Table Of Contents

Yerukola Eswara Prasad

Pooja Parvatkar

Advanced Materials: Exploring the Marvel

The chemical industry is always under a constant innovative approach, which leads to the launch of products catering to various end-use industries. Various sub-fields in the chemical industry witnessed various strategic developments in 2023. One of these technologies is advanced materials.

Advanced Materials

Advanced materials refer to materials that are engineered to possess superior properties compared to traditional materials. These properties include higher strength, improved durability, high temperature resistance, high performance, enhanced electrical or thermal conductivity, and greater resistance to corrosion or wear. Advanced materials have a combination of these properties, leading to improved product duration, low maintenance and overall low product life cost. Some of the most prominent advanced materials having a large-scale incorporation are discussed in this article.

Carbon Nanotubes

Carbon nanotube is an advanced carbon material formed by rolling up a single sheet of graphene (single-walled carbon nanotubes [SWCNT]) or by rolling up multiple sheets of graphene (multi-walled carbon nanotubes [MWCNT]). They have attracted significant research interest due to their outstanding physical, chemical, and electronic properties. Significant advancements in the manufacturing processes of MWCNTs have led to price reduction and increase in their applicability. Low price, wide array of applications, and significant supply from industry players have increased the adoption of MWCNTs for various applications, thereby driving the carbon nanotubes demand. According to a study by Allied Market Research, the Carbon Nanotube market is anticipated to register a CAGR of more than 16% between 2021 and 2030.

Conductive plastics based on carbon nanotubes have been widely used in the electronic industry for electrostatic discharge protection and prevention. Similarly, fuel line systems in automotive are made from carbon nanotubes to reduce the chances of a fuel line rupture. It controls static electricity discharges that could otherwise lead to fire in the fuel system. Carbon nanocomposites are lightweight, but strong to be made into tire reinforcements, car interior, & exterior parts. For instance, CNTs are utilized in the automotive industry to produce energy storage components; printable, thermoformable, capacitive touch sensors for replacing membrane switches in automotive interiors; interior panels and many more. They can enhance the strength of vehicle bodies and decrease their weight, resulting in improved fuel efficiency.

Shape Memory Alloys

Shape memory alloys are often defined as alloys that revisit to their original shape when deformed. These alloys are lightweight and are alternatives to conventional actuators such as pneumatic, motor-based, hydraulic systems.

Shape memory alloys are used in various applications such as biomedical, electronic components, panels components and many more. Shape memory alloys are frequently used in biomedical applications, owing to their biocompatibility, especially in medical implants. Mechanical properties of implant materials have a big role in the treatment after an implant surgery. Owing to their bend resistance, pressure stability, high ductility, and corrosion resistance, nickel titanium shape memory alloys are often used in medical implants. Also, shape memory alloys are used in a variety of applications in the automotive industry, including actuators (thermal or electrical) that improve comfort, safety, and control. Shape memory alloys improve safety, performance, energy efficiency, and comfort of automobiles. Shape memory actuators have the advantage of not requiring a heavy and complex mechanical design to function, as active element (e.g., shape memory alloys wire or spring) can be deformed with a small amount of external force and return to their original shape, when exposed to thermomechanical or magnetic variation. Below are the major biomedical device companies and their revenue.

?

Many of the countries in the Asia-Pacific region, including China and India are among the fastest-growing nations, in terms of population size, which propels demand for automobile. Increase in demand from the automobile industry is the primary driving factor for growth of shape memory alloys. Furthermore, rise in industrialization and urbanization further boost demand for shape memory alloys in Asia-Pacific. Also, an increase in government spending in the healthcare and defense sector is expected create lucrative opportunities for the shape memory alloys demand in the coming years. According to a study by Allied Market Research, the shape memory alloys market is expected to grow at a CAGR of more than 8% between 2021 and 2030.

Glass Fiber Reinforced Composites

Glass fiber, also known as fiberglass, is a material made from extremely fine fibers of glass. These fibers can be woven into fabrics or used as a reinforcement in various composites. Glass fiber composites exhibit various properties such as high strength, high temperature resistance, impact resistance and so on making them useful in different end-use industries.

Glass fiber reinforced composites are used in automotive & transportation, aerospace & defense, sporting goods, pharmaceutical, building & construction and other end-use industries predominantly. The glass fiber reinforced composites market for aerospace applications is influenced by several factors that highlight the unique properties of glass fibers and their suitability for various aerospace components. Glass fiber composites can contribute to noise reduction in aircraft. Components such as acoustic panels and insulation materials made with glass fibers help mitigate noise levels within the cabin. The aerospace industry, especially in the context of unmanned aerial vehicles (UAVs) and drones, may use glass fiber-reinforced materials in the construction of wind turbine blades for alternative propulsion systems. Glass fibers, being recyclable and with a lower environmental impact compared to some alternative materials, align with the sustainability goals of industry.

Lightweight materials are in high demand in the automotive industry to improve fuel efficiency and reduce emissions. Glass fiber-reinforced composites, known for their high strength-to-weight ratio, are used in the manufacturing of automotive components, including body panels, interiors, and structural elements. The use of glass fiber composites helps automotive manufacturers reduce the weight of vehicles, contributing to improved fuel efficiency. This is crucial for meeting regulatory standards and addressing environmental concerns. The growth in the market for electric and hybrid vehicles places a premium on lightweight materials to extend the range and improve the overall efficiency of these vehicles. Glass fibers exhibit excellent electrical insulation properties. They are used in the manufacturing of electrical insulating materials such as laminates, tapes, and sheets, providing insulation against electrical currents. Glass fiber-reinforced composites are commonly used in the production of PCBs. Glass fiber-reinforced epoxy laminates are widely employed as substrates for PCBs due to their excellent dimensional stability, mechanical strength, and electrical insulation properties. Glass fiber-reinforced plastics (GFRP) are used in the fabrication of electronic enclosures and housing components.

China is a global manufacturing hub, and its rapid industrialization and infrastructure development have driven the demand for materials such as glass fiber composites. The manufacturing sector uses glass fiber composites for various applications, including automotive components and construction materials. India has been investing in renewable energy projects, and the role of glass fiber composites in the wind energy sector supports the growth of the industry. Government initiatives promoting infrastructure development, manufacturing, and sustainability contribute to the increased use of glass fiber in various applications. Japan has a strong presence in both the automotive and aerospace industries. Glass fiber composites is used in the manufacturing of lightweight components for vehicles and aircraft. Due to these factors the demand for glass fiber reinforced composites is expected to increase considerably. According to a study by Allied Market Research, the demand for glass fiber reinforced composites is expected to witness a CAGR of more than 6% during 2021-2032.

Carbon Nanomaterials

Carbon nanoparticles are a unique class of materials that have widespread applications in biomedical fields, such as drug delivery, biomedical imaging, biosensors, tissue engineering, and cancer therapy. Carbon nanomaterials can have numerous forms, including nanodiamonds, nanotubes, and graphene. These materials can be customized for a particular purpose owing to their diverse electrical, chemical, and magnetic properties as well as their exceptional structural strength.

Various end-use industries, such as the medical, automotive, chemical, and energy sectors, are increasing their need for carbon nanomaterials to produce stronger, lighter, more durable, and more reactive materials. Carbon nanomaterials are widely employed in medicine and pharmaceuticals for the sensitive detection of essential biological molecules, more accurate and safer imaging of sick tissues, and innovative forms of treatment, owing to their electrical, optical, mechanical, and chemical capabilities. Several therapeutic and diagnostic agents based on carbon nanoparticles have been created for the treatment of cancer, diabetes, pain, asthma, allergy, and infections, resulting in a burgeoning market for these nanomaterials. Also, owing to their better mechanical qualities and lightweight properties, has prompted the automobile industry to use carbon nanoparticles into the design and production of car interiors and exteriors. Carbon nanomaterials are commonly employed in vehicles to lower weight of the aluminum engine, to improve grip and minimize rolling resistance; in Li-ion batteries to shorten the recharging time, raise the tensile strength, and to reduce the weight of automobiles.

According to a study by Allied Market Research, the carbon nanomaterials market is anticipated to register a growth rate of more than 27% between 2022 and 2031.

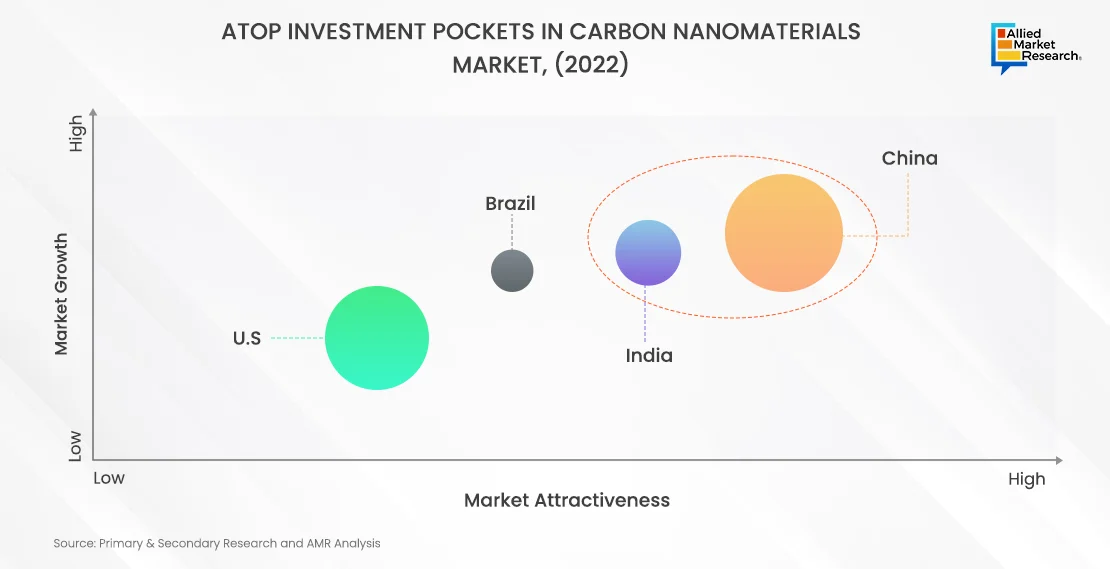

The above figure illustrates China and India as having the highest investment potential in carbon nanomaterials market. Due to rapid industrialization and rise in investments in the medical and automotive sectors in developing nations such as China, India, South Korea, and Singapore, Asia-Pacific is anticipated to witness the highest growth rate. Increase in production in different industries, including automotive, defense, marine and aerospace, is expected to drive regional demand for the product during the forecast period. The vast graphite resources present in China offer enormous scope to the local manufacturers to enter the graphene market. China is the leading producer of graphene films, which are widely used in cell phones and computer touch screens.

The market for carbon nanomaterials has a significant amount of unrealized potential in underdeveloped sectors such as the aerospace and energy industries.

Key Takeaways

As we navigate an era marked by rapid technological evolution, the role of advanced materials becomes increasingly integral. Their continuous development and application promise not only improved performance but also contribute to the creation of sustainable and environmentally friendly solutions. Get in touch with AMR analysts for deeper insights on the market.