Waterjet Cutting Machines Market Research - 2030

The global waterjet cutting machines market size was valued at $1,098.90 million in 2020, and is projected to reach $1,986.40 million by 2030, growing at a CAGR of 6.1% from 2021 to 2030.

The waterjet cutting machine is flexible and can cut irregular shapes from any material with high precision and edge quality. The abrasive-coated waterjet cutting machine can cut about any shape and thickness, including bonded laminated materials such as rubber-lined wear plates and aluminum composite panels. It is a cold cutting technique, which avoids heat distortion and hardened edges. It offers an advantage for delicate metal production and products that require extra machining after cutting. In addition, the waterjet cutting machine provides excellent cutting quality, ensuring a precise output without the need for a second finishing step. This saves time by increasing the speed of cutting process and improving the overall efficiency.

Market Dynamics

Waterjet cutting machines are highly adopted in industries such as automotive, aerospace, electronics, textile, construction, and mining. These machines are used in the automobile industry to cut titanium and steel and other metals. These machines are used for production of metal gaskets for vintage automobiles, disc brakes, clutches, and other components for racing cars, custom vehicle bodywork, and delicate fittings and brackets. These machines are used for a variety of tasks in the electronics industry, including circuit board cutting and design, control panels, generator components, electrical enclosures, and other related equipment. Such wide range of applications are expected to provide lucrative growth in the waterjet cutting machines market.

Furthermore, advance technologies such as 3D cutting and multi-axis waterjet cutting machines are expected to make the waterjet cutting process easier to use and expand its global reach. Nano jet cutting and micro waterjet cutting are examples of newer advancements that might help the global waterjet cutting machines market’s expansion. To meet the demands of a wider consumer base, market companies have created low-cost waterjet cutting equipment. For instance, in January 2021, Belotti Spa introduced NOVA, a Nesting Series CNC waterjet cutting technology. This series can be used for machining even small and very precise final products. It can operate at very high-quality standards and tight tolerance range.

The novel coronavirus (COVID19) has rapidly spread across various countries and regions, causing enormous impact on the lives of people and the overall community globally. It began as a human health condition and has now become a significant threat to global trade, economy, and finance. The COVID-19 pandemic has halted production of many products in the waterjet cutting machines market, owing to lockdowns. Furthermore, the number of COVID-19 cases is expected to reduce in the future as the vaccine for COVID-19 is introduced in the market. This has led to the reopening of waterjet cutting machines companies at their full-scale capacities. This is expected to help the market recover by the start of 2022. After COVID-19 infection cases begin to decline, equipment & machinery producers must focus on protecting their staff, operations, and supply networks to respond to urgent emergencies and establish new methods of working.

Segmental Overview

The market is segmented on the basis of type, dimension cutting, end-user industry, and region.

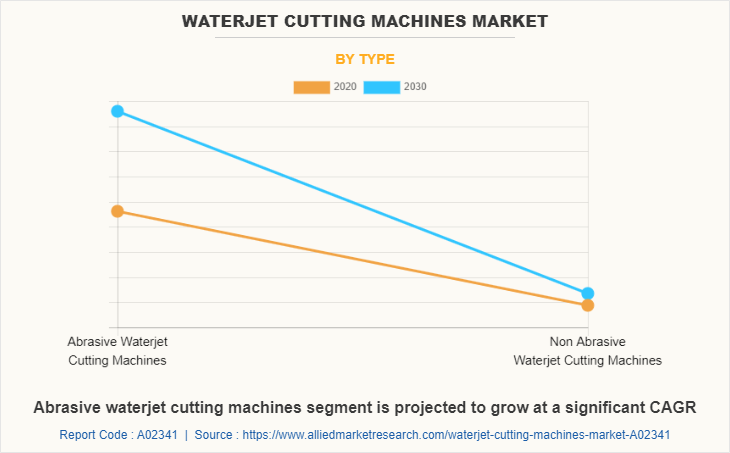

On the basis of type, the market is classified into abrasive waterjet cutting machines and non-abrasive waterjet cutting machines. By dimension cutting, the market is divided into one-dimensional cutting, two-dimensional cutting, and others.

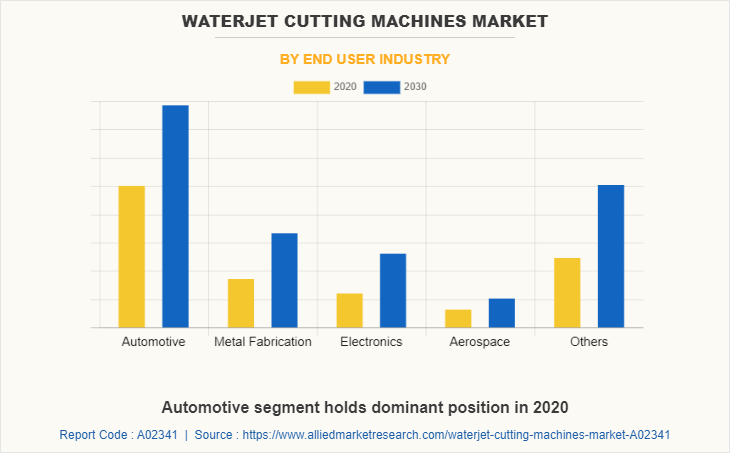

By end-user industry, it is classified as automotive, metal fabrication, electronics, aerospace, and others.

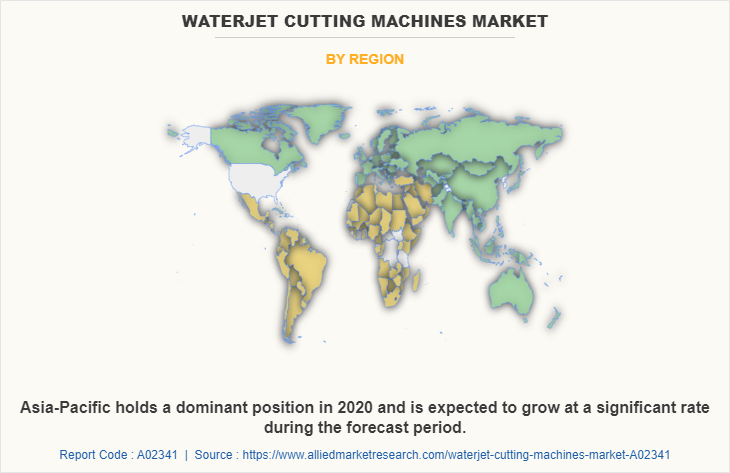

Region-wise, the global market analysis is conducted across North America (the U.S., Canada, and Mexico), Europe (the UK, France, Germany, Italy, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, and Rest of Asia-Pacific), and LAMEA (Latin America, the Middle East, and Africa).

Competition Analysis

The key players operating in the global waterjet cutting machine are Colfax Corporation, Conzzeta (Bystronic Laser AG), Dardi International Corporation, Flow International Corporation (Shape Tech Group), KMT Waterjet, OMAX Corporation, Resato International B.V., Jet Edge, and Wardjet, Belotti SPA.

Key Benefits for Stakeholders

- The report provides an extensive analysis of the current and emerging waterjet cutting machines market trends and dynamics.

- In-depth waterjet cutting machines market analysis is conducted by constructing market estimations for key market segments between 2021 and 2030.

- Extensive analysis of the waterjet cutting machines market growth is conducted by following key product positioning and monitoring of top competitors within the market framework.

- A comprehensive analysis of all the regions is provided to determine the prevailing opportunities.

- The global waterjet cutting machines market forecast analysis from 2021 to 2030 is included in the report.

- The key players within waterjet cutting machines market are profiled in this report and their strategies are analyzed thoroughly, which help understand the competitive outlook of the waterjet cutting machines industry.

Waterjet Cutting Machines Market Report Highlights

| Aspects | Details |

| By Type |

|

| By Dimension Cutting |

|

| By End User Industry |

|

| By Region |

|

| Key Market Players | Colfax Corporation, Flow International Corporation, SpaceClaim Corporation, Resato International BV, Hypertherm, Inc, Jet Edge, Inc, Dardi International Corporation, Koike Aronson, Inc, OMAX Corporation, Shape Technologies Group |

Analyst Review

The waterjet cutting machines market is projected to witness significant growth owning to introduction of new technologies, advancements in 3D design, enhanced cooling systems, and adopting micro waterjet cutting systems, robotic, and high-pressure waterjet. Waterjet cutting machines are used for cutting and drilling in a variety of sectors, including aerospace and defense, automotive, metal fabrication, and electronics. Furthermore, robotic waterjets offer heat and smoke-free cutting solutions. In addition, the high-pressured waterjets enable accurate and rapid cutting with less heat distortion of materials. Also, adoption of micro waterjet cutting machines are perfect for heat sensitive materials and provide accurate and fast precision.

Various key players introduce new and advanced waterjet cutting machines for various industries. For instance, in November 2020, Wardjet Inc. introduced X-2040 waterjet cutting machine. The new cutting machine can operate with high-speed and accuracy with maximum cutting speed of 20 meters/minute. It also has special sensors, which adjust height automatically. As a result, such advanced products from key players are expected to provide lucrative growth in the waterjet cutting machines market during the forecast period.

The waterjet cutting machines market size was valued at $1,098.9 million in 2020.The waterjet cutting machines market is projected to reach $1,986.5 million by 2030.

Based on region, the Asia-Pacific holds the maximum market share of the waterjet cutting machines market in 2020.

The leading application of waterjet cutting machines includes automotive, metal fabrication, electronics, aerospace and others.

Growth in manufacturing sector and growing demand for waterjet cutting machines among end user industries are the key trends in the waterjet cutting machines market.

The company profile has been selected on factors such as geographical presence, market dominance (in terms of revenue and volume sales), various strategies and recent developments.

The product launch is key growth strategy of waterjet cutting machines industry players.

Loading Table Of Content...