Metal Seals Market Research, 2034

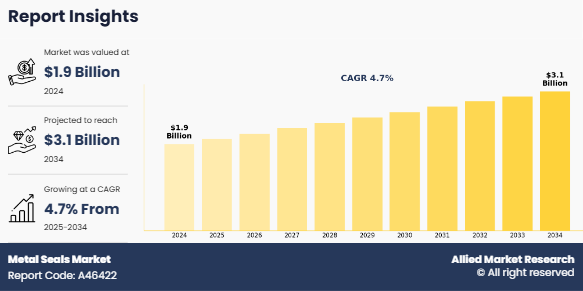

The global metal seals market size was valued at $1.9 billion in 2024, and is projected to reach $3.1 billion by 2034, growing at a CAGR of 4.7% from 2025 to 2034.

Metal seals are high-performance sealing components designed to withstand extreme conditions such as high pressure, high temperature, vacuum, and corrosive environments. Unlike elastomeric seals, metal seals are made from materials such as stainless steel, Inconel, copper, or aluminum and offer superior mechanical strength, chemical resistance, and long-term durability. These seals are widely used in critical applications across industries such as aerospace and defense, oil and gas, automotive, and energy, where failure is not an option. They are commonly available in various forms, including metal O-rings, C-rings, and E-rings, to meet diverse sealing requirements.

The metal seals market forecast indicates consistent growth through the coming years, driven by the increasing demand for high-performance sealing solutions in extreme environments. Industries such as aerospace, defense, oil & gas, and semiconductors continue to adopt metal seals due to their durability and ability to maintain integrity under high pressure and temperature.

The metal seals market outlook remains positive, supported by growing applications in high-stakes industries such as aerospace, energy, and electronics. With increased emphasis on safety, reliability, and environmental standards, companies are turning to metal seals for their superior resistance to extreme conditions. There is significant metal seals market opportunity emerging from the rapid growth of industries requiring ultra-reliable sealing systems. The development of space programs, advancements in semiconductor manufacturing, and the global shift toward clean energy are creating new avenues for high-performance metal sealing solutions.

Seal tight conduit is widely used in industrial and commercial electrical systems to protect wiring from moisture, chemicals, and physical damage. It features a flexible metal core with a liquid-tight plastic jacket, making it ideal for harsh environments and outdoor installations. Metal truck seals are essential security devices used in the transportation and logistics industries to safeguard cargo during transit. These tamper-evident seals are designed to indicate unauthorized access and are often used on shipping containers, trailers, and freight trucks. With growing concerns over cargo theft and regulatory compliance, the use of metal truck seals is becoming increasingly important across global supply chains.

The metal seals market growth is fueled by rising demand in sectors such as aerospace, energy, semiconductors, and chemical processing. As these industries require seals that can withstand extreme pressure, temperature, and corrosive conditions, metal seals are gaining significant traction. The ongoing push for higher performance and longer-lasting components is accelerating metal seals market growth across both developed and developing regions.

Market Dynamics

Growing Demand from Aerospace and Defense Sectors

The aerospace and defense industries are significant contributors to the metal seals market. As these sectors strive for higher performance and safety standards, the need for metal seals capable of withstanding extreme temperatures, pressures, and corrosive environments has intensified. In aerospace applications, metal seals are crucial for maintaining the integrity of critical systems like engines and fuel lines. Similarly, the defense sector increasingly adopts advanced metal seals for reliable performance in harsh conditions, thereby driving market growth.

Expansion of the Oil and Gas Industry

The oil and gas industry continues to be a major consumer of metal seals, especially as exploration and extraction activities venture into more challenging environments like deep-water and ultra-deep-water locations. These harsh conditions, characterized by extreme pressures, high temperatures, and corrosive substances, necessitate the use of robust and reliable seals. The industry's growth, coupled with stringent safety and environmental regulations, further amplifies the demand for high-performance metal sealing solutions.

Technological Advancements and Material Innovations

Advancements in material science and manufacturing techniques have led to the development of more effective and durable metal seals. The adoption of high-performance materials like Inconel, Hastelloy, and other superalloys offers exceptional resistance to extreme temperatures, corrosive chemicals, and high pressures. These innovations enable the production of seals that can endure harsh environments, such as deep-sea exploration and space missions, thereby expanding the application scope and driving market growth

Increasing Regulatory and Compliance Requirements

Stricter industry standards and environmental regulations compel manufacturers to adopt high-quality metal seals that prevent leaks and reduce potential environmental risks. This regulatory environment fuels the adoption of sophisticated sealing solutions across various industries, including chemical processing and pharmaceuticals, where leak prevention and contamination control are paramount.

High Manufacturing Costs and Complex Production Processes

One of the primary restraints in the metal seals market is the high cost associated with the manufacturing and processing of metal seals. Unlike elastomeric seals, metal seals require precision engineering, specialized materials like Inconel or Hastelloy, and complex fabrication processes such as welding, heat treatment, and machining. These factors significantly increase production time and costs, making metal seals less cost-effective for certain applications, especially in price-sensitive industries like automotive or consumer goods.

Limited Reusability and Maintenance Challenges

Another key limitation is the limited reusability of metal seals. In many high-pressure or high-temperature applications, metal seals undergo permanent deformation to achieve a leak-tight seal, making them difficult or impossible to reuse. This drives up replacement and maintenance costs for end users, particularly in sectors where frequent disassembly is required. Additionally, installation requires skilled labor, and incorrect installation can lead to seal failure, further complicating the maintenance process.

Emerging Applications in Space Exploration and Semiconductor Manufacturing

The rapid growth of the space industry and semiconductor manufacturing presents significant opportunities for the metal seals industry. In space exploration, where extreme vacuum and temperature conditions prevail, the demand for high-integrity, leak-proof sealing systems is critical. Metal seals, particularly those made from high-performance alloys, are ideal for space vehicles, satellites, and ground-based test chambers. Similarly, the semiconductor sector requires ultra-clean, vacuum-compatible seals for fabrication processes, creating a lucrative niche for metal seal manufacturers.

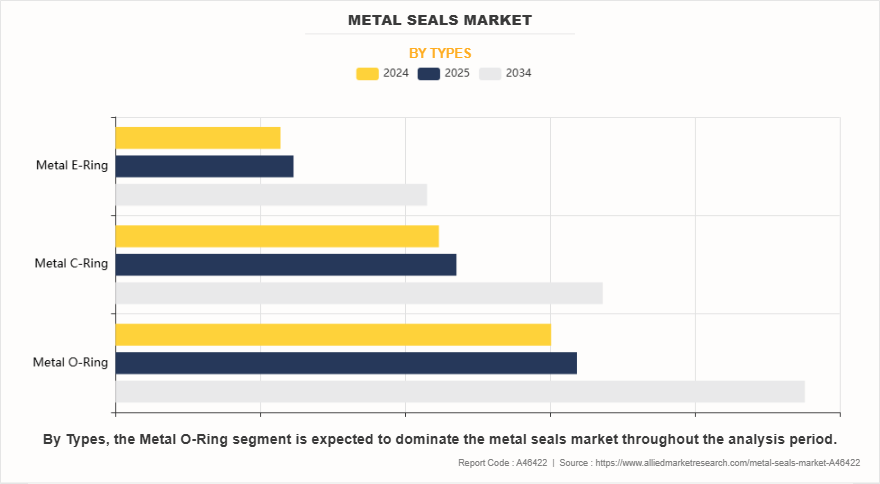

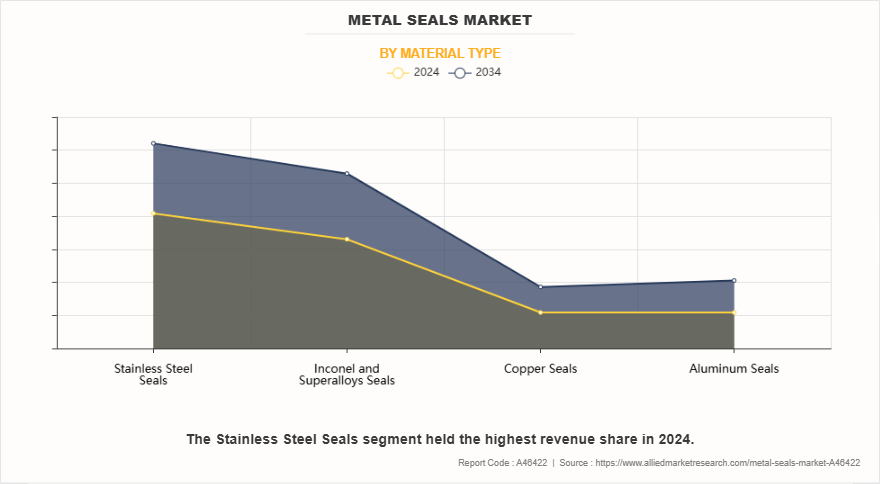

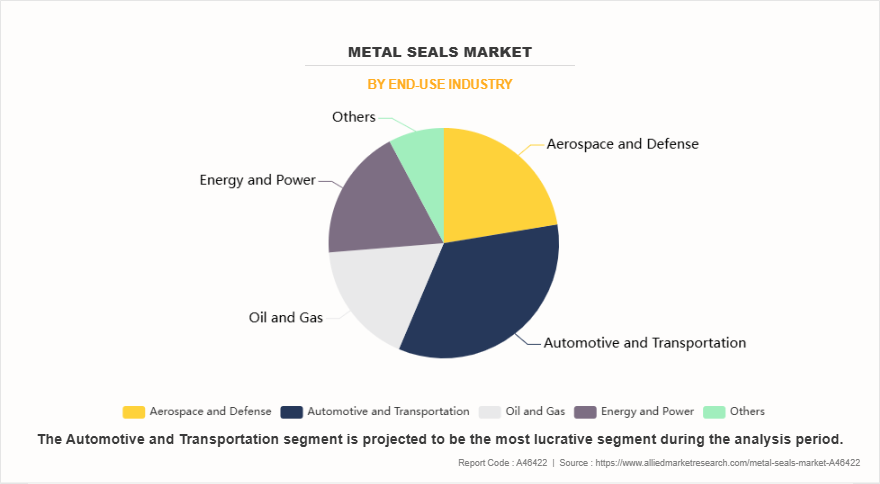

The metal seals market is segmented into Types, Material Type and End-Use Industry. Based on type, the market is segmented as Metal O-Ring, Metal C-Ring, Metal E-Ring), Based MaterialType, the market is segmented as Stainless Steel Seals, Inconel and Superalloys Seals, Copper Seals, Aluminium Seals. By End-User Industry, it is bifercated as Aerospace and Defence, Automotive and Transportation, Oil and Gas, Energy and Power, Others.

The metal O-ring segment dominated the global market share, in terms of revenue. The metal O-ring segment accounted for a higher market share in 2024. These seals are widely used in applications requiring high-performance sealing in extreme pressure and temperature environments. Their superior sealing capabilities make them ideal for aerospace, nuclear, and cryogenic systems. Increasing demand for leak-proof and durable sealing solutions is fueling their adoption globally.

The stainless-steel seal segment dominated the market in 2024. The stainless-steel seal segment is the leading segment that dominated the global market in 2024. It is preferred in harsh environments such as oil & gas, aerospace, and chemical processing industries. The widespread availability and cost-effectiveness of stainless steel further contribute to its high market share. It continues to be the material of choice for long-lasting, high-integrity seals.

The automotive and transportation segment dominated the global market share in terms of revenue. The automotive and transportation segment dominated the global market share in 2024. Metal seals are extensively used in both commercial and military aircraft due to their ability to withstand extreme operational conditions. Rising global air travel, increasing defense budgets, and growing space exploration initiatives are boosting demand in this segment.

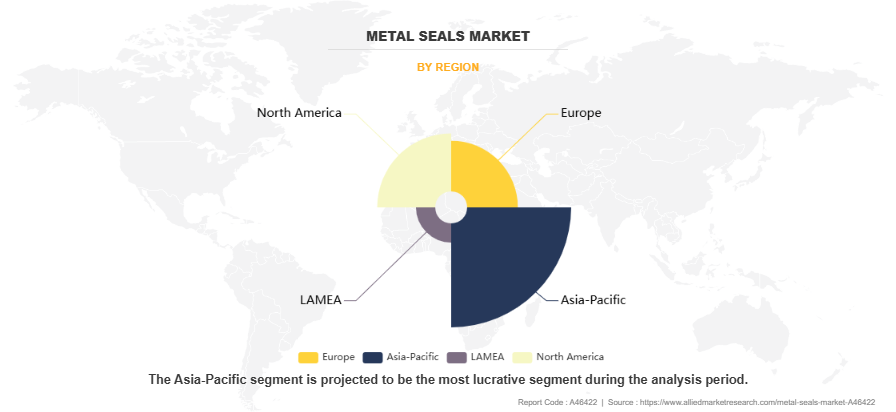

The Asia-Pacific dominates the metal seals market share in terms of revenue in 2024. In 2024, Asia-Pacific holds the maximum share in the metal seals industry in the Asia-Pacific region. This growth is driven by rapid industrialization, expanding aerospace and semiconductor sectors, and increased oil & gas activities across countries like China, Japan, South Korea, and India. The region's rising demand for high-performance sealing solutions in advanced manufacturing and infrastructure further propels market expansion.

Competition Analysis

Key companies profiled in the metal seals industry report include Calvo Sealing, S.L., Omniseal Solutions, Texpack, Jetseal, AB SKF, Micro Seals, United Seal and Rubber Inc., Technetics Group, EagleBurgmann, and SAP Parts Pvt. Ltd. These players have adopted different strategies such as new product launches, expansion, and acquisitions to increase their market share and maintain dominant shares in different regions.

Key Benefits For Stakeholders

This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the metal seals market analysis from 2024 to 2034 to identify the prevailing metal seals market opportunities.

The market research is offered along with information related to key drivers, restraints, and opportunities.

Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

In-depth analysis of the metal seals market segmentation assists to determine the prevailing metal seals market opportunity.

Major countries in each region are mapped according to their revenue contribution to the global market.

Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

The report includes the analysis of the regional as well as global metal seals market trends, key players, market segments, application areas, and metal seals market growth strategies.

Metal Seals Market Report Highlights

| Aspects | Details |

| Market Size By 2034 | USD 3.1 billion |

| Growth Rate | CAGR of 4.7% |

| Forecast period | 2024 - 2034 |

| Report Pages | 185 |

| By Types |

|

| By Material Type |

|

| By End-Use Industry |

|

| By Region |

|

| Key Market Players | Micro Seals, Technetics Group, United Seal and Rubber Inc., AB SKF, SAP PARTS Pvt. Ltd., Texpack, Omniseal Solutions, Calvo Sealing, S.L., EagleBurgmann, Jetseal |

Increased Use in Space and Satellite Applications: With the rise in private and government-funded space programs, demand for high-performance seals in satellite propulsion systems and vacuum environments is growing.

The aerospace and defense segment is the leading application of the metal seals market. These industries demand highly reliable, leak-proof seals capable of withstanding extreme temperature and pressure variations in engines, fuel systems, cryogenic tanks, and control systems.

North America is currently the largest regional market for metal seals, owing to the strong presence of aerospace, defense, semiconductor, and oil & gas industries in the U.S. The region benefits from high R&D investments, advanced manufacturing capabilities, and early adoption of high-performance sealing technologies. However, Asia-Pacific is projected to be the fastest-growing market due to rapid industrialization and rising demand in China, India, Japan, and South Korea.

The global metal seals market was valued at $1,914.2 million in 2024

Calvo Sealing, S.L., Omniseal Solutions, Texpack, Jetseal, AB SKF, Micro Seals, United Seal and Rubber Inc., Technetics Group, EagleBurgmann, and SAP Parts Pvt. Ltd.

Loading Table Of Content...

Loading Research Methodology...