Ultra-High Performance Concrete Market Research, 2034

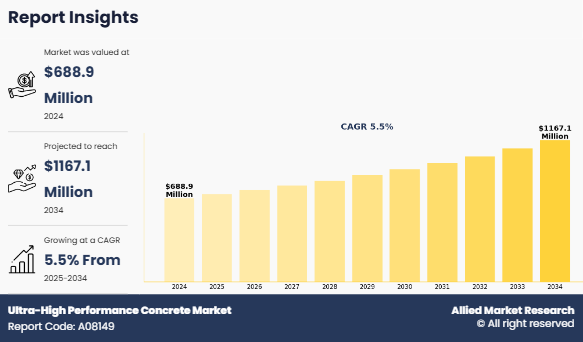

The global ultra-high performance concrete market size was valued at $688.9 million in 2024, and is projected to reach $1167.1 million by 2034, growing at a CAGR of 5.5% from 2025 to 2034.

Ultra-High-Performance Concrete (UHPC) is a cutting-edge material offering unprecedented strength, durability, and longevity compared to traditional concrete. With compressive strengths exceeding 150 MPa (megapascal) and exceptional tensile strength, UHPC is achieved through a dense matrix and the inclusion of steel or synthetic fibers.

Ultra-High Performance Concrete (UHPC) offers several advantages, making it a preferred material in modern construction. Its exceptional compressive strength, often exceeding 150 MPa, allows for the design of slimmer, lighter, and more durable structures. UHPC has high resistance to environmental factors such as corrosion, freeze-thaw cycles, and chemical attacks, significantly extending the lifespan of infrastructure with minimal maintenance. Its low permeability prevents water infiltration, reducing damage in harsh conditions. Additionally, UHPC enhances structural efficiency by enabling prefabrication, reducing construction time and labor costs. Its sustainability benefits include reduced material consumption and lower carbon footprint over time. With superior durability and long-term cost savings, UHPC is an ideal solution for resilient and high-performance construction projects.

The rapid expansion of infrastructure projects globally is a major driver for the Ultra-High Performance Concrete Industry. Governments and private organizations are investing heavily in roads, bridges, tunnels, and high-rise buildings that require high-strength, durable, and long-lasting construction materials. UHPC superior mechanical properties, including high compressive strength, corrosion resistance, and low permeability, make it ideal for critical infrastructure applications. Additionally, smart city initiatives are accelerating the demand for UHPC due to its ability to enhance structural efficiency while reducing maintenance costs. As urbanization increases, the need for resilient and sustainable construction materials continues to grow, positioning UHPC as a key solution for future infrastructure projects.

However, the high cost of Ultra-High Performance Concrete is a significant restraint to its widespread adoption. UHPC requires specialized raw materials, including high-grade cement, silica fume, and steel or synthetic fibers, which increase production costs compared to conventional concrete. Additionally, its complex manufacturing process demands advanced mixing techniques, specialized curing methods, and skilled labor, further raising overall construction expenses. Small and medium-sized construction firms often hesitate to use UHPC due to budget constraints. The lack of standardized production methods and limited awareness about UHPCs long-term benefits also hinder its adoption. Overcoming these cost barriers requires technological advancements in cost-effective UHPC production and greater industry awareness of its lifecycle savings.

Furthermore, the increasing focus on sustainable construction practices presents a significant opportunity for the ultra-high performance concrete market growth. With global initiatives to reduce carbon emissions and enhance energy efficiency, UHPC long lifespan and minimal maintenance align well with sustainability goals. Its durability reduces material consumption over time, lowering the environmental impact associated with frequent repairs and replacements. Additionally, UHPCs compatibility with prefabrication techniques minimizes waste generation and improves construction efficiency. As governments introduce stricter regulations for green building certifications, demand for UHPC is expected to rise. Investing in research and development to create cost-effective and eco-friendly UHPC formulations will further accelerate market growth and adoption in sustainable infrastructure projects.

Segmental overview

The ultra-high performance concrete market is segmented into Product Type, Application and End-User Industry.

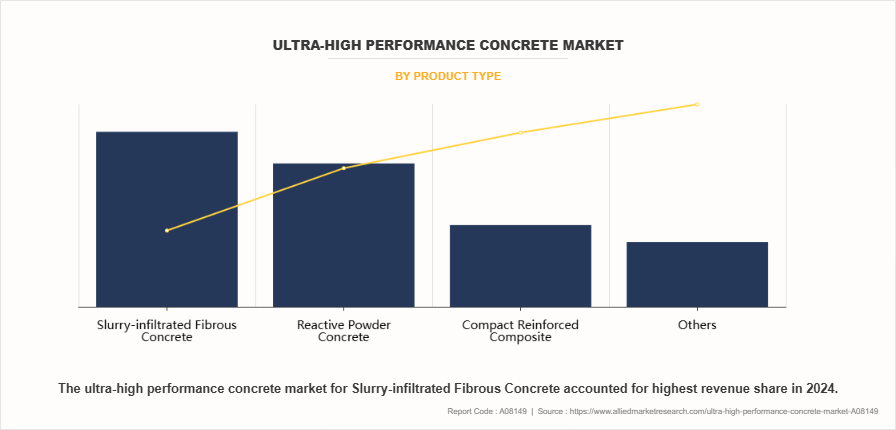

On the basis of Product Type, the market is divided into Slurry-infiltrated Fibrous Concrete, Reactive Powder Concrete¸ Compact Reinforced Composite, and Others.

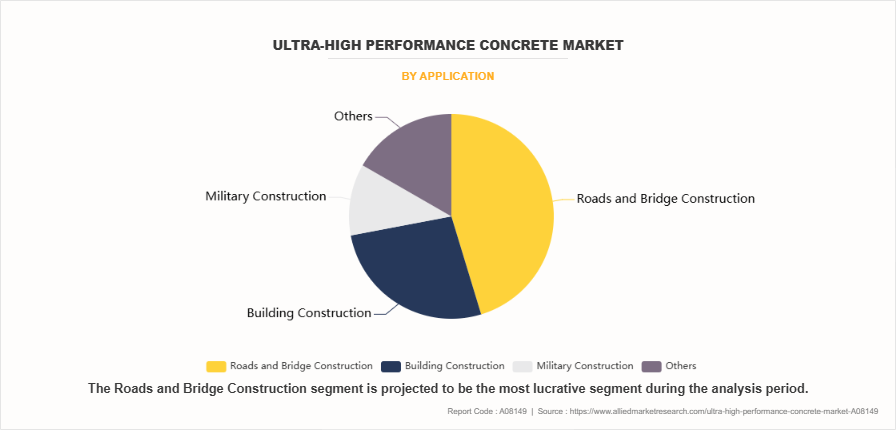

On the basis of Application, the market is segmented into Roads and Bridge Construction, Building Construction, Military Construction, and Others.

On the basis of End-User Industry, the ultra-high performance concrete industry is fragmented into Construction Industry, and Marine Industry.

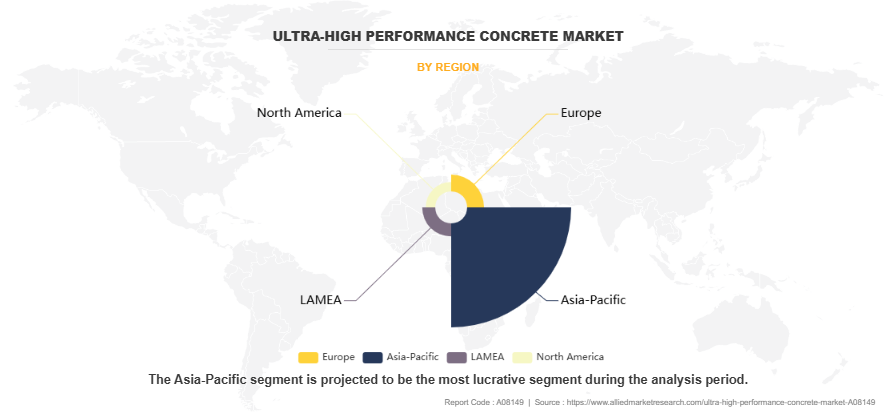

Region wise, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

Competitive Analysis

The key players analyzed in Ultra-High Performance Concrete market includes Heidelberg Materials, Steelike, Inc., TAKTL, ceEntek, UHPC India Pvt. Ltd., HOLCIM, Elementbau Osthessen GmbH & Co., ELO KG, UltraTech Cement Ltd., Sika AG, Gulf Precast, RAMPF Group, Vicat are new product development and collaboration. Market players have adopted various strategies such as product launch, investment, and acquisition to expand their foothold in the Ultra-High Performance Concrete Market Outlook.

Recent Developments in Ultra-High Performance Concrete Industry.

- In February 2024, Heidelberg Materials launched the net-zero concrete, leading the industry's decarbonization. It highlights carbon capture and storage's crucial role, expected to achieve 60% of the UK's carbon savings by 2050.

- In July 2024, Holcim announced the acquisition of the business of King William Sand & Gravel Co., Inc., a private company with a long-standing presence in King William County, Virginia. With this strategic transaction, Holcim gains high-quality sand and gravel reserves that serve the construction needs of customers in the Central Virginia area of the Mid-Atlantic region.

- In February 2023, Sika AG acquired MBCC Group, enhancing its global presence and product range in construction. This acquisition, which required divestitures to Cinven, strengthens Sika sustainable offerings. The combined entity, with 6,200 employees and 95 facilities, anticipated $1,295 million in sales for 2023.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the ultra-high performance concrete market analysis from 2024 to 2034 to identify the prevailing Ultra-High Performance Concrete Market Opportunity.

- The market research is offered along with information related to Ultra-High Performance Concrete Market key drivers, Ultra-High Performance Concrete Market restraints, Ultra-High Performance Concrete Market Share, and Ultra-High Performance Concrete Market Forecast.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the ultra-high performance concrete market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global Ultra-High Performance Concrete market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global ultra-high performance concrete market trends, UHPC Market key players, UHPC market segments, Advanced Concrete application, High-Strength Concrete market growth strategies.

Ultra-High Performance Concrete Market Report Highlights

| Aspects | Details |

| Market Size By 2034 | USD 1167.1 million |

| Growth Rate | CAGR of 5.5% |

| Forecast period | 2024 - 2034 |

| Report Pages | 300 |

| By Product Type |

|

| By Application |

|

| By End-User Industry |

|

| By Region |

|

| Key Market Players | Elementbau Osthessen GmbH & Co., ELO KG, RAMPF Group, Steelike, Inc., Gulf Precast, Vicat, UHPC India Pvt. Ltd.,, ceEntek, Heidelberg Materials, TAKTL, UltraTech Cement Ltd., Sika AG, HOLCIM |

Increased Adoption in Sustainable and Green Construction, and Advancements in 3D Printing and Prefabrication Using UHPC are the upcoming trends of Ultra-High Performance Concrete Market in the globe

Roads and Bridge Construction is the leading application for Ultra-High Performance Concrete Market

Asia-Pacific is the largest regional market for Ultra-High Performance Concrete

$0.69 billion was the estimated industry size of Ultra-High Performance Concrete in 2024.

Heidelberg Materials, Steelike, Inc., TAKTL, ceEntek, UHPC India Pvt. Ltd.,, HOLCIM, Elementbau Osthessen GmbH & Co., ELO KG, UltraTech Cement Ltd., Sika AG, Gulf Precast, RAMPF Group, Vicat are the top companies to hold the market share in Ultra-High Performance Concrete

Loading Table Of Content...

Loading Research Methodology...