Industrial Low-voltage Alternator Market Research, 2032

The global industrial low-voltage alternator market size was valued at $1.5 billion in 2022, and is projected to reach $3.4 billion by 2032, growing at a CAGR of 8.7% from 2023 to 2032. Low-voltage alternators use electromagnetic induction as their power source. When a conductor, usually in the form of wire coils, rotates inside a magnetic field, it produces alternating current (AC). This alternating current (AC) output is then utilized to power electrical equipment or rectified into direct current (DC). These alternators are widely used in various industrial environments, including manufacturing facilities, oil & gas refineries, mining activities, and naval applications.

They are used to provide backup power, supplement primary power supply, and assure continuous operation in critical areas. Industrial low-voltage alternators are engineered to fulfil the unique demands of industrial applications. They are frequently constructed with durable materials to resist harsh weather conditions and have modern cooling mechanisms to prevent overheating after extended use. Alternators are categorized according to their design and construction. Brushless alternators are more dependable and need less maintenance than brushed alternators, while synchronous alternators are designed to run in tandem with the utility grid.

Low-voltage alternators are chosen due to their capacity to meet the specific power needs of industrial machinery and equipment. These alternators are intended to generate energy at voltages appropriate for powering a wide range of industrial equipment, including motors, pumps, and compressors. Moreover, these alternators enable maximum performance and efficiency of industrial equipment by supplying the appropriate voltage levels, resulting in greater production and less downtime. Another important consideration is the dependability and durability of low-voltage alternators. Industrial environments are severe, characterized by dust, moisture, and vibration.

Low-voltage alternators are designed to survive these circumstances, with strong construction and high-quality components that provide long-term operation with minimal maintenance or repair. This dependability is critical for industrial processes, as any downtime results in severe losses. Furthermore, low-voltage alternators are very efficient, converting mechanical energy to electrical energy with little losses. This efficiency saves energy and cuts operational expenses for industrial operations. These factors are anticipated to boost the industrial low-voltage alternator market growth.

One major restraint in industrial low-voltage alternator market opportunity is vulnerability to voltage changes. Industrial low-voltage alternators are frequently built to operate within voltage ranges; departures from these ranges result in inefficiency or even damage to equipment connected to the alternator. Voltage variations are caused by several factors, including changes in load demand, fluctuations in input power, and grid instability. Mitigating these oscillations necessitates advanced voltage control techniques, which increases the complexity and expense of the alternator system. Furthermore, low-voltage alternators have difficulty in sustaining power quality. Power quality is the consistency and dependability of an electrical supply, which includes criteria such as voltage stability, frequency control, and harmonic distortion.

In industrial settings with sensitive equipment, maintaining excellent power quality is critical to avoiding interruptions, equipment damage, and safety issues. However, low-voltage alternators struggle to achieve high power quality standards, especially under dynamic load situations or when subjected to non-linear loads that cause harmonics. Another downside of industrial low-voltage alternators is their low scalability. While small alternators are appropriate for applications with relatively low power outputs, scaling up to meet larger power demands is difficult.

One of the key growth drivers for industrial LV alternator market is rise in demand for efficient and sustainable power solutions. As enterprises across the globe attempt to reduce their environmental impact and optimize energy use, there is a rising emphasis on using energy-efficient solutions. Industrial LV alternator market players plays an important part in this shift by providing power production options that are both dependable and environmentally benign. Manufacturers are investing in R&D to improve alternator efficiency and performance, coinciding with the changing demands of companies seeking sustainable power solutions.

Furthermore, high rate of industrialization and infrastructure development in emerging nations creates considerable potential opportunities for the low-voltage alternator industry. As countries undertake ambitious development projects and grow their industrial base, there is an increase in demand for dependable power production equipment. Low-voltage alternators, due to their adaptability and scalability, meet the different needs of sectors ranging from manufacturing and mining to oil & gas. This rising demand is prompting manufacturers to increase their production capabilities and enter new market areas, boosting industry growth.

Key players profiled in industrial low-voltage alternator market report include Cummins Inc., Mecc Alte SpA, Nidec Motor Corporation, Linz Electric S.p.A., ENGGA (Yangjiang) Electric Co., Ltd., ABB, DINGOL Power Generation, FARADAY, Taiyo Electric Co., Ltd., and Soga S.p.A. Sogaenergyteam. Product innovation & development and user experience are common strategies followed by major market players. For instance, in July 2021, Nidec Leroy-Somer announced the launch of the LSA 47.3 industrial alternator. The LSA 47.3 offered increased efficiency and starting kVA over its predecessor and benefited from the implementation of the latest technologies developed by Nidec Leroy-Somer.

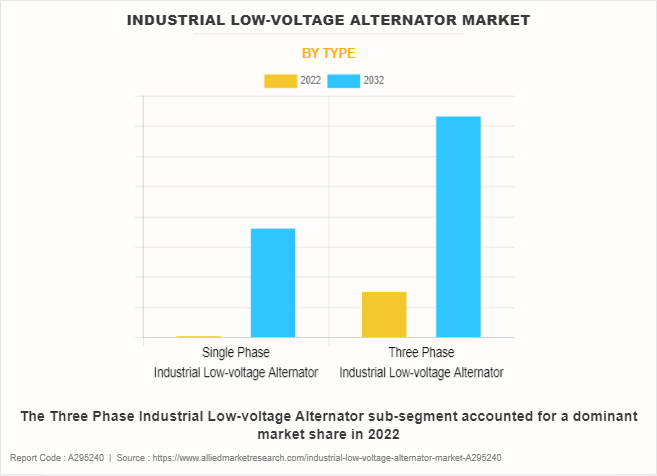

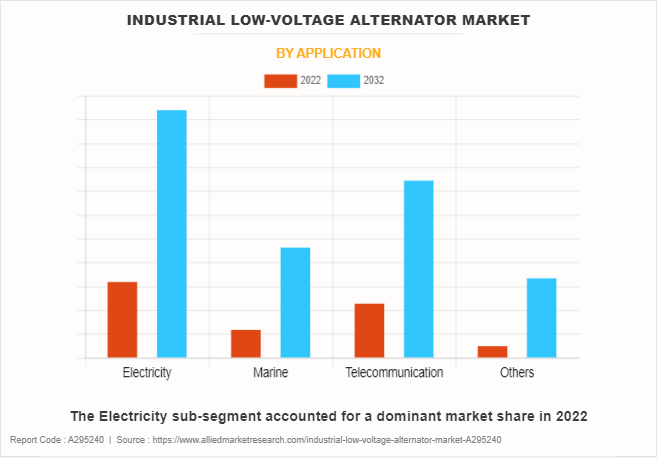

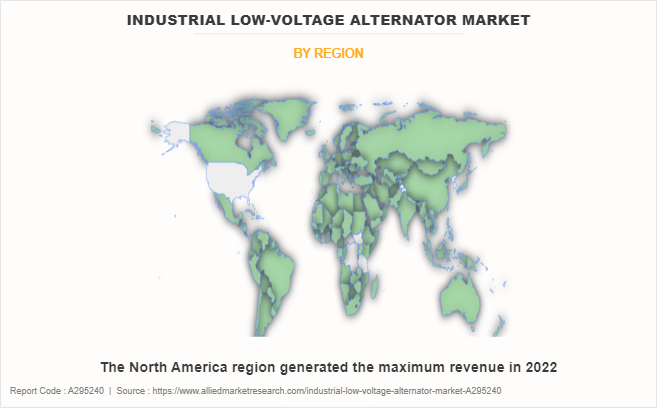

The industrial low-voltage alternator market forecast is segmented into type, application, and region. By type, the market is bifurcated into single phase industrial low-voltage alternator and three phase industrial low-voltage alternator. Depending on application, it is classified into electricity, marine, telecommunication, and others. By region, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

The industrial low-voltage alternator market is segmented into Type and Application.

By type, the three-phase industrial low-voltage alternator segment dominated the global industrial low-voltage alternator market share in 2022. One of the key reasons is the balanced nature of three-phase electricity. Compared to single-phase power, which has considerable variations and possible power loss, three-phase power delivers a more consistent and continuous supply of electricity. This balance is achieved by creating three independents and synchronized alternating currents, each offset by 120 degrees. Therefore, the combination of these three currents generates a more even total power output, limiting the possibility of voltage dips and assuring a steady power supply to industrial machinery & equipment.

Another important reason is that three-phase alternators produce more power than single-phase alternators. These generate more power while using smaller wire diameters and fewer conductors than single-phase systems. Due to their great efficiency, three-phase alternators are perfect for industrial applications with large power needs, allowing heavy machinery, motors, and other equipment to run without losing performance or durability.

By application, the electricity industrial low-voltage alternator segment dominated the global industrial low-voltage alternator market share in 2022. Technological innovation is a major driving factor in the growth of low-voltage alternators in industrial applications. Advances in materials science, electromagnetic design, and manufacturing techniques have enabled the development of alternators with improved efficiency, reliability, and performance. For instance, using high-strength, lightweight materials in rotor and stator construction leads to better power-to-weight ratios and lower losses, leading in more efficient energy conversion.

Furthermore, advances in digital control systems and power electronics have permitted the deployment of complex control methods, such as accurate voltage & frequency regulation and seamless interaction with smart grid technology. The growing demand for energy efficiency and sustainability has emerged as a major driving force in the development and deployment of low-voltage alternators in industrial applications. With rising environmental consciousness and rising energy prices, industrial firms are under pressure to optimize their energy use and decrease their carbon footprint.

By region, North America dominated the global industrial low-voltage alternator industry in 2022. North America's substantial industrial sector continues to fuel the demand for dependable power generating solutions. As varied sectors such as manufacturing, oil & gas, mining, and construction grow, so does the demand for industrial low-voltage alternators to support these increasing activities. Technological advancements have considerably improved low-voltage alternators' efficiency, dependability, and performance.

Manufacturers are always working to fulfil the changing demands of North American businesses by including features such as smart monitoring systems, remote diagnostics, and energy-efficient designs. North America is progressively prioritizing the use of renewable energy sources into its industrial infrastructure. Low-voltage alternators are critical components of renewable energy systems such as wind turbines and solar power plants, turning mechanical energy into electrical power and contributing to the region's sustainability goals.

Key Benefits For Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the industrial low-voltage alternator market analysis from 2022 to 2032 to identify the prevailing industrial low-voltage alternator market opportunities.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the industrial low-voltage alternator market segmentation assists to determine the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes the analysis of the regional as well as global industrial low-voltage alternator market trends, key players, market segments, application areas, and market growth strategies.

Industrial Low-voltage Alternator Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 3.4 billion |

| Growth Rate | CAGR of 8.7% |

| Forecast period | 2022 - 2032 |

| Report Pages | 310 |

| By Type |

|

| By Application |

|

| By Region |

|

| Key Market Players | ABB, DINGOL Pwoer Generation, Cummins Inc., Taiyo Electric Co., Ltd., Mecc Alte Spa, linz electric s.p.a., Nidec Motor Corporation, Soga S.p.A. Sogaenergyteam, ENGGA (Yangjiang) Electric Co., Ltd. , FARADAY |

The industrial low-voltage alternator market size is expected to grow due to industrial expansion and infrastructure development globally. In addition, the market is driven by rise in investments in industrial automation.

The major growth strategies adopted by the industrial low-voltage alternator market players are product innovation & development and user experience.

Rise of renewable energy, rise in awareness among people about the benefits of industrial low-voltage alternator, and surge in the expansion of industrial infrastructure drive the global industrial low-voltage alternator market.

Asia-Pacific is expected to provide more business opportunities for the global industrial low-voltage alternator market in the future.

Industrial machinery & equipment is expected to experience a growth in adoption, as industrial low-voltage alternators power a wide range of machinery and equipment used in manufacturing, processing, and assembly operations.

Cummins Inc., Mecc Alte SpA, Nidec Motor Corporation, Linz Electric S.p.A., ENGGA (Yangjiang) Electric Co., Ltd., ABB, DINGOL Power Generation, FARADAY, Taiyo Electric Co., Ltd., and Soga S.p.A. Sogaenergyteam., are major players in the industrial low-voltage alternator market.

Manufacturing industries are major customers in the global industrial low-voltage alternator market.

The three-phase industrial low-voltage alternator sub-segment of the type segment acquired the maximum share of the global industrial low-voltage alternator market in 2022.

The report provides an extensive qualitative & quantitative analysis of the current trends and future estimations of the global industrial low-voltage alternator market from 2022 to 2032 to determine the prevailing opportunities.

Loading Table Of Content...

Loading Research Methodology...