Welding Consumables Market Outlook, 2032

The global welding consumables market size was valued at $16.1 billion in 2022, and is projected to reach $27.5 billion by 2032, growing at a CAGR of 5.5% from 2023 to 2032.

Report Key Highlighters

- The report provides competitive dynamics by evaluating business segments, product portfolios, target market revenue, geographical presence and key strategic developments by prominent manufacturers.

- The welding consumables market is fragmented in nature among prominent companies such as Kobe Steel, Ltd., The Lincoln Electric Company, VDM Metals, ESAB, Royal Arc, DAndH Scheron, ESS AAR INDUSTRIES, Weldcom Electrodes Pvt. Ltd., Senor Metals Pvt. Ltd., Sharp Electrodes (P) LTD.

- The study contains qualitative information such as the market dynamics (drivers, restraints, challenges, and opportunities), public policy analysis, pricing analysis, and Porter’s Five Force Analysis across North America, Europe, Asia-Pacific, LAMEA regions.

- Latest trends in global welding consumables market such as undergoing R&D activities, public policies, and government initiatives are analyzed across 16 countries in 4 different regions.

- More than 3,500 welding consumables-related product literatures, industry releases, annual reports, and other such documents of key industry participants along with authentic industry journals and government websites have been reviewed for generating high-value industry insights for global welding consumables market.

"Welding materials" is a broad term that refers to the various components, substances, and materials used in the welding process to join two or more pieces of metal together. These materials are essential for creating a strong and reliable weld.

Filler materials such as welding electrodes, welding wires, and flux-cored wires, are added to the joint during welding to help fuse the base metals together. They are selected based on the welding process, the type of base metals being joined, and the specific requirements of the weld.

Shielding gases are used to protect the weld zone from atmospheric contamination in some welding processes. Common shielding gases include argon, helium, carbon dioxide, and gas mixtures. These gases are typically used in processes such as gas metal arc welding (GMAW or MIG welding) and gas tungsten arc welding (GTAW or TIG welding).

Growing population base has led to rapid urbanization in both, developed and developing economies such as the U.S., China, India, and others. This has increased government spending on the building & construction sector to develop various upcoming infrastructure projects. For instance, according to a report published by National Investment Promotion and Facilitation Agency, the infrastructure activities accounted for 13% share of the total foreign direct investment (FDI) inflows in 2021. Furthermore, rapid development of water supply, sanitation, urban transport, schools, and healthcare aid in the growth of the building & construction sector where welding consumables are widely used for connecting steel beams, trusses, columns, and footers, to support the walls, roofs, and others.

The demand for welding consumables is closely tied to infrastructure development projects, such as the construction of buildings, bridges, highways, and pipelines. As countries invest in infrastructure development, there is a growing need for welding to join and fabricate structural components.

Moreover, welding is an integral part of the automotive and transportation industry for manufacturing vehicles, trailers, and components. As this industry evolves with new technologies and materials, the demand for welding consumables, including specialized ones for aluminum and high-strength steel, continues to grow.

However, the welding consumables market is sensitive to economic fluctuations. During economic downturns, construction, and manufacturing activities often slow down, leading to reduced demand for welding consumables. Economic instability can constrain the market growth.

On the contrary, advances in welding technology, such as the development of new welding processes, robotic welding systems, and consumable materials with improved performance, drive the market growth as industries seek more efficient and cost-effective solutions. This factor is expected to offer lucrative opportunities for the welding consumables market during the forecast period.

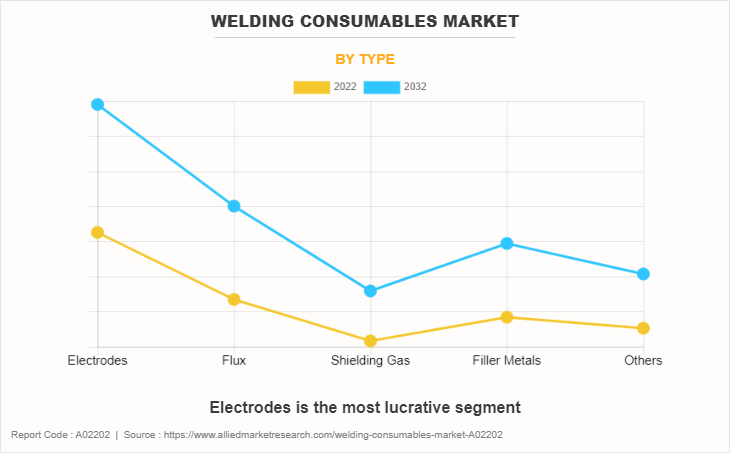

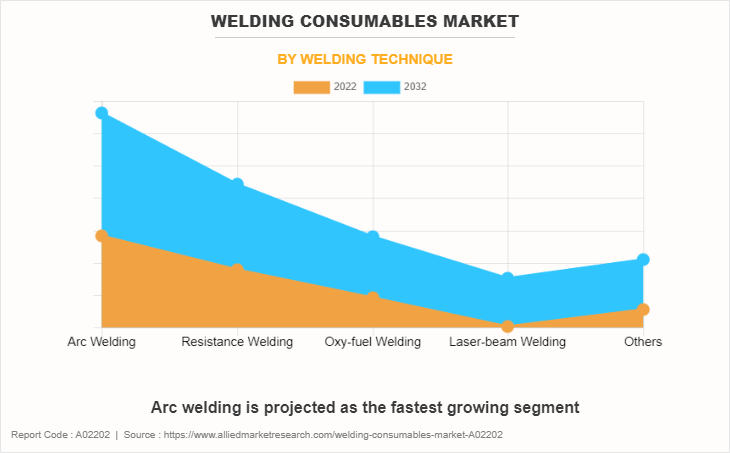

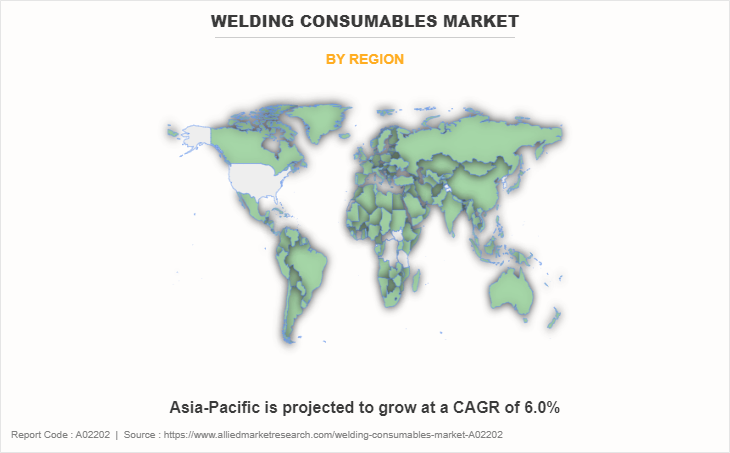

The welding consumables market is segmented on the basis of type, welding technique, and region. On the basis of type, the market is categorized into electrodes, flux, shielding gas, filler metals, and others. On the basis of welding technique, it is divided into arc welding, resistance welding, oxy-fuel welding, laser-beam welding, and others. Region-wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

Welding Consumables Market By Type

In 2022, the electrodes segment was the largest revenue generator, and is anticipated to grow at a CAGR of 5.4% during the forecast period. As urbanization and infrastructure development continue to rise globally, there is a growing demand for welding in the construction of buildings, bridges, roads, and other infrastructure projects. Electrodes are commonly used in various welding processes to join structural components, reinforcing the demand for electrodes. Furthermore, many industries, including automotive, aerospace, shipbuilding, and manufacturing, rely heavily on welding processes to fabricate and assemble components. The expansion of these industries leads to an increased need for electrodes for various welding application; thus, fueling the market growth.

Welding Consumables Market By Welding Technique

By welding technique, the arc welding segment dominated the global market in 2022, and is anticipated to grow at a CAGR of 6.0% during forecast period. Arc welding is a versatile process that can be applied to a wide range of materials, including carbon steel, stainless steel, aluminum, and various alloys. Its versatility makes it suitable for a broad spectrum of applications across different industries.

Furthermore, arc welding is often considered a cost-effective welding process. The equipment and consumables required for arc welding are relatively affordable compared to some other welding methods, making it an attractive option for many businesses. Moreover, while mastering any welding process requires training and skill development, arc welding is often considered more accessible for beginners compared to some of the more complex processes. This accessibility makes it a popular choice for training programs and welding schools. These factors altogether may lead the welding consumables market for arc welding technique to witness a significant growth.

Welding Consumables Market By Region

The Asia-Pacific welding consumables market size is projected to grow at the highest CAGR of 6.0% during the forecast period and accounted for 43.4% of welding consumables market share in 2022. The Asia-Pacific region represents a significant and rapidly growing market for welding consumables. Factors such as rapid industrialization, urbanization, and infrastructure development are driving the demand for welding products and services. Furthermore, the ongoing industrialization and urbanization in countries such as China and India are the major drivers of the welding consumables market. Increase in construction, manufacturing, and infrastructure development activities contributes to the market growth.

Moreover, infrastructure projects, including the construction of buildings, bridges, roads, railways, and energy facilities, drive the demand for welding consumables. Investments in new and upgraded infrastructure are substantial in many countries across the region. In addition, the automotive and transportation industries in Asia-Pacific are significant consumers of welding consumables. With the growth of the automotive sector and the shift toward electric vehicles (EVs), there is a need for advanced welding technologies and materials. These factors are anticipated to boost the demand for welding consumables in the Asia-Pacific region.

The global welding consumables market profiles leading players that include Kobe Steel, Ltd., The Lincoln Electric Company, VDM Metals, ESAB, Royal Arc, DAndH Scheron, ESS AAR INDUSTRIES, Weldcom Electrodes Pvt. Ltd., Senor Metals Pvt. Ltd., Sharp Electrodes (P) LTD. The global welding consumables market report provides in-depth competitive analysis as well as profiles of these major players.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the welding consumables market analysis from 2022 to 2032 to identify the prevailing welding consumables market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the welding consumables market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global welding consumables market trends, key players, market segments, application areas, and market growth strategies.

Welding Consumables Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 27.5 billion |

| Growth Rate | CAGR of 5.5% |

| Forecast period | 2022 - 2032 |

| Report Pages | 330 |

| By Type |

|

| By Welding Technique |

|

| By Region |

|

| Key Market Players | The Lincoln Electric Company, Weldcom Electrodes Pvt. Ltd., Kobe Steel, Ltd., ESAB, VDM Metals, D&H Scheron, ESS AAR INDUSTRIES, Senor Metals Pvt. Ltd., Sharp Electrodes (P) LTD., Royal Arc |

Analyst Review

The global welding consumables market is expected to exhibit high growth potential, owing to expansion into emerging markets where infrastructure development and industrialization are driving the demand for welding products. CXOs are more focused in investing in research and development to create advanced welding consumables that improve efficiency, reduce environmental impact, and meet evolving industry standards. Development of eco-friendly welding consumables that appeal to environmentally conscious industries and customers may boost the demand for welding consumables during the forecast period.

Furthermore, CXOs are exploring opportunities to integrate robotic welding systems and welding management software into customer offerings. In addition, CXOs are expected to invest in digital tools and platforms for supply chain optimization, production monitoring, and customer engagement. These technologies can provide real-time insights and enhance decision-making which in turn may further augment the growth of the welding consumables market.

Escalating demand from building and construction sector, robust demand from automotive and transportation sector, and increase in demand from oil and gas sector are the upcoming trends of welding consumables market.

Arc welding is the leading application of welding consumables.

Asia-Pacific is the largest regional market for welding consumables.

The welding consumables market was valued for $16.1 billion in 2022 and is estimated to reach $27.5 billion by 2032, exhibiting a CAGR of 5.5% from 2023 to 2032.

Kobe Steel, Ltd., The Lincoln Electric Company, VDM Metals, ESAB, Royal Arc, DAndH Scheron, ESS AAR INDUSTRIES, Weldcom Electrodes Pvt. Ltd., Senor Metals Pvt. Ltd., Sharp Electrodes (P) LTD are the top companies to hold the market share in welding consumables market.

Loading Table Of Content...

Loading Research Methodology...