Machine Sensor Market Statistics, 2032

The global machine sensor market was valued at $16.5 billion in 2022 and is projected to reach $35.8 billion by 2032, growing at a CAGR of 8.2% from 2023 to 2032. A machine sensor is a device that is used to detect or measure the physical properties of a machine or its environment, such as temperature, pressure, vibration, or acceleration. These sensors are often used in industrial applications to monitor the health and performance of machines and to detect potential problems before they become critical.

Machine sensors can be wired or wireless and can be connected to a variety of systems such as data loggers, controllers, or cloud-based platforms. They can also be integrated with artificial intelligence or machine learning algorithms to provide predictive maintenance, fault diagnosis, or optimization of machine performance.

Machine sensors are used in a wide range of applications across various industries. One of the primary applications of machine sensors is predictive maintenance, where they are used to detect potential problems in machines before they become critical. This allows companies to prevent downtime, reduce maintenance costs, and improve the safety and reliability of their operations.

Segment Overview

The machine sensor market is segmented into Type and End-Use Industries.

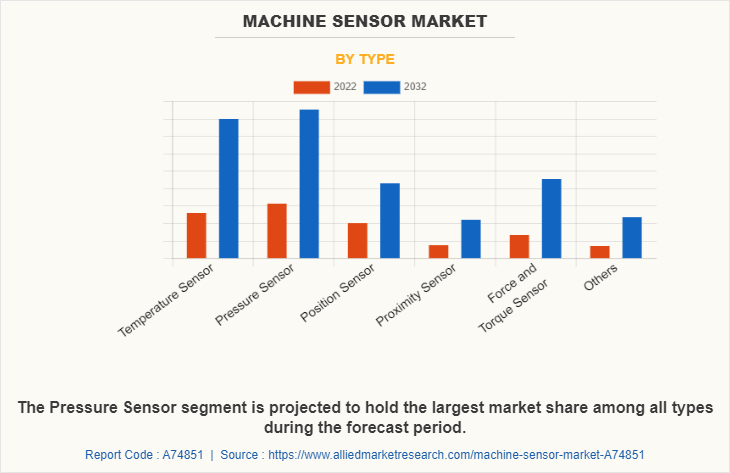

By type, the machine sensor market is divided into temperature sensors, pressure sensors, position sensors, proximity sensors, force & torque sensors, and others. The pressure sensor segment is projected as the most lucrative segment.

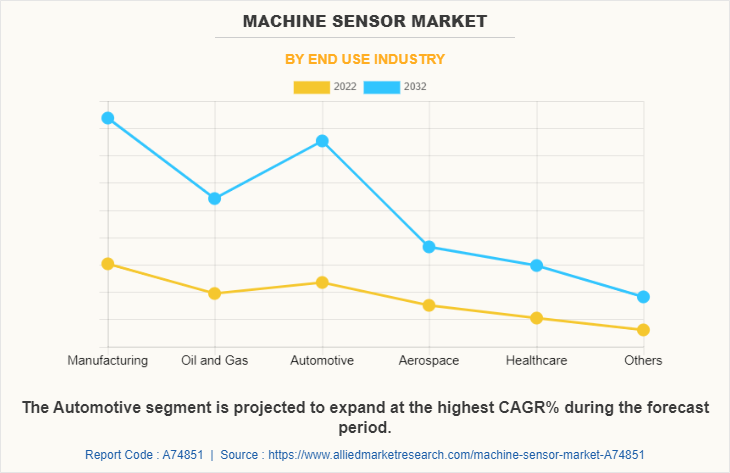

By end-use industry, the machine sensor market is segregated into manufacturing, oil and gas, automotive, aerospace, healthcare, and others. The automotive segment was the highest revenue contributor to the market. By region, the machine sensor industry is analyzed across North America (U.S., Canada, and Mexico), Europe (UK, Germany, France, and the rest of Europe), Asia-Pacific (China, Japan, India, South Korea, and the rest of Asia-Pacific) and LAMEA (Latin America, Middle East, and Africa).

Country-wise, the U.S. acquired a prime share in the machine sensor market in the North American region and is expected to grow at a significant CAGR during the forecast period of 2023-2032. One of the main reasons for the U.S.'s strong position in the North American machine sensor market is the presence of several established machine sensor solution providers in the country. Companies such as Sensata Technologies, Inc., Honeywell, FUTEK Advanced Sensor Technology, Inc., Tekscan, Inc., and ATI Industrial Automation, Inc. have a significant market presence and offer a wide range of machine sensor products and services. These companies have invested heavily in R&D and have developed advanced machine sensor systems that cater to the specific needs of various industries.

In Europe, Germany dominated the machine sensor market size, in terms of revenue in 2022. Germany's domination of the machine sensor market in Europe can be attributed to its strong technological expertise, robust industrial base, and emphasis on quality. German manufacturers have a long-standing reputation for technological innovation and engineering excellence, enabling them to develop advanced sensor technologies that meet industry demands. With a diverse industrial landscape encompassing key sectors like automotive, machinery, and automation, Germany has created a significant demand for machine sensors. German companies have responded to this demand by offering high-quality and reliable sensor solutions that cater to specific industry needs. The country's commitment to quality and adherence to stringent standards has further solidified its position as a trusted provider of machine sensors.

In the Asia-Pacific region, China is expected to emerge as a significant market for the machine sensor industry. China's vast population and expanding middle class are driving the demand for consumer electronics, smart devices, and automation solutions, all of which heavily rely on machine sensors for their functioning. As China continues to urbanize and embrace emerging technologies, the demand for machine sensors is expected to further increase. Furthermore, the Chinese government's focus on promoting advanced manufacturing technologies, including initiatives like Made in China 2025 and the Belt and Road Initiative, has accelerated the adoption of sensor-based automation and smart manufacturing systems. These initiatives drive the demand for machine sensors to enable the digitalization and integration of manufacturing processes.

In the LAMEA region, Latin America dominated the machine sensor market share, in terms of revenue, in 2022, and is expected to follow the same trend during the forecast period. Latin America is a region with a growing industrial sector and a significant focus on sectors such as automotive, manufacturing, mining, agriculture, and oil and gas. These industries rely on machine sensors for various applications, including process control, automation, and monitoring. As the region continues to develop and invest in advanced manufacturing technologies, the demand for machine sensors is expected to increase.

The emergence of new applications and use cases for machine sensors is driving the machine sensor market growth. Companies are recognizing the potential benefits of using sensors in various industries such as healthcare, agriculture, and smart cities. For example, sensors in healthcare can remotely monitor patients' vital signs and provide real-time data to healthcare providers for early intervention and improved patient outcomes. In agriculture, sensors can optimize crop yield and reduce waste by monitoring soil conditions, weather patterns, and plant growth. Additionally, sensors in smart cities can monitor traffic, air quality, and other environmental factors to improve public safety and the overall quality of life.

However, maintenance and calibration are significant challenges associated with machine sensors, which require regular maintenance and calibration to ensure they are functioning correctly. This can be time-consuming and expensive, especially for large numbers of sensors or sensors that are difficult to access. To overcome these challenges, manufacturers and suppliers of machine sensors may need to develop sensors that require less maintenance or can be remotely calibrated to reduce costs and improve convenience.

An opportunity for the machine sensor market is the adoption of artificial intelligence (AI) and machine learning (ML) in conjunction with sensors. Combining real-time data from sensors with advanced analytics and ML algorithms can help organizations gain deeper insights into machine performance, make more informed decisions, optimize processes, reduce costs, and improve product quality. As the use of AI and ML becomes more prevalent in various industries such as manufacturing, logistics, and healthcare, the demand for sensors capable of providing accurate and reliable data is likely to increase, creating new opportunities for the machine sensor market.

The machine sensor market is currently experiencing a significant boost due to the growing demand for advanced technologies like machine vision sensors, sensor networks, and industrial sensors. Industries have recognized the crucial role these sensors play in achieving higher levels of automation, efficiency, and precision across various applications. As a result, the machine sensor market outlook predicts substantial growth in the coming years, driven by the increasing adoption of advanced sensor technologies to enhance automation and optimize operational efficiency. This upward trend reflects the industry's recognition of the value that these sensors bring to their processes.

Top Impacting Factors

The machine sensor market is being driven by the need for automation, digitization, energy efficiency, and sustainability in various industries. Machine sensors provide real-time data on machine performance, enabling predictive maintenance and optimizing energy consumption. However, the high cost of machine sensors can be a significant barrier for smaller businesses and price-sensitive industries. The development of smart sensors with real-time data processing and analysis capabilities presents an opportunity for the machine sensor market to further enhance operational efficiency and product quality while reducing downtime.

Competitive Analysis

The machine sensor market is highly competitive, owing to the strong presence of existing vendors. Vendors of the machine sensor market with extensive technical and financial resources are expected to gain a competitive advantage over their competitors because they can cater to market demands. The competitive environment in this market is expected to increase as product launches, funding, acquisitions, agreements, collaboration, expansion, and partnerships, like different strategies adopted by key vendors, increase. Competitive analysis and profiles of the major machine sensor market players that have been provided in the report include AB Elektronik GmbH, ATI Industrial Automation, Inc., Baumer Group, FUTEK Advanced Sensor Technology, Inc., Honeywell International Inc., Infineon Technologies AG, OMRON Corporation, Sensata Technologies, Inc., TE Connectivity Ltd., and Tekscan, Inc.

Key Developments/ Strategies

According to the latest machine sensor market forecast, TE Connectivity Ltd., OMRON Corporation, Sensata Technologies, Inc., FUTEK Advanced Sensor Technology, Inc., Infineon Technologies AG, and Baumer Group are the top 6 key players in the machine sensor market. Top market players have adopted various strategies, such as product launches, funding, acquisitions, agreements, collaboration, expansion, and partnerships, to expand their foothold in the machine sensor market.

- In January 2023, TE Connectivity (TE) released M8M12 cable assemblies for applications that include sensors, robotics, and production equipment, where adverse weather is likely to be encountered. The new M8M12 cable assemblies have a protection rating of IP67, which means they are dustproof, as well as waterproof down to 1m, while also protecting from other common industrial elements, including EMI, chemicals, and mechanical stress.

- In May 2023, OMRON announced its new strategic partnership with LAMBDA Automation. In collaboration with OMRON, Strategic Partners use OMRON products and technology to accelerate the innovation of industrial automation solutions to cover the demands of End Users across important markets, including Food and Commodities, Pharma, Automotive, and Warehousing and Logistics.

- In June 2022, Sensata Technologies announced that it had developed an Intelligent Tire Pressure Monitoring System (TPMS) for vehicle OEMs to help improve vehicle safety and performance. Sensata’s Intelligent TPM Sensor is designed to be equipped with Bluetooth low-energy wireless technology. Interest in TPMS, which is compatible with Bluetooth wireless technology, is on the rise as vehicles become more connected, electrified, and autonomous.

Key Benefits for Stakeholders

- This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the machine sensor market from 2022 to 2032 to identify the prevailing machine sensor market opportunity.

- The market research is offered along with information related to key drivers, restraints, and opportunities.

- Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders to make profit-oriented business decisions and strengthen their supplier-buyer network.

- In-depth analysis of the machine sensor market segmentation assists in determining the prevailing market opportunities.

- Major countries in each region are mapped according to their revenue contribution to the global market.

- Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

- The report includes an analysis of the regional as well as global machine sensor market trends, key players, market segments, application areas, and market growth strategies.

Machine Sensor Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 35.8 billion |

| Growth Rate | CAGR of 8.2% |

| Forecast period | 2022 - 2032 |

| Report Pages | 243 |

| By Type |

|

| By End Use Industry |

|

| By Region |

|

| Key Market Players | TE Connectivity Ltd., KYOCERA AVX Components (Werne) GmbH, ATI Industrial Automation, Honeywell International Inc.,, FUTEK Advanced Sensor Technology, Inc., OMRON Corporation, Sensata Technologies, Inc., Infineon Technologies AG, Tekscan, Inc., Baumer |

Analyst Review

The machine sensor market is expected to grow in the coming years. This growth is due to various factors, such as government regulations, technological advancements, and the rising demand for predictive maintenance solutions. By utilizing predictive maintenance, organizations can identify potential machine problems before they escalate, thereby reducing downtime, maintenance costs, and enhancing operational safety and reliability. As a result, the market is witnessing the emergence of advanced sensor technologies like vibration, temperature, and acoustic sensors, designed to detect and diagnose machine faults. Key market players are keen on broadening their product range and boosting their market share through strategic initiatives. All things considered; the machine sensor market is likely to continue its growth momentum in the forthcoming years.

The Machine Sensor Market is expected to grow at a CAGR of 8.17% from 2023 to 2032.

The Automotive segment is the leading application segment of Machine Sensor Market.

Asia-Pacific is the largest regional market for Machine Sensor.

The industry size of the Machine Sensor Market is estimated to be $16,460.12 million in 2022.

The top companies to hold the market share in Machine Sensor are TE Connectivity Ltd., OMRON Corporation, Sensata Technologies, Inc., FUTEK Advanced Sensor Technology, Inc., Infineon Technologies AG, and Baumer Group.

Loading Table Of Content...

Loading Research Methodology...