Table Of Contents

- Natural Rubber’s Role in Advancing Healthcare Safety and Hygiene

- Consumer Shift toward Sustainable and Eco-Friendly Options

- Challenges and Risk Factors

- The Far-Reaching Consequences of Climate Change

- Labor and Ethical Concerns Amid Natural Rubber Cultivation

- Booming Automotive Sector: A Profitable Growth Opportunity

- Sustainability Initiatives and Ethical Sourcing

- ChallengeMichelin, a global leader in tire manufacturing, faced increasing pressure to address environmental and social concerns associated with natural rubber production. The rubber industry has been associated with deforestation, biodiversity loss, and poor labor conditions, particularly in Southeast Asia, where most natural rubber is sourced. Michelin worked to keep its supply chain sustainable while ensuring quality and responsibility.

- SolutionMichelin launched a comprehensive sustainable natural rubber sourcing initiative in 2023. The company partnered with local farmers, NGOs, and governments to promote environmentally friendly practices and improve livelihoods. Key initiatives included reforestation programs, training farmers in sustainable agroforestry, and implementing traceability systems to monitor rubber supply chains. By 2023, the initiative covered over 50,000 hectares of rubber plantations, ensuring compliance with environmental standards and improving yields by 20%.

- Approach

- OutcomeMichelin focused on sustainable rubber sourcing by preventing deforestation, supporting farmers' livelihoods, and ensuring a transparent supply chain, setting a high industry standard. This approach boosted the company’s reputation and strengthened its supply chain for the long run, supporting global sustainability goals. Michelin’s efforts show how teamwork and innovation help make resource-heavy industries more sustainable. Stakeholders across the natural rubber supply chain are prioritizing sustainability through initiatives like traceability programs, certification schemes (e.g., FSC, PEFC), and carbon offset projects. These initiatives ensure ethical sourcing, reduce environmental impact, and meet consumer and regulatory demands for eco-friendly practices. Such measures enhance transparency, build brand trust, and drive long-term resilience in the industry

- Expanding Opportunities through Supply Diversification

- Technological Advancements

- Clonal Propagation: Clonal propagation in natural rubber involves developing high-yield, disease-resistant rubber tree clones to enhance productivity and sustainability. By selecting superior genetic traits, these clones offer increased latex yield, faster growth, and resistance to diseases like South American Leaf Blight. This technology helps farmers improve output while reducing deforestation and chemical dependency, ensuring a more stable and eco-friendly rubber supply amid rising global demand and climate challenges.

- Automated Tapping: Automated tapping is a breakthrough technology in natural rubber production that replaces traditional manual tapping with mechanized systems. This innovation ensures precise, consistent latex extraction, reducing human error and labor dependency. Automated tapping optimizes tree health by minimizing bark damage, extending the productive lifespan of rubber trees. Additionally, it enhances efficiency by increasing latex yield while lowering operational costs. With labor shortages and sustainability concerns rising, this technology is helping plantations boost productivity and manage resources better.

- Maximizing Natural Rubber’s Potential with Smart R&D Investments

- Strategic Business Development

- AMR Verdict

Yerukola Eswara Prasad

Koyel Ghosh

Natural Rubber: The Essential Commodity Powering Modern Industries

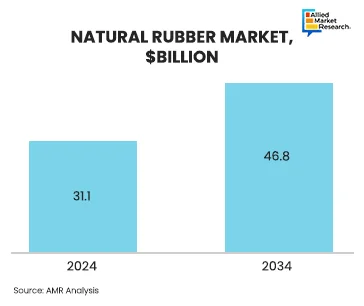

Natural rubber is an important material used in many industries, like automotive and healthcare. Its supply chain involves a network of producers, processors, manufacturers, and users. As a key commodity, natural rubber has significant economic, environmental, and social implications. It is derived primarily from the latex of the Hevea brasiliensis tree and has unique properties such as elasticity, durability, and resistance to wear and tear. The demand for eco-friendly materials is rising worldwide and natural rubber has now become a key part of the global economy.

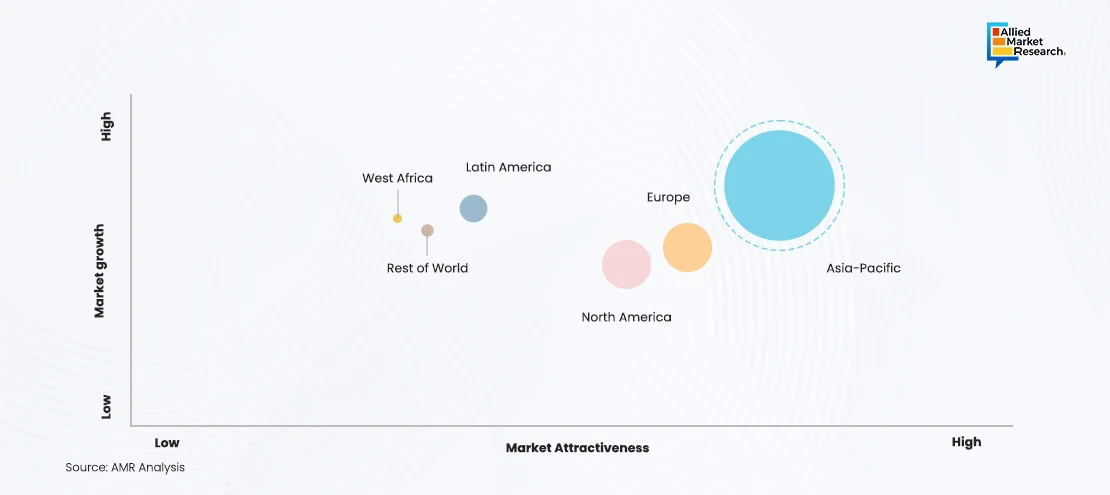

Natural rubber is a multibillion-dollar industry, with major producers including Thailand, Indonesia, and Malaysia. Most natural rubber, about 70%, is used for making tires, while other industries like footwear, medical supplies, and adhesives also rely on it.

Natural Rubber’s Role in Advancing Healthcare Safety and Hygiene

The healthcare sector's need for rubber-based products and medical equipment has risen, especially in the wake of global health concerns. Natural rubber is used in the production of gloves, catheters, and other medical supplies. For instance, companies like Top Glove and Hartalega have capitalized on the rising demand for rubber gloves, while Ansell focuses on sustainable rubber-based medical devices. Additionally, natural rubber's biocompatibility and elasticity make it ideal for wound care and surgical equipment. As healthcare spending and hygiene awareness are growing, manufacturers are investing in research to improve product quality and sustainability, making natural rubber essential for both healthcare and environmental standards.

Consumer Shift toward Sustainable and Eco-Friendly Options

There is a growing demand for biodegradable and sustainable rubber-based products. Businesses that develop eco-friendly alternatives to plastic, such as natural rubber packaging and footwear, are gaining popularity. For instance, Allbirds, a San Francisco-based company, uses natural rubber in their sustainable shoe soles, catering to environmentally conscious consumers. Moreover,Vivobarefootuses natural rubber in biodegradable shoe soles to create eco-friendly footwear, reducing environmental impact and aligning with sustainable fashion trends while maintaining durability and performance. Patagonia incorporates natural rubber into wetsuits to enhance sustainability, reducing reliance on synthetic materials and minimizing environmental impact in their eco-conscious product line. Ecoalf, on the other hand, uses natural rubber in recycled fashion items, combining sustainability with innovation to create eco-friendly products that reduce waste and promote sustainable fashion practices.

Challenges and Risk Factors

Despite its potential, the natural rubber industry faces certain challenges:

The Far-Reaching Consequences of Climate Change

Climate change significantly impacts the natural rubber industry by altering weather patterns, increasing temperatures, and causing extreme weather events. In 2024, regions like Southeast Asia, which produce over 90% of the world's natural rubber, face reduced yields due to prolonged droughts and unpredictable rainfall. For instance, Thailand and Indonesia, major rubber producers, have reported lower latex output as rising temperatures stress rubber trees, making them more susceptible to diseases like Phytophthora. According to Association of Natural Rubber Producing Countries (ANRPC), the rubber production witnessed a decline during the first quarter of 2024 with production in Thailand, Malaysia, and Vietnam having decreased by approximately 18%, 15%, and 2.7% respectively on an annual basis. Additionally, frequent floods disrupt harvesting and transportation, raising production costs. These challenges lead to supply shortages, higher global rubber prices, and economic strain on smallholder farmers. Consequently, industries reliant on rubber, such as automotive and manufacturing, face increased costs, potentially slowing economic growth and innovation in 2024.

Labor and Ethical Concerns Amid Natural Rubber Cultivation

The natural rubber industry often faces labor and ethical concerns, particularly in regions including Southeast Asia and West Africa, where child labor, low wages, and poor working conditions are prevalent. For instance, in Thailand and Indonesia, reports have highlighted the exploitation of migrant workers on rubber plantations, who endure long hours, inadequate pay, and limited access to healthcare. In Liberia, child labor has been documented in rubber production, with children exposed to hazardous conditions. Governments and organizations have taken steps to address these issues. For example, the Thai government has implemented labor protection laws and partnered with NGOs to improve worker rights. Similarly, the Forest Stewardship Council (FSC) and Rainforest Alliance have introduced certification programs to promote ethical labor practices and sustainable rubber production.

Booming Automotive Sector: A Profitable Growth Opportunity

The growing automotive industry is boosting the natural rubber market since rubber is essential for making tires, seals, hoses, and vibration dampeners. With the rise in vehicle production, especially in emerging markets like India and China, the demand for this component has surged. For instance, tire manufacturers such as Michelin and Bridgestone rely heavily on natural rubber for durable, high-performance tires. Additionally, the shift toward electric vehicles has further boosted demand, as EVs often require specialized tires to handle their weight and torque. However, automakers like Tesla and Toyota are looking for eco-friendly rubber alternatives due to sustainability concerns, shaping how both industries adapt to changing consumer and environmental needs.

Sustainability Initiatives and Ethical Sourcing

Companies and governments are promoting eco-friendly options, making natural rubber more popular than synthetic rubber, which comes from petroleum. Let’s explore this with a case study.

Case Study: Sustainable Natural Rubber Sourcing by Michelin

Challenge

Michelin, a global leader in tire manufacturing, faced increasing pressure to address environmental and social concerns associated with natural rubber production. The rubber industry has been associated with deforestation, biodiversity loss, and poor labor conditions, particularly in Southeast Asia, where most natural rubber is sourced. Michelin worked to keep its supply chain sustainable while ensuring quality and responsibility.

Solution

Michelin launched a comprehensive sustainable natural rubber sourcing initiative in 2023. The company partnered with local farmers, NGOs, and governments to promote environmentally friendly practices and improve livelihoods. Key initiatives included reforestation programs, training farmers in sustainable agroforestry, and implementing traceability systems to monitor rubber supply chains. By 2023, the initiative covered over 50,000 hectares of rubber plantations, ensuring compliance with environmental standards and improving yields by 20%.

Approach

Reforestation and Biodiversity: Michelin invested in reforestation projects to restore degraded lands and protect ecosystems.

Farmer Training: The company trained farmers in eco-friendly methods like intercropping and using fewer chemicals to boost yields and protect the environment.

Traceability: Michelin adopted blockchain technology to track rubber from plantations to factories, ensuring transparency and accountability.

Community Engagement: The company worked closely with local communities to improve labor conditions, ensure fair wages, and support education and healthcare initiatives.

Outcome

Michelin focused on sustainable rubber sourcing by preventing deforestation, supporting farmers' livelihoods, and ensuring a transparent supply chain, setting a high industry standard. This approach boosted the company’s reputation and strengthened its supply chain for the long run, supporting global sustainability goals. Michelin’s efforts show how teamwork and innovation help make resource-heavy industries more sustainable. Stakeholders across the natural rubber supply chain are prioritizing sustainability through initiatives like traceability programs, certification schemes (e.g., FSC, PEFC), and carbon offset projects. These initiatives ensure ethical sourcing, reduce environmental impact, and meet consumer and regulatory demands for eco-friendly practices. Such measures enhance transparency, build brand trust, and drive long-term resilience in the industry

Expanding Opportunities through Supply Diversification

Diversifying natural rubber supply by expanding cultivation to non-traditional regions like Africa and Latin America reduces reliance on Southeast Asia, which dominates global production. This strategy mitigates risks from climate change, disease, and geopolitical instability, ensuring a more resilient supply chain. It also promotes economic growth in emerging regions while meeting rising global demand sustainably.

The global natural rubber industry faces challenges such as supply-demand imbalances, price volatility, and regulatory pressures. However, Events like the RubberMove 2024 International Rubber Conference in the Philippines showcase growth opportunities through better productivity, new markets, and sustainable practices. Stakeholders should explore these to stay ahead in the changing industry.

Technological Advancements

Technological advancements and government support in areas like Industry 4.0, smart cities, and smart manufacturing are driving the demand for natural rubber. These initiatives often require materials that offer durability and flexibility, characteristics inherent to natural rubber.

These factors collectively contribute to the dynamic growth and evolving landscape of the natural rubber industry. For instance, innovations in rubber cultivation and processing are helping to address some of these challenges. A few of them are as follows:

Clonal Propagation: Clonal propagation in natural rubber involves developing high-yield, disease-resistant rubber tree clones to enhance productivity and sustainability. By selecting superior genetic traits, these clones offer increased latex yield, faster growth, and resistance to diseases like South American Leaf Blight. This technology helps farmers improve output while reducing deforestation and chemical dependency, ensuring a more stable and eco-friendly rubber supply amid rising global demand and climate challenges.

Automated Tapping: Automated tapping is a breakthrough technology in natural rubber production that replaces traditional manual tapping with mechanized systems. This innovation ensures precise, consistent latex extraction, reducing human error and labor dependency. Automated tapping optimizes tree health by minimizing bark damage, extending the productive lifespan of rubber trees. Additionally, it enhances efficiency by increasing latex yield while lowering operational costs. With labor shortages and sustainability concerns rising, this technology is helping plantations boost productivity and manage resources better.

Maximizing Natural Rubber’s Potential with Smart R&D Investments

Thailand is advancing biotechnology applications for natural rubber serum, exploring its potential in medical and industrial sectors. The Ministry of Higher Education is supporting rubber serum biotechnology research at Prince of Songkla University. This initiative aims to develop innovative uses for natural rubber serum, enhancing the value proposition of Thailand's rubber industry.

Moreover, In the US, the Ohio State University received $26 million in federal funding from the National Science Foundation to establish the "Transformation of American Rubber through Domestic Innovation for Supply Security" (TARDISS) Engineering Research Center. This center aims to bolster domestic natural rubber production and develop a skilled workforce to support the emerging industry, reducing reliance on international sources.

Strategic Business Development

Sri Trang Agro-Industry, a prominent player in the natural rubber sector, reported a net profit of 854.3 million baht ($25 million) for the fourth quarter ending December 2024, rebounding from a net loss of 422 million baht ($12.5 Million) in the same period the previous year. This turnaround Shows the company’s strength and smart market

Additionally, the Association of Natural Rubber Producing Countries (ANRPC) anticipates a 1.8% increase in global natural rubber demand in 2024 compared to the previous year, signaling a potential market recovery. This projection reflects optimism within the industry, despite recent challenges posed by environmental factors and market fluctuations.

AMR Verdict

Natural rubber is an essential commodity with a far-reaching impact on the global economy and society. While the industry faces significant challenges, including climate change, labor shortages, and price volatility, it also presents numerous opportunities for growth and innovation

We help businesses in the natural rubber industry grow by providing deep insights into market trends, supply chains, and customer needs. Our expertise helps companies deal with challenges like price changes, sustainability rules, and climate issues. We offer useful information on improving production, finding new suppliers, and meeting eco-friendly standards. By studying different industries and market conditions, we help businesses create new products and expand. Moreover, with customized strategies, we help organizations stay competitive, manage risks, and take advantage of the rising demand for natural rubber, ensuring long-term success. Connect with our specialists today for deeper insights into the natural rubber industry and its evolving landscape!