Microporous Materials Market Research, 2031

The global microporous materials market was valued at $5.3 billion in 2021, and is projected to reach $8.4 billion by 2031, growing at a CAGR of 4.9% from 2022 to 2031.

Report Key Highlighters:

- The microporous materials market study covers 20 countries. The research includes a segment analysis of each country in terms of both value ($million) and volume (kilotons) for the projected period 2021-2031.

- The study integrated high-quality data, professional opinions and analysis, and critical independent perspectives. The research approach is intended to provide a balanced view of global markets and to assist stakeholders in making educated decisions in order to achieve their most ambitious growth objectives.

- Over 3,700 product literatures, annual reports, industry statements, and other comparable materials from major industry participants were reviewed to gain a better understanding of the market.

- The microporous materials market is highly fragmented, with several players including AGC CHEMICALS PVT. LTD., Axens, BASF SE, PIDC, PQ, Solvay, Sorbead India, Sumitomo Chemical Co., Ltd., Zeochem AG, Zeolyst International. Also tracked key strategies such as acquisitions, product launches, mergers, expansion etc. of the players operating in microporous materials market.

Microporous material is available in compact powder or fiber form with microporous materials which offer compressive strength, minimal thermal shrinkage, excellent fire barrier, and resistance to liquids, vibration, and chemicals as similar to opacifiers. As microporous materials are inorganic and non-combustible, they are suitable for passive fire protection end-use industry. Besides this, they are widely used in refining and petrochemical manufacturing plants for industrial process piping and equipment. Microporous materials are utilized in filler material for mattresses, cassettes, heat shields, and expansion joints across the globe.

Microporous materials are found in various types of materials which include zeolites, metal-organic frameworks, clays, activated alumina, and others. Microporous materials have a unique cage-like framework that lends to a wide range of end-use industry including power generations and petrochemicals. Microporous zeolites are used in a variety of end-use industry, including industrial or medical absorbents, water treatment softeners and filters, detergents, nuclear waste removal, concrete production, and industrial catalysis.

The cage-like structure, large surface area, high adsorption capacity, uniform and intricate channels, high thermal stability, and well-defined qualities of microporous materials all contribute to excellent selectivity and catalytic performance. Microporous silica is an inorganic material with an amorphous structure in a wide temperature range and can be sintered in dry atmosphere at temperatures around 400–700∘C. Microporous silica is highly porous and has exceptionally small pores showing molecular sieving characteristics. There are several syntheses methods for producing microporous silica, including sol-gel, templating approach, and chemical vapor deposition (CVD).

Microporous materials is also used as chemical vapor deposition (CVD) which is another way of producing microporous silica, usually a membrane or film on a particular substrate. They could be effectively applied for the deposition of silicon oxide or metal oxide on porous substrates to modify their porous structures. The CVD technique consists of the thermal decomposition of a silicon-based precursor and a chemical reaction with an oxidant gas in contact with a hot substrate.

Sol-gel processes can be used to create microporous materials with tailored properties. The substrate to be coated with the sol–gel is a microporous ceramic tube formed by a slip-coating-sintering technique. A microporous membrane behaves almost like a fiber filter and separates particles based on their size using by a sieving mechanism determined by the pore diameter and particle size. Organic and inorganic materials are used in making such membranes. The pores in the membranes may vary between 0.3 nm and 100 μm.

Increasing demand for highly thermal resistant insulation materials in oil & gas industry is projected to drive the growth of the microporous materials market.

Microporous materials provide high-temperature insulation with thermal conductivity ranging from 0.021 to 0.034 W/M. They have four to five times the thermal efficiency of traditional materials, making them ideal for oil and gas application where insulation is critical. They also have high flame and extreme weather resistance, as well as excellent thermal performance. Microporous materials offer ultra-thin and lightweight insulation solutions for refineries and petrochemical plants, allowing products to maximize energy efficiency while taking advantage of even the smallest spaces. The extremely low thermal conductivity of microporous materials reduces heat loss to an absolute minimum and guarantees an optimal protection providing effective insulation for oil and gas application.

Thermal-resistant insulation is becoming increasingly popular in oil and gas pipe insulation, as it reduces energy loss and helps to control energy prices. Insulation pipes are used in power plants to transport superheated steam, feedwater, discharge fluid, and other substances, and in the petrochemical industry to transport fluid. Cold insulation prevents condensation of cold surfaces from forming and collecting moisture on the surface of the piping system. Pipe insulation is necessary for most heavy industries, including power, petrochemical, and oil and gas.

However, high manufacturing cost of microporous materials is predicted to hinder the market growth of microporous materials. Microporous insulation boards and panels are made from silica and zirconia inorganic oxides, among other things. Opacifiers with controlled particle size and thermal stability are also used in the process and are distributed uniformly across the surface area. These opacifiers help to keep thermal transmission to a minimum and are held tightly using glass filaments, which provide handling strength and prevent moisture absorption. The final product has the lowest thermal conductivity possible, but the cost of the entire process and technology is three to five times that of conventional insulating materials. Furthermore, factors such as a lack of commercialization and a lack of industrial production capacity are to be held responsible for the high production costs.

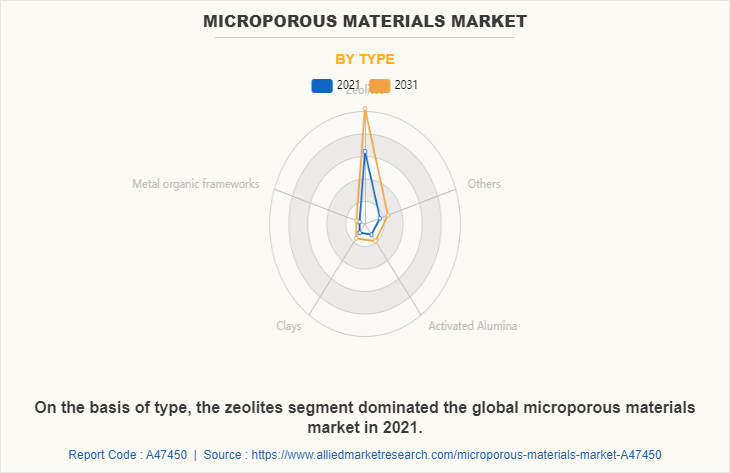

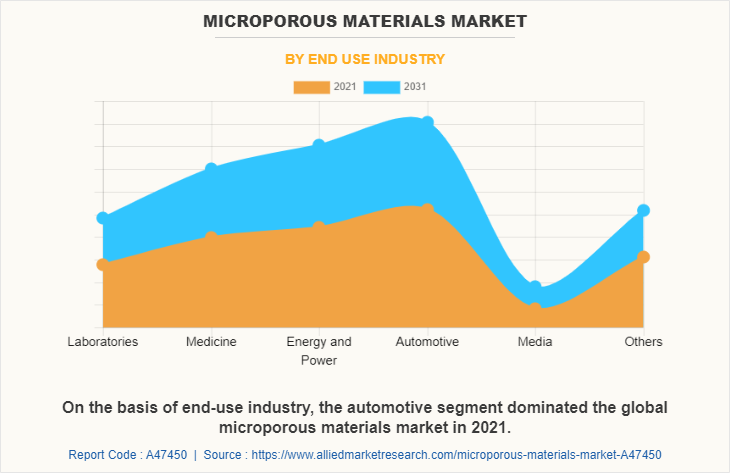

The microporous materials market is segmented into type, end-use industry, and region. On the basis of type, the market is categorized into zeolites, metal-organic frameworks, clays, activated alumina, and others. On the basis of end-use industry, the market is categorized into laboratories, medicine, energy & power, automotive, media, and others. Region-wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

On the basis of type, the zeolites segment dominated the global microporous materials industry in 2021. Microporous zeolites are commonly used as catalysts in chemical reactions due to their high surface area and unique pore structure. They are used in a wide range of applications, such as in the production of fuels, chemicals, and polymers. Microporous zeolites are effective adsorbents for gases and liquids due to their high surface area and porosity. They are used in various applications, such as in gas separation and purification, water treatment, and air pollution control. They Microporous zeolites are effective adsorbents for gases and liquids due to their high surface area and porosity. They are used in various applications, such as in gas separation and purification, water treatment, and air pollution control.

On the basis of end-use industry, the automotive segment dominated the global microporous materials market in 2021.Microporous materials in automotive applications are most commonly used in air filters. Microporous membranes or non-woven materials with a high surface area are used to capture small particles, such as dust and pollen, from the air before it enters the engine. These materials are designed to be both efficient and durable, with high airflow rates and long service lives. Microporous materials can also be used for thermal insulation in the automotive industry. They can be applied to engine components, exhaust systems, and other areas to help reduce heat transfer and improve energy efficiency. In addition to providing thermal insulation, microporous materials can also help to reduce noise and vibration in the vehicle.

On the basis of region, the Asia-Pacific segment dominated the global microporous materials market in 2021. Microporous materials, such as activated alumina, are widely employed in the water treatment and oil and gas industries in Asia-Pacific. In Asia-Pacific, microporous materials are used to extract formaldehyde and noble gases like N2 and O2 from natural gas streams, which includes industrial gas drying, filtering, and separation. In Asia-Pacific, microporous materials such as low-grade natural gas are treated using synthetic zeolites to remove water, carbon dioxide, and sulphur dioxide.

Major players operating in the global microporous materials market includes AGC CHEMICALS PVT. LTD., Axens, BASF SE, PIDC, PQ, Solvay, Sorbead India, Sumitomo Chemical Co., Ltd., Zeochem AG, Zeolyst International. These players adopted several growth strategies to strengthen their position in the market. For instance, in April 2019, BASF SE expanded its business by investing in the modernization of its silica plant at the Dusseldorf-Holthausen site. The silica plant in Dusseldorf-Holthausen is one of the world’s largest plants. Silicates are produced by fusing sand and soda and have a wide range of end-use industry, including in the manufacture of precipitated silica for use in tire making, as thickeners in mortars and plasters, in foundry molds and mineral paints, as surface sealants in the construction industry, and others. This investment will increase the production of silicates leading to a rising demand for microporous materials.

Historical Trends

Microporous high-performance insulation material was developed in the 1940s by US military scientists, in the process of finding materials that would provide highly efficient thermal insulation for use in aircraft. It provides a fire-proof and heat-resistant covering for interiors and exteriors without the need for a vacuum.

In December 2013, Promat International N.V., a manufacturer of fire protection and high-performance insulation, opened a new plant in Maryville, Tennessee, to assemble microporous protection items. This aided the organization in strengthening its position in the microporous protection market and expanding its operations in North America.

Morgan Advanced Materials, a designer and manufacturer of specialty products, acquired Porextherm Dämmstoffe GmbH, one of the leading producers of microporous protection boards, in July 2014. This acquisition aided the company in strengthening its product line of microporous protection and vacuum insulation panels.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the microporous materials market analysis from 2021 to 2031 to identify the prevailing microporous materials market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the microporous materials market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global microporous materials market trends, key players, market segments, application areas, and market growth strategies.

Microporous Materials Market Report Highlights

| Aspects | Details |

| Market Size By 2031 | USD 8.4 billion |

| Growth Rate | CAGR of 4.9% |

| Forecast period | 2021 - 2031 |

| Report Pages | 350 |

| By Type |

|

| By End Use Industry |

|

| By Region |

|

| Key Market Players | zeolyst international, Sumitomo Chemical Co., Ltd., Sorbead India, PIDC, Zeochem AG, PQ, AGC CHEMICALS PVT. LTD., Axens, BASF SE, Solvay |

Analyst Review

According to the opinions of various CXOs of leading companies, the microporous materials market is driven by increasing demand for highly thermal resistant insulation materials in the oil & gas industry. Microporous insulating materials have four to five times the thermal efficiency of traditional materials like glass-filled foams, fibers, and metals. The superior thermal resistance of microporous insulation holds enormous promise in oil and gas application where insulation is critical. Microporous insulating materials have high flame and extreme weather resistance, as well as excellent thermal performance.

However, the high manufacturing cost of microporous materials is expected to restrain industry expansion. Microporous materials help to keep thermal transmission to a minimum and are held tightly using glass filaments that provide handling strength and prevent moisture absorption. The final product has the lowest thermal conductivity possible, and the cost of the entire process and technology is three to five times that of conventional insulating materials.

The Asia-Pacific region is projected to register robust growth during the forecast period. Adsorbents such as microporous-activated alumina are widely employed in Asia-Pacific household appliances, business structures, and food storage containers. Activated alumina absorbs a lot of moisture and has many anti-acid properties. Microporous materials can be employed as a heat insulation material for insulating glass due to their remarkable thermal stability at high temperatures.

Asia-Pacific is the largest regional market for Microporous Materials.

The leading end-use industry of microporous materials market are laboratories, medicine, energy & power, automotive, media, and others.

Increasing demand for highly thermal resistant insulation materials in oil and gas industry are the key drivers for Microporous Materials.

AGC CHEMICALS PVT. LTD., Axens, BASF SE, PIDC, PQ, Solvay, Sorbead India, Sumitomo Chemical Co., Ltd., Zeochem AG, Zeolyst International are the top companies to hold the market share in Microporous Materials.

The global microporous materials market was valued at $5.3 billion in 2021, and is projected to reach $8.4 billion by 2031, growing at a CAGR of 4.9% from 2022 to 2031.

Loading Table Of Content...