea and hybrid coatings that provide industrial-grade protection in the harshest environments. They may be spray-applied in a wide range of environmental conditions for long lasting abrasion, water and chemical resistance.

In addition, containment systems used in the oil & gas sector use polyurea coatings to stop spills and leaks. These coatings provide an impermeable barrier that protects against potential hazards to the environment and operations related to the transportation and storage of hazardous materials. Polyurea is an efficient material for secondary containment structures owing to its capacity to produce a strong and seamless barrier, which minimizes the ecological impact of potential leaks and ensures compliance with environmental laws.

Moreover, polyurea coatings are used by the LAMEA oil & gas sector to protect offshore structures including rigs and platforms. The coatings provide protection from sand and marine debris abrasion, harsh weather, and saltwater corrosion. The rapid application and cure periods of polyurea coatings help to reduce downtime during maintenance tasks in offshore settings, hence enhancing overall operational efficiency. Thus, increase in use of polyurea coatings in the oil & gas sector is expected to boost the market growth in LAMEA.

The surge in the infrastructural developments is poised to drive significant expansion in the LAMEA polyurea coatings market.

Rise in investments in infrastructure developments drives the growth of the LAMEA polyurea coating market. According to the International Trade Administration, the United Arab Emirates (UAE) has an extensive list of transport and road infrastructure projects. These include the $11 billion Etihad rail project, the $5.9 billion projected hyperloop project connecting Dubai and Abu Dhabi, and the $2.7 billion Sheikh Zayed double-deck road project. The government aims to expand transport infrastructure, as there is a growing need for urban transportation.

Polyurea coatings have become the material of choice for protecting various infrastructure components, including pipelines, bridges, highways, factories, and water treatment plants. The durable characteristics of polyurea coatings—such as their remarkable toughness, resilience to chemicals, and quick cure time—address typical problems caused by weather, corrosive chemicals, and mechanical damage. Polyurea is superior to conventional coating materials in that it effectively guards against corrosion, abrasion, and chemical exposure, prolonging the life of structures and reducing the need for routine maintenance.

Polyurea coatings not only improve durability but also help achieve sustainability goals by lowering the total life cycle costs of infrastructure projects. Polyurea coatings' quick cure times allow for faster project completion, which reduces downtime and improves the efficiency of the construction schedule. This quality is very helpful for projects that have a strict deadline, like building new infrastructure or renovating existing infrastructure. Thus, rapid infrastructure development boosts the growth of the LAMEA polyurea coating market during the forecast period.

However, the market expansion for LAMEA polyurea coating is restricted by the fluctuating cost of raw materials. Polyurea coatings, comprising vital components such as amines and isocyanates derived from petrochemical feedstocks, face cost fluctuations influenced by external factors. The demand for petrochemicals, disruptions in supply chains, and geopolitical developments collectively impact the costs of these raw materials. The inherent uncertainties exacerbate the volatility in raw material expenses, posing challenges for both producers in predicting production costs and end users in budgeting for projects involving polyurea coatings.

The dynamics of petrochemical supply and demand significantly influence the pricing of raw materials crucial to polyurea coating technologies. Petrochemical feedstocks, sourced from crude oil and natural gas derivatives, are pivotal in isocyanate production—an integral part of polyurea formulations. Rapid and unpredictable variations in the prices of these essential raw materials result from shifts in oil prices, international conflicts, or disruptions in the petrol and oil supply chain. Such market volatility presents challenges for producers in maintaining cost stability, impacting their ability to offer clients fixed prices. Thus, fluctuations in the raw material prices restrain the growth of the polyurea coatings market.

Technological advancements in LAMEA polyurea coating has significantly expanded growth opportunities for the market. These developments have led to a transformation in protective coatings, offering enhanced sustainability, application efficiency, and overall performance. One notable innovation is the introduction of hybrid polyurea formulations, combining the strengths of polyurea with other polymers like epoxy or polyurethane. These hybrids boast improved adhesion, flexibility, and UV resistance, catering to specific application needs across diverse sectors.

In response to environmental concerns, researchers have focused on developing low-VOC and solvent-free polyurea coatings, meeting the demand for eco-friendly solutions. Advancements in application technology, including state-of-the-art plural-component spray equipment, precise mixing ratios, and improved temperature control, ensure optimal curing and coating performance. Automated spray systems further enhance efficiency and reduce errors, while smart application equipment with real-time monitoring capabilities provides users with greater control. Thus, these technological advancements have created a lucrative growth opportunity for the polyurea coating market in the LAMEA.

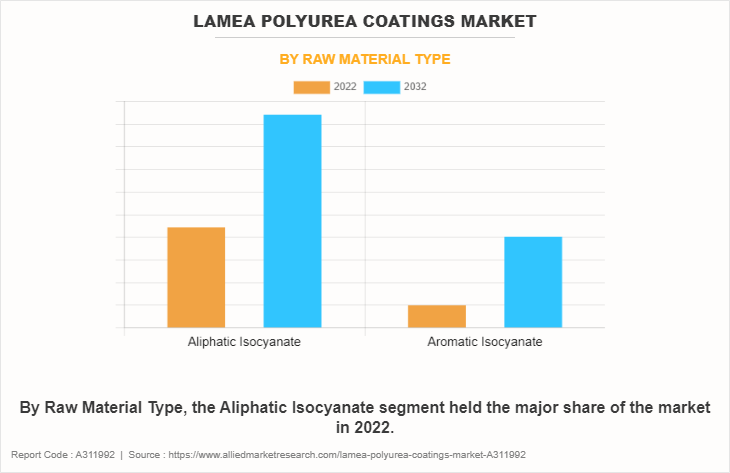

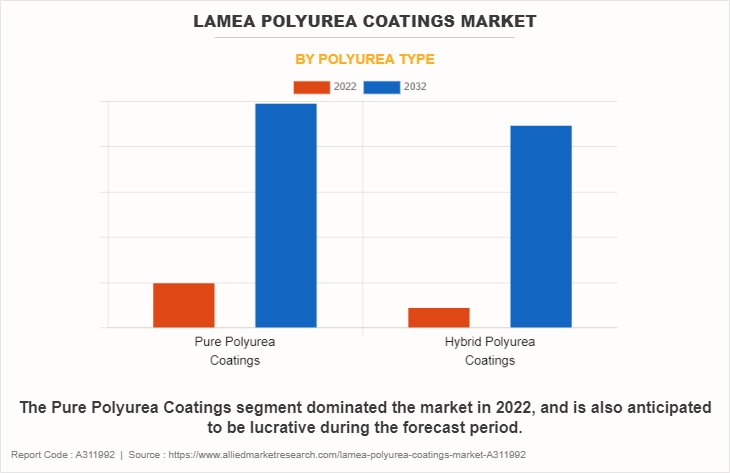

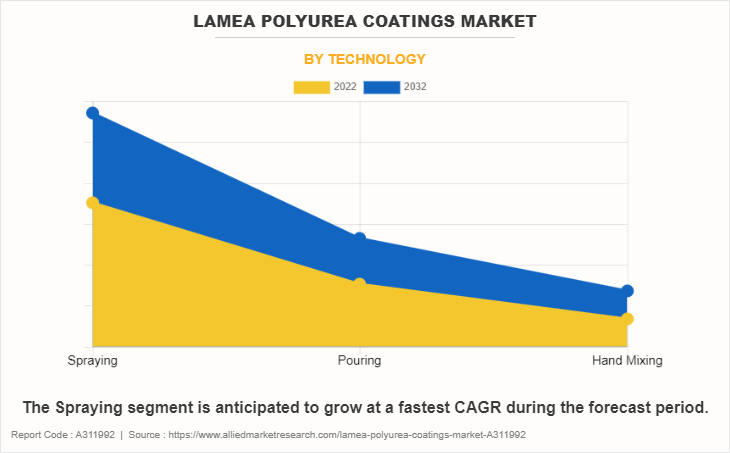

The LAMEA polyurea coating market is segmented into raw material type, polyurea type, technology, end-use industry, and country. By raw material type, the market is bifurcated into aliphatic isocyanate and aromatic isocyanate. On the basis of polyurea type, it is categorized into pure polyurea coatings and hybrid polyurea coatings. Depending on technology, the market is divided into spraying, pouring, and hand mixing. By end-use industry, it is categorized into building and construction, transportation, industrial, and others. Country-wise, the market is studied across Brazil, Saudi Arabia, South Africa, and rest of LAMEA.

The aliphatic isocyanate segment accounted for the largest share in 2022 and is expected to register the highest CAGR of 4.0%. This can be attributed to its excellent UV stability, weather resistance, and color retention properties. These characteristics make it a preferred choice for outdoor applications, providing durable protection against environmental factors. Industries such as construction, automotive, and infrastructure benefit from their versatile and reliable performance.

The pure polyurea coatings segment accounted for the largest share in 2022 owing to its unmatched versatility, rapid curing, and seamless application. Offering a durable, elastic, and chemical-resistant protective layer, it is extensively employed across industries. Its effectiveness in providing long-lasting protection against diverse environmental factors contributes to its dominance in the market.

The hybrid polyurea coatings segment is expected to register the highest CAGR of 4.0% due to its unique combination of polyurea and polyurethane properties. This results in enhanced flexibility, abrasion resistance, and prolonged durability, making it a preferred choice for various applications, contributing to its dominance in the market.

The spraying segment accounted for the largest share in 2022 and is expected to register the highest CAGR of 4.1%. This can be attributed to its efficiency and versatility. The method allows for quick and uniform application over various surfaces, facilitating seamless protection. Its ease of use supports large-scale projects, making it the preferred choice in industries such as construction, infrastructure, and manufacturing for its cost-effective and time-saving benefits.

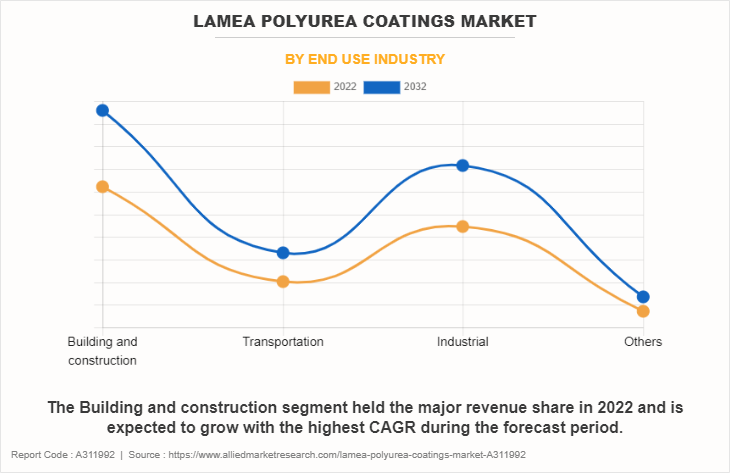

The building and construction segment accounted for the largest share in 2022 due to the polyurea coatings' exceptional protective properties. Offering durability, chemical resistance, and waterproofing, they are vital for applications like roofing, flooring, and infrastructure. The construction industry relies on polyurea coatings for long-lasting and reliable protection against environmental factors.

The industrial segment is expected to register the highest CAGR of 4.2% due to the increasing demand for robust protective solutions. Polyurea coatings exhibit superior resistance to chemicals, abrasion, and corrosion, making them essential for industrial applications like pipelines, tanks, and machinery. This drives their widespread adoption and growth within the industrial sector.

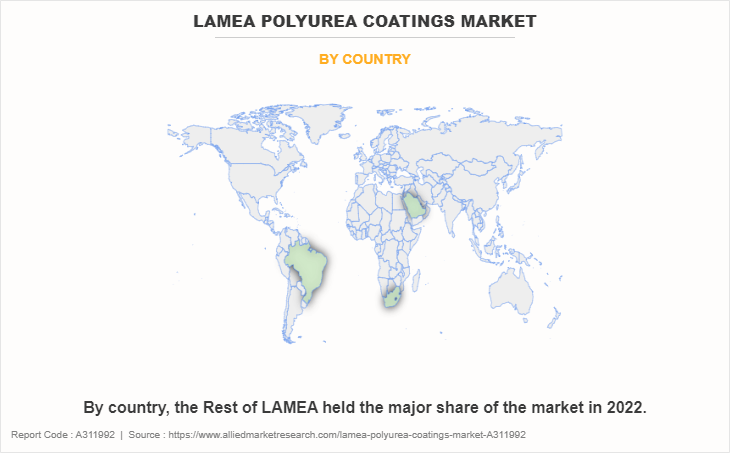

Rest of LAMEA garnered the largest share in 2022. This can be attributed to its robust industrial base, extensive infrastructure development, and high demand across various sectors. The country's advanced automotive, construction, and manufacturing industries contribute to the dominant position, driving the widespread use of polyurea coatings for diverse applications.

The major players operating in the LAMEA polyurea coating market are AHT Services LLC, Akfix, Artic Installation, Pearl Polyurethane, Polycare Insulation Works LLC, Rezayat Group, and Specialized Coating Systems (Pty) Ltd.

Strategic developments undertaken by key players

In April 2023, Pearl Polyurethane launched the polyurea-based DuraPearl elastomer system. The new DuraPearl product is one of the most robust solutions on the market as it can be customized for harsh climates across the globe. This product launch will boost the growth of the LAMEA polyurea coating market.

Historic trends

- The demand for polyurea coatings is often tied to industrial growth and infrastructure development. Increased construction activities, particularly in emerging economies within LAMEA, drive the demand for protective coatings, including polyurea.

- LAMEA, particularly the Middle East, is known for its significant presence in the oil & gas industry. The use of polyurea coatings in this sector for corrosion protection, containment, and other applications can be influenced by the performance and cost-effectiveness of polyurea compared to other coating materials.

- The automotive and transportation sectors also contribute to the demand for polyurea coatings. These coatings are used for truck bed liners, protective coatings for vehicles, and other applications. The growth or contraction of these industries may impact the polyurea market.

- Polyurea coatings find applications in mining and chemical processing for corrosion protection and containment. The performance of these industries may impact the demand for polyurea coatings.

- Changes in environmental regulations influence the choice of coatings in various industries. Polyurea coatings are known for their environmental benefits, such as low VOC emissions, which might be a factor driving their adoption.

- Advances in polyurea technology, such as new formulations, improved application methods, and enhanced properties, can drive market growth. Industries are likely to adopt these innovations for better performance and efficiency.

- The presence of key market players, their strategies, and collaborations within LAMEA may impact market trends. Merger and acquisition activities may further influence the competitive landscape.

Key Benefits For Stakeholders

- The report provides a comprehensive analysis of the current market estimations through 2022-2032, which would enable the stakeholders to capitalize on prevailing market opportunities.

- Major countries are mapped according to their revenue contribution to the lamea polyurea coatings market.

- In-depth analysis of the lamea polyurea coatings market segmentation assists to determine the prevailing market opportunities.

- Identify key players and their strategic moves in lamea polyurea coatings market.

- Assess and rank the top factors that are expected to affect the growth of lamea polyurea coatings market.

- Analyze the market factors in various countries and understand business opportunities.

- Player positioning provides a clear understanding of the present position of key market players.

LAMEA Polyurea Coatings Market, by Raw Material Type Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 127 million |

| Growth Rate | CAGR of 3.9% |

| Forecast period | 2022 - 2032 |

| Report Pages | 108 |

| By Raw Material Type |

|

| By Polyurea Type |

|

| By Technology |

|

| By End Use Industry |

|

| By Country |

|

| Key Market Players | Saudi Aramco, Gazprom, Eni, Kuwait Petroleum Corporation, Sabic, OCP Group, EGAS, Sonatrach, Qatar Petroleum, Lukoil |

The LAMEA Polyurea Coatings Market is estimated to reach $127 million by 2032

Saudi Aramco, Sabic, Qatar Petroleum, OCP Group, Sonatrach, Kuwait Petroleum Corporation, Lukoil, EGAS, Gazprom, Eni are the leading players in LAMEA Polyurea Coatings Market

1. The report provides a comprehensive analysis of the current market estimations through 2022-2032, which would enable the stakeholders to capitalize on prevailing market opportunities. 2. Major countries are mapped according to their revenue contribution to the lamea polyurea coatings market. 3. In-depth analysis of the lamea polyurea coatings market segmentation assists to determine the prevailing market opportunities. 4. Identify key players and their strategic moves in lamea polyurea coatings market. 5. Assess and rank the top factors that are expected to affect the growth of lamea polyurea coatings market. 6. Analyze the market factors in various countries and understand business opportunities. 7. Player positioning provides a clear understanding of the present position of key market players.

LAMEA Polyurea Coatings Market is classified as by raw material type, by polyurea type, by technology, by end use industry

Loading Table Of Content...

Loading Research Methodology...