Metal Polishing Compound Market Research, 2032

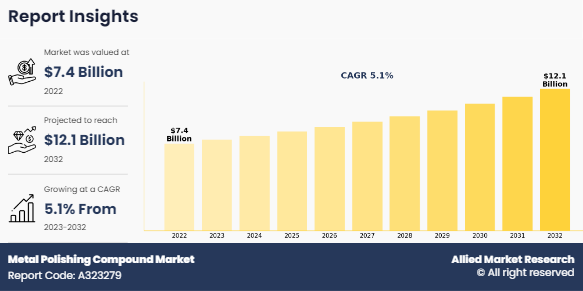

The global metal polishing compound market size was valued at $7.4 billion in 2022, and is projected to reach $12.1 billion by 2032, growing at a CAGR of 5.1% from 2023 to 2032. Metal polishing employs various compounds to achieve desired finishes. Rouge substances, containing fine abrasive particles like iron oxide, excel in polishing delicate metals like gold and silver, imparting a high sheen. Tripoli compounds, comprising crushed abrasives such as pumice or rottenstone, effectively remove scratches on softer metals like copper and brass. Emery compounds, derived from crushed emery rock, are renowned for their abrasive properties, ideal for tougher metals like steel and iron. Compounds incorporating aluminum oxide offer versatility, catering to both soft and hard metals by providing different levels of abrasiveness. These are commonly used in preliminary polishing stages to eliminate scuffs and prepare the metal surface for final polishing.

The compounds containing diamonds boast the highest level of abrasiveness due to micron-sized diamond particles. They are essential for polishing exceptionally hard metals and gemstones. Each compound type plays a crucial role in the metal polishing process, addressing specific needs based on the metal's hardness and desired finish, enhancing the appearance and reflectivity of metallic objects.

The rising demand for jewelry is projected to drive growth of the metal polishing compound market. With the global fascination for decorations increasing, the need for high-quality metal polishing compounds is experiencing a corresponding rise. Jewelry products are observing a positive growth, driving the demand for polishing material for quality and attractive ornament making. In response to this trend, manufacturers of metal polishing compounds are experiencing an increase in orders as jewelry makers seek superior products to enhance the luster and brilliance of their creations. The intricate designs and intricate details of jewelry pieces necessitate meticulous polishing to achieve a flawless finish, further emphasizing the need for advanced metal polishing compounds and thus would help in progressing metal polishing compound market growth.

Moreover, the growing preference for customized and unique jewelry pieces increases the demand for specialized polishing compounds tailored to different metal types and finishes. As consumers increasingly seek personalized and one-of-a-kind items, jewelry artisans rely on innovative metal polishing compounds to achieve distinctive results that meet individual preferences and design specifications. This rise in demand not only benefits metal polishing compound manufacturers but also stimulates innovation within the industry as companies strive to develop innovative formulations and technologies to meet the evolving needs of jewelry makers. Therefore, the metal polishing compound market is witnessing rapid growth, driven by the expanding jewelry industry and the pursue for excellence in craftsmanship and aesthetics, this would congruently secure metal polishing compound market forecast.

The metal polishing compound industry faces a formidable obstacle in its path to sustained growth due to the variable costs of raw materials, particularly those of abrasives and binding agents. As these raw materials are the major constituent for the formation of polishing compounds, the change in pricing hampers cost structures and competitive standing within the market landscape. Abrasives, indispensable for the abrasive efficacy integral to the polishing process, frequently undergo price fluctuations due to multifaceted factors such as shifts in global supply-demand dynamics or disruptions in key production regions. Likewise, the volatility in binding agent prices, crucial for cohesive integration of abrasive particles, exerts significant consequences on manufacturing expenses.

Manufacturers find themselves uncertainly positioned, inclined to abrupt rises in raw material costs that not only erode profit margins but also impede prospects for expansion. The inherent instability of these fluctuations worsens the challenge, leaving companies vulnerable to market instability. Moreover, the formidable task of mitigating increased costs while maintaining competitiveness adds another layer of complexity. Attaining a delicate balance between price adjustments and maintaining market relevance becomes imperative amidst such unrestrained conditions.

The increasing consumer demand for quality metal polishing compounds marks a pivotal platform for manufacturers, presenting a favorable opportunity to broaden their product ranges and expand into niche market sectors. This increase in demand highlights a transformative environment where personalization and flexibility control are primary. As a result of this paradigm shift, manufacturers are poised to expand their collection, creating polishing compounds tailored to the unique demands of disparate industries. Whether catering to the automotive, aerospace, or medical industries, each sector presents its distinct set of prerequisites and specifications, necessitating unique solutions. This rising demand for specialized polishing compounds signifies a change from conventional one-size-fits-all methodologies, indicating a beginning of precision and refinement. As consumers increasingly opt for solutions precisely calibrated to meet their exacting standards, manufacturers are able to obtain substantial rewards by aligning their product development curves with this evolving landscape. This strategic pivot towards customization not only enhances market relevance but also augments brand resonance and consumer loyalty.

Competitive Analysis:

The key players profiled in this report are Foshan Hotech Tube Mill Co., Ltd., Zhengzhou Ruizuan Diamond Tool Co., Ltd., Shital Industries, Metkorp Equipments Pvt. Ltd., Europolish Deutschland GMBH, New Western Abrasive, Menzerna Polishing Compounds GmbH & Co. KG, Renegade Products USA, JETS INC., and Maverick Abrasives.

Acquisition and strategic partnership are common strategies followed by major market players. For instance, in March 2020, Jason Industries Inc., based in Milwaukee, Wisconsin, completed the acquisition of the Matchless Metal Polish Company, located in Chicago, Illinois, for $5 million. Matchless Metal Polish Company is recognized for its comprehensive range of metal finishing products and services, encompassing buffing compounds, buffing wheels, abrasives, and chemicals, boasting an impressive annual revenue of approximately $8 million. This strategic acquisition aligns with Jason Industries' objective of expanding its polishing product line offerings within the North American market. The integration of Matchless Metal Polish Company into Jason's Industrial segment, operating within Osborn in Richmond, Indiana, presents significant opportunities for synergies and growth. Osborn is a global provider of surface preparation and finishing solutions, cleaning and containment products, as well as material and structural positioning solutions. Its product portfolio includes brushes, polishing buffs and compounds, abrasives, and roller technology. By integrating Matchless Metal Polish Company into Osborn's operations, Jason Industries aims to further strengthen its position in the market and enhance its ability to meet the evolving needs of customers in the metal finishing industry.

Segment Analysis:

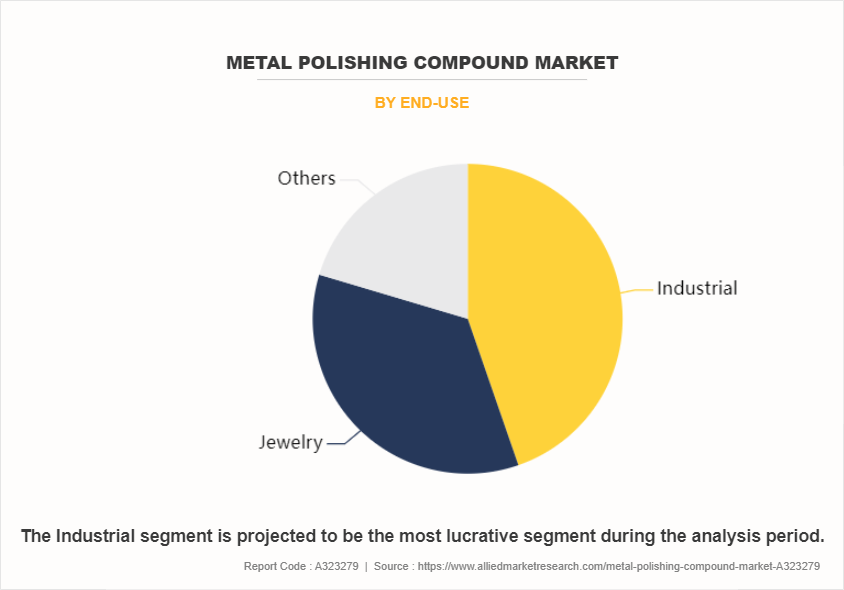

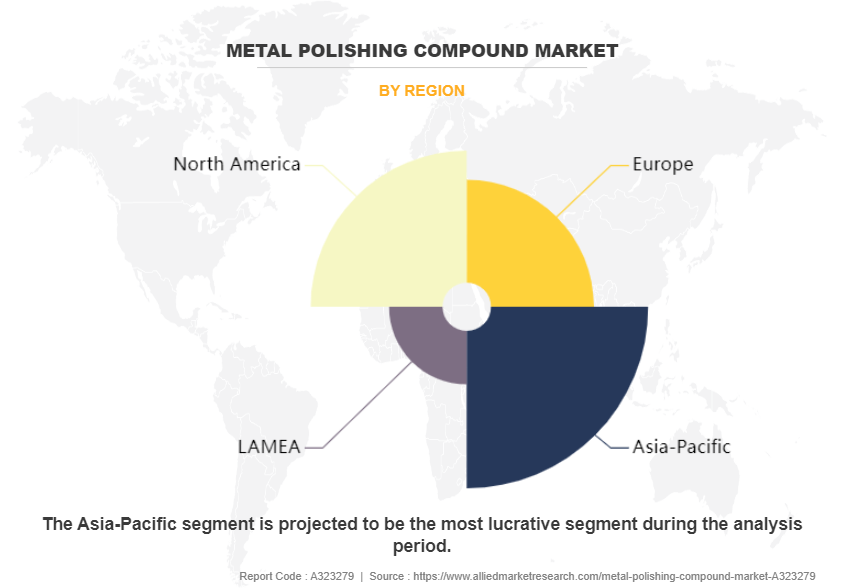

The metal polishing compound market share is segmented on the basis of type, end-user, and region. By type, the market is classified into rouge, tripoli, aluminum oxide, and others. By end-user, the market is divided into industrial, jewelry, and others. By region, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

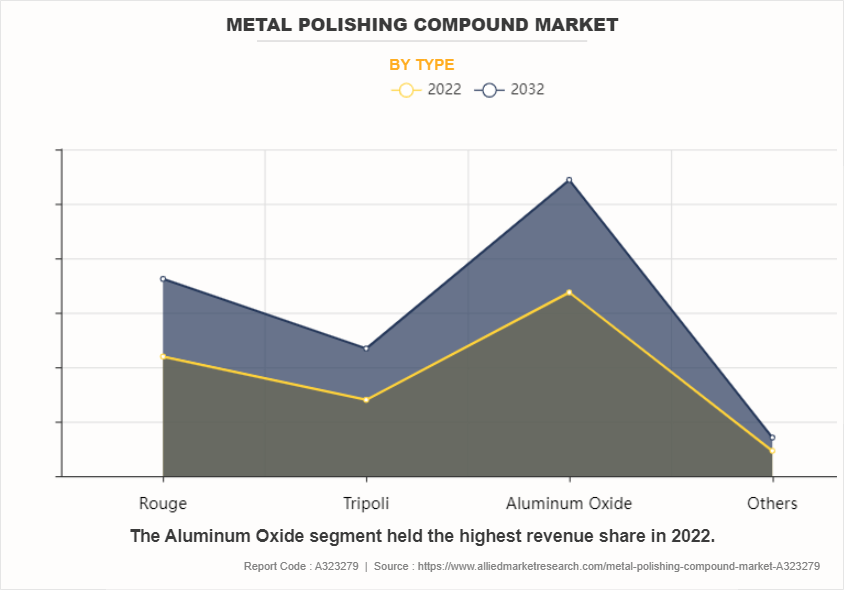

By type, the aluminum oxide sub-segment dominated the global metal polishing compound market in 2022. Aluminum oxide is a major adopted type among metal polishing compounds due to its hardness and abrasive ability. Its ability to precisely abrade metal surfaces provides a glossy, polished surface, which is a desirable attribute in a variety of industries, such as aerospace and automotive. The compound's continued use demonstrates its dependability and unique consistency in producing high-quality polishing outcomes, making it a popular choice for both producers and customers. Its broad use not only confirms its effectiveness but also emphasizes how important part it plays in improving the look and capability of metal items.

By end-user, the industrial sub-segment dominated the global metal polishing compound market in 2022. Metal polishing compounds play a major role in numerous industrial sectors, such as automotive, aerospace, and electronics, where achieving superior surface finishes is crucial. These compounds are vital for enhancing the quality, functionality, and visual appeal of metal components. In the highly demanding landscape of manufacturing, where large quantities of polished metal parts are required, the reliance on effective polishing compounds remains constant. Their consistent demand highlights their critical importance in ensuring the desired outcomes in industrial settings. Whether it is for improving product performance or meeting customer expectations, these compounds are instrumental in achieving quality surface finishes. Their significant contribution is evident in the functioning and quality assurance of various manufacturing operations across diverse sectors. As industries continue to prioritize excellence in surface finish, the reliance on these compounds is projected to increase, emphasizing their role in modern manufacturing processes.

By region, Asia-Pacific dominated the metal polishing compound market in 2022. Due to increasing industrialization and a robust manufacturing sector, Asia-Pacific is a major hub for metal polishing compound consumption and production. The region's developing automotive, electronics, and construction industries contribute substantially to the demand for metal polishing compounds. China, in particular, plays a major role as a manufacturing powerhouse and a key consumer of metal polishing compounds. Its extensive manufacturing industry, driven by rapid urbanization and infrastructure development, leads to an increase in the demand for high-quality metal finishing products. In addition, Japan and South Korea's advanced technological capabilities further boost the region's dominance in the market. Furthermore, India's emergence as a manufacturing hub and its increasing focus on industrialization drives the demand for metal polishing compounds across various sectors. Asia-Pacific's dominance highlights its economic vitality and industrial competence, positioning it as a critical player in the global metal polishing compound market.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the metal polishing compound market analysis from 2022 to 2032 to identify the prevailing metal polishing compound market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the metal polishing compound market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global metal polishing compound market trends, key players, market segments, application areas, and market growth strategies.

Metal Polishing Compound Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 12.1 billion |

| Growth Rate | CAGR of 5.1% |

| Forecast period | 2022 - 2032 |

| Report Pages | 305 |

| By Type |

|

| By End-use |

|

| By Region |

|

| Key Market Players | Shital Industries, JETS INC., Renegade Products USA, Menzerna Polishing Compounds GmbH & Co. KG, Foshan Hotech Tube Mill Co., Ltd., Metkorp Equipments Pvt. Ltd., Europolish Deutschland GMBH, New Western Abrasive, Zhengzhou Ruizuan Diamond Tool Co., Ltd., Maverick Abrasives |

The global metal polishing compound market is experiencing significant growth attributed to the increasing popularity of polishing of industrial equipment owing to rapid industrialization.

The major growth strategies adopted by the metal polishing compound market players are product launches and partnership agreements.

Asia-Pacific will provide more business opportunities for the global metal polishing compound market in the future.

Foshan Hotech Tube Mill Co., Ltd., Zhengzhou Ruizuan Diamond Tool Co., Ltd., Shital Industries, Metkorp Equipments Pvt. Ltd., Europolish Deutschland GMBH, New Western Abrasive, Menzerna Polishing Compounds GmbH & Co. KG, Renegade Products USA, JETS INC., and Maverick Abrasives are the major players in the metal polishing compound market.

The aluminum oxide sub-segment of the type segment acquired the maximum share of the global metal polishing compound market in 2022.

The industrial sector is one of the major customers in the global metal polishing compound market.

The report provides an extensive qualitative and quantitative analysis of the current trends and future estimations of the global metal polishing compound market from 2022 to 2032 to determine the prevailing opportunities.

The widespread utilization of metal polishing compounds in industrial sectors highlights their critical importance in enhancing the surface finish of metal components across diverse fields including automotive, aerospace, and electronics.

Incorporating nanoparticles into metal polishing compounds presents a revolutionary advancement, signaling excellent opportunities in various industries. By integrating these miniature particles, manufacturers achieve quality precision and efficiency in metal polishing processes.

Loading Table Of Content...

Loading Research Methodology...