Plastic Extrusion Machine Market Insights, 2032

The Global Plastic Extrusion Machine Market Size was valued at $6,315.1 million in 2019 and is projected to reach $11,002.1 million by 2032, registering a CAGR of 4.8% from 2019 to 2032.

Plastic extrusion machine market overview includes continuous manufacturing method that involves melting thermoplastic material in the form of powder, pellets, or granules and then pushing it out of a shaping die using pressure. In screw extrusion, the pressure is created by the rotation of the screw against the barrel wall. The plastic material takes on the shape of the die hole as it passes through the die and exits the extruder. The resulting product is referred to as extrudate.

Market Dynamics

Furthermore, the plastic pipe industry has placed significant emphasis on sustainability, leading to the integration of eco-friendly attributes in extrusion lines. Among these attributes is the inclusion of recycled materials during the extrusion process. Recycled plastic pellets are used by manufacturers to cut down on the need for new materials and curb the environmental implications associated with making plastic pipes.

There is an increasing demand for the production of sustainable and quality standard plastic pipes, these breakthroughs are needed to meet this increased demand within this sector. The use of intelligent manufacturing technologies has never been this high leading to more automation and data centered operations. This involves real-time monitoring and control systems which further help boost efficiency and productivity.

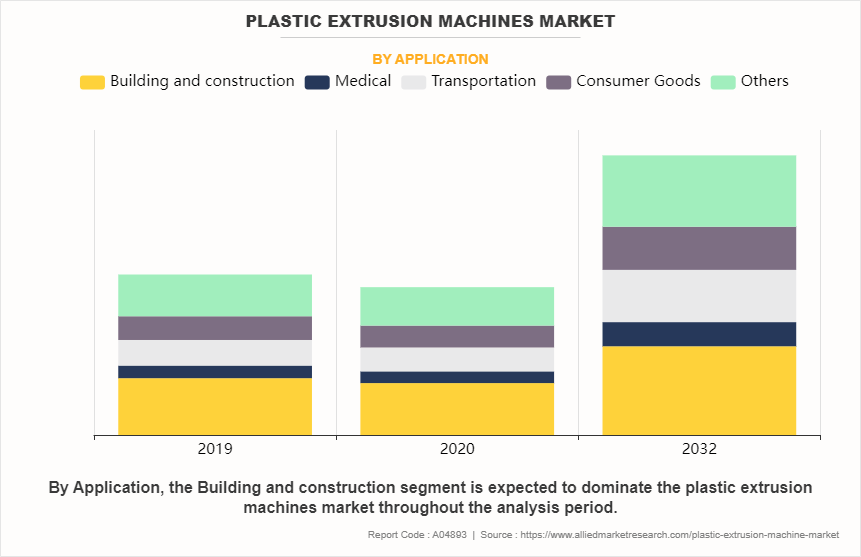

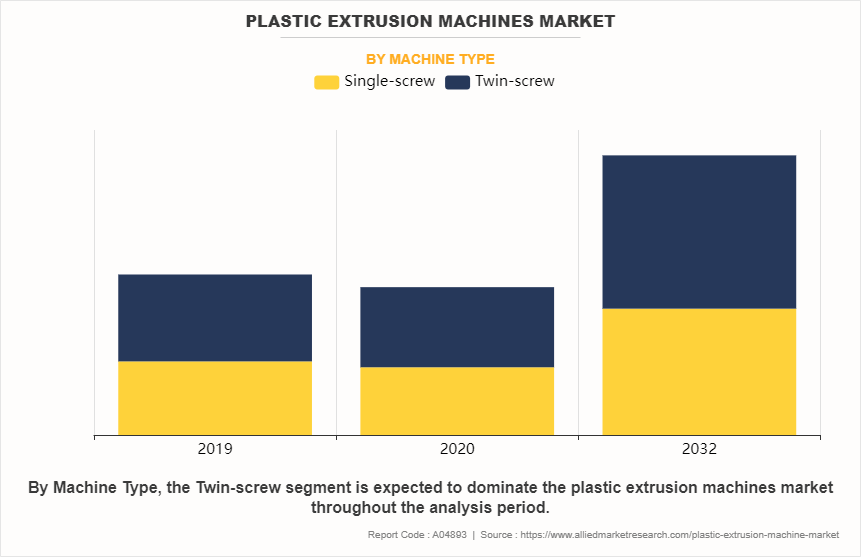

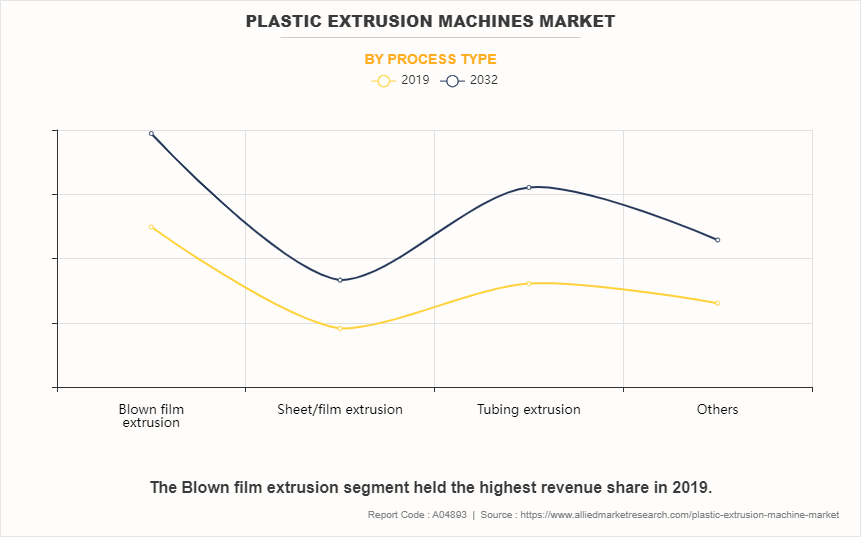

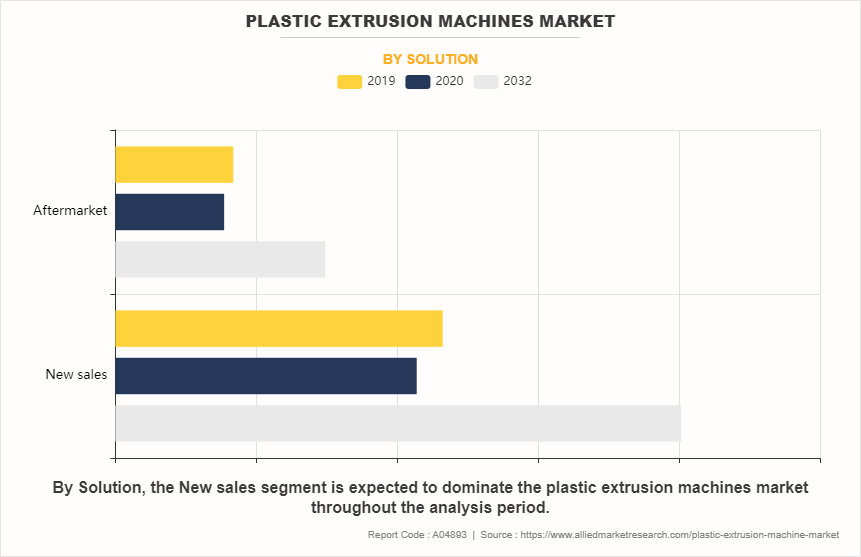

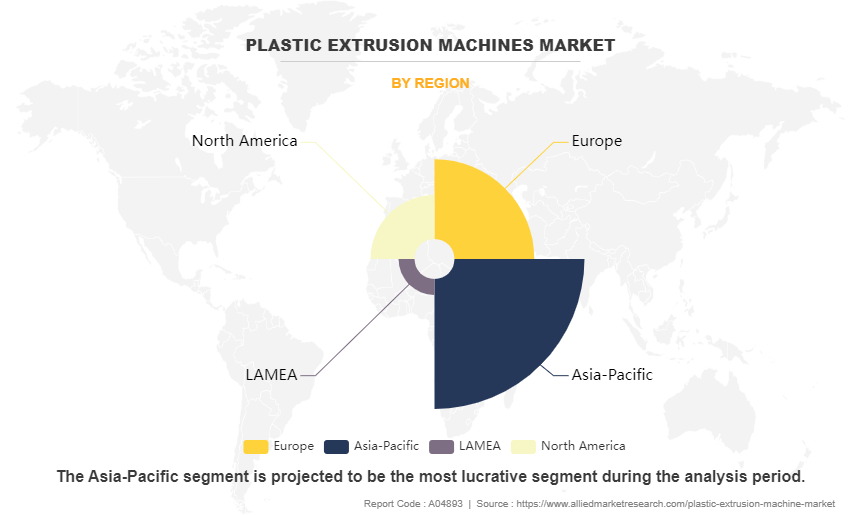

The global plastic extrusion machine market is segmented based on machine type, solution, process type, application, and region. Based on machine type, the market is divided into twin-screw and single screw. Based on solution, the market is bifurcated into new sales and aftermarket. Based on Application the market is segmented into building and construction, medical, transportation, consumer goods, and others. Based on process type, the market is further divided into blow film extrusion, sheet/film extrusion.

Report Key Highlighters

The plastic extrusion machine market studies more than 16 countries. The analysis includes a country-by-country breakdown analysis in terms of value ($million) available from 2022 to 2032.

The research combined high-quality data, professional opinion and research, with significant independent opinion. The research methodology aims to provide a balanced view of the global market, and help stakeholders make educated decisions to achieve ambitious growth objectives.

The research reviewed more than 3,700 product catalogs, annual reports, industry descriptions, and other comparable resources from leading industry players to gain a better understanding of the market.

The plastic extrusion machine market share is marginally fragmented, with players such as Costruzioni Meccaniche Luigi Bandera SpA, KOLSITE GROUP (KABRA EXTRUSIONTECHNIK LTD.), Sinochem Holdings Corporation Ltd., Hillenbrand Inc., REIFENHÄUSER GMBH & CO. KG MASCHINENFABRIK, Bausano & Figli S.p.A., The Japan Steel Works, LTD., Windsor Machines Pvt. Ltd., Shibaura Machine Co. Ltd., and Union Officine Meccaniche Spa.

High speed and bulk production advantage

High demand for extruded plastic products

The plastic extrusion machine market is experiencing remarkable growth due to several key factors. The building and construction sector's increasing demand for these machines is a significant driver, as they are essential for shaping various plastic products used in construction projects. Additionally, the transportation industry's reliance on extruder machines for manufacturing parts and components is also contributing to plastic extrusion machine market size.

Moreover, utilization of these machines is driving significant growth in the food and beverage sector, as it offer efficient production processes for various products in this industry. Moreover, China, the U. s. the automotive industry is growing, which is driving up demand for high-performance plastic products in Germany and India. This is driving up the market for plastic extrusion machines. It is projected, for instance, that India's automobile industry will grow from $118 billion in 2021 to $300 billion by 2030. As demand is witness significant rise across industries, the market share of plastic extrusion machines is expected to rise. The increasing demand for extruded plastic products across several markets has led to a boom in the plastic extrusion machine market share.

Newer technological advancements

Technological advancements in market are anticipated to drive growth in the plastic extrusion machine market forecast during projected period. Leading players like KraussMaffei Berstorff GmbH, Costruzioni Meccaniche Luigi Bandera SpA, and Theysohn Extrusionstechnik GmbH are dedicated to introducing energy-efficient, reliable, and cutting-edge plastic extrusion machines.

For instance, Theysohn Extrusionstechnik GmbH specializes in plastic extruders featuring the latest technology in parallel twin-screw extrusion. The enhanced gearbox design by Theysohn has resulted in significant energy savings. Furthermore, at K 2022, Davis-Standard demonstrated its commitment to value, innovation, and sustainability by showcasing machinery and process solutions. The company introduced several enhancements and advancements to its extensive machinery portfolio. One notable addition is the SHO Extruder (3.5-inch, 90mm), which not only saves space but also boosts outputs by over 20 percent compared to existing groove feed models. This impressive feat is achieved through the integration of a new gearbox, an optimized feed section, and a high-performance, energy-efficient DSB barrier screw. Therefore, rise in applications and elevated competition inspire companies to focus on technological advancements to meet the consumer demand, thereby creating remunerative opportunities for the market.

Competitive Analysis

Competitive analysis and profiles of the major global plastic extrusion machine market players that have been provided in the report include Costruzioni Meccaniche Luigi Bandera SpA, KOLSITE GROUP (KABRA EXTRUSIONTECHNIK LTD.), Sinochem Holdings Corporation Ltd., Hillenbrand Inc., REIFENHÄUSER GMBH & CO. KG MASCHINENFABRIK, Bausano & Figli S.p.A., The Japan Steel Works, LTD., Windsor Machines Pvt. Ltd., Shibaura Machine Co. Ltd., and Union Officine Meccaniche Spa. Major strategies such as contracts, partnerships, expansion, and other strategies of players operating in the market are tracked and monitored.

Top Impacting Factors

Rise in awareness about energy saving globally propels the plastic extrusion machine market growth. Hence, plastic extrusion machine manufacturers are increasingly focusing toward manufacturing efficient and reliable twin-screw plastic extrusion machine to boost the growth of the plastic extrusion machines industry.

Key Developments/ Strategies in Plastic extrusion machine market

For Instance, In July 2023, Coperion has manufactured a ZSK Mc18 twin screw extruder and its accompanying peripherals for a Plastics2chemicals (P2C) facility being constructed by Indaver, a waste management company based in Belgium, with the purpose of chemically recycling plastic waste.

For instance, November 2022, Brabender introduced the B-TSE-S 30/40 Big Compounder, an electrically heated twin-screw extruder. This extruder serves as a bridge between laboratory and pilot plant operations, boasting a compact design that combines both the drive and processing unit.

For Instance, In October 2022, Norner has made a new investment in a 7-layer cast/film extruder to enhance support for packaging circularity. It has completed the installation of a cutting-edge 7-layer cast/ film extrusion line.

For instance, In July 2022, W. Müller revealed the enhancement of the production process for plastic bottles using its cutting-edge technology for the Netherlands-based packaging manufacturer Flestic. By incorporating new extrusion heads into their current machinery, the company managed to decrease material consumption without compromising quality. Additionally, this optimization led to a reduction in cycle time and energy consumption

For Instance, In May 2022, Germany-based extrusion technology specialist Gneuss showcased four of its innovative solutions at the Plastics Recycling Show Europe (PRSE) in Amsterdam, 22-23 June. The Gneuss Processing Unit includes a Gneuss MRS extruder renowned for its outstanding devolatilisation and decontamination performance, along with the highly effective Gneuss Rotary Filtration System and an online viscometer VIS for intelligent dynamic viscosity regulation. Initially developed for PET, the MRS is currently utilized in polyolefin, polyamide, polylactam, and polystyrene applications, with further materials and applications undergoing evaluation.

For Instance, May 2022, Gneuss has presented a variety of cutting-edge extrusion technologies at PRSE in Amsterdam, featuring the Gneuss Process Unit (GPU). This unit includes a Gneuss MRS extruder known for its exceptional devolatilisation and decontamination capabilities, paired with a highly effective Gneuss Rotary Filtration System and an online viscometer VIS for advanced dynamic viscosity management. This MRSjump extruder features a redesigned and extended MRS screw section, allowing for the viscosity of polyester to be adjusted to the desired level during the extrusion process by utilizing a specially developed vacuum unit.

For instance, In March 2021, VEKA Compounds, a sector of VEKA Recycling and a member of the VEKA UK Group, has revealed the addition of a cutting-edge extrusion line at its Wellingborough facility. With the total investment of over £500,000, enables the company to leverage a pair of cutting-edge Krauss Maffei compounding lines.

For Instance, In February 2021, Boston Matthews, a manufacturer of extrusion machinery, unveiled a revolutionary design for their compact Universal Co-Extruder. The BMU offers users unparalleled operational flexibility, allowing it to function as a Co-Extruder in various orientations, including horizontal, vertical, and even at user-defined angles such as 45 degrees.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the plastic extrusion machine market analysis from 2019 to 2032 to identify the prevailing plastic extrusion machine market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the plastic extrusion machine market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global plastic extrusion machine market trends, key players, market segments, application areas, and market growth strategies.

Plastic Extrusion Machines Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 11 billion |

| Growth Rate | CAGR of 4.8% |

| Forecast period | 2019 - 2032 |

| Report Pages | 292 |

| By Application |

|

| By Machine Type |

|

| By Process type |

|

| By Solution |

|

| By Region |

|

| Key Market Players | UNION OFFICINE MECCANICHE SPA, SHIBAURA MACHINE CO. LTD., THE JAPAN STEEL WORKS, LTD. (JSW), Windsor Machines Pvt. Ltd., Sinochem Holdings Corporation Ltd., KOLSITE GROUP (KABRA EXTRUSIONTECHNIK LTD.), REIFENHÄUSER GMBH & CO. KG MASCHINENFABRIK, HILLENBRAND INC., Bausano & Figli S.p.A., Costruzioni Meccaniche Luigi Bandera SpA |

The global plastic extrusion machines market was valued at $11,002.1 million by 2032, registering a CAGR of 4.8% from 2019 to 2032.

The base year calculated in the plastic extrusion machine market report is 2019.

The forecast period in the plastic extrusion machine market report is 2019 to 2032.

The blow film extrusion segment is the most influential segment in the plastic extrusion machine market.

The top companies analyzed for plastic extrusion machine market report are Costruzioni Meccaniche Luigi Bandera SpA, KOLSITE GROUP (KABRA EXTRUSIONTECHNIK LTD.), Sinochem Holdings Corporation Ltd., Hillenbrand Inc., REIFENHÄUSER GMBH & CO. KG MASCHINENFABRIK, Bausano & Figli S.p.A., The Japan Steel Works, LTD., Windsor Machines Pvt. Ltd., Shibaura Machine Co. Ltd., and Union Officine Meccaniche Spa

The company profile has been selected on the basis of revenue, product offerings, and market penetration.?

The market value of the plastic extrusion machine market in 2019 was $6,315.1 million.

The building and construction market segment holds the maximum market share of the plastic extrusion machine market.

Loading Table Of Content...

Loading Research Methodology...