Spiral Freezer Market Research: 2032

The Global Spiral Freezer Market Size was valued at $4.1 billion in 2020, and is projected to reach $7.3 billion by 2032, growing at a CAGR of 4.9% from 2023 to 2032. Spiral freezing is a highly freezing system that freezes a large number of products in a limited space. it is of two types such as single spiral freezer and double spiral freezer. it is widely used for ferenting and cooling bread, freezing seafood, pastry, meat, poultry, ice cream etc. It typically uses cryogenic and mechanical cooling methods.

Market Dynamics

Spiral freezers are used in the meat processing industry to retain frozen and fresh meat products. They are efficient parts of machinery that can be found anywhere, from local butcher shops, food trucks, and restaurants to huge retailers such as Walmart and Costco in their retail locations and warehouses. Spiral freezers are most commonly used in the seafood and fish industries. They are used in the food processing industry to quickly freeze items at temperatures of -20°C or below. The cold air drops into a chamber containing the product to be treated, causing it to freeze quickly.

This type of technology is especially useful when dealing with high-value fresh food such as seafood and fish products, where maintaining quality is important for long-term storage stability after harvest. However, factors such as strict government regulations and carbon emissions are anticipated to restrain the spiral freezer market growth.

In addition, freezing is a means of preserving food quickly. When the temperature drops below a specific level, the water condenses into ice crystals. Rapid freezing prevents the development of crystals. A spiral freezer is an adaptable device that is used in industry to quickly freeze and cool items individually or in batches. The components of these systems are extremely durable due to wide temperature ranges and tremendous mechanical stresses involved in their operation.

Spiral freezers use a mechanical conveyor system to transport food through a series of freezing operations. They reduce the amount of space surrounding the belt while allowing access to the sections. The spiral freezer's design is dependent on the individual installation, but they are an excellent alternative if floor space is limited since they make greater use of vertical space than other freezing systems that take up a lot of room. Spiral freezer machines are simple to put together and take apart. They are particularly developed to enhance efficiency in the specific production line. Spiral freezers provide constant cooling without compromising product quality. All such factors are expected to boost the spiral freezer market growth.

The spiral freezer market is witnessing various obstructions in its regular operations due to the COVID-19 pandemic and inflation. Earlier, the worldwide lockdowns resulted in reduced industrial activities, eventually leading to reduced demand for spiral freezers from various sectors such as food & beverages. However, COVID-19 has subsided, and the major manufacturers in 2023 are performing well. Contrarily, the rise in global inflation is a new major obstructing factor for the entire industry.

The inflation, which is a direct result of the Ukraine-Russia war, and few long-term impacts of the coronavirus pandemic, has introduced volatility in the prices of raw materials used for manufacturing spiral freezers. However, India and China are performing relatively well. In addition, inflation is expected to worsen in the coming years, as the possibility of ending the war between Ukraine and Russia is less. Moreover, as inflation worsens, manufacturers of spiral freezers will be required to adjust to the uneasy buying patterns of consumers. In addition, food prices have increased substantially over the last year, which is estimated to lead to reduced total inventory held by retailers and total food products traded. This is expected to lead to reduced demand for cold storage of food in the coming years; thereby, reducing the demand for spiral freezers in this sector.

Segmental Overview

The spiral freezer market is segmented into Capacity, Application, Business, and region. By type, it is divided into small capacity, medium capacity, and large capacity. By business, it is bifurcated into OEM and aftermarket. By application, it is classified into meat processing, seafood, bakery products, and others. By region, it is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

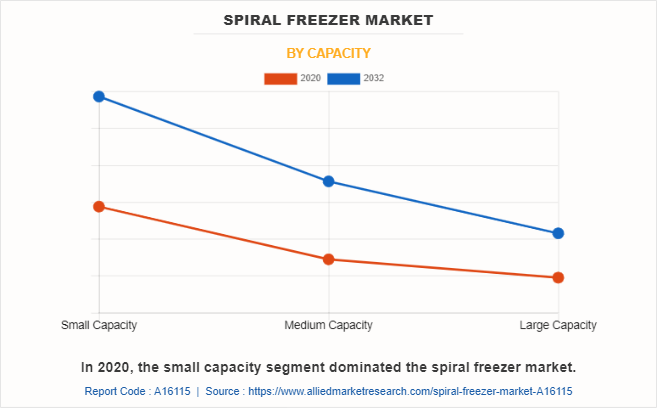

By Capacity:

The spiral freezer market is divided into small capacity, medium capacity, and large capacity. In 2020, the small capacity segment dominated the spiral freezer market, in terms of revenue, and medium capacity is expected to maintain this trend during the forecast period. Mini or small spiral freezers are ideal for processors looking for a scalable solution that is fully welded, mechanical, and compact. Moreover, the increase in consumption of seasonal food throughout the year has fueled the growth of the segment.

For small capacities, compact spiral freezers are fully assembled in the factory prior to shipping. Self-cleaning with an internal center drum washer manifold as a standard feature, continuous inline food freezing, and gentle smooth handling of products are a few benefits of small-capacity spiral freezers. Such factors are driving the segment growth. Moreover, key players in the market are implementing strategic moves such as partnerships and business expansion to improve their market position. For instance, in March 2019, Marlen International, Inc., a global manufacturer of highly engineered food processing equipment and systems, formally partnered with MT Food Systems to better support the growth of food processing equipment solutions in Asia/Oceania. Such factors are driving the spiral freezer market growth.

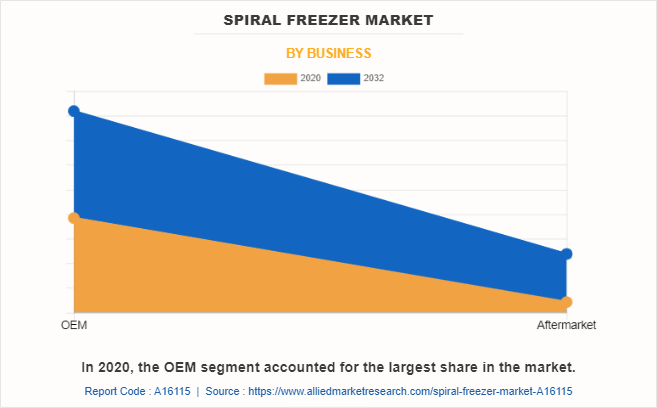

By Business:

The spiral freezer market is classified into OEM and aftermarket. In 2020, the OEM segment accounted for the largest share of the market, and the aftermarket is expected to grow rapidly during the forecast period. Various spiral freezer manufacturers including VDL Systems, GEA Group, FPS Food Processing Solutions, ICS Spiral Freezers, RMF Works, Mayekawa, and others are having healthy competition in manufacturing spiral freezers and their technologies. For instance, VDL Systems designs and manufactures several types of spiral freezers.

These machines find their way to the end market through several OEMs of food processing equipment. In addition to building traditional site-built systems, VDL Systems has developed a unique, hygienic, and modular packaged concept that significantly reduces the on-site construction time. This unique spiral system is entirely constructed of stainless steel and can be prefabricated and then installed on-site.

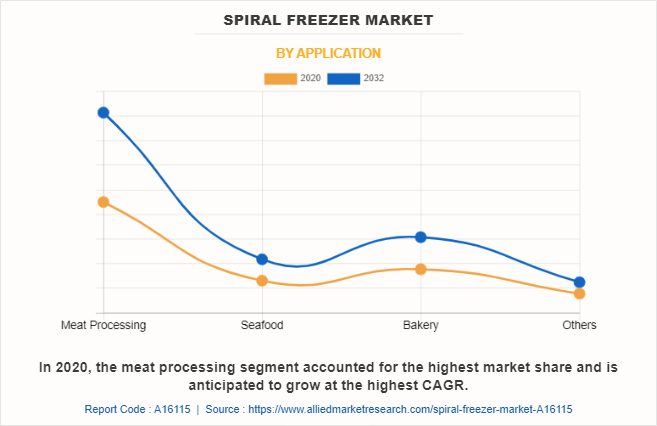

By Application:

The spiral freezer market is categorized into meat processing, seafood, bakery products, and others. In 2020, the meat processing segment accounted for the highest market share and is anticipated to grow at the highest CAGR. Spiral freezer helps in increasing production capacity and efficiency. It also optimizes hygiene procedures and increases flexibility to provide opportunities for long-term business planning. The advanced spiral system helps to maximize uptime and requires minimal ongoing maintenance.

Furthermore, temperature control and a unique airflow are specially designed for delicate products such as skin on sausages, ensuring product quality. Hence, such factors are fueling the growth of the spiral freezer market for the meat processing segment.

Moreover, the increase in population in countries like U.S., China, India, Germany, Brazil, and others leads to an increase in the consumption of meat. The U.S. was the largest consumer of beef in the world in 2020 followed by China, the EU, Brazil, and India. Meat processing is the largest industry group in food and beverage manufacturing, based on sales, value-added, and employment. Meat processing includes livestock and poultry slaughter, processing, and rendering. According to the U.S. Department of Agriculture, it is the largest industry group in food and beverage manufacturing, with 26.2% of sales in 2021. All such factors are expected to boost the spiral freezer market growth during the forecast period.

By Region:

The spiral freezer market is analyzed across North America, Europe, Asia-Pacific, and LAMEA. In 2021, Asia-Pacific held the highest spiral freezer market share and is anticipated to secure the leading position during the forecast period, due to extensive demand from the growing population for frozen food. Growth in the food & beverage industry in developing and developed countries such as India, China, Japan, and Singapore is expected to surge demand for spiral freezers during the forecast period. Various rules and regulations in the food & beverages sector have led to a rise in demand for spiral freezers.

These regulations affect many industries including the food and beverage processing industries to manufacture fresh and safe foods. In addition, population growth, health awareness, expanding the food and beverage industry, and stringent environmental regulations are propelling the growth of the spiral freezer market in the region. For instance, in October 2020, Nestle India Ltd. based in India announced to invest $351 million in Gujarat, India to set up a new plant for the production of food and bakery products. Similarly, in September 2021, a multinational food processing company, ADM revealed its new 27,000 square meter fully automated foods & beverages production facility in Pinghu, China. As a result, such factors provide lucrative growth opportunities for the spiral freezer market during the forecast period.

Competitive Analysis

Competitive analysis and profiles of the major players in the Spiral Freezer end-user, such as Dantech Freezing Systems, FPS food process solutions, Scanico a/s, Sinteco Impianti, ICS Spiral Freezers, Mayekawa, GEA Group AG, LINDE PLC, RMF Works, and VDL Systems BV are provided in this report. There are some important players in the market such as GEA Group, FPS food process solutions, and Linde PLC. Major players have adopted product launch and acquisition as key developmental strategies to improve the product portfolio of the Spiral Freezer market.

Some examples of product launches in the market

In May 2021, Food Process Solutions launched its spiral immersion system (SIS) for food processors in North America. This system enhances greater performance and saves energy and labor costs. Heat is transported 25 times quicker in water or brine solution and is more flexible than cooling or freezing in air. Continuous immersion processing can be carried out on a spiral conveyor in a liquid tank at temperatures ranging from 40 °C to + 90 °C.

In March 2021, Dantech Freezing Systems introduced spiral sous vide and freezer lines at IN Foods Danish Food Factory. This freezing system is fully automated and saves manpower, cost, and water usage. This innovative breakthrough lowers production costs while saving a lot of energy.

Key Benefits For Stakeholders

- The report provides an extensive analysis of the current and emerging Spiral Freezer market trends and dynamics.

- An in-depth spiral freezer market analysis is conducted by constructing market estimations for the key market segments between 2020 and 2032.

- An extensive analysis of the Spiral Freezer market outlook is conducted by following key product positioning and monitoring of the top competitors within the market framework.

- A comprehensive analysis of all regions is provided to determine the prevailing opportunities.

- The spiral freezer market forecast analysis from 2023 to 2032 is included in the report.

- The key market players within the Spiral Freezer market are profiled in this report and their strategies are analyzed thoroughly, which helps understand the competitive outlook of the Spiral Freezer industry.

Spiral Freezer Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 7.3 billion |

| Growth Rate | CAGR of 4.9% |

| Forecast period | 2020 - 2032 |

| Report Pages | 220 |

| By Capacity |

|

| By Application |

|

| By Business |

|

| By Region |

|

| Key Market Players | GEA Group AG, Dantech Freezing Systems, VDL Systems BV, Linde plc, RMF Works, SCANICO A/S, ICS Spiral Freezers, Sinteco impianti, FPS food process solutions, Mayekawa |

Analyst Review

The spiral freezer market has witnessed significant growth in the past few years, owing to an increase in demand for meat processing, seafood & fish, and bakery products. Moreover, the rise in demand for seasonal food has fueled market growth throughout the year. Moreover, there is a rise in demand for frozen and chilled food due to changes in people's lifestyles and food preferences. In addition, the frozen and chilled food demand by consumers changes daily, resulting in a wide range of processed products being produced.

The rise in demand for spiral freezers in countries such as the U.S., Canada, the UK, Germany, and China is fueled due to increase in the consumption of meat and seafood. Furthermore, the surge in preference for consuming good quality food products is positively influencing the market growth. Medium-capacity spiral freezers are extensively used in the food & beverages manufacturing sector owing to their larger capacities and lower energy costs. Apart from these positive factors, the market is negatively impacted by strict government regulations regarding food & beverage manufacturing.

Moreover, the integration of the latest advanced technologies such as automation in the freezing technology is providing lucrative opportunities for the growth of the market.

The global spiral freezer market was valued at $4,125.2 million in 2020, and is projected to reach $7,275.8 million by 2032, registering a CAGR of 4.9% from 2023 to 2032.

The base year considered in the global Spiral Freezer market report is 2022.

Meat Processing s the leading application of the Spiral Freezer Market.

Asia-Pacific is the largest regional market for Spiral Freezer.

The rise in demand for frozen foods is the upcoming trend of the Spiral Freezer Market in the world.

Dantech Freezing Systems, FPS food process solutions, Scanico a/s, Sinteco Impianti, ICS Spiral Freezers, Mayekawa, GEA Group AG, LINDE PLC, RMF Works, and VDL Systems BV are the top companies to hold the market share in Spiral Freezer.

The top 10 market players are selected based on two key attributes- competitive strength and market positioning.

The report contains an exclusive company profile section, where leading 10 companies in the market are profiled. These profiles typically cover company overview, geographical presence, market dominance (in terms of revenue and volume sales), various strategies and recent developments.

Loading Table Of Content...

Loading Research Methodology...