Powder Coatings Market Overview:

The global powder coatings market size was valued at $13.3 billion in 2022, and is projected to reach $20.8 billion by 2032, growing at a CAGR of 4.6% from 2023 to 2032.

Key Market Insights

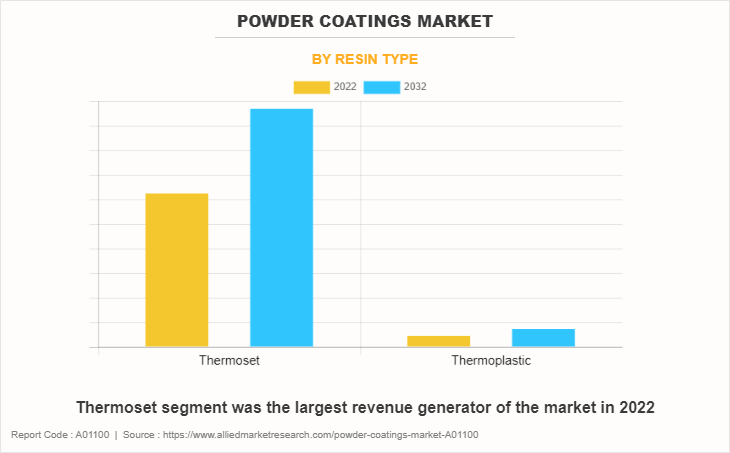

- By Resin Type: Thermoset was the top revenue-generating segment in 2022.

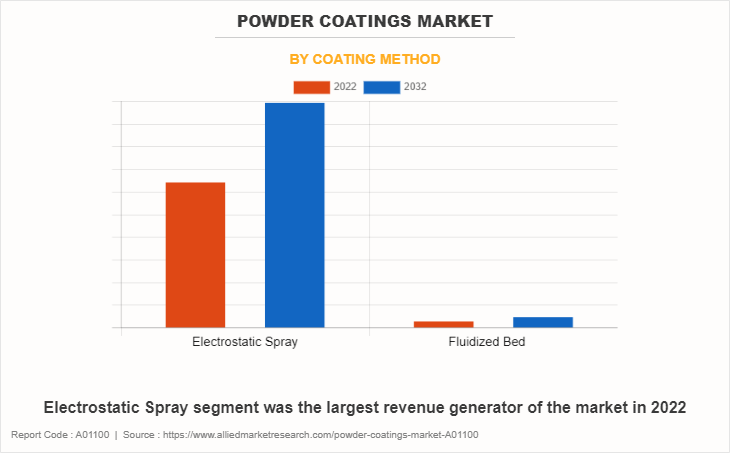

- By Coating Method: Electrostatic spray led the market in revenue in 2022.

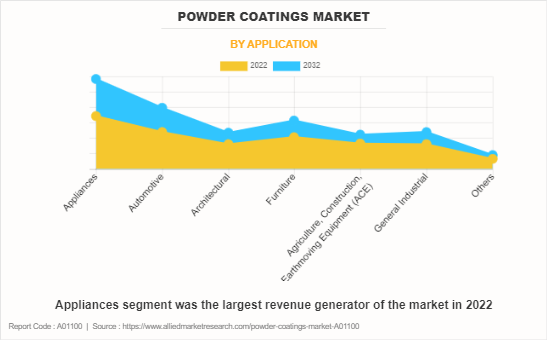

- By Application: Appliances were the highest revenue contributor in 2022.

- By Region: Asia-Pacific dominated market revenues in 2022.

Market Size & Forecast

- 2032 Projected Market Size: USD 20.8 Billion

- 2023 Market Size: USD 13.3 Billion

- Compound Annual Growth Rate (CAGR) (2023-2032): 4.6%

How to Describe Powder Coating

Powder coating is a type of coating that is applied as a dry, free-flowing powder. It is a popular method for finishing surfaces on a variety of materials, including metals, plastics, and ceramics. The process involves electrostatically applying charged powder particles to an object and then curing the coating by heat, which causes the powder to flow and form a durable, hard finish.

Powder coatings provide a robust and durable finish that is resistant to chipping, scratching, fading, and other wear and tear. Unlike traditional liquid coatings, powder coatings do not contain solvents, reducing the release of volatile organic compounds (VOCs) into the environment. This makes powder coatings a more environmentally friendly option. The electrostatic application of powder results in a more uniform coating, even on complex shapes and surfaces.

Powder coatings provide a durable and high-performance finish that is resistant to corrosion, chemicals, abrasion, and UV radiation. The industries such as automotive, appliances, and architecture appreciate the long-lasting protection offered by powder coatings. Powder coatings can be applied to a wide variety of substrates, including metal, plastic, wood, and composites. This versatility makes powder coatings suitable for a broad range of industries, from automotive and electronics to furniture and architecture.

Report Key Highlighters:

- The global powder coatings market study covers 20 countries. The research includes a segment analysis of each country in terms of both value ($million) and volume (kilotons) for the projected period 2023-2032.

- More than 3,700 product literatures, annual reports, industry statements, and other comparable materials from major industry participants were reviewed to gain a better understanding of the market.

- The study integrated high-quality data, professional opinions and analysis, and critical independent perspectives. The research approach is intended to provide a balanced view of global markets and to assist stakeholders in making educated decisions to achieve their most ambitious growth objectives.

- The powder coatings market is highly fragmented, with several players including AkzoNobel N.V., PPG Industries, Sherwin Williams, BASF SE, Axalta Coating Systems, Kansai Nerolac Paints Limited, Jotun, IFS Coatings, The Valspar Corporation, and Tiger Coatings. Key strategies such as acquisitions, product launches, mergers, and expansion of the players operating in the powder coatings market have further been tracked.

Environmental regulations and sustainability are expected to drive the powder coatings market growth during the forecast period

With increasing environmental awareness and stringent regulations on volatile organic compounds (VOCs), powder coatings have gained popularity as an environmentally friendly alternative to liquid coatings. Powder coatings are solvent-free and release little to no VOCs during application, aligning with sustainability goals. Many countries and industries are aligning with global sustainability goals and initiatives. The powder coatings market is poised to benefit from this trend as companies seek eco-friendly and sustainable coating solutions to reduce their environmental impact.

Moreover, in the construction and architectural sectors, green building practices are gaining prominence. Powder coatings, which meet the low-VOC criteria and are durable, corrosion-resistant, and versatile, are well-suited for use in eco-friendly building projects. In addition, consumer awareness and demand for sustainable and environmentally friendly products are growing. Industries catering to consumer goods, such as appliances and furniture, are likely to choose powder coatings to meet these preferences and enhance their market appeal.

Further, numerous companies are incorporating environmental sustainability into their corporate responsibility strategies. Choosing powder coatings aligns with these initiatives, allowing businesses to demonstrate their commitment to reducing their carbon footprint and environmental impact. Ongoing research and development in the coatings industry continue to improve powder coatings formulations, making them more environmentally friendly while maintaining high-performance standards. This innovation contributes to the market's growth as industries seek cutting-edge, sustainable solutions.

Powder Coatings Market Segment Review:

The global powder coatings market is segmented into resin type, coating method, application, and region. By resin type, the market is divided into thermoset and thermoplastic. Depending on coating method, it is categorized into electrostatic spray and fluidized bed. On the basis of application, it is categorized into appliances, automotive, architectural, furniture, agriculture, construction, and earthmoving equipment (ACE), general industrial, and others. Region wise, the powder coatings market share is studied across North America, Europe, Asia-Pacific, and LAMEA.

Asia-Pacific was the largest revenue generator of the market in 2022. With a rising middle class and increased consumer spending, there's a growing demand for durable and aesthetically pleasing products, such as appliances, furniture, and electronics. Powder coatings provide a durable and attractive finish, making them popular in the production of consumer goods. The powder coatings market in Asia-Pacific is characterized by a competitive landscape with both local and multinational players. This competition often leads to advancements, improved product offerings, and cost-effective solutions for manufacturers.

Thermoset segment was the largest revenue generator of the market in 2022. Thermoset powder coatings are a type of powder coating that undergo a chemical reaction during the curing process, resulting in a crosslinked and durable finish. Unlike thermoplastic powder coatings, which melt and flow when reheated, thermoset coatings cannot be remelted or reprocessed once they have undergone the curing process.

Thermoset powder coatings are suitable for a broad range of applications, including automotive parts, appliances, outdoor furniture, architectural components, industrial equipment, and more. The durability and versatility of thermoset coatings make them popular in industries where a long-lasting, high-quality finish is essential. Thermoset powder coatings are available in a wide array of colors and finishes, including glossy, matte, textured, and metallic options. This versatility allows manufacturers to achieve diverse aesthetic effects to meet consumer preferences.

Electrostatic Spray segment was the largest revenue generator of the market in 2022. The powder coating material is a mixture of finely ground particles of resin and pigment. The formulation can be customized based on the specific requirements of the application, such as desired color, finish, and performance characteristics. Before applying the powder coating, the substrate is thoroughly cleaned and prepared. Surface preparation may involve cleaning, degreasing, and applying pre-treatments to enhance adhesion and corrosion resistance.

The powder coating material is charged with an electrostatic charge as it passes through the spray gun. The spray gun is equipped with an electrode that imparts a positive charge to the powder particles. This electrostatic charge causes the powder particles to repel each other, ensuring an even dispersion. The object or substrate to be coated is grounded. This grounding creates an electrostatic attraction between the charged powder particles and the grounded substrate. The powder particles adhere to the grounded object, covering it uniformly.

The charged powder is sprayed onto the grounded object using an electrostatic spray gun. The electrostatic force ensures that the powder particles adhere evenly to all surfaces, including recessed or hard-to-reach areas, resulting in a uniform coating thickness.

Appliances segment was the largest revenue generator of the market in 2022. Appliances are often exposed to moisture, humidity, and varying temperatures. Powder coatings, especially those with corrosion-resistant properties, help protect appliance surfaces from rust and corrosion, enhancing the longevity of the products. Powder coatings are environmentally friendly compared to some liquid coatings. They contain little to no volatile organic compounds (VOCs), reducing air pollution during application. This aligns with the growing emphasis on sustainable and eco-friendly manufacturing practices.

Which are the Leading Companies in Powder Coatings

The players operating in the global powder coatings industry are AkzoNobel N.V., PPG Industries, Sherwin Williams, BASF SE, Axalta Coating Systems, Kansai Nerolac Paints Limited, Jotun, IFS Coatings, The Valspar Corporation, and Tiger Coatings. Other players include Asian Paints Limited, Nippon Paint Holdings Co., Ltd., IGP Powder Coatings, TCI Powder, and Berger Paints India Limited.

Strategic Developments By Key Players:

- In 2021, Jotun partnered with Graco, a leading manufacturer of fluid handling equipment, to provide efficient and reliable solutions for the application of powder coatings.

- In 2020, AkzoNobel introduced Interpon D3000 Fluoromax, a next-generation fluoropolymer powder coating, providing enhanced durability and sustainability for architectural applications. In the same year, TIGER Coatings collaborated with Wagner Group, a manufacturer of coating equipment, to provide comprehensive solutions for powder coating applications.

- In 2019, Axalta acquired TCI Powder Coatings, a leading manufacturer of powder coatings, to strengthen its position in the powder coatings market and expand its product portfolio.

What are the Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the powder coatings market analysis from 2022 to 2032 to identify the prevailing powder coatings market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the powder coatings market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global powder coatings market trends, key players, market segments, application areas, and market growth strategies.

Powder Coatings Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 20.8 billion |

| Growth Rate | CAGR of 4.6% |

| Forecast period | 2022 - 2032 |

| Report Pages | 250 |

| By Resin Type |

|

| By Coating Method |

|

| By Application |

|

| By Region |

|

| Key Market Players | Kansai Nerolac Paints Limited, Sherwin Williams, The Valspar Corporation, BASF SE, Tiger Coatings, Jotun, Axalta Coating Systems, Akzonobel N.V., IFS Coatings, PPG Industries Inc |

Analyst Review

According to the insights of the CXOs of leading companies, advancements in technology play a crucial role in driving the growth and adoption of powder coatings in various industries. These technological innovations contribute to improving the performance, efficiency, and sustainability of powder coating processes.

Researchers are working on developing self-healing powder coatings that can repair minor damages, such as scratches, over time. These coatings can contribute to extending the lifespan of coated surfaces and reducing maintenance requirements. Incorporating nanoparticles into powder coatings can enhance properties such as scratch resistance, UV resistance, and anti-corrosion capabilities. Nanotechnology allows for the development of coatings with improved performance and durability.

Moreover, advancements in resin technology have led to the development of polyester-TGIC-free powder coatings, which address environmental concerns by eliminating the use of toxic compounds such as triglycidyl isocyanurate (TGIC). Furthermore, integration of smart process control systems in powder coating lines improves efficiency, reduces waste, and ensures consistent coating quality.

Growth in the appliances, construction, and automotive sectors is a significant driver of the powder coatings market.

Asia-Pacific is the largest regional market for Powder Coatings.

The powder coatings market was valued at $13.3 billion in 2022, and is estimated to reach $20.8 billion by 2032, growing at a CAGR of 4.6% from 2023 to 2032.

The key players operating in the global powder coatings market are AkzoNobel N.V., PPG Industries, Sherwin Williams, BASF SE, Axalta Coating Systems, Kansai Nerolac Paints Limited, Jotun, IFS Coatings, The Valspar Corporation, and Tiger Coatings.

Appliances is the leading application of Powder Coatings Market.

Loading Table Of Content...

Loading Research Methodology...