Submersible Pumps Market Research, 2032

The global submersible pumps market size was valued at $12.7 billion in 2022, and is projected to reach $24.4 billion by 2032, growing at a CAGR of 6.9% from 2023 to 2032. Urbanization and industrialization are driving the need for efficient water management systems, thus fueling the demand for submersible pumps in wastewater treatment plants.

Report Key Highlighters:

- The submersible pumps industry covers 20 countries. The research includes a segment analysis of each country in terms of value ($million) for the projected period 2023-2032.

- The study integrated high-quality data, professional opinions and analysis, and critical independent perspectives. The research approach is intended to provide a balanced view of global submersible pumps markets and to assist stakeholders in making educated decisions in order to achieve their most ambitious growth objectives.

- Over 3,700 product literature, annual reports, industry statements, and other comparable materials from major industry participants were reviewed to gain a better understanding of the market.

- The submersible pumps market share is highly fragmented, with several players including EBARA CORPORATION, Franklin Electric Co., Inc., Grundfos Pumps India Private Ltd., KIRLOSKAR BROTHERS LIMITED, KSB Limited, Pentair, Sulzer Ltd, TSURUMI MANUFACTURING CO., LTD., WILO SE, and Xylem. Also tracked key strategies such as acquisitions, product launches, mergers, expansion etc. of the players operating in the submersible pumps market growth.

Introduction

Submersible pumps are a class of mechanical devices used to move liquid from one place to another while being submerged in the liquid. They are designed to operate underwater and are commonly used to transport water, sewage, and other fluids. These pumps consist of a hermetically sealed motor that is closely coupled to the pump body. The entire assembly is submerged in the fluid to be pumped. This design ensures that the pump operates without the need for external priming, and it is well-suited for various applications.

Submersible pumps play a critical role in modern agriculture by efficiently irrigating fields and providing water for livestock. These pumps submerged in wells, boreholes, or water sources, ensuring a consistent water supply for farming operations. Submersible pumps are commonly used in residential water supply systems, as well as in municipal water distribution networks. They are employed to pump water from underground sources such as wells and boreholes, ensuring that clean and safe water reaches homes and communities.

In agriculture, submersible pumps play a critical role in irrigation systems. Farmers use these pumps to draw water from underground wells or natural bodies of water such as rivers or lakes. This ensures the proper irrigation of crops, even in regions where rainfall is scarce. By efficiently lifting large volumes of water to the surface, these pumps help sustain agricultural productivity and ensure food security. Another common application of submersible pumps is in the mining industry. Mining operations often deal with large quantities of water, either from underground aquifers or the mining process itself. Submersible pumps are used to dewater mining sites, ensuring that mining operations can proceed without the risk of flooding. Additionally, in the oil and gas industry, submersible pumps—particularly electrical submersible pumps (ESPs) are employed to lift oil from underground reservoirs to the surface. These pumps are highly efficient and can operate under extreme conditions, making them vital to industry.

In the construction industry, submersible pumps serve a crucial role in dewatering operations.

Increase in demand of submersible pumps for dewatering operations is expected to drive the growth of the submersible pumps market. Dewatering is the process of removing excess water from construction sites, foundation excavations, and basements to ensure that construction projects proceed smoothly and safely. Submersible pumps are the equipment of choice for these tasks due to their efficiency, reliability, and ability to operate underwater. Large construction sites are vulnerable to water accumulation, especially during rainy seasons. Submersible pumps are strategically located in low-lying areas to quickly pump out standing water, preventing work delays and potential damage to heavy machinery.

Municipal wastewater treatment plants are responsible for collecting, treating, and safely disposing of sewage and wastewater from households, commercial establishments, and other sources. Submersible pumps are submerged directly in sewage or wastewater, allowing them to draw in the liquid and effectively transport it to the treatment processes. This submersion eliminates the need for external priming, making them highly reliable in these critical applications. They handle a wide range of flow rates and are designed to manage both liquid and solid waste, including suspended solids, sludge, and organic matter.

The mining industry relies on submersible pumps to remove water from deep mine shafts.

These pumps are essential for keeping mines dry and ensuring safe working conditions for miners. Deep underground mines often encounter water seepage or flooding due to natural aquifers. Water infiltration into mining operations poses substantial safety hazards to miners and can disrupt mining activities. Submersible pumps play a crucial role in removal of this water from the mine shafts.

Submersible pumps are commonly employed in oil wells to extract crude oil from deep underground reservoirs. These pumps are part of the artificial lift systems used in the oil industry. They are typically submerged in the wellbore and are responsible for lifting the oil to the surface. Submersible pumps are well-suited for this purpose due to their efficiency and ability to handle the demanding conditions of oil wells. In the natural gas industry, submersible pumps are used for similar purposes. They aid in the extraction of natural gas from underground reservoirs. These pumps are capable of handling the challenges posed by gas wells, including the presence of gas, liquids, and solids. Submersible pumps ensure a consistent flow of natural gas and contribute to the efficient operation of gas production facilities.

In addition to submersible pumps used in wells on land, offshore drilling platforms in the oil and gas industry rely on submersible pumps for various tasks including the movement of drilling mud, which is essential for drilling operations in deep-sea environments. They also play a role in handling wastewater and ensuring the safe operation of offshore facilities.

Clogging and abrasion of submersible pumps is expected to hinder growth during the forecast period. The use of submersible pumps in situations with water containing high levels of solids or debris leads to common challenges such as clogging and abrasion. Clogging occurs when solid particles in the water disrupt the pump's flow, reducing or blocking water flow. Abrasion is the deterioration of pump components caused by abrasive solids in the water. The size and composition of these solids play a significant role, with larger particles causing clogs and abrasive materials leading to component wear. Dealing with frequent clogging and abrasion requires frequent maintenance and cleaning, resulting in costly downtime and disruptions to critical processes.

Segments Overview

The submersible pumps market is segmented into type, capacity, application, end-use industry, and region. On the basis of type, the market is divided into electric, hydraulic, and air driven. As per capacity, the market is categorized into low, medium, and, high. Based on application, the market is bifurcated into open pit, and borewell. Depending on end-use industry, the market is classified into water and wastewater, oil & gas, mining and construction, and others. Region wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

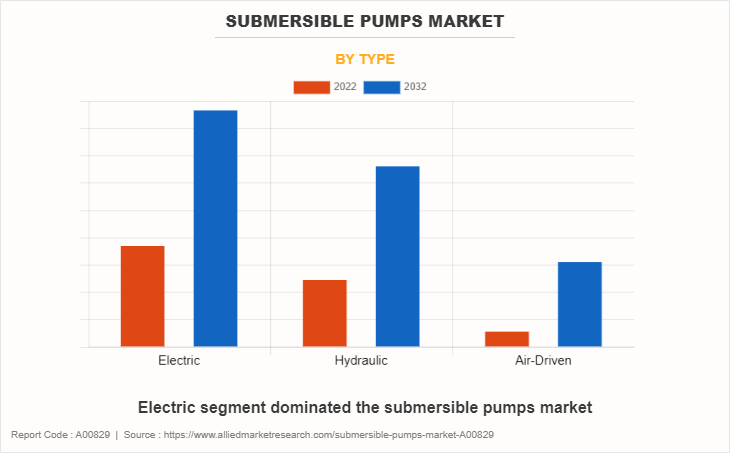

By Type

By type, the electric segment dominated the global submersible pumps market and accounted for more than one-third of the market revenue in 2022. It is expected to witness a CAGR of 6.7% during the forecast period. Electric submersible pumps are used in a wide array of sectors, including agriculture for irrigation, oil and gas for extracting liquids, and construction for dewatering sites. Their ability to handle both clean and contaminated water, as well as harsh environments, makes them versatile in different applications. Furthermore, advances in technology have led to more durable, corrosion-resistant materials and more efficient motor designs, thus enhancing the performance and lifespan of electric submersible pumps in challenging industries.

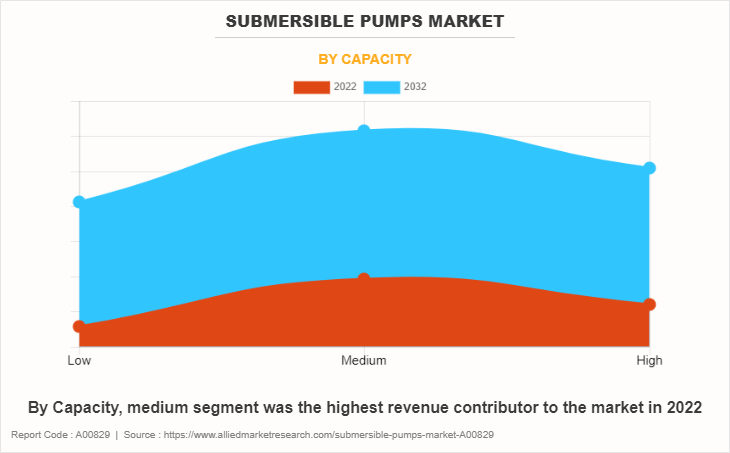

By Capacity

On the basis of capacity, the medium segment dominated the submersible pumps market in 2022 and is expected to witness a CAGR of 6.5% during the forecast period. Medium capacity submersible pumps typically have a capacity ranging from 20 to 200 gallons per minute (GPM). It is crucial to determine the maximum submersion depth that the pump will be subjected to. This depth refers to how far below the liquid surface the pump will be placed. It is important to choose a pump that is suitable for the intended depth and has the necessary sealing mechanisms to prevent water ingress. Submersible pumps with medium capacity typically range from 1/2 HP to 1 HP. However, larger applications may require higher horsepower options, which ranges from 1 HP to several hundred HP, for commercial or industrial purposes.

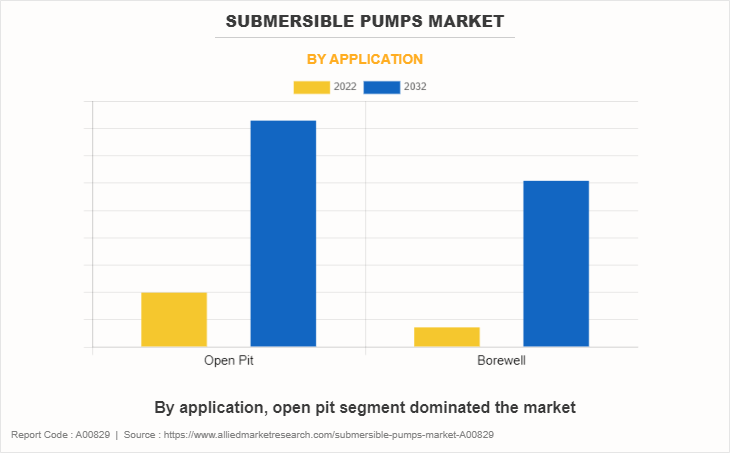

By Application

By application, the open pit segment dominated the submersible pumps market in 2022 and is expected to witness a CAGR of 6.7% during the forecast period. In open-pit dewatering, submersible slurry pumps are commonly used to remove standing water from the bottom of a construction excavation area. These pumps are reliable and inexpensive to operate, and they can handle high solid content in the water. They can be powered by either diesel or electric drive units, and they can be lowered into the pit to remove the standing water.

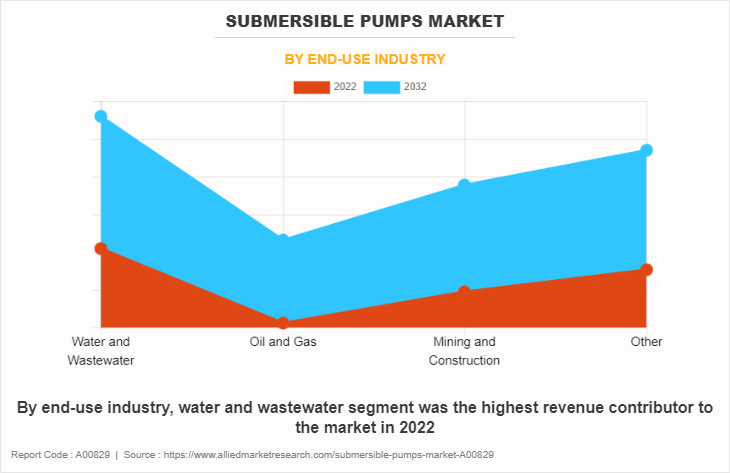

By End use Industry

By end-use industry, the water and wastewater segment dominated the market in 2022 and is expected to witness a CAGR of 6.5% during the forecast period. Submersible pumps are widely used in the grit and wastewater industry. They are often used in pump and lift stations as they are compact and less costly to install than other pumps. Sewage treatment requires submersible pumps, such as grinder pumps, that can transport solid material without obstruction from pump inlet to discharge. These pumps often reduce sewage material to particles for easier handling and downstream treatment. Deep-well submersible pumps and vertical turbine pumps are the two most common submersible pump configurations used for irrigation.

By Region

Region wise Asia-Pacific was the highest revenue contributor in the submersible pumps market accounting for more than one-third of the market share and is expected to witness a CAGR of 7.2% during the forecast period. Asia-Pacific is experiencing rapid urbanization and infrastructure development. These pumps effectively drain water out of basements, excavations, and other building sites, saving time and ensuring worker safety. To prevent water intrusion, submersible pumps are widely used in the building industry in nations like South Korea, Japan, and India. Countries such China, India, Indonesia, and Thailand, rely heavily on submersible pumps to ensure water supply for both agricultural and domestic purposes, thus addressing the challenges of water scarcity and management. Additionally, the growing urbanization in cities across the region has increased the demand for reliable submersible pump systems in municipal water and sewage applications.

Competitive Analysis

The major players operating in the submersible pumps market include EBARA CORPORATION, Franklin Electric Co., Inc., Grundfos Pumps India Private Ltd., KIRLOSKAR BROTHERS LIMITED, KSB Limited, Pentair, Sulzer Ltd, TSURUMI MANUFACTURING CO., LTD., WILO SE, and Xylem.

Historic Trends of Submersible Pumps Market:

- In 1950s the concept of submersible pumps gained attention as a more efficient and compact solution for water pumping compared to traditional above-ground pumps. Early applications were primarily focused on groundwater extraction for agricultural and domestic purposes.

- In 1980s the advancements in materials and pump design led to improved efficiency and durability of submersible pumps. During this period, the technology expanded its reach to industrial and municipal water supply systems. Submersible pumps became recognized for their reliability and ability to operate in various environments.

- In 1990s growing concerns about water conservation and energy efficiency drove the adoption of submersible pumps in water management systems. The technology saw increased use in wastewater treatment, aquaculture, and mining applications. Innovations in pump design and motor technology further enhanced performance.

- In the early 2000s a surge in the use of submersible pumps, driven by the need for sustainable water management solutions. Advanced sensor technologies and remote monitoring capabilities were integrated into submersible pumps, allowing for improved control and maintenance.

- In 2010s stricter regulations on water usage and a focus on renewable energy in pumping systems led to the continued growth of submersible pump installations. Smart technologies, such as variable frequency drives, became more prevalent, optimizing energy consumption and increasing overall efficiency.

- In 2020s the demand for submersible pumps continued to rise as water scarcity issues intensified globally. Ongoing research and development efforts focused on enhancing pump performance, exploring new materials, and integrating digital technologies for better monitoring and control. The submersible pump became an integral component in sustainable water solutions and was widely adopted in agricultural, industrial, and municipal sectors.

Key Benefits for Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the submersible pumps market analysis from 2022 to 2032 to identify the prevailing submersible pumps market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the submersible pumps market forecast to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global submersible pumps market trends, key players, market segments, application areas, and market growth strategies.

Submersible Pumps Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 24.4 billion |

| Growth Rate | CAGR of 6.9% |

| Forecast period | 2022 - 2032 |

| Report Pages | 300 |

| By Type |

|

| By Capacity |

|

| By Application |

|

| By End-Use Industry |

|

| By Region |

|

| Key Market Players | TSURUMI MANUFACTURING CO., LTD., Sulzer Ltd., Xylem Inc., Pentair, EBARA CORPORATION, Franklin Electric, KSB Limited, Kirloskar Brothers Limited., WILO SE, Grundfos Pumps India Private Ltd. |

Analyst Review

According to the opinions of various CXOs of leading companies, the global submersible pumps market was dominated by the electric segment. In electric applications, submersible pumps are frequently used to aerate attractive ponds and fountains. In circulating water around and providing oxygen, these pumps enhance the quality of the water and produce eye-catching water features. The submerged design preserves the water feature's attractiveness by hiding the pump from view.

Increase in focus on water resource management drives the growth of the submersible pumps market. Submersible pumps play a crucial role in accessing groundwater, especially in areas with limited surface water sources. They are submerged in wells or boreholes to efficiently extract water from deep underground, ensuring a reliable water supply. These pumps are also vital for wastewater treatment, as they help move sewage and wastewater in treatment plants, effectively handling various contaminants and solids.

However, clogging and abrasion of submersible pumps are expected to restrain industry expansion. Submersible pumps often face challenges with clogging and abrasion, particularly in environments where water contains high levels of solid particles or debris. Clogging occurs when these particles disrupt the pump's flow, leading to reduced or blocked water flow. Abrasion happens when abrasive particles in the water cause wear and tear on the pump's components. The size and composition of these particles are key factors in these issues. Larger particles are more likely to cause clogs, while smaller abrasive lead to component degradation.

The Asia-Pacific region is projected to register robust growth during the forecast period. The Asia-Pacific area has an abundance of mineral resources, and mining is a common industry. For controlling water buildup in underground mines, submersible pumps are used in mining operations. These pumps are a dependable option for dewatering in mining due to their ability to endure challenging circumstances. Many countries in the area, including Australia, Indonesia, and Mongolia, have sizable mining industries that depend on submersible pumps.

Smart pumping solutions in submersible pumps and water recycling and treatment are the upcoming trends of submersible pumps market in the world.

Open pit are the leading application in submersible pumps market.

Asia-Pacific is the largest region in the submersible pumps market.

The global submersible pumps market was valued at $12.7 billion in 2022, and is projected to reach $24.4 billion by 2032, growing at a CAGR of 6.9% from 2023 to 2032.

Increase in focus on water resource management and surge in mining and construction industry are the main drivers of the submersible pumps market.

The top companies to hold the market share of submersible pumps includes EBARA CORPORATION, Franklin Electric Co., Inc., Grundfos Pumps India Private Ltd., KIRLOSKAR BROTHERS LIMITED, KSB Limited, Pentair, Sulzer Ltd, TSURUMI MANUFACTURING CO., LTD., WILO SE, and Xylem.

Clogging and abrasion of submersible pumps are the restraint factor of the submersible pumps market.

Loading Table Of Content...

Loading Research Methodology...