Polypropylene & High-impact Polystyrene Market Research, 2031

The global polypropylene & high-impact polystyrene market was valued at $49.6 billion in 2021, and is projected to reach $81.1 billion by 2031, growing at a CAGR of 5.1% from 2022 to 2031.

Injection molding involves the production of plastic products by injecting molten materials into a mold, where it is melted, cooled, and solidified to form the final product. Thermoplastic as well as thermosetting injection-molded plastics are used for the production of several parts and components that are used in various applications. The prime thermoplastic polymers used in injection molding, include polypropylene, high impact polystyrene, low density polyethylene, high density polyethylene, polycarbonate, polystyrene, polyvinyl chloride, polyurethane, and polysulphone. In addition, epoxy resin, polyester, and melamine formaldehyde are some of the prominent thermosetting polymers used for injection molding. There is an increase in the demand for injection-molded plastics in the market over the last decade.

Injection-molded plastics are used in the production of complex and intricate-shaped parts to ensure precision and minimize wastage. Hence, injection-molded plastics are used in the production of automotive components, interior wrapping, and numerous assembly parts. It is majorly used in packaging applications to manufacture packaging parts and components to increase the aesthetic value and consumer friendliness of packaging products. Popularity of injection-molded plastics in building and construction applications is on the rise, owing to strength, durability, and texture of the injection-molded plastic parts. These plastic parts or components are mainly used in building and construction, for piping systems, insulations, wall boards, and roofing purposes. The healthcare industry is anticipated to be the fastest growing application segment for injection-molded plastic industry during the forecast period. Moreover, blood sample analysis cuvettes, pregnancy test devices, housings for needles, and medical devices components are the other application areas of these plastics, owing to their light weight and cost-effectiveness.

Injection-molded polypropylene and high-impact polystyrene use automated processes to reduce the manufacturing cost. It also reduces the waste production in production process. Factors such as low production waste and faster production process boost the growth of the polypropylene & high-impact polystyrene market for injection molding market. Furthermore, technological advancements in injection molding process, where robots are deployed for performing different operations, such as finishing and assembling injection-molded parts and loading components into the injection molding are expected to foster the growth of the market. However, high initial tooling cost and volatile prices of crude oil are projected to hamper the growth of the market.

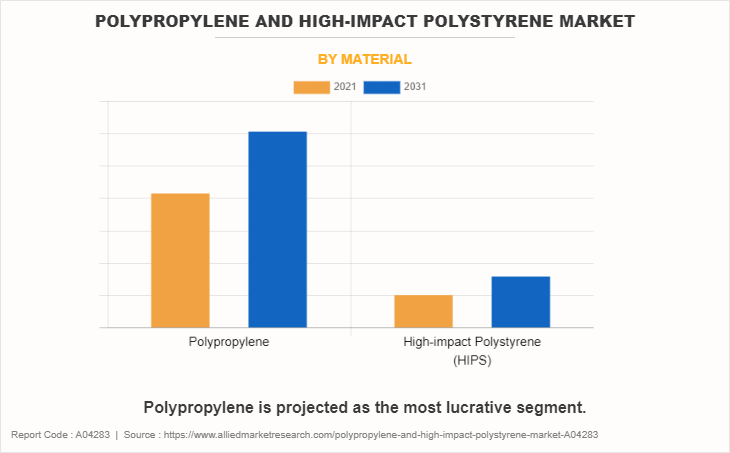

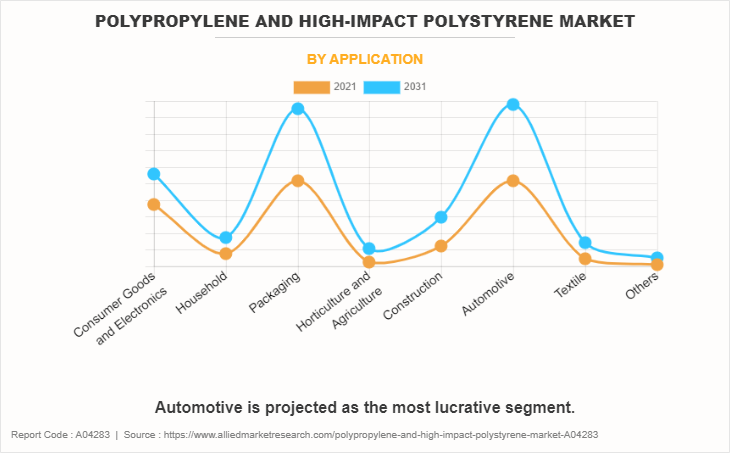

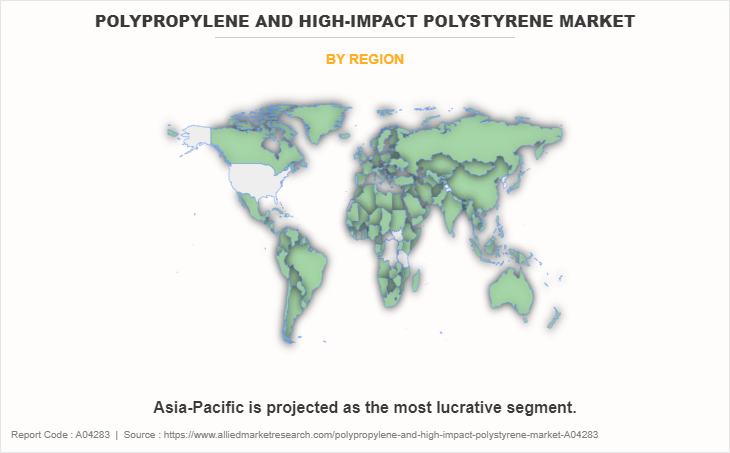

The polypropylene & high-impact polystyrene market for injection molding is segmented on the basis of material, application, and region. By material, the market is segregated into polypropylene and high-impact polystyrene. On the basis of application, it is fragmented into consumer goods & electronics, household, packaging, horticulture & agriculture, construction, automotive, textile, and others. Region-wise, it is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

The key players profiled in this report include LyondellBasell, SABIC, Exxon Mobil Corporation, INEOS, KISCO LTD., Innova, Resilient Plastics Pvt. Ltd., King Plastic Corporation, China Petroleum & Chemical Corporation (Sinopec Limited), and Khushi Enterprises. The global polypropylene & high-impact polystyrene market for injection molding report provides in-depth competitive analysis as well as profiles of these major players

By material, the polypropylene segment accounted for around 90.0% of the global polypropylene & high-impact polystyrene market for injection molding share in 2021. Polypropylene is the most popular plastic used for packaging materials globally. Polypropylene has a relatively slippery surface, which can make it a possible substitute for plastics such as Acetal (POM) in low friction applications like gears or for use as a contact point for furniture.

On the basis of application, the automotive segment accounted for around 24.9% of the global polypropylene & high-impact polystyrene market for injection molding share in 2021. The low density and recyclability properties are expected to drive the use of polypropylene and high impact polystyrene in the automotive industry during the forecast period.

Region-wise, the Asia-pacific segment accounted for around 55.6% of the polypropylene & high-impact polystyrene market for injection molding share in 2021. Polypropylene’s can be engineered into a wide range of packaging that help protect products users rely on every day, from medicine to yogurt to baby food. High-impact Polystyrene (HIPS) is a low cost, tough plastic that is easy to thermoform and fabricate, and is often used for countertop point of purchase displays and indoor signs where ease of fabrication is essential.

Impact of COVID-19 on Global Polypropylene & High-impact Polystyrene Market for Injection Molding

- The outbreak of COVID-19 led to partial or complete shutdown of production facilities that do not come under essential goods, owing to prolonged lockdown in major countries, including the U.S., China, Japan, India, and Germany. It led to either closure or suspension of production activities in most of the industrial units across the globe.

- The COVID-19 pandemic stagnated production activities in various areas, such as consumer goods & electronics, household, packaging, horticulture & agriculture, construction, automotive, and textile making. Supply chain disruptions of raw materials to these industries led to decline in the demand for polypropylene & high-impact polystyrene.

- In addition, the price of crude oil fell significantly due to decrease in demand for oil from various industries, subdued production activities in various industries, and increase in restrictions due to lockdown globally, which further reduced operating rates.

- However, the demand for plastic products from the healthcare and food packaging industries is on the rise again due to the rise in preference for single use healthcare products and packaged food & beverages.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the polypropylene & high-impact polystyrene market analysis from 2021 to 2031 to identify the prevailing polypropylene & high-impact polystyrene market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the polypropylene & high-impact polystyrene market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global polypropylene & high-impact polystyrene market trends, key players, market segments, application areas, and market growth strategies.

Polypropylene & High-impact Polystyrene Market Report Highlights

| Aspects | Details |

| Market Size By 2031 | USD 81.1 billion |

| Growth Rate | CAGR of 5.1% |

| Forecast period | 2021 - 2031 |

| Report Pages | 124 |

| By Application |

|

| By Material |

|

| By Region |

|

| Key Market Players | China Petrochemical & Chemical Corporation, Ineos, Videolar-Innova SA, Exxon Mobil Corporation, Resilient Plastics Pvt. Ltd., Kisco Ltd., Khushi Enterprises, SABIC, King Plastic Corporation, LyondellBasell Industries Holdings |

Analyst Review

There is an increase in demand for injection-molded plastics in the polypropylene & high-impact polystyrene market over the last decade. Furthermore, rise in demand for injected molded polypropylene and high-impact polystyrene is witnessed in various end-user industries across the globe. Injection-molded polypropylene and high-impact polystyrene use automated processes to reduce the manufacturing cost. It also reduces the waste production in production process. Factors such as low production waste and faster production process boost the growth of the polypropylene and high-impact polystyrene market for injection molding. Furthermore, technological advancements in the injection molding process, where robots are deployed for performing different operations, such as finishing and assembling injection-molded parts and loading components into the injection molding are expected to foster the growth of the market. However, high initial tooling cost and volatile prices of crude oil are projected to hamper the growth of the market.

In building and construction, these plastic parts or components are mainly used for piping systems, insulations, wall boards, and roofing purposes.

The market players are adopting various growth strategies and also investing in R&D extensively to develop technically advanced unique products which are expected to drive the market size.

Asia-Pacific region will provide more business opportunities for Polypropylene & High-impact Polystyrenes market in coming years

LyondellBasell, SABIC, Exxon Mobil Corporation, INEOS, KISCO LTD., Innova, Resilient Plastics Pvt. Ltd., King Plastic Corporation, and China Petroleum & Chemical Corporation (Sinopec Limited) are the top players in Polypropylene & High-impact Polystyrenes market.

By material segment holds the maximum share of the Polypropylene & High-impact Polystyrenes market

Household, packaging, horticulture & agriculture, construction, and automotive application are the potential customers of Polypropylene & High-impact Polystyrenes industry

Increase in usage of Polypropylene & High-impact Polystyrenees in the packaging industry significantly drives the growth of global Polypropylene & High-impact Polystyrene Market, as paraffin Polypropylene & High-impact Polystyrenees used for packaging offer resistance towards heat. Moreover, rise in use of Polypropylene & High-impact Polystyrene as a base ingredient in cosmetic products boosts the market growth.

Some of the prominent trends that the market is witnessing include the adoption of automation in the injection molding process, increasing use of lightweight materials and growing innovations in packaging.

Loading Table Of Content...

Loading Research Methodology...