Pressure Sensitive Adhesives Market Research, 2033

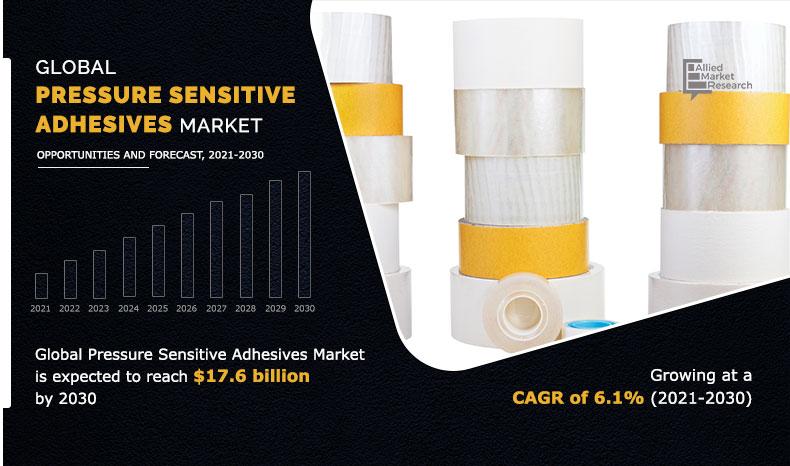

The global pressure sensitive adhesives market forecast was valued at $9.8 billion in 2020, and is projected to reach $17.6 billion by 2030, growing at a CAGR of 6.1% from 2021 to 2030. The rising adoption of pressure-sensitive adhesives in the automotive industry is driven by their ability to support lightweight vehicle designs, enhance fuel efficiency, and meet the demand for advanced bonding solutions in electric and autonomous vehicles. Pressure sensitive adhesives are widely used in applications such as window assembly, automotive trims, and sealing to improve safety, durability, and ease of assembly. As a result, these factors drive the demand for the pressure sensitive adhesives market.

Introduction

Pressure-sensitive adhesives are a type of adhesive that forms a bond with a surface when pressure is applied, without the need for heat, water, or solvent activation. They are designed to provide a balance of tackiness and cohesive strength (resistance to shear), enabling strong and durable adhesion under various environmental conditions. PSAs are commonly used in applications such as labels, tapes, medical devices, and automotive parts due to their versatility, ease of use, and ability to bond to a wide range of substrates.

Market Dynamics

Acrylic based pressure sensitive adhesives (PSA) are thermoplastic in nature and can be formulated with acrylic monomers and polymers with low glass transition temperature. These pressure sensitive adhesives are versatile, low-cost, and offer enhanced performance characteristics making them suitable for label applications. Acrylic PSA are polar in nature and tend to stick well to polar materials or substrates such as metals, glass, polyesters, polycarbonates, and neoprene. These are the major pressure sensitive adhesives market growth factors. Flexible packaging is the most economical method utilized for packaging, distributing, and preserving food, pharmaceuticals, beverages, and other products, which need extended shelf life. The flexible packaging industry has witnessed significant growth over the past decade, due to rise in demand from end users. Thus, pressure-sensitive adhesives are being utilized as a common tool by packaging engineers, as they assist in keeping the packaging in place until it reaches its required location. All these factors collectively boost the demand for pressure sensitive adhesives, thereby augmenting the market growth, globally.

However, fluctuation in cost of raw materials is anticipated to restrain the pressure sensitive adhesives market growth. The growth of pressure-sensitive adhesives market is restricted, owing to the escalation in price of raw materials required for their production. Furthermore, deficit in the supply of a key raw material for the production of water-based and other adhesives acts as a major challenge in the adhesives industry. The shortage of VAM in the market is attributed to the shutdown of few production plants in Europe, the U.S., and Asia-Pacific, due to plant failure, accidents, or for regular maintenance scheduled work.

On the contrary, increase in demand for bio-based pressure sensitive adhesives is predicted to offer new opportunity in the forecast period. Growth in demand for sustainable solutions globally has created a need for bio-based pressure sensitive adhesives. A bio-based pressure sensitive adhesive is made by combining a commercially available acrylate with bio-based monomer chain. Around 60% of the materials utilized in production of this product are bio-based and these adhesives do not lack in performance as compared to traditional products. Bio-based pressure sensitive adhesives are compatible with traditional production techniques such as mini-emulsion polymerization emulsion & conventional emulsion, and thus can be easily manufactured.

The global pressure sensitive adhesives market analysis is done on the basis of chemical composition, technology, application, end use, and region. Depending on chemical composition, the pressure sensitive adhesives market is segregated into acrylic, rubber, ethylene vinyl acetate, silicone, polyurethane, and others. On the basis of technology, the global pressure sensitive adhesives market is divided into water-based, radiation cured, solvent-based, and hot melt. The applications covered in the study include tapes, labels, graphic, and others. By on end user, the global pressure sensitive adhesives market is segmented into packaging, automotive, healthcare, building & construction, electronics, consumer goods, and others. Region-wise, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

The major companies profiled in this report include The 3M Company, Henkel Ag & Co. KGAA, The Dow Chemical Company, Sika Group, Exxonmobil Corporation, Avery Dennison Corporation, H.B. Fuller, Arkema Group, Ashland Global Holdings Inc., and Wacker Chemical Corporation.

Pressure sensitive adhesives market, by region

The Asia-Pacific pressure sensitive adhesives market size is projected to grow at the highest CAGR of 6.9% during the forecast period and acquired 49.2% of pressure sensitive adhesives market share in 2020.

This is attributed to the rise in infrastructural activities in countries such as India and China. In addition, rise in demand for construction chemicals consequently increases the requirement of pressure sensitive adhesives. Further, the rise in demand for low volatile organic compound (VOCs) content adhesives from countries such as China, Japan, and India increases the demand for water based pressure sensitive adhesives.

By Region

Asia-Pacific would exhibit highest CAGR of 6.9% during 2021-2030.

Pressure sensitive adhesives market, by chemical composition

In 2020, the acrylic segment was the largest revenue generator, and is anticipated to grow at CAGR 4.9% in the forecast period, acrylic based pressure sensitive adhesives are versatile, low-cost, and offer enhanced performance characteristics making them suitable for label applications. Acrylic PSA are polar in nature and tend to stick well to polar materials or substrates such as metals, glass, polyesters, polycarbonates, and neoprene. High adhesion property of PSA based on acrylics are used in label and packaging applications is escalating the growth of the global pressure sensitive adhesives market.

By Chemical Composition

Polyurethane type is the most lucrative segment

Pressure sensitive adhesives market, by technology

By technology, the water-based segment dominated the global market in 2020, and is anticipated to grow at CAGR of 5.3% during forecast period. This is attributed to the fact that, water-based pressure sensitive adhesives are produced from a combination of water, polymers, and additives. It is ideal for porous and non-puros substrates. Moreover, different types of monomers can be used during formulation of water-based PSAs to achieve chosen properties such as peel strength, shear strength, and tackiness. Water based pressure sensitive adhesives are used for tapes & labels, paper & packaging, and woodworking.

By Technology

Hot-melt technology is projected as the fastest growing segment

Pressure sensitive adhesives market, by application

In 2020, the tapes application segment was the largest revenue generator, and is anticipated to grow at CAGR 5.5% in the forecast period, application of PSA tapes include masking tape, electrical tape, gasketing, sealing, dampening vibrations, heat management, and others. In addition, PSA tapes are used in sectors such as automotive, food & beverages, packaging, electrical & electronics, and healthcare is escalating the growth of global pressure sensitive adhesives market.

By Application

Graphic application is projected as the fastest growing segment

Pressure sensitive adhesives market, by end-use

By end use, the packaging segment dominated the global market in 2020, and is anticipated to grow at CAGR of 5.0% during forecast period. This is attributed to the fact that, pressure sensitive adhesives act as a catalyst for the packaging industries as it offers several benefits such as less retention time, no physical transformation or chemical reaction, and others, which saves times and increases productivity.

By End-user

Others end-user is projected as the fastest growing segment

Key benefits for stakeholders

- Porter’s five forces analysis helps analyze the potential of buyers & suppliers and the competitive scenario of the industry for strategy building.

- It outlines the current pressure sensitive adhesives market trends and future estimations from 2020 to 2030 to understand the prevailing opportunities and potential investment pockets.

- The major countries in the region have been mapped according to their individual revenue contribution to the regional pressure sensitive adhesives market.

- The key drivers, restraints, and opportunities and their detailed impact analysis are explained in the study.

- The profiles of key players and their key strategic developments are enlisted in the report.

Analyst Review

The global pressure sensitive adhesives market is expected to exhibit high growth potential, rubber based pressure sensitive adhesives have high initial adhesion buildup, good shear strength, moderate temperature resistance, and others. They are used in applications such as masking tapes, packaging tapes, and double coated tapes. Rubber-based pressure sensitive adhesives can also be manufactured from synthetic rubber that are derived from monomers such as isoprene or butadiene. Moreover, these PSAs can also be blended with natural rubber to improve its durability and oxygen & heat resistance. Pressure sensitive property of rubber based PSA can also be altered or improved by addition of tackifiers, plasticizers, antioxidants, and pigments & fillers. Not only pressure sensitivity is enhanced but other factors such as cos reduction and optimal physical properties can also be achieved. In addition, ethylene vinyl acetate based pressure sensitive adhesives are utilized in diverse applications such as bonding paper to paper, carboard tubes, plastic film to paper, and others. EVA based PSAs offer improved adhesiveness property at low and high temperature range and they offer enhanced adherence with polyolefins. Ethylene vinyl acetate (EVA) is used predominantly in the production of hot melt type of pressure sensitive adhesives, which is predicted to offer lucrative growth opportunities in the future.

Pressure sensitive adhesives act as a catalyst for the packaging industries as they offer several benefits such as less retention time, no physical transformation or chemical reaction, and others, which saves times and increases productivity. Key-players in pressure sensitive adhesives market are developing new products and technologies to gain high market share from packaging sector. PSAs are gaining importance for broad range of packaging applications and they are swiftly altering the way goods are packed and delivered to different consumers across retail and e-commerce sector. This is not only gaining immense attention in the market but is also emerging as a key strategy in terms of gaining additional market demand. Furthermore, properly packed food items or any other products can be sold to consumers easily on different sales level.

Pressure sensitive adhesives are also used for packaging of medical devices that are delivered securely to different healthcare professionals. Double sided pressure sensitive adhesives tapes offer numerous advantages such as flexibility, instant bond, and variety of application. Due to instant bonding capability the speed of packaging increases, i.e. no time is spent waiting for the adhesives to cure, it will bond instantly just by the application of some pressure. It is a huge benefit for large volume packaging operations, thereby contributing toward the global market growth.

Pressure Sensitive Adhesives Market Report Highlights

| Aspects | Details |

| By CHEMICAL COMPOSITION |

|

| By TECHNOLOGY |

|

| By Application |

|

| By End Use |

|

| By Region |

|

| Key Market Players | H.B. FULLER, HENKEL AG & CO. KGAA, WACKER CHEMICAL CORPORATION, ARKEMA GROUP, SIKA GROUP, THE DOW CHEMICAL COMPANY, AVERY DENNISON CORPORATION, ASHLAND GLOBAL HOLDINGS INC., THE 3M COMPANY, EXXONMOBIL CORPORATION |

Analyst Review

The global pressure sensitive adhesives market is expected to exhibit high growth potential, rubber based pressure sensitive adhesives have high initial adhesion buildup, good shear strength, moderate temperature resistance, and others. They are used in applications such as masking tapes, packaging tapes, and double coated tapes. Rubber-based pressure sensitive adhesives can also be manufactured from synthetic rubber that are derived from monomers such as isoprene or butadiene. Moreover, these PSAs can also be blended with natural rubber to improve its durability and oxygen & heat resistance. Pressure sensitive property of rubber based PSA can also be altered or improved by addition of tackifiers, plasticizers, antioxidants, and pigments & fillers. Not only pressure sensitivity is enhanced but other factors such as cos reduction and optimal physical properties can also be achieved. In addition, ethylene vinyl acetate based pressure sensitive adhesives are utilized in diverse applications such as bonding paper to paper, carboard tubes, plastic film to paper, and others. EVA based PSAs offer improved adhesiveness property at low and high temperature range and they offer enhanced adherence with polyolefins. Ethylene vinyl acetate (EVA) is used predominantly in the production of hot melt type of pressure sensitive adhesives, which is predicted to offer lucrative growth opportunities in the future.

Pressure sensitive adhesives act as a catalyst for the packaging industries as it offers several benefits such as less retention time, no physical transformation or chemical reaction, and others, which saves times and increases productivity. Key-players in pressure sensitive adhesives market are developing new products and technologies to gain high market share from packaging sector. PSAs are gaining importance for broad range of packaging applications and they are swiftly altering the way goods are packed and delivered to different consumers across retail and e-commerce sector. This is not only gaining immense attention in the market but is also emerging as a key strategy in terms of gaining additional market demand. Furthermore, properly packed food items or any other products can be sold to consumers easily on different sales level.

Pressure sensitive adhesives are also used for packaging of medical devices that are delivered securely to different healthcare professionals. Double sided pressure sensitive adhesives tapes offer numerous advantages such as flexibility, instant bond, and variety of application. Due to instant bonding capability the speed of packaging increases, i.e. no time is spent waiting for the adhesives to cure, it will bond instantly just by the application of some pressure. It is a huge benefit for large volume packaging operations, thereby contributing toward the global market growth.

Growth in flexible packaging industry and surge in demand for pressure sensitive adhesives from various end-use industries are the other major growth factors in the pressure sensitive adhesives market

The global pressure sensitive adhesives market forecast was valued at $9,814.2 million in 2020, and is projected to reach $17,563.2 million by 2030, growing at a CAGR of 6.1% from 2021 to 2030.

The 3M Company, Henkel Ag & Co. KGAA, The Dow Chemical Company, Sika Group, Exxonmobil Corporation, Avery Dennison Corporation, H.B. Fuller, Arkema Group, Ashland Global Holdings Inc., and Wacker Chemical Corporation are the most established players of the global pressure sensitive adhesives market.

Packaging industry is projected to increase the demand of pressure sensitive adhesives market

The pressure sensitive adhesives market is segmented on the basis of chemical composition, technology, application, end-use, and region. On the basis of chemical composition, the market is categorized into acrylic, rubber, ethylene vinyl acetate, silicone, polyurethane, and others. On the basis of technology, the market is categorized into water-based, radiation cured, solvent based, and hot melt. The applications covered in the study include tapes, labels, graphic, and others. By end use, the market is divided into packaging, automotive, healthcare, building & construction, electronics, consumer goods, and others. Region wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

Innovation in product formulations and manufacturing procedures of pressure sensitive adhesives is expected to drive the market growth. New innovative formulations, such as rise in weight ratio of tackifier in rubber-based pressure sensitive adhesives, are anticipated to offer pressure sensitive adhesive solutions having stronger cross-linking structure. Stronger cross-linking structure is expected to increase the application scope of these adhesives in various industries. The high-temperature resistance limitation of rubber-based pressure sensitive adhesives is anticipated to increase the amount of silicone utilized in production of pressure sensitive adhesives. It is the major growth factor in the pressure sensitive adhesives market.

Tapes and label applications are expected to drive the adoption of pressure sensitive adhesives.

COVID-19 has impacted negatively on the pressure sensitive adhesives market. This is attributed due to • The novel coronavirus is an incomparable global pandemic that has spread to over 180 countries and caused huge losses of lives and the economy around the globe. • The pressure sensitive adhesives market witnessed negative impact due to the wake of the COVID-19 pandemic. The major end-users of pressure sensitive adhesives include automotive, electronics, building & construction, consumer goods, and others. Pressure sensitive adhesives are used in numerous applications in the automotive industry, which include assemblies, fixing carpets to various vehicle interior substrates, brake shims, cable wrapping, foam & fiber bonding, fixing gaskets in multitude configurations, and others. • However, due to negative impact on automotive industry there has been decline the demand of PSAs from automotive sector. Factors such as disruption in value chain analysis has impacted large scale manufacturers in automotive sector. For instance, major exporter of automotive parts from China has been hit due to travel ban across globe and temporary closure of manufacturing hubs which in turn has pivoted automotive manufacturers across Europe. In addition, automotive assembly plants across the U.S. are shut due to risk of infection among workers which has created pressure on distressed supply of automotive cars. In addition, the declining income of customers has to lead to the contraction for the demand of ornamental plants and flowers amid the COVID-19 period. • Construction and roofing tapes are other applications that uses hot melt pressure sensitive adhesives. In addition, connecting two wood components with tapes that are made up of pressure sensitive adhesives offers benefits such as enhanced combined ductility and seal protection from water imposition damages that are usually caused due to hurricanes. Particular country economic development is largely dependent upon construction industry. • Rise in number of COVID-19 infections has forced governmental bodies to impose strict lockdown which in turn has affected the deadlines of construction projects being delayed. Moreover, construction sector accounted for 7.7% of global employment and it was projected to reach 13.4% by 2022. However, current pandemic situation has created stress among workers and downfall in the revenue from construction & building sector has impacted negatively on this sector. These all factors have indirectly affected on the production and supply of pressure sensitive adhesives that are used in building & construction end-use. • Doubles sided tapes incorporates pressure sensitive adhesives that are used in electronic appliances such as smartphone speakers and display frames. In addition, these tapes are used for various bonding applications owing to advantages such as immediate adhesion. The electronics sector is also hit negatively due to COVID-19 impact. According to report by Wakefield, the overall revenue from electronic sector has been decreased by 5-10%. However, there are some sectors in electronic industry that has seen rise in demand for the products such as industrial semiconductors utilized in medical sector. In addition, mobility sector among automotive and aviation industry is also been impacted negatively due to COVID-19 outbreak.

Loading Table Of Content...