X-Ray Detector for Non-Destructive Testing Market Overview:

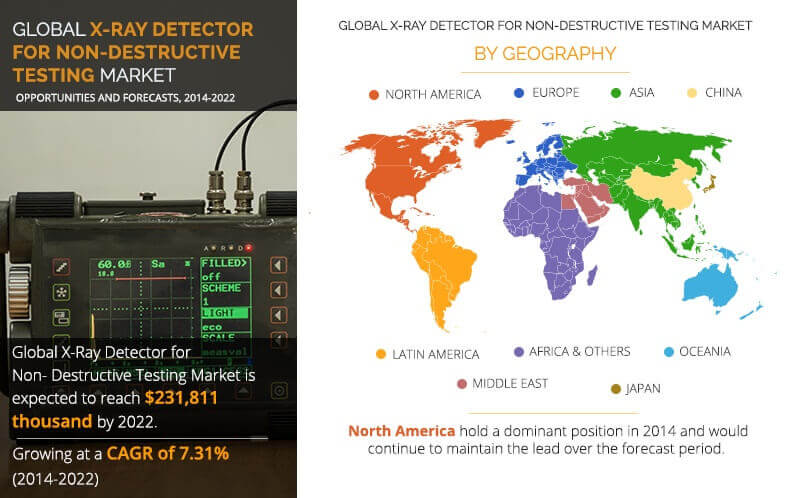

X-Ray Detector for Non-Destructive Testing Market was valued at $ 129,939 thousand in 2014 and is projected to reach $ 231,811 thousand by 2022, growing at a CAGR of 7.31% from 2014 to 2022.

An X-ray detector is an electronic device that detects radiation of X-ray or gamma rays for imaging purposes. X-ray imaging is an important non-destructive testing (NDT) technique for products such as circuit boards, concrete parts, and metals. This technique is also useful for detecting Cracks and very fine manufacturing defects, thus maintaining quality, product reliability, and various other physical properties of the materials. NDT uses various testing methods to evaluate the object, material, or system without damaging or destroying it. This testing assures that the structural and mechanical components perform their function in a safe, reliable, and cost-effective manner.

The key factor that drives the growth of the global X-ray detector for the NDT market includes technological advancements in hardware, such as tubes, sources, and detectors. In addition, continuous upgrades in software have contributed significantly toward improving the efficiency of X-ray inspection systems. Industries such as aerospace and automotive witness high adoption rates of X-ray detectors due to their ability to provide high image quality and accuracy. In addition, fully automated industries have implemented these detectors to monitor the quality of the material and the finished product. These detectors are highly priced and require high maintenance costs, which restrict their use due to affordability.

The key players operating in the X-ray detector for NDT market include Canon Inc., FONA Dental Systems Co. Ltd., FUJIFILM Holdings Corporation, Hamamatsu Photonics K.K., Konica Minolta Inc., Olympus Corporation, PerkinElmer Inc., Rayence Inc., Teledyne DALSA Inc., Toshiba Electron Tubes and Devices Co. Ltd., Trixell S.A.S., Detection Technology, Image Tech, MatriX Technologies GmbH, and X-Scan Imaging Corporation.

The global X-ray detector for NDT market is segmented based on type, application, and region. The type segment is further divided into CR system, static flat panel detector, dynamic flat panel detector, and linear sensor.

Based on application, the market is categorized into aerospace & defense, automotive, construction, electronic & semiconductors, energy & power, explosive ordnance disposal (EOD) & improvised explosive device (IED), heavy industries, manufacturing, marine, oil & gas, security, transportation, food, drugs & drinks, and others (archaeology and forensics). Based on region, the market is analyzed across North America (U.S., Canada, and Mexico), Latin America (Brazil and others), Europe (UK, Germany, France, Russia, and rest of Europe), Middle East (Saudi Arabia, Iran, and others), China, Japan, Asia (India, Taiwan, Korea, and others, excluding China and Japan), Oceania (Australia and others), and Africa and Others.

Top Impacting Factors

Improved Quality and Reduced Prices

The decline in prices of X-ray detectors has increased the adoption of X-ray detection systems in industries such as food, drinks, & drugs, construction, and transportation to improve detection quality, finished product quality (especially for food, drinks & drugs, and construction industry), and simultaneously reduce detection time to increase productivity.

Increase in Demand for Automated Technology

In the present scenario, market players have witnessed a technological shift and have focused on process automation to minimize human intervention. The aerospace & defense, automotive, and oil & gas sectors have witnessed extensive use of automated X-ray detector systems, owing to the time constraints associated with the execution of multiple detection tasks simultaneously with better accuracy.

Flat Panel X-ray Detectors Gaining Popularity

Progressive changes in technology starting from computed radiography to digital radiography along with the use of flat panel detectors have improved the efficiency of X-ray detectors, thereby creating an opportunity shortly.

Key Benefits for Stakeholders

- This report provides an extensive analysis of the current and emerging market trends and dynamics in the X-ray detectors for the NDT market.

- In-depth analysis is conducted by constructing market estimations for the key market segments between 2014 and 2022.

- Extensive analysis of the market is conducted by following key product positioning and monitoring the top competitors within the market framework.

- Key players are profiled and their strategies are analyzed thoroughly to understand the competitive outlook of the global X-ray detectors for the NDT market.

X-Ray Detector for Non-Destructive Testing Market Report Highlights

| Aspects | Details |

| By Type |

|

| By Application |

|

| By Geography |

|

| Key Market Players | CANON INC., TRIXELL, TELEDYNE DALSA INC., KONICA MINOLTA, INC., GENERAL ELECTRIC CORPORATION, PERKINELMER, COMPUTERISED INFORMATION TECHNOLOGY LTD., SENS-TECH LTD., DETECTION TECHNOLOGY, HAMAMATSU PHOTONICS, IRAY TECHNOLOGY, OLYMPUS, IMAGE TECH, INC., RAYENCE, TOSHIBA ELECTRON TUBES & DEVICES CO., LTD., IBA DOSIMETRY, ANALOGIC CORPORATION, ICRCO, MATRIX TECHNOLOGIES GMBH, FUJIFILM CORPORATION, X-SCAN IMAGING CORPORATION, VARIAN MEDICAL SYSTEMS, INC. |

Analyst Review

An X-ray detector is an electronic device that detects radiation of X-ray or gamma ray for imaging purposes. X-ray imaging is an important non-destructive testing (NDT) technique for products such as circuit boards, concrete parts, and metals. The X-ray for non-destructive testing market is expected to reach $231,811 million by 2022, owing to improved quality and reduced prices of X-ray detector. The different X-ray for non-destructive testing market includes CR system, static flat panel detector, dynamic FPD, and linear sensor.

In 2014, North America was the highest contributor, in terms of revenue, in the X-ray for non-destructive testing market. In addition, aerospace & defense for non-destructive testing market has contributed significant revenue to the market, majorly from the U.S. Furthermore, the solar X-ray for non-destructive testing market is anticipated to witness the highest growth during the forecast period, due to continuous upgrades in software have contributed significantly towards improving the efficiency of X-ray inspection systems.

Key market players have adopted various strategies, such as new product launch, business expansion, and strategic alliances to increase awareness about X-ray for non-destructive testing market across various countries.

Loading Table Of Content...