Solvent-based Laminating Adhesive Market Research, 2032

The global solvent-based laminating adhesive market size was valued at $1,412.5 million in 2022, and is projected to reach $2,599.3 million by 2032, growing at a CAGR of 6.3% from 2023 to 2032. Solvent based laminating adhesives are used in a variety of industries, such as packaging, printing, and laminating. The liquid adhesive has compatibility with a wide variety of materials. Its unique quality is to form a strong link between materials, a viscidity that is attained when the solvent evaporates, leaving behind an adherent layer that has hardened and improved overall material integrity. Despite its efficiency and strength, the adhesive is characterized by a potent odor, necessitating the application process to occur in well-ventilated areas. This precaution is crucial to mitigate potential health concerns for individuals involved in the adhesive application.

Additionally, the solvent used in the adhesive formulation can be flammable, underscoring the critical importance of strictly adhering to safety protocols. Operations involving this adhesive should ideally take place in environments equipped to handle and mitigate the associated risks effectively.

The adoption of solvent-based laminating adhesive market share in the food and beverage industry has witnessed a significant escalation, marking a transformative shift in packaging practices. This trend underscores the industry's commitment to enhancing product safety, durability, and overall packaging performance. Solvent-based laminating adhesive industry, characterized by their robust bonding properties and versatility, have emerged as a preferred choice for manufacturers seeking to address the demanding requirements of the food and beverage sector. The versatility of solvent based laminating adhesives is another factor propelling their adoption in the food and beverage sector. These adhesives accommodate diverse packaging formats and materials, allowing manufacturers to innovate and differentiate their products on the shelves. As consumer preferences evolve, the flexibility offered by solvent-based laminating adhesives enables the industry to adapt swiftly, ensuring that packaging meets both functional and aesthetic requirements. Furthermore, the heightened emphasis on sustainability in the packaging industry aligns with the solvent based laminating adhesives' eco-friendly attributes. Manufacturers are increasingly recognizing the importance of adopting adhesives that not only offer superior performance but also contribute to reducing the environmental impact of packaging materials. Solvent based adhesives when effectively utilized can contribute to the development of more sustainable packaging solutions, meeting the evolving expectations of environmentally conscious consumers.

Solvent based laminating adhesive plays a pivotal role in bonding different layers of materials in packaging applications, providing essential properties such as durability and barrier protection. However, the reliance on raw materials subject to price fluctuations adds a layer of complexity to the industry's operations. The prices of key raw materials which may include solvents and various chemical components, can be influenced by factors such as geopolitical events, supply chain disruptions, and global economic conditions. These fluctuations pose challenges for manufacturers and stakeholders in the solvent based laminating adhesive market, as they need to navigate through a landscape of changing production costs. The need to adapt to such variations can impact pricing strategies, supply chain management, and overall profitability. Companies operating in this market must employ robust risk mitigation strategies and closely monitor raw material markets to anticipate and respond effectively to price movements. To overcome the hurdles imposed by fluctuating raw material prices, industry participants may explore alternative formulations, invest in research and development to identify cost-effective materials, or engage in strategic partnerships to secure a stable supply chain.

The solvent-based laminating adhesive market growth is tied to the growing demand for flexible packaging. As industries evolve and consumer preferences shift, the flexible packaging sector has witnessed a substantial surge, propelling the demand for laminating adhesives that cater to these dynamic needs. With the ability to adhere to various substrates, these adhesives contribute significantly to the production of versatile and durable flexible packaging materials. This versatility addresses the diverse requirements of industries ranging from food and beverages to pharmaceuticals, where packaging demands vary widely. The increasing emphasis on sustainability and eco-friendly packaging solutions has also played a role in shaping the market dynamics. Solvent based laminating adhesives have evolved to meet these environmental considerations, with manufacturers introducing formulations that minimize ecological impact without compromising performance. This dual focus on functionality and sustainability aligns with the broader industry trends, positioning solvent based laminating adhesives as vital components in the quest for responsible packaging solutions.

The key players profiled in this report are Henkel Corporation, Arkema Group, Ashland, Dow Chemical Company, Evonik Industries, H.B. Fuller, 3M, COIM Group, Flint Group, and Morchem. Acquisition and strategic partnership are common strategies followed by major market players. For instance, in June 2022, Toyo-Morton, a Japanese manufacturer of laminating adhesives and a member of the Toyo Ink Group, has recently enhanced its laminating adhesives portfolio to introduce a range of food-safe products, reinforcing its commitment to delivering high-quality and compliant solutions. Notably, these new additions to the portfolio are distinguished by their exclusion of epoxy silanes and organic tin compounds, aligning with evolving industry standards and addressing growing concerns about food safety. The updated portfolio encompasses two key series: the solvent based Tomoflex and the solvent-free Ecoad series of laminating adhesives. These products cater to a diverse array of multilayer flexible packaging applications, demonstrating versatility in meeting the demands of various packaging scenarios. Specifically, the Tomoflex solvent based series introduces the TM-2470 formulation, designed with precision for liquid pouch applications.

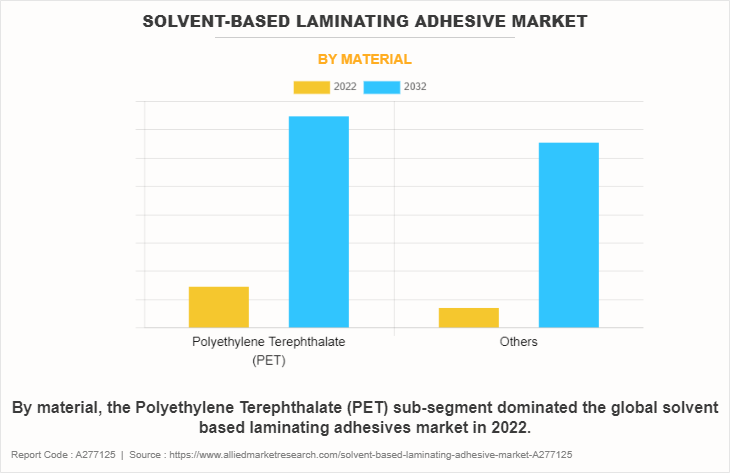

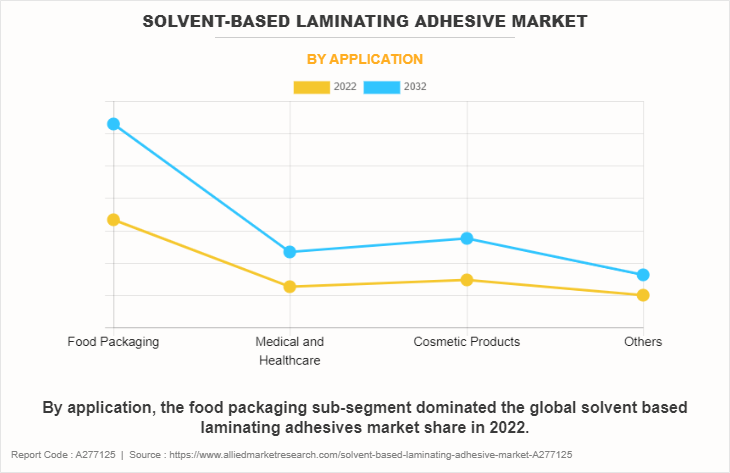

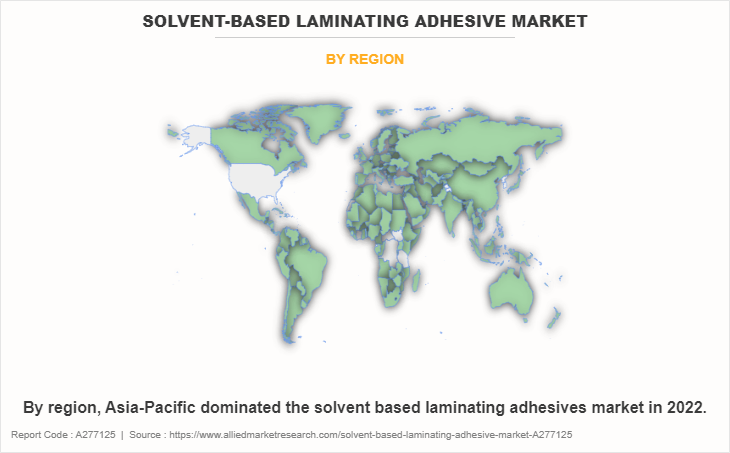

The solvent based laminating adhesives market is segmented on the basis of material, application, and region. By material, the market is divided into Polyethylene Terephthalate (PET), and others. By application, the market is classified into food packaging, medical & healthcare, cosmetic products, and others. By region, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

By material, the Polyethylene Terephthalate (PET) sub-segment dominated the global solvent based laminating adhesives market in 2022. The surging demand for Polyethylene Terephthalate (PET) within the packaging industry has emerged as a pivotal force propelling the growth of the solvent-based laminating adhesive market. PET, renowned for its versatility and widely acknowledged thermoplastic properties, stands out for its benefits like clarity, strength, and superior barrier attributes, rendering it an ideal choice for diverse packaging applications. The surge in PET's popularity can be attributed to its capacity to meet the stringent requirements across various sectors, including food and beverages, pharmaceuticals, and consumer goods. The solvent based laminating adhesive market is experiencing a notable increase as it adeptly addresses the specific challenges posed by PET packaging. Comprising a solvent carrier and diverse resins, these adhesives offer a dependable means for bonding multiple layers of packaging films. This becomes pivotal in the creation of laminates that not only showcase heightened strength but also exhibit enhanced flexibility and resilience against environmental factors. As consumer preferences continually evolve and regulatory standards push for advanced packaging solutions, the symbiotic relationship between PET and solvent based laminating adhesives becomes increasingly considerable.

By application, the food packaging sub-segment dominated the global solvent based laminating adhesives market share in 2022. The growing food packaging industry is poised to significantly propel the demand for solvent based laminating adhesives, thereby fostering market growth. As consumer preferences evolve and lifestyles become more fast-paced, the demand for convenient and efficiently packaged food products has experienced an unprecedented surge. This paradigm shift in consumer behavior has led to an increased reliance on advanced packaging solutions that not only preserve the freshness and quality of food but also enhance the overall consumer experience. Solvent based laminating adhesives play a pivotal role in meeting the stringent requirements of modern food packaging. These adhesives offer a robust and versatile solution for bonding various layers of packaging materials, providing crucial functionalities such as barrier protection, heat resistance, and adhesion strength. In the context of food packaging, where maintaining the integrity of the contents is paramount, solvent based laminating adhesives emerge as a preferred choice for manufacturers seeking reliable and efficient bonding solutions.

By region, Asia-Pacific dominated the solvent based laminating adhesives market in 2022. The growth of the solvent based laminating adhesives market in the Asia Pacific region is fueled by the continuous expansion of the industrial landscape. This expansion creates a conducive environment for the increased demand and application of solvent-based adhesives, as industries seek reliable and effective solutions to meet their evolving production requirements. As the manufacturing sector in the Asia Pacific continues to thrive, the solvent-based laminating adhesives market is poised for sustained growth, affirming its integral role in supporting the region's industrial advancement. The adaptability of solvent based laminating adhesives becomes evident in their significant contributions to the widespread adoption of these adhesives throughout the industrial spectrum. The automotive sector benefits from their application in seamlessly bonding materials within interiors, ensuring both durability and aesthetic appeal. Simultaneously, the electronics industry relies on the precision and reliability of these adhesives in assembling intricate electronic components. The textiles industry experienced the positive impact of solvent based laminating adhesives in enhancing the quality and functionality of various textile products.

Impact of COVID-19 on the Global Solvent Based Laminating Adhesives Industry

- The pandemic has disrupted global supply chains, affecting the availability and cost of raw materials used in the production of laminating adhesives. This led to increased prices or challenges in securing necessary inputs.

- Lockdowns, social distancing measures, and workforce disruptions impacted the production of laminating adhesives. Manufacturers faced challenges in maintaining regular production schedules, leading to potential delays in supply.

- The demand for certain products, and consequently the adhesives used in their production, have shifted due to changes in consumer behavior during the pandemic. For example, increased demand for packaging materials for online shopping impacted the demand for laminating adhesives in the packaging industry.

- The pandemic has led to changes in regulatory environments that affect the production, distribution, or use of certain chemicals, including adhesives.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the solvent-based laminating adhesive market analysis from 2022 to 2032 to identify the prevailing solvent-based laminating adhesive market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the solvent-based laminating adhesive market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global solvent-based laminating adhesive market trends, key players, market segments, application areas, and market growth strategies.

Solvent-based Laminating Adhesive Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 2.6 billion |

| Growth Rate | CAGR of 6.3% |

| Forecast period | 2022 - 2032 |

| Report Pages | 310 |

| By Material |

|

| By Application |

|

| By Region |

|

| Key Market Players | Ashland, Dow Chemical Company, Henkel Corporation, Evonik Industries, H.B. Fuller, Arkema Group, Morchem, COIM Group, Flint Group, 3M |

Food packaging companies are the major customers in the global solvent based laminating adhesive market.

The report provides an extensive qualitative and quantitative analysis of the current trends and future estimations of the global solvent based laminating adhesive market from 2022 to 2032 to determine the prevailing opportunities.

The food and beverage industry's growing need for solvent based laminating adhesives is crucial since these adhesives guarantee the integrity and security of packaging for consumable goods.

The increasing demand for advanced flexible packaging presents a significant opportunity for the growth of the solvent based laminating adhesive market.

The solvent based laminating adhesive market size is expected to grow due to an increase in demand for flexible packaging globally.

The major growth strategies adopted by the solvent based laminating adhesive market players are product launches and partnership agreements.

Asia-Pacific will provide more business opportunities for the global solvent based laminating adhesive market in the future.

Henkel Corporation, Arkema Group, Ashland, Dow Chemical Company, Evonik Industries, H.B. Fuller, 3M, COIM Group, Flint Group, and Morchem are the major players in the solvent based laminating adhesive market.

The food packaging sub-segment of the application acquired the maximum share of the global solvent based laminating adhesive market in 2022.

Loading Table Of Content...

Loading Research Methodology...