Solder Materials Market Research, 2032

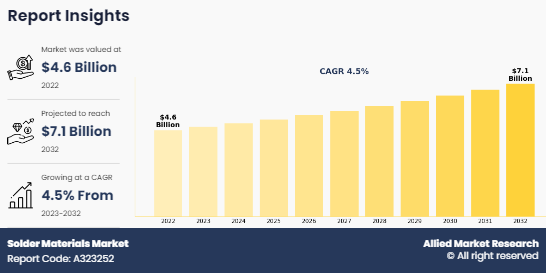

The global solder materials market size was valued at $4.6 billion in 2022, and is projected to reach $7.1 billion by 2032, growing at a CAGR of 4.5% from 2023 to 2032. The increase in demand for electronic devices, such as smartphones, tablets, laptops, and wearables, is a significant driver for the growth of the solder materials market. Solder is essential in assembling electronic components onto printed circuit boards (PCBs), and as the electronics industry continues to expand, so does the demand for solder materials.

Moreover, with the trend toward smaller, lighter, and more portable electronic devices, there is a surge in need for solder materials that facilitate the assembly of compact and lightweight components without sacrificing performance or reliability. This drives the demand for advanced solder alloys with improved properties such as high strength, low melting points, and excellent electrical conductivity.

Introduction

Solder is a fusible metal alloy used to join together metal workpieces, usually electronics components or plumbing pipes, to form a permanent bond. The most common solder materials include tin-lead (Sn-Pb), lead-free alloys, tin-bismuth (Sn-Bi), and Flux.

Solder materials are used in various applications across different industries. Soldering is widely used in electronics manufacturing for assembling components onto printed circuit boards (PCBs). Surface mount technology (SMT) and through-hole soldering are common techniques employed in electronics assembly. Soldering is also used for repairing and reworking electronic devices, such as replacing faulty components or fixing broken connections on PCBs. In plumbing, soldering is used to join copper pipes and fittings together, creating leak-proof connections. This process is often referred to as sweating or brazing. Moreover, soldering is a fundamental technique in jewelry making for joining metal components together, such as attaching clasps, setting stones, or creating intricate designs.

Key Takeaways

- The key players in the solder materials market are Indium Corporation, Alpha Assembly Solutions, Kester, Senju Metal Industry Co., Ltd., AIM Solder, Weller Tools GmbH, Nihon Superior Co., Ltd., MG Chemicals, Balver Zinn, and Qualitek International, Inc.

- More than 6,765 product literatures, industry releases, annual reports, and other such documents of major industry participants along with authentic industry journals, trade associations' releases, and government websites have been reviewed for generating high-value industry insights.

- The segment analysis of each country in terms of value during the forecast period 2022-2032 is covered in the global solder materials market report.

Market Dynamics

The automotive sector engages in the design, development, manufacturing, marketing, and sale of motor vehicles, including cars, trucks, buses, motorcycles, and other commercial and recreational vehicles. It is a significant contributor to the global economy and plays a crucial role in various aspects of modern society, such as transportation, employment, and technological advancement. The automotive sector is a significant consumer of solder materials for applications such as wiring harnesses, sensors, and electronic control units. With the surge in adoption of electric vehicles (EVs), advanced driver-assistance systems (ADAS), and in-vehicle connectivity features, the demand for solder materials in automotive electronics is expected to rise.

Moreover, the expansion of the automotive industry drives solder materials market growth. For instance, as per India Brand Equity Foundation, India has a strong manufacturing base for heavy vehicles, including trucks, buses, and construction equipment. It is the largest tractor producer, second-largest bus producer, and third-largest heavy truck manufacturer worldwide. India’s annual production of automobiles in FY22 was 22.93 million vehicles. Total passenger vehicle sales reached 334,130 in 2023. Besides sales in 2023 have been the highest, with a marginal growth of 3.7%, compared to November 2022.

Solder materials are composed of various metal alloys, and fluctuations in the prices of raw materials such as tin, silver, copper, and lead impact production costs and profit margins for solder manufacturers. Volatile raw material prices make it challenging to forecast costs accurately and require adjustments to pricing strategies.

Nevertheless, the adoption of Industrial Internet of Things (IIoT) technologies and Industry 4.0 initiatives in manufacturing and industrial sectors presents opportunities for solder materials used in industrial sensors, control systems, and smart manufacturing equipment. Solder manufacturers collaborate with industrial automation companies to develop solder materials optimized for IIoT applications, such as high-temperature resistance, vibration tolerance, and long-term reliability in harsh industrial environments. Moreover, there is a rise in demand for customized solder solutions tailored to specific customer requirements and applications. Solder manufacturers differentiate themselves by offering value-added services such as technical support, process optimization, failure analysis, and custom alloy development, enhancing customer satisfaction and loyalty.

Segments Overview

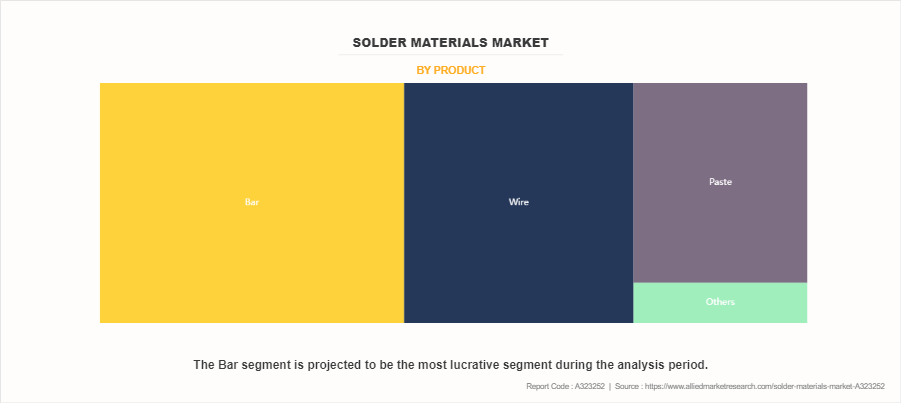

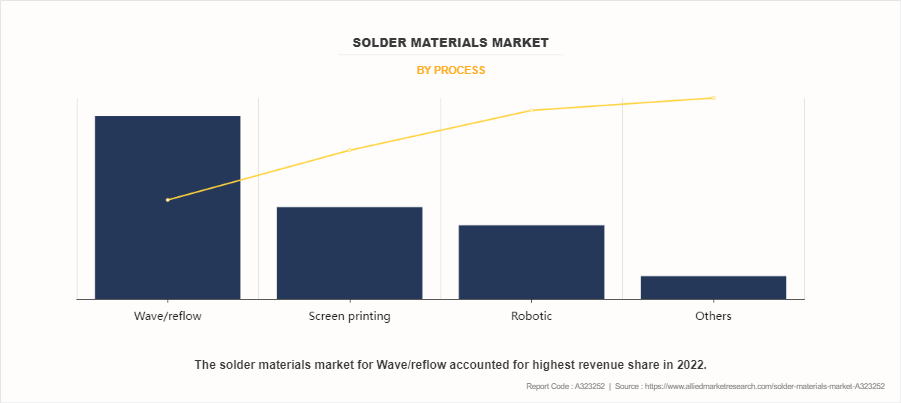

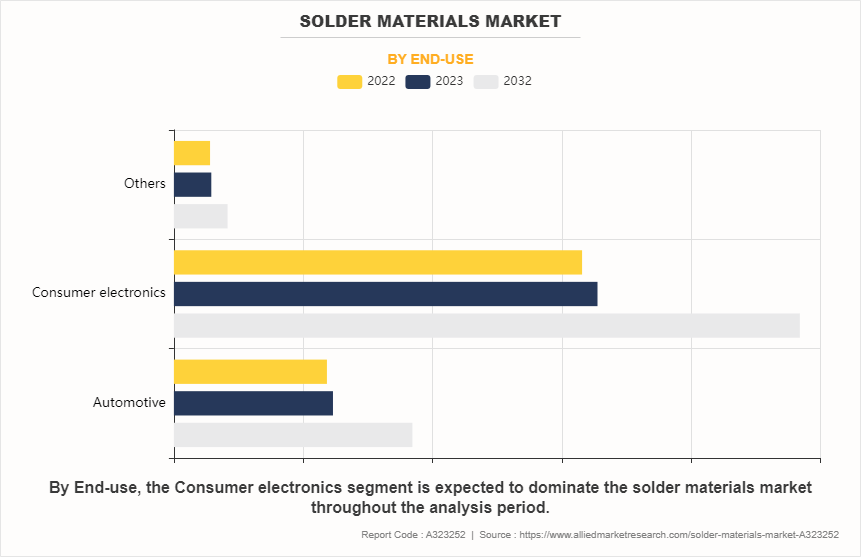

The solder material market is segmented on the basis of product, process, end-use industry, and region. By product, it is categorized into bar, wire, paste, and flux. By process, it is categorized into wave/reflow, screen printing, robotic, laser. By end-use industry, it is categorized into consumer electronics, automotive, others. Region-wise, the solder materials market share is studied across North America, Europe, Asia-Pacific, and LAMEA.

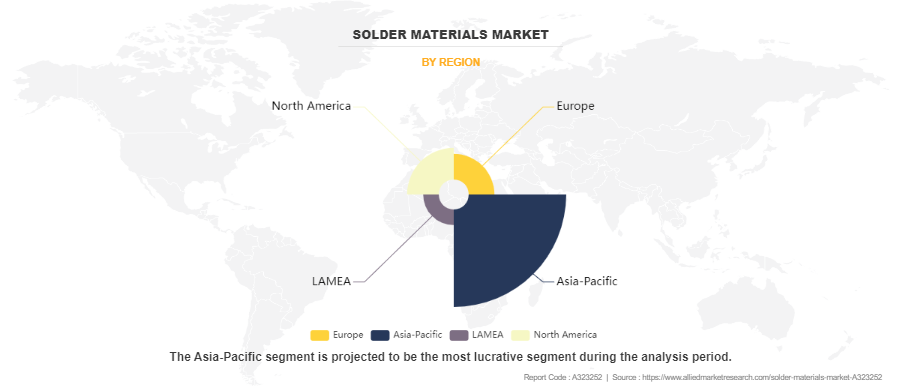

The Asia-Pacific region dominates the global solder materials market, accounting for more than half of the market revenue in 2022, and is expected to continue its dominance during the forecast period with a projected CAGR of 4.7% from 2023 to 2032. The strong electronics manufacturing industry, technological advancements, government initiatives, and increasing demand for consumer electronics, automotive electronics, and advanced electronic devices are key factors driving the growth of the solder material market in the Asia-Pacific region.

The bar segment is a dominant and growing segment within the global solder materials industry. Its importance in the electronics manufacturing process, coupled with the increasing demand for electronic devices and the transition towards lead-free soldering solutions, is driving significant solder materials market growth. The projected CAGR of 4.1% from 2023 to 2032 indicates a promising future for the solder bar market, with ample opportunities for innovation and product development.

The wave/reflow segment, encompassing both wave soldering and reflow soldering processes, is a dominant and growing segment within the global solder materials market. Its significance in the electronics manufacturing industry, particularly in the context of increasing miniaturization of electronic devices and the shift towards lead-free soldering, is driving substantial market growth. Reflow soldering, in particular, is gaining prominence due to its ability to provide high-quality and reliable solder joints for modern electronic components.

Consumer electronics segment accounted for the largest share in 2022, contributing to more than two-thirds of the global solder materials market revenue, and is projected to maintain its lead position during the forecast period. It is projected to grow at a CAGR of 4.4% from 2023 to 2032.The significance of soldering in the manufacturing of a wide range of consumer electronic devices, from smartphones to home appliances, is a key driver for the demand for solder materials.

Competitive Analysis

The major players operating in the global solder materials market are Indium Corporation, Alpha Assembly Solutions, Kester, Senju Metal Industry Co., Ltd., AIM Solder, Weller Tools GmbH, Nihon Superior Co., Ltd., MG Chemicals, Balver Zinn, and Qualitek International, Inc.

Historical Trends of Solder Materials Market

- Industrial Revolution: The Industrial Revolution in the 18th and 19th centuries brought significant advancements in metallurgy and manufacturing processes, including soldering. The development of mass production techniques led to increased demand for solder materials for applications such as plumbing, electronics, and metalworking.

- 20th Century: The 20th century witnessed further advancements in soldering technology, driven by the rapid expansion of industries such as electronics, automotive, aerospace, and telecommunications. Lead-tin solder alloys, particularly the eutectic alloy (63% tin, 37% lead), became widely used in electronics assembly due to their low melting point, good wetting properties, and reliability.

- Lead-Free Movement: Concerns about the environmental and health impacts of lead-based solder led to the development and adoption of lead-free solder alternatives in the late 20th and early 21st centuries. Regulatory initiatives such as the European Union's RoHS directive mandated the reduction or elimination of hazardous substances, including lead, in electronic products.

- Advancements in Solder Alloys: Over the years, solder alloy compositions have been continuously refined to meet the evolving needs of various industries. Lead-free solder alloys on the basis of combinations of tin, silver, copper, bismuth, and other metals have been developed to provide alternatives to traditional lead-based solders while maintaining performance, reliability, and environmental compliance.

- Technological Innovations: Technological advancements in soldering equipment, flux formulations, and process control have enhanced the efficiency, precision, and reliability of soldering operations. Automation, robotics, and laser soldering technologies have improved productivity and quality in electronics manufacturing and other industries.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the solder materials market analysis from 2022 to 2032 to identify the prevailing solder materials market opportunities.

- The solder materials market statistics is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the solder materials market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global solder materials market forecast.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global solder materials market trends, key players, market segments, application areas, and market growth strategies.

Solder Materials Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 7.1 billion |

| Growth Rate | CAGR of 4.5% |

| Forecast period | 2022 - 2032 |

| Report Pages | 200 |

| By Product |

|

| By Process |

|

| By End-use |

|

| By Region |

|

| Key Market Players | Alpha Assembly Solutions, Kester, KMG Chemicals, Inc., Nihon Superior Co., Ltd., Senju Metal Industry Co., Ltd, Weller Tools GmbH, Balver Zinn, Indium Corporation, AIM Solder, LLC, Qualitek International, Inc. |

Analyst Review

According to the insights of the CXOs of leading companies, rapid urbanization and infrastructure development coupled with increase in automotive production drives the growth of the market. The construction and infrastructure sectors drive demand for solder materials, particularly in plumbing applications. As urbanization and infrastructure development projects continue worldwide, there is an ongoing need for solders to join copper pipes and fittings in plumbing systems.

The automotive industry is a significant consumer of solder materials for various applications, including wiring harnesses, sensors, circuit boards, and electronic components. As automotive production volumes rise, driven by factors such as growing population, increasing disposable income, and technological advancements (e.g., electric vehicles, advanced driver-assistance systems), so does the demand for solder materials.

Further, environmental regulations, such as RoHS (Restriction of Hazardous Substances) directives, drive the adoption of lead-free solder materials in various industries, including electronics manufacturing. Compliance with regulatory standards motivates manufacturers to invest in alternative solder alloys and environmentally friendly soldering processes, influencing market dynamics.

The global solder materials market size was valued at $4.6 billion in 2022, and is projected to reach $7.1 billion by 2032, growing at a CAGR of 4.5% from 2023 to 2032.

Asia-Pacific is the largest regional market for Solder Materials.

The solder materials market is expected to possess high growth potential in the coming years, due to the proliferation of electronic devices such as smartphones, laptops, and IoT (Internet of Things) devices.

Consumer electronics is the leading application of Solder Materials Market.

The major players operating in the global solder materials market are Indium Corporation, Alpha Assembly Solutions, Kester, Senju Metal Industry Co., Ltd., AIM Solder, Weller Tools GmbH, Nihon Superior Co., Ltd., MG Chemicals, Balver Zinn, and Qualitek International, Inc.

Loading Table Of Content...

Loading Research Methodology...