Plastic Adhesives Market Research, 2033

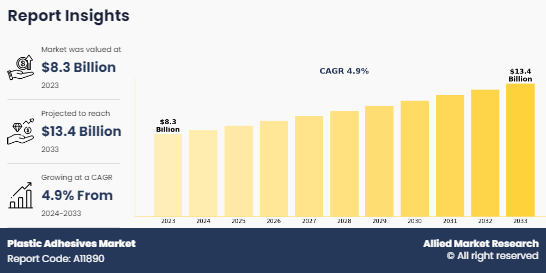

The global plastic adhesives market was valued at $8.3 billion in 2023, and is projected to reach $13.4 billion by 2033, growing at a CAGR of 4.9% from 2024 to 2033. Increase in demand for lightweight materials is expected to drive the growth of plastic adhesives market. The growth of the global plastic adhesives market is majorly driven by an increase in demand for automotive and aerospace industries. However, health and safety concerns are expected to pose a notable restraint in the plastic adhesive market. The surge in medical device assembly is expected to provide lucrative opportunities in the plastic adhesive market during the forecast period.

Introduction

Plastic adhesive, also known as plastic glue or plastic cement, is a type of adhesive specifically formulated to bond various types of plastics together. These adhesives are designed to create strong, durable bonds that withstand the stresses and strains encountered in a wide range of applications. Plastic adhesives work by forming a strong molecular bond between the surfaces of the plastics being joined, creating a unified structure that effectively combines the strength and durability of the individual materials.

In the automotive industry, plastic adhesives are commonly used in the assembly of vehicle components. These adhesives are used to bond plastic parts such as interior trim panels, exterior body panels, and dashboard components. By using plastic adhesives, manufacturers create strong, lightweight bonds that help improve the overall structural integrity of the vehicle while reducing the need for mechanical fasteners, such as screws or rivets.

In the construction industry, plastic adhesives are often used in the installation of plastic building materials such as PVC pipes, vinyl siding, and acrylic panels. These adhesives provide a reliable way to bond plastic components together, ensuring leak-proof seals and strong connections that withstand the rigors of the construction process and the elements.

Key Takeaways

- The plastic adhesive industry market study covers data for a minimum of 20 countries. The research includes a segment analysis of each country in terms of value ($million) and volume (kiloton) for the projected period (2024-2033).

- The study integrates high-quality data, professional opinions and analysis, and critical independent perspectives. The research approach is intended to provide a balanced view of the global plastic adhesive market and to assist stakeholders in making educated decisions to achieve their growth objectives.

- Over 3,700 product literature, annual reports, industry statements, and other comparable materials from major industry participants were reviewed to gain a better understanding of the market.

- The plastic adhesive market is highly fragmented with several players, including Henkel Corporation, 3M, H.B. Fuller Company, SIKA CORPORATION, Arkema, Huntsman International LLC., Dow, MAPEI Corporation, Jowat Corporation, and Avery Dennison Corporation. These players have adopted key developmental strategies such as acquisitions, product launches, mergers, and expansion to strengthen their foothold in the market.

Market Dynamics

The demand for lightweight materials in industries such as automotive and aerospace has been a significant driver for the increased use of plastic adhesives. In the automotive industry, reducing vehicle weight is crucial for improving fuel efficiency and reducing emissions. Lightweight plastics offer a viable solution for achieving these goals without compromising on safety or performance. Plastic adhesives play a key role in bonding lightweight plastic components together, enabling manufacturers to design and produce vehicles that consume less fuel and have lower environmental impact.

In June 2023, ZF unveiled EVbeat an electric concept vehicle emphasizing utmost compactness, minimal weight, and optimized efficiency in actual use. In this electric vehicle by ZF, the elements of an electric drivetrain are finely tuned and integrated into a cohesive system. Plastic adhesives are gaining popularity in bond structural components of EVs, such as body panels, roof frames, and floor pans. This helps to improve the overall stiffness and rigidity of the vehicle while reducing weight compared to traditional welding methods.

Plastics offer greater design flexibility compared to traditional materials like metal, allowing for innovative and aerodynamic vehicle and aircraft designs. Plastic adhesives enable the assembly of complex structures and components, facilitating the integration of lightweight materials into modern vehicle and aircraft designs without compromising on strength or durability. In July 2022, four major Chinese airlines placed a significant order for 292 aircraft from Airbus, amounting to $37.3 billion. Boeing forecasts a robust demand for aircraft from Chinese airlines over the next two decades, estimating a purchase of 8,600 new aircraft valued at $1.4 trillion. Additionally, Boeing anticipates a considerable increase in demand for commercial aviation services in China, reaching $1.7 trillion within the same period. Modern aircraft, particularly newer models, utilize composite materials such as carbon fiber reinforced polymers (CFRP) for their structures. Plastic adhesives are often used to bond these composite components together, providing a strong and lightweight connection.

Many traditional plastic adhesives contain hazardous chemicals such as volatile organic compounds (VOCs), solvents, and formaldehyde, which pose risks to human health. Prolonged exposure to these chemicals, either through inhalation or skin contact, leads to respiratory issues, skin irritation, and other health problems for workers involved in adhesive application and manufacturing processes. Products bonded with plastic adhesives, such as automotive parts, electronics, and packaging, release harmful chemicals over time, especially if the adhesive undergoes degradation or off-gassing. This pose risks to consumers, particularly in applications where adhesives are in close contact with food, beverages, or sensitive materials.

Segments Overview

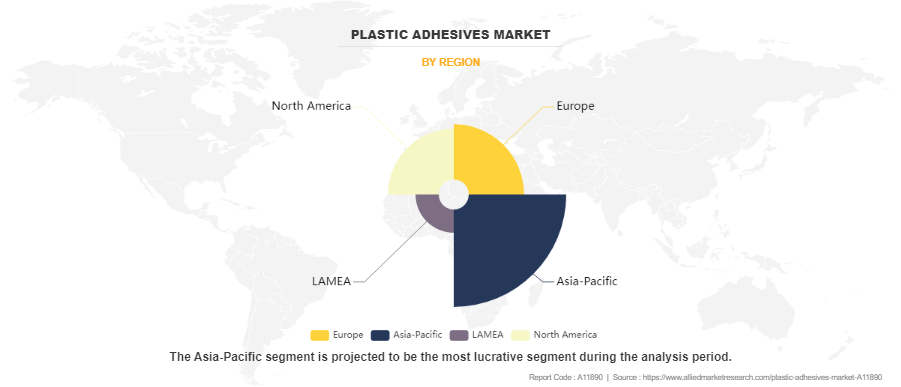

The plastic adhesive market is segmented into resin type, technology, end-use, and region. On the basis of resin type, the market is classified into epoxy, polyurethane, acrylic, silicone and others. On the basis of technology, the market is divided into solvent based, water based. By end-use, the market is categorized into automotive, construction and building, electrical and electronics, medical packaging, and others. Region-wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

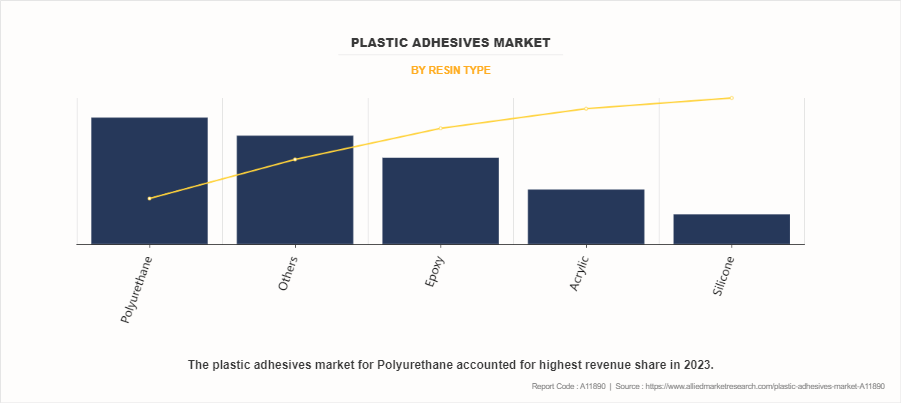

On the basis of resin type, the polyurethane segment dominated the plastic adhesive market and accounting for more than one-fourth of the market share in the market. Plastic adhesives are used in automotive applications involving polyurethane, such as bonding PU foam to metal or plastic substrates for interior components like dashboards, door panels, and headliners. They are also used in structural bonding applications, such as bonding polyurethane body panels or components. In November 2023, Henkel launched pioneering bio-based polyurethane (PU) adhesives, under the brand name Loctite. Specifically designed for load-bearing timber construction, these adhesives, known as HB S ECO and CR 821 ECO, boast a remarkable CO2eq emission reduction of over 60% compared to traditional fossil-based alternatives.

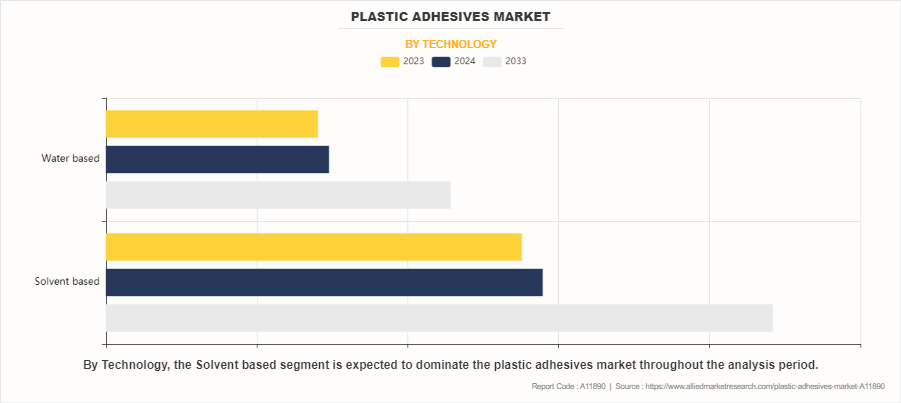

On the basis of technology, the solvent based segment dominated the plastic adhesive market accounting for more than half of the market share. Plastic adhesives are used in the construction industry for bonding plastic materials, such as PVC pipes, plastic panels, and insulation boards. They are also used for installing flooring materials, such as vinyl tiles and laminates. Acrylic solvent adhesives are commonly used in bonding acrylic plastics, as well as other types of plastics such as polycarbonate and ABS (acrylonitrile butadiene styrene). PVC solvent adhesives are specifically designed for bonding PVC (polyvinyl chloride) plastics, which are commonly used in pipes, fittings, and other construction materials.

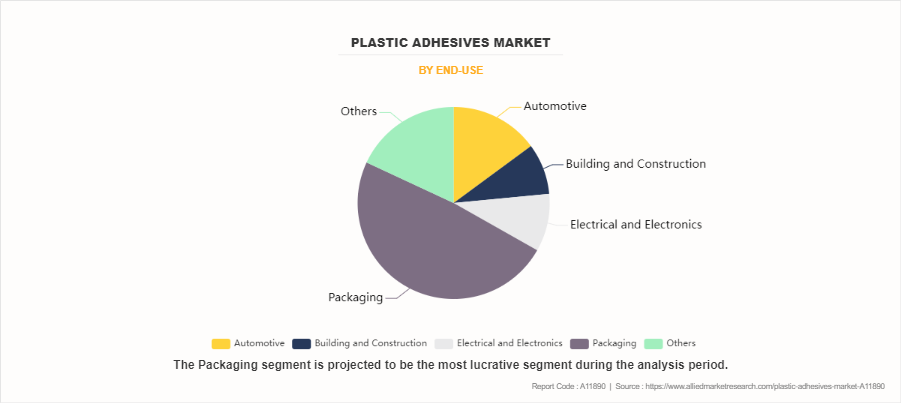

On the basis of end-use, the packaging segment dominated the plastic adhesive market accounting for more than one third of the market share. Adhesive films can be used to secure items within a package, preventing them from shifting during transit. This is particularly important for fragile or delicate items. Adhesive labels or tapes with special tamper-evident features are used to provide evidence of tampering or unauthorized access. Once applied, these seals cannot be removed without leaving a visible mark, ensuring the integrity of the package.

Region-wise, Asia-Pacific dominated the plastic adhesive market growing with a CAGR of 5.4% during the forecast period. Plastic adhesive usage in Asia-Pacific countries varies depending on factors such as industrial activity, manufacturing trends, and consumer demand. China, as the world's largest manufacturer, likely has the highest usage of plastic adhesives in the region. Its vast manufacturing capabilities and extensive infrastructure projects contribute to significant consumption of adhesives for bonding various plastic materials in industries such as automotive, electronics, packaging, and construction.

Competitive Analysis

The major players operating in the plastic adhesive market include Henkel Corporation, 3M, H.B. Fuller Company, SIKA CORPORATION, Arkema, Huntsman International LLC., Dow, MAPEI Corporation, Jowat Corporation, and Avery Dennison Corporation.

Recent key developments in the plastic adhesive market

- In April 2023, Dow and Avery Dennison introduced a pioneering hotmelt label adhesive, facilitating the mechanical recycling of polyolefin filmic labels with polypropylene (PP) or polyethylene (PE) packaging. This innovative adhesive, the first of its kind, is endorsed by Recyclass for recycling in the HDPE colored stream (Class B).

- In July 2022, Arkema unveiled its strategic move to acquire Polimeros Especiales, a prominent provider of waterborne acrylic resins based in Mexico. The acquisition aligns with Arkema's objective of bolstering its presence in the rapidly expanding market of the region.

- In May 2022, 3M launched nitrile high performance plastic adhesive which is a medium viscosity grade for most brush or flow applications. It provides strong, flexible bonds having resists weathering, water, fuels, oil and plasticizers.

Historic Trends of the Plastic Adhesive Market

- In 1927, the first synthetic resin adhesive was developed by Dr. Paul Cope, known as Casco glue. It was made from synthetic resins and was used mainly for woodworking.

- In 1942, cyanoacrylate adhesives were discovered by Dr. Harry Coover Jr. and Fred Joyner while searching for materials to make clear plastic gun sights during World War II. However, they were not commercialized until later.

- In the 1970s, epoxy resins offered exceptional bonding strength, especially when adhering plastics to other materials or each other. This strength makes them suitable for a wide range of applications, including structural bonding in aerospace, automotive, and construction industries.

- In the 1980s, advancements in polymer science led to the development of specialized plastic adhesives tailored to specific applications. Silicone adhesives gained popularity for their flexibility and heat resistance, making them suitable for bonding plastic components in electronic devices and automotive applications.

- In 2003, water-based plastic adhesives offered environmentally friendly alternatives to solvent-based adhesives. Solvent-based adhesives, which release volatile organic compounds (VOCs) into the atmosphere during application and curing, came under scrutiny for their environmental impact.

10 Best Adhesives for Plastic to Plastic

- Best Liquid Epoxy Glue for Plastic—Super Glue Plastic Fusion Epoxy Adhesive

- Best Epoxy UV Resin for Plastic—Bondic Pro UV Resin Kit Liquid Plastic Welding Kit

- Best Affordable Plastic Glue—E6000 2 oz. Clear Adhesive

- Best Non-Drip Plastic Glue—Gorilla Super Glue Gel

- Best Super Glue for Plastic—Sdintar PR40 Plastic Special Adhesive

- Best Epoxy Putty for Plastic—J-B Weld 8237 PlasticWeld Plastic Repair

- Best Plastic Glue with a Strong Bond—Rhino Tough-Instant Ultra Glue Gel

- Best Solvent Cement for Plastic—Plastruct Plastic Weld

- Best Water-Resistant Plastic Glue—Loctite Super Glue Plastic Bonding System

- Best Overall Plastic Glue—3M Scotch-Weld Plastic & Rubber Instant Adhesive PR40

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the plastic adhesives market analysis from 2023 to 2033 to identify the prevailing plastic adhesives market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the plastic adhesives market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global plastic adhesives market trends, key players, market segments, application areas, and market growth strategies.

Plastic Adhesives Market Report Highlights

| Aspects | Details |

| Market Size By 2033 | USD 13.4 billion |

| Growth Rate | CAGR of 4.9% |

| Forecast period | 2023 - 2033 |

| Report Pages | 300 |

| By Resin Type |

|

| By Technology |

|

| By End-Use |

|

| By Region |

|

| Key Market Players | MAPEI Corporation, Arkema, Avery Dennison Corporation, Henkel Corporation, 3M, Sika Corporation, Jowat Corporation, H.B. Fuller Company, Huntsman International LLC., Dow |

Analyst Review

According to the opinions of various CXOs of leading companies, the global plastic adhesive market was dominated by the polyurethane segment.

The expansion of the automotive industry drives the growth of the plastic adhesive market. Automotive manufacturers are increasingly turning to lightweight materials such as plastics to improve fuel efficiency and reduce emissions. Plastics offer a high strength-to-weight ratio, making them ideal for replacing heavier materials like metal in various vehicle components. Plastic adhesives play a crucial role in bonding these lightweight materials together, enabling the construction of lighter and more fuel-efficient vehicles. In March 2022, Bostik signed an agreement with DGE - Smart Specialty Chemicals for distribution throughout Europe, Middle East & Africa. The agreement includes Born2BondTM engineering adhesives developed for 'by-the-dot' bonding applications in specific industries, such as automotive, electronics, luxury packaging, medical devices, and MRO.

However, volatility in raw material prices is expected to restrain the growth of the plastic adhesive market during the forecast period. The volatility in raw material prices, particularly fluctuations in petrochemical derivatives used in plastic adhesives, poses a significant restraint on the market. The price variations disrupt production planning and increase manufacturing costs for adhesive manufacturers. Such unpredictability makes it challenging to maintain stable profit margins and pricing strategies, impacting the overall profitability of businesses in the plastic adhesive sector. Moreover, reliance on petrochemical-derived raw materials exposes manufacturers to external factors such as geopolitical tensions and supply chain disruptions, further exacerbating the risk associated with raw material price fluctuations.

The Asia-Pacific region is projected to register robust growth during the forecast period. China's manufacturing sector is one of the largest in the world, contributing to high demand for plastic adhesives in industries such as electronics, automotive, packaging, and construction. Japan is known for its advanced technology and precision manufacturing, leading to extensive usage of plastic adhesives in industries like electronics, automotive, and aerospace.

The global plastic adhesive market was valued $8.3 billion in 2023 and is projected to reach $13.4 billion by 2033, growing at a CAGR of 4.9% from 2024 to 2033.

Henkel Corporation, 3M, H.B. Fuller Company, SIKA CORPORATION, Arkema, Huntsman International LLC., Dow, MAPEI Corporation, Jowat Corporation, and Avery Dennison Corporation. These are the top companies to hold the market share in plastic adhesives market.

The plastic adhesive market is segmented into resin type, technology, end-use, and region. On the basis of resin type, the market is classified into epoxy, polyurethane, acrylic, silicone and others. On the basis of technology, the market is divided into solvent based, water based. By end-use, the market is categorized into automotive, construction and building, electrical and electronics, medical packaging, and others. Region-wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

Asia-Pacific is the largest region of plastic adhesives market.

Health and safety concerns are the restraint factor of plastic adhesives market.

Increase in demand for lightweight materials are the upcoming trends of plastic adhesives market in the world.

Polyurethane is the leading application of plastic adhesives market.

Loading Table Of Content...

Loading Research Methodology...