Steel Powder For 3D Printing Market Research, 2033

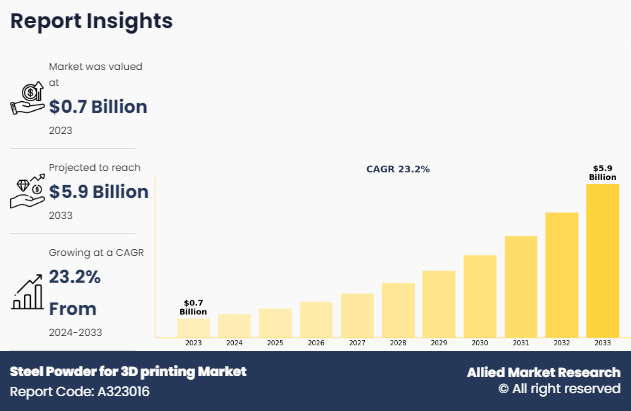

The global steel powder for 3d printing market was valued at $0.7 billion in 2023,, and is projected to reach $5.9 billion by 2033, growing at a CAGR of 23.2% from 2024 to 2033. The global steel powder for 3D printing market has experienced growth due to several factors such as advancements in additive manufacturing technology, properties of steel powder, and an increase in demand for customization. However, the high initial investment costs, technical challenges, and regulatory hurdles limit the market expansion. However, the expansion in healthcare applications and innovations in steel powder properties provide lucrative opportunities for steel powder for 3D printing market growth.

Introduction

Steel powder for 3D printing is a finely ground steel used as a raw material in various metal additive manufacturing processes. These powders are crafted to exhibit specific properties such as uniform particle size (typically between 15 to 45 microns), excellent flowability, and optimal packing density to ensure high-quality prints. They come in various compositions, including stainless steel, tool steel, and maraging steel, each tailored to achieve desired outcomes such as strength and corrosion resistance.

Steel powder is used in printing technologies such as Selective Laser Melting (SLM) and Electron Beam Melting (EBM). Furthermore, steel powder enables the creation of complex, customized metal parts in sectors such as aerospace, automotive, and medical. The properties of steel powders, such as their flowability and particle size distribution, play crucial roles in the precision and strength of the final printed products.

Market Dynamics

Additive manufacturing, commonly known as 3D printing, has made significant technological strides since 2014, particularly with the ability to print using a variety of materials, including metals such as steel. Innovations in printer design, printing processes, and material handling have improved the quality and efficiency of 3D-printed metal components. For steel powder, these advancements mean enhanced usability and broader application possibilities. Improved layer adhesion, increased printing speed, and finer resolution allow for more complex part geometries and better mechanical properties, which in turn boosts the demand for high-quality steel powder. As 3D printers become more capable, the steel powder optimized for these systems grows critically, expanding its market.

The cost of steel powder for 3D printing is a significant restraint on the market, primarily due to the complexities involved in its production and the quality required for end-use applications. Producing steel powder suitable for 3D printing involves atomizing molten steel into fine particles under controlled conditions, a process that demands specialized equipment and high energy input. In addition, the steel powder must meet stringent specifications in terms of particle size distribution, shape, and purity to ensure high-quality prints, which further escalates production costs. These high costs are then transferred to the consumers, making 3D-printed steel components less competitive against traditional manufacturing methods, particularly in sectors sensitive to price fluctuations. The result restricted market growth as potential users hesitated to adopt this technology due to its initial and operational cost implications.

The healthcare industry continually seeks advanced materials to improve the quality and efficiency of medical devices and implants. Steel powder for 3D printing offers significant opportunities in this sector due to its capacity to create complex, customized shapes with high precision and mechanical strength. For instance, 3D-printed steel is used to manufacture bespoke surgical tools, orthopedic implants, and prosthetics that precisely match a patient's anatomy, improving patient outcomes. As regulatory bodies increasingly approve 3D-printed medical products, demand for steel powders with biocompatibility and superior mechanical properties is expected to rise, driving growth in this segment.

Segments Overview

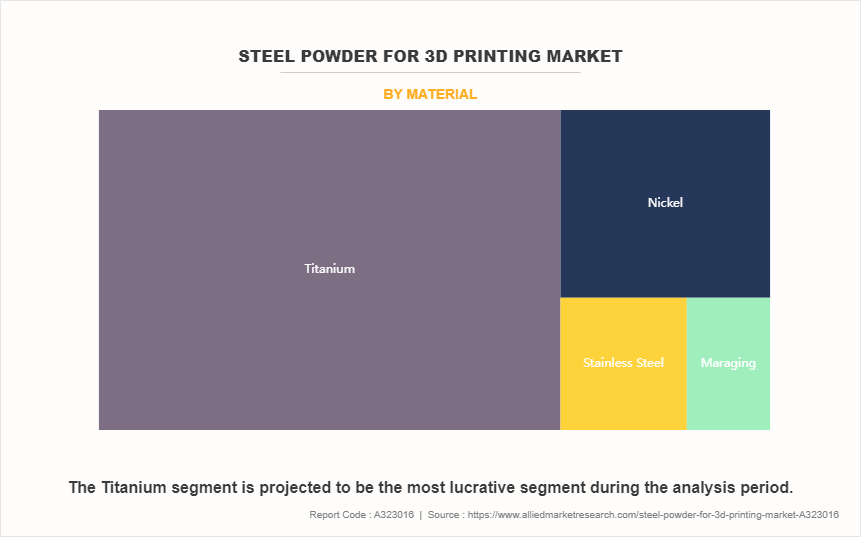

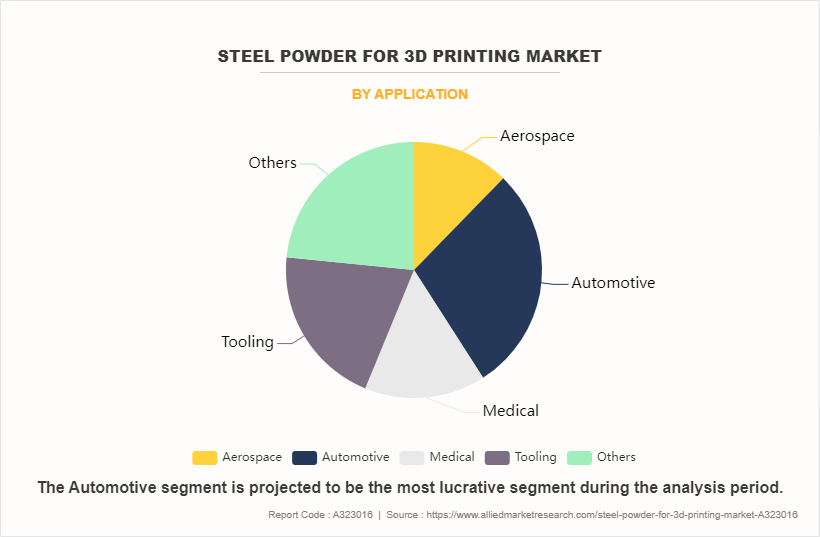

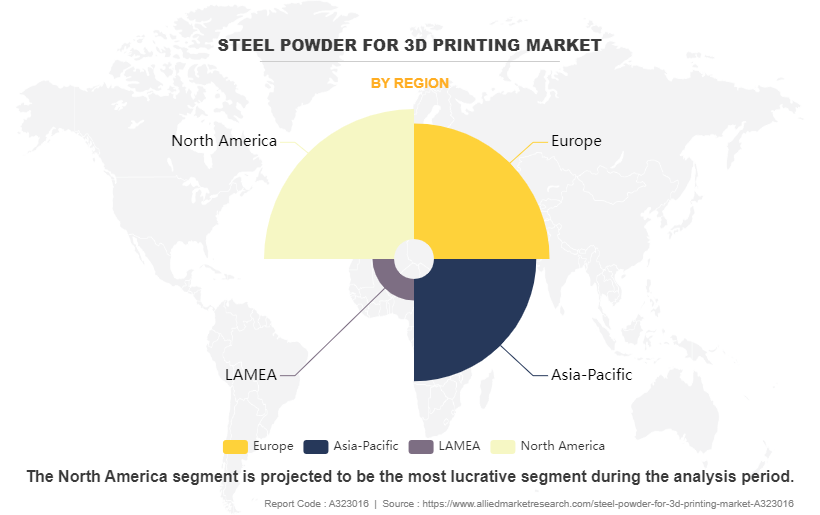

The steel powder for 3D printing market is segmented into material, application, and region. On the basis of material, the market is divided into stainless steel, nickel, titanium, and maraging. On the basis of application, the market is classified into aerospace, automotive, healthcare, tooling, and others. On the basis of region, the steel powder for 3D printing market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

By material, the titanium segment dominates the steel powder for 3D printing market size due to its unique properties, which are highly advantageous in key industries utilizing additive manufacturing. Titanium's exceptional strength-to-weight ratio is crucial in sectors such as aerospace and automotive, where reducing material weight while maintaining structural integrity significantly enhances performance and fuel efficiency.

In addition, titanium's superior corrosion resistance makes it ideal for harsh environments such as marine and chemical processing applications, extending the lifespan of parts exposed to corrosive elements. In the medical field, titanium's biocompatibility is essential for implants, such as those used in orthopedics and dentistry, due to its ability to integrate with human bone without adverse effects. Its resilience at high temperatures suits applications such as jet engines and other aerospace components, where materials must withstand extreme conditions. Finally, titanium's relatively low elastic modulus allows for a degree of flexibility necessary for certain biomedical applications, mimicking the mechanical properties of human bone. These distinctive attributes, coupled with the capability of 3D printing to produce complex and precise designs, firmly establish titanium as a preferred material in the steel powder for 3D printing market forecast.

By application, the automotive segment dominates the steel powder for 3D printing market share. The automotive industry seeks to innovate and improve vehicle performance, efficiency, and cost-effectiveness through 3D printing technology. 3D printing with steel powder allows for the production of complex, lightweight, and robust parts that are often too intricate or uneconomical to manufacture using traditional methods. Components such as engine parts, transmission components, and customized exhaust systems are designed with internal structures that reduce weight without compromising strength, leading to better fuel efficiency and reduced emissions. Sintavia signed a contract with Bechtel Plant Machinery Inc. to create a dedicated AM facility, also in the Ft. Lauderdale area, in support of the U.S. Navy Nuclear Propulsion Program. Sintavia also received a strategic investment from Lockheed Martin in the summer of 2023.

In addition, the ability to rapidly prototype with steel powders significantly accelerates the development process, enabling faster iterations and a shorter time-to-market for new vehicle designs. Moreover, the localized and on-demand production capabilities of 3D printing align with the automotive industry's push toward more sustainable manufacturing practices by reducing waste and transportation costs. Thus, the unique advantages offered by steel powder for 3D printing meet the critical demands of the automotive sector, making it a primary market for this technology.

North America has a well-established industrial base and infrastructure, which aids in the manufacturing, distribution, and extensive commercialization of advanced manufacturing technologies, including those involving steel powder. This comprehensive ecosystem, coupled with a strong push toward technological innovation and a favorable business climate, positions North America as a leading player in the global steel powder for 3D printing market.

In addition, the region benefits from the presence of major aerospace, automotive, and healthcare industries, which are leading sectors that have adopted 3D printing technologies for production purposes. These industries demand high-performance materials with specific properties, such as steel powders, to create complex, lightweight, and durable components. Moreover, the U.S. government and its regulatory frameworks actively support the additive manufacturing industry through initiatives and funding, further encouraging exploration and adoption of 3D printing technologies.

Competitive Analysis

The major players operating in the steel powder for 3D printing market include Daido Steel Co., Ltd., Toray Precision Co., Ltd., Fushun Special Steel, US Research Nanomaterials, Inc., Luoyang Tongrun Nano Technology Co., Ltd, CNPC powder, American elements, Hoganas AB, EOS GmbH, and Markforged.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the steel powder for 3d printing market analysis from 2023 to 2033 to identify the prevailing steel powder for 3d printing market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the steel powder for 3d printing market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global steel powder for 3d printing market trends, key players, market segments, application areas, and steel powder for 3D printing industry growth strategies.

Steel Powder for 3D printing Market Report Highlights

| Aspects | Details |

| Market Size By 2033 | USD 5.9 billion |

| Growth Rate | CAGR of 23.2% |

| Forecast period | 2023 - 2033 |

| Report Pages | 291 |

| By Material |

|

| By Application |

|

| By Region |

|

| Key Market Players | American Elements Corporation, Markforged, Inc., EOS GmbH, U.S. Research Nanomaterials, Inc., Fushun Special Steel Co., Ltd., CNPC Powder, Daido Steel Co., Ltd., Toray Precision Co., Ltd., Luoyang Tongrun Nano Technology Co., Ltd., Höganäs AB |

Analyst Review

CXOs in the steel powder 3D printing industry are aware of the significant growth opportunities ahead during the forecast period. The global steel powder 3D printing market is set to experience robust demand, primarily driven by the increase in the adoption of additive manufacturing across various sectors, including aerospace, automotive, and healthcare. The capability of 3D printing to produce complex parts with high precision and reduced waste fuels this growth trajectory, thereby creating a favorable market landscape.

In pursuit of innovation and market leadership, CXOs understand the critical role of steel powder as a fundamental material in 3D printing that offers exceptional strength and durability for printed parts. With a range of steel powder types, such as stainless steel, tool steel, and maraging steel, the industry provides solutions that meet a wide array of customer specifications and requirements.

CXOs are confident in their strategies to leverage several market drivers, including the strong industrial shift toward lightweight and durable manufacturing materials. In addition, the support of technological advancements in 3D printing machines and techniques, which enhance the properties and usability of steel powder, boosts market adoption. The surge in the adoption of metal 3D printing for production applications in key industries such as aerospace, automotive, and construction presents lucrative opportunities for growth and expansion.

According to historical trends in 2023, the stainless-steel powder segment emerged as a significant player, capturing a considerable share of the 3D printing materials industry due to its corrosion resistance and strength, appealing to industries such as medical devices and automotive manufacturing. The growth in the aerospace sector, which heavily relies on precise and durable components, boosts the increased demand for high-performance steel powders throughout the forecast period.

CXO predictions indicate that the industrial application segment of steel powder 3D printing is expected to experience the highest growth rate during the forecast period. Recognizing this potential, CXOs are strategically positioning their operations, whether in sales or production, to cater to this rise in demand and capture a significant share of the market growth.

The automotive sector has proven to be a critical contributor, holding a substantial market share in 2023. CXOs expect this trend to continue in the coming years, driven by continuous innovations in automotive design and manufacturing technologies, particularly in emerging economies.

$5.9 billion is the estimated industry size of steel powder for 3D printing market in 2033.

The upcoming trends in the steel powder for 3D printing market: 1. Increased Use of Maraging Steel 2. Integration with Industry 4.0 Technologies 3. Expansion in Healthcare Applications 4. Enhanced Recycling Processes 5. Advancements in Atomization Techniques

Automotive is the leading application of Steel Powder for 3D Printing Market in 2023.

North America is the largest regional market for Steel Powder for 3D printing Market in 2023.

Daido Steel Co., Ltd., Toray Precision Co., Ltd., Fushun Special Steel, US Research Nanomaterials, Inc., Luoyang Tongrun Nano Technology Co., Ltd, CNPC powder, American elements, Hoganas AB, EOS GmbH, and Markforged. are the top companies to hold the market share in Steel Powder for 3D printing Market.

Loading Table Of Content...

Loading Research Methodology...