Membrane Bioreactor Market Research, 2032

The global membrane bioreactor market size was valued at $3.0 billion in 2022, and is projected to reach $6.7 billion by 2032, growing at a CAGR of 8.6% from 2023 to 2032.

Report Key Highlighters:

- The membrane bioreactor market has been analyzed in value. The value of the membrane bioreactor market is analyzed in millions.

- Global membrane bioreactor market is fragmented in nature with many players such as Toray Industries, Inc., Koch Separation Solutions, KUBOTA Corporation, Mitsubishi Chemical Corporation, Evoqua Water Technologies LLC, Veolia, General Electric, WEHRLE-WERK AG, Asahi Kasei Corporation., and Aquatech International LLC. Also tracked key strategies such as product launches, acquisitions, mergers, expansion etc. of various manufacturers of membrane bioreactor.

- Included more than 20 countries in the report which covers market volume as well as market value for all the countries of membrane bioreactor market.

- Covered the detailed list of manufacturers by application of the membrane bioreactor market. It covers the product information, application, trends, membrane bioreactor market forecast and geographical presence of the companies.

- Conducted primary interviews with raw material suppliers, wholesalers, suppliers, and manufacturers of the membrane bioreactor market to understand the market trends, membrane bioreactor market growth factors, pricing, and key players competitive strategies.

A Membrane Bioreactor (MBR) is an advanced wastewater treatment technology that combines biological treatment with membrane filtration. It's used to treat sewage or industrial wastewater by utilizing a combination of biological processes and membrane separation. The basic principle of an MBR involves using microorganisms to break down and treat organic pollutants in the wastewater through a biological process known as activated sludge treatment. This process occurs in a bioreactor tank where bacteria and other microorganisms digest and transform organic matter in the water into simpler substances. What sets MBRs apart from conventional activated sludge systems is the use of membrane filtration for solid-liquid separation.

In a traditional activated sludge system, the treated water is separated from the solids through settling, which can be less efficient and can result in higher levels of suspended solids in the treated water. In an MBR, however, membranes are used to physically filter out the suspended solids, bacteria, and other microorganisms from the treated water. This results in a high-quality effluent with very low levels of suspended solids and bacteria.

There are two main types of membranes used in MBRs: microfiltration (MF) and ultrafiltration (UF). These membranes have pore sizes that are small enough to capture suspended solids, bacteria, and other particles, while allowing treated water to pass through. Membrane Bioreactors offer several advantages such as higher quality effluent, MBRs produce high-quality treated water with low levels of suspended solids and pathogens, making it suitable for reuse or environmentally friendly discharge. Furthermore, MBRs generally require less space compared to conventional wastewater treatment systems since biological treatment and solid-liquid separation occur in the same unit.

The membrane filtration process removes a significant portion of solids from the system, resulting in less sludge production. Moreover, MBRs can handle variations in influent quality and flow rates more effectively than some other treatment methods. Moreover, the high-quality effluent produced by MBRs can be used for non-potable applications like irrigation or industrial processes, contributing to water conservation. These benefits of membrane bioreactors will drive the market growth during the forecast period.

Environmental regulations have become more stringent globally, necessitating the need for advanced wastewater treatment technologies that can effectively remove pollutants and ensure compliance with discharge standards. MBRs offer a reliable solution for achieving high-quality treated effluent that meets regulatory requirements. Furthermore, as water scarcity becomes a pressing issue in many regions, the demand for treated wastewater that can be safely reused for non-potable applications such as irrigation, industrial processes, and landscaping has grown. MBRs provide an effective means of producing reclaimed water of high quality, making them valuable for addressing water scarcity challenges. These factors will drive the membrane bioreactor market growth during the forecast period.

Rise in demand for advanced wastewater treatment technology

The rise in demand for advanced wastewater treatment technology is a key driving factor for the growth of the membrane bioreactor (MBR) market. As industries and municipalities face increasing regulatory requirements, environmental concerns, and the need for sustainable water management practices, the demand for advanced solutions like MBRs is on the rise. Environmental regulations are becoming more stringent globally, necessitating the use of advanced technologies that can reliably meet these standards. MBRs offer a robust solution for achieving high-quality treated effluent that adheres to strict discharge limits.

MBRs combine biological treatment with membrane filtration, resulting in the efficient removal of suspended solids, pathogens, and pollutants. The superior effluent quality makes MBRs a preferred choice for industries and municipalities striving for improved wastewater treatment performance. Furthermore, increasing awareness of environmental issues has led to a demand for sustainable wastewater treatment solutions. MBRs align with this demand by producing treated water of higher quality and minimizing the impact on surrounding ecosystems.

In addition, rapid urbanization and industrial expansion lead to greater wastewater generation and increased pollution. MBRs can handle higher organic loads and varying influent characteristics, making them well-suited for managing the wastewater challenges associated with growth. In summary, the rising demand for advanced wastewater treatment technology driven by regulatory compliance, environmental concerns, sustainability goals, and water scarcity issues is a significant factor propelling the growth of the membrane bioreactor market.

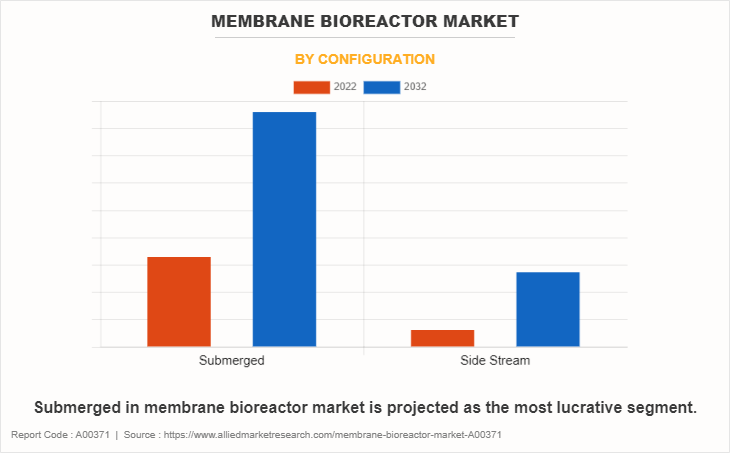

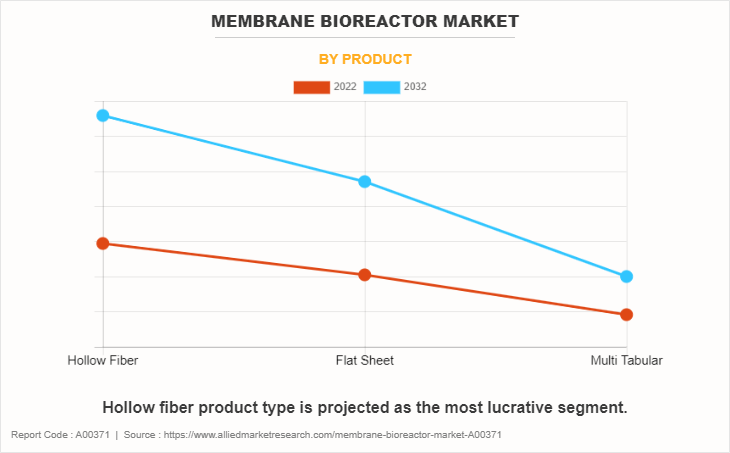

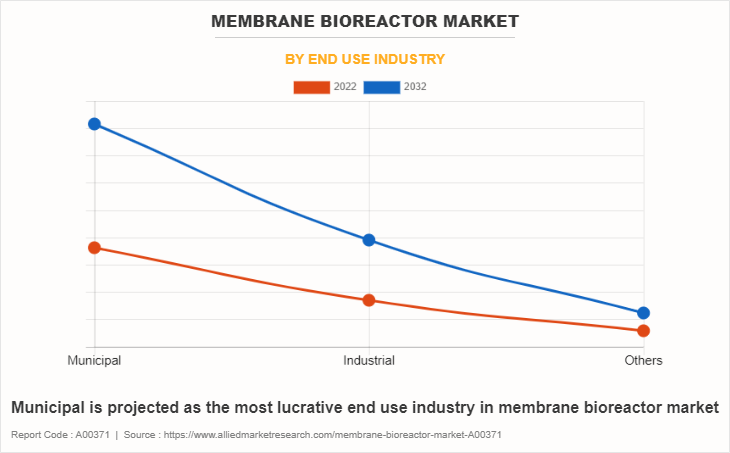

The membrane bioreactors market is segmented on the basis of product, configuration, end-use industry and region. By product, the market is hollow fiber, flat sheet and multi-tubular. By configuration, the market is categorized into submerged and side stream. By end-use industry, the market is fragmented into municipal, industrial and others. By region, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

The major players operating in the industry include Toray Industries, Inc., Koch Separation Solutions, KUBOTA Corporation, Mitsubishi Chemical Corporation, Evoqua Water Technologies LLC, Veolia, General Electric, WEHRLE-WERK AG, Asahi Kasei Corporation., and Aquatech International LLC. These players have adopted product launch as their key strategy to increase their market shares.

Based on the configuration, the submerged segment dominated the largest market share in 2022 as submerged MBR configurations typically involve immersing the membrane modules directly into the mixed liquor. This design helps minimize the fouling of membranes, as the continuous movement of water across the membrane surface helps prevent the accumulation of solids. Reduced fouling translates to longer operational periods between maintenance cycles.

Based on product, the hollow fiber membrane segment dominated the largest market share in 2022 as the hollow fiber membranes provide a large surface area for filtration within a compact design. This allows for efficient separation of solids and microorganisms from the liquid phase in bioreactor systems.

Based on end-use industry, the municipal segment dominated the largest market share in 2022 as municipal wastewater treatment is subject to increasingly stringent environmental regulations globally. Membrane bioreactors offer an advanced and effective solution for meeting strict effluent quality standards, including the removal of contaminants such as suspended solids, pathogens, and nutrients.

Based on region, the Asia-Pacific region dominated the highest membrane bioreactor market share in 2022. The Asia-Pacific region has a large and growing population, resulting in increased demand for clean water. MBRs play a vital role in providing efficient and high-quality wastewater treatment, contributing to the sustainable management of water resources.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the membrane bioreactor market analysis from 2022 to 2032 to identify the prevailing membrane bioreactor market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the membrane bioreactor market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global membrane bioreactor market trends, key players, market segments, application areas, and market growth strategies.

Membrane Bioreactor Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 6.7 billion |

| Growth Rate | CAGR of 8.6% |

| Forecast period | 2022 - 2032 |

| Report Pages | 350 |

| By CONFIGURATION |

|

| By PRODUCT |

|

| By End Use Industry |

|

| By Region |

|

| Key Market Players | Mitsubishi Chemical Corporation., General Electric, KUBOTA Corporation, Koch Separation Solutions, Asahi Kasei Corporation., WEHRLE-WERK AG, Evoqua Water Technologies LLC, TORAY INDUSTRIES, INC., Aquatech International LLC., Veolia |

Analyst Review

According to CXO perspective, Rapid urban growth and industrial expansion have led to increased wastewater generation. MBRs can handle higher organic loads and varying influent characteristics, making them suitable for managing the wastewater challenges associated with urbanization and industrial development. Furthermore, MBRs offer superior effluent quality compared to conventional wastewater treatment methods. The combination of biological treatment and membrane filtration results in excellent removal of suspended solids, pathogens, and pollutants, leading to improved water quality outcomes. These factors will drive the market growth during the forecast period.

However, MBR systems generally have higher initial capital costs compared to conventional wastewater treatment methods. The cost of membranes associated equipment, and installation can be significant, which might deter some potential users, especially in regions with limited financial resources.

The rise in demand for advanced wastewater treatment technology is a key driving factor for the growth of the membrane bioreactor (MBR) market.

Municipal is the leading end use industry of Membrane Bioreactor Market.

Asia-Pacific is the largest regional market for Membrane Bioreactor.

The Membrane Bioreactor Market was valued for $3 billion in 2022 and is estimated to reach $6.7 billion by 2032, exhibiting a CAGR of 8.6% from 2023 to 2032.

The major players operating in the industry include Toray Industries, Inc., Koch Separation Solutions, KUBOTA Corporation, Mitsubishi Chemical Corporation, Evoqua Water Technologies LLC, Veolia, General Electric, WEHRLE-WERK AG, Asahi Kasei Corporation., and Aquatech International LLC.

Loading Table Of Content...

Loading Research Methodology...