U.S. Extruded Polystyrene (XPS) Insulation Material Market Outlook - 2022-2031

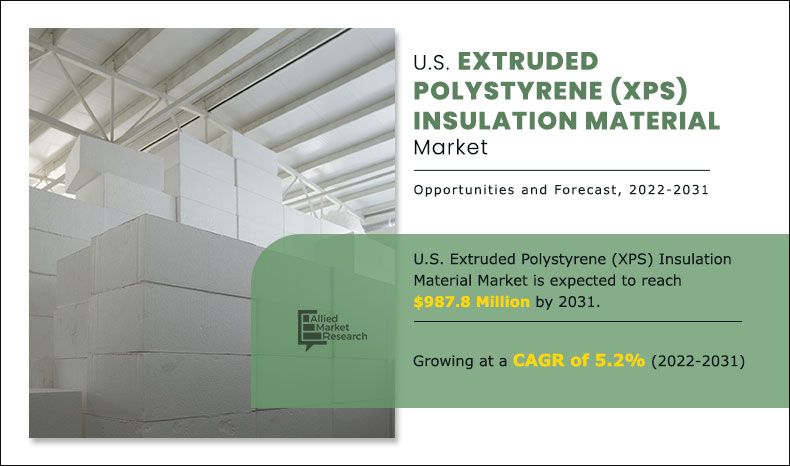

The U.S. extruded polystyrene (XPS) insulation material market size was valued at $596.6 million in 2021, and is projected to reach $987.8 million by 2031, growing at a CAGR of 5.2% from 2022 to 2031.

Report Key Highlighters:

- The study covers 50 states. The segment analysis of each state in terms of value and volume during the forecast period 2021-2031 is covered in the U.S. extruded polystyrene (XPS) insulation material market report.

- The West and Southeast U.S. extruded polystyrene (XPS) insulation material market is highly fragmented, with key-players including DuPont, Williams Foam, Owens Corning, Morgan Advanced Materials, Sika Sarnafil, Pactive LLC, Soprema, Inc., Kingspan Group plc, Knauf Insulation, and TeMa North America LLC.

- More than 3,000 product literatures, industry releases, annual reports, and other such documents of key industry participants along with authentic industry journals and government websites have been reviewed for generating high-value industry insights.

Extruded polystyrene (XPS) insulation materials are a type of rigid foam insulation used in construction to provide thermal insulation for walls, roofs, and floors. Extruded polystyrene insulation is made by combining polystyrene polymer with other additives, such as blowing agents and flame retardants, and then extruding the mixture through a die to form rigid foam panels. Extruded polystyrene insulation is known for its high thermal resistance, durability, and moisture resistance. It is commonly used in both residential and commercial construction projects, as well as in industrial applications.

Governments all over the world are enforcing strict building codes and regulations to encourage the use of energy-efficient insulation systems. The increasing demand for energy-efficient buildings is driving the demand for U.S. extruded polystyrene (XPS) insulation materials, as they provide effective insulation which helps to reduce energy consumption. The rise in construction activity, particularly in the non-residential sector, is increasing the demand for extruded polystyrene insulation materials.

The U.S. extruded polystyrene (XPS) insulation material market is driven owing to growth in demand for XPS insulation material in residential construction.

Extruded polystyrene (XPS) is a type of foam plastic that is commonly used as thermal insulation in residential buildings as well as in other applications such as packaging, crafts, and model-making. XPS is created by combining polystyrene resin with a blowing agent and extruding the mixture through a die to create a rigid, closed-cell foam.

Extruded polystyrene has several desirable properties, including high thermal resistance, low moisture absorption, and excellent compressive strength, thus making it an ideal insulation material across residential buildings. In addition, lightweight and easy to work, make extruded polystyrene a good choice for insulating roofs, walls, and foundations in residential construction. The growing demand for energy-efficient and sustainable homes has attracted residential building homeowners to focus on finding ways to reduce their energy costs and carbon footprint. XPS insulation is gaining popularity as a means of achieving high levels of thermal insulation in homes.

XPS insulation is a highly effective thermal insulator, with a high R-value per inch of thickness. This means that it can help to reduce the amount of energy required for the HVAC system, resulting in lower energy costs. As building codes and standards are becoming more stringent, there is a greater demand for extruded polystyrene insulation materials that meet these requirements. As a result, a wider range of insulation materials is being used in homes, which may have an impact on the market share of XPS insulation. In addition to that XPS insulation can also help to improve comfort by maintaining a consistent indoor temperature across residential buildings. This can result in a more comfortable living environment. All these factors have escalated the demand for extruded polystyrene insulation material in residential construction.

The West region has dominated the U.S. extruded polystyrene (XPS) insulation material market, and it is anticipated to grow at a CAGR of 5.7% from 2022 to 2031. This growth is attributed to factors such as the growth in the residential and non-residential construction activities. many building owners and developers are looking for environmentally friendly building materials such as extruded polystyrene insulation. This trend is expected to continue as building codes and regulations become more stringent and energy-efficient. With rising energy costs and a growing awareness of the need to reduce carbon emissions, many building owners are looking for ways to improve energy efficiency of non-residential buildings.

The U.S. extruded polystyrene (XPS) insulation material market is segmented on the basis of application and region. By application, market is divided into residential construction and non-residential construction.

Region-wise, U.S. extruded polystyrene (XPS) insulation material market share is analyzed across Southeast, West, Northeast, Midwest, and Southwest. In addition, the region have been further segmented on the basis of states. Southeast region includes states such as Alabama, Arkansas, Florida, Georgia, Kentucky, Louisiana, Mississippi, North Carolina, South Carolina, Tennessee, Virginia, and West Virginia. West region states include Alaska

California, Colorado, Hawaii, Idaho, Montana, Nevada, Oregon, South Dakota, Utah, Washington, and Wyoming. Northeast region includes states such as Connecticut, Delaware, Maine, Maryland, Massachusetts, New Hampshire, New Jersey, New York, Pennsylvania, Rhode Island, and Vermont. Midwest states include Illinois, Indiana, Iowa, Kansas, Michigan, Minnesota, Missouri, Nebraska, North Dakota, Ohio, and Wisconsin.

Key players engaged in development and production of extruded polystyrene (XPS) insulation material across U.S. include DuPont, Williams Foam, Owens Corning, Morgan Advanced Materials, Sika Sarnafil, Pactive LLC, Soprema, Inc., Kingspan Group plc, Knauf Insulation, and TeMa North America LLC.

By Application

Non-residential application is projected as the most lucrative segment.

U.S. extruded polystyrene (XPS) insulation material market, by application

Non-residential application is the most lucrative segment and is anticipated to grow at a CAGR of 5.5% in the forecast period. Governments across the world are enforcing strict building codes and regulations to encourage the use of energy-efficient insulation systems to reduce environmental concerns. Thus, many building owners and developers are looking for environmentally friendly building materials such as extruded polystyrene insulation. This trend is expected to continue as building codes and regulations become more stringent and energy-efficient. With rising energy costs and a growing awareness of the need to reduce carbon emissions, many building owners are looking for ways to improve energy efficiency of non-residential buildings.

The non-residential construction market is expanding as businesses, governments and other organizations invest in new infrastructure and facilities. According to the U.S. Census Bureau, the value of construction spending in 2022 was $1,792.9 billion, which is 10.2% more than the $1,626.4 billion spent in 2021. XPS insulation is well-suited for use in non-residential buildings, particularly those with high energy demands, such as hospitals, schools, and office buildings. In addition to that, XPS insulation is moisture resistant, fire resistant and has high compressive strength with a longer lifespan. All these factors have escalated the demand for extruded polystyrene insulation material in non-residential construction.

By Region

West region is projected as the most lucrative segment.

U.S. extruded polystyrene (XPS) insulation material market, by region

West region was the highest revenue contributor to the market in 2021. Extruded polystyrene insulation is a versatile material that can be used in a wide range of non-residential applications including roofs, walls, and floors. It is also simple to work with and can be cut to size and shape, making it an appealing option for builders looking for an easy-to-install material. Several factors are driving this trend across West region, including the need to reduce greenhouse gas emissions, comply with energy efficiency regulations, and lower operating costs.

Many building codes and energy efficiency standards now mandate the use of R-value or U-factor rated insulation materials. XPS insulation can assist non-residential building owners in meeting these requirements, making it an appealing option for those seeking to comply with building codes and regulations. In addition, extruded polystyrene insulation material has durability, sustainability, versatility, and fire resistance property. All these factors have escalated the demand for extruded polystyrene insulation material in West region.

KEY BENEFITS FOR STAKEHOLDERS

- The report provides in-depth analysis of the U.S. extruded polystyrene (XPS) insulation material market along with the current trends and future estimations.

- This report highlights the key drivers, opportunities, and restraints of the market along with the impact analysis during the forecast period.

- Porter’s five forces analysis helps to analyze the potential of the buyers & suppliers and the competitive scenario of the U.S. extruded polystyrene (XPS) insulation material market for strategy building.

- A comprehensive market analysis covers the factors that drive and restrain the U.S. extruded polystyrene (XPS) insulation material market growth.

- The qualitative data about market dynamics, trends, and developments is provided in the report.

U.S. Extruded Polystyrene (XPS) Insulation Material Market Report Highlights

| Aspects | Details |

| By Application |

|

| By Region |

|

| Key Market Players | Kingspan Group plc, Williams Foam, Knauf Insulation, Pactive LLC, Soprema Inc., Owens Corning, TeMa North America LLC, DuPont, Morgan Advanced Materials, Sika Sarnafil |

Analyst Review

According to the opinions of various CXOs of leading companies, the U.S. extruded polystyrene (XPS) insulation materials market is expected to witness increased demand during the forecast period. The surge in the demand for energy-efficient buildings across the U.S. and the increase in the demand for proper thermal insulation have a significant impact on the development of the market.

Extruded polystyrene (XPS) insulation is a rigid foam insulation extensively used in the construction sector to increase building energy efficiency. It is made from molten polystyrene resin and other additives that are then pressed through a shaping die, resulting in a continuous sheet of closed-cell foam insulation.

The market is being driven by rise in demand for thermal insulation and energy-efficient buildings. The non-residential building sector is rising as businesses, governments, and other organizations invest in new infrastructure and services. XPS insulation is well-suited for use in non-residential buildings, particularly those with high energy demands such as hospitals, schools, and office buildings. These facts indicate that the extruded polystyrene insulation material market will expand considerably throughout the projected period.

Growing demand for extruded polystyrene insulation material across residential construction is boosting the demand for U.S. extruded polystyrene (XPS) insulation material market.

• The U.S. extruded polystyrene (XPS) insulation material market size was valued at $596.6 million in 2021, and is projected to reach $987.8 million by 2031, growing at a CAGR of 5.2% from 2022 to 2031.

Key players engaged in development and production of extruded polystyrene insulation material across U.S. include include DuPont, Williams Foam, Owens Corning, Morgan Advanced Materials, Sika Sarnafil, Pactive LLC, Soprema, Inc., Kingspan Group plc, Knauf Insulation, and TeMa North America LLC.

Residential construction industry is projected to increase the demand for U.S. extruded polystyrene (XPS) insulation material.

The U.S. extruded polystyrene (XPS) insulation material market is segmented on the basis of application and region. By application, market is divided into residential and non-residential. Region-wise, U.S. extruded polystyrene (XPS) insulation material market share is analyzed across Southeast, West, Northeast, Midwest, and Southwest.

Extruded polystyrene has several desirable properties, including high thermal resistance, low moisture absorption, and excellent compressive strength, thus making it an ideal insulation material across residential buildings. In addition, lightweight and easy to work, make extruded polystyrene a good choice for insulating roofs, walls, and foundations in residential construction.

Loading Table Of Content...