Table Of Contents

Sonia Mutreja

Koyel Ghosh

Electrifying the Construction Industry: Exploring the Rising Demand for Electric Construction Equipment

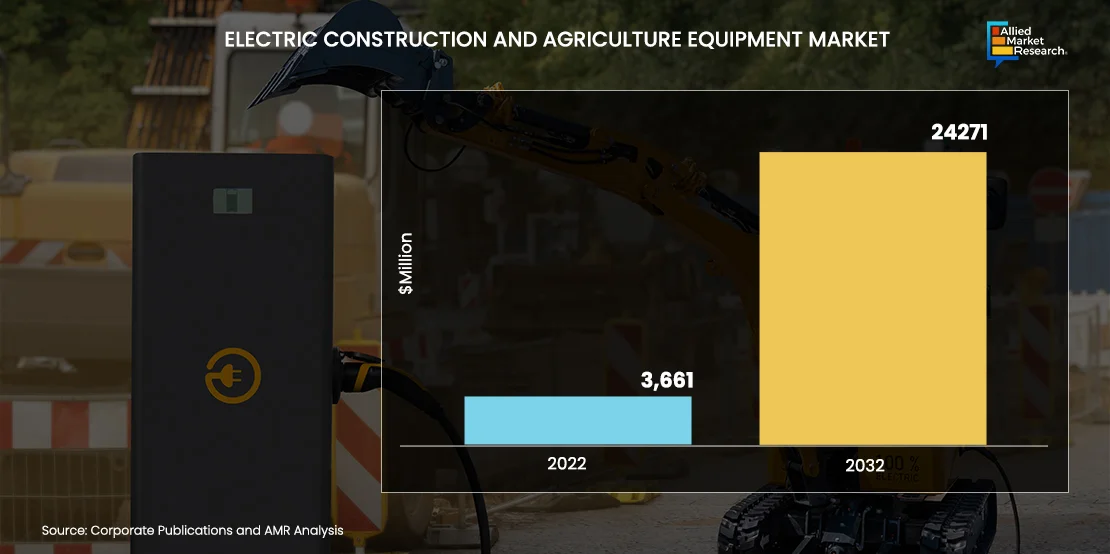

In the last few years, there’s been a significant growth in the use of electric construction equipment, driven by the escalating demand for eco-friendly and efficient machinery within the construction domain. As of 2023, the sector has been witnessing a substantial shift toward electrification, primarily fueled by the need to reduce greenhouse gas emissions and promote sustainability. The electric construction and agriculture equipment industry was valued at $3,661.3 million in 2022 and is estimated to grow at a CAGR of over 20% from 2023 to 2032.

A pivotal factor driving the industry is the innovation in battery technology and electric propulsion systems, making electric construction equipment more viable and attractive. Companies like Komatsu and Volvo CE are leading the way, introducing electric excavators and other equipment that promise zero emissions, reduced noise levels, and lower operational costs??. For instance, Volvo's ECR25 Electric excavator, used in the construction and installation of electric vehicle charging points, exemplifies the market's shift toward machines that offer robust performance while eliminating emissions and reducing noise and vibrations. Similarly, Komatsu's display of electrified equipment at international trade exhibitions highlights the industry's commitment to lowering emissions globally.

Regions such as Asia-Pacific, Europe, and North America are leading in adopting electric construction equipment, driven by stringent environmental regulations, government incentives, and a collective commitment to achieving carbon neutrality. The Asia-Pacific region is projected to emerge as the largest market, with China, Japan, and South Korea leading the trail owing to their significant advancements in battery manufacturing and electric equipment production.

Challenges such as high initial costs and the need for charging infrastructure are being addressed through technological advancements and strategic partnerships. Advancements in equipment with larger battery capacities (over 500 kWh) are anticipated. These developments aim to meet the demands of tougher construction tasks, overcoming previous limitations. They also set the standard for the broader adoption of electric construction equipment. The industry is set to grow significantly due to advancements in technology, support from regulations, and a move toward eco-friendly construction practices. This growth reflects the industry's determination to innovate and promote environmental responsibility.

Challenges and Constraints

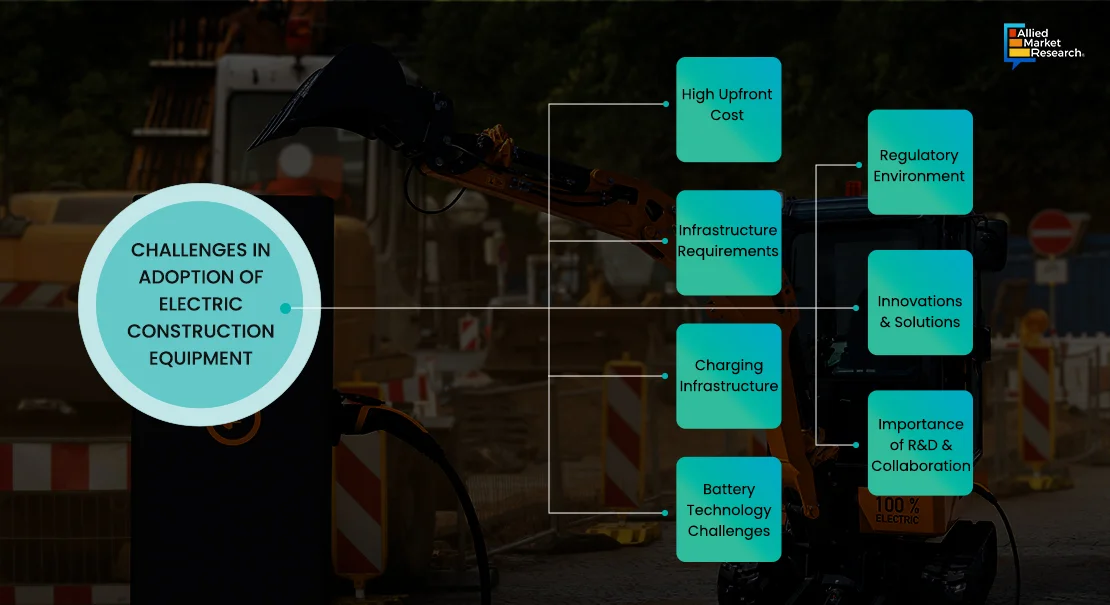

The growth of the Electric Construction Equipment Market faces certain obstacles and limitations. This is due to the hurdles related to initial costs, infrastructure requirements, and technological limitations.

One of the primary challenges is the high upfront cost of electric construction equipment, which can be 20-50% more expensive than conventional machinery. This price discrepancy stems from the costly battery technology and specialized components needed for electric systems. Furthermore, the existing infrastructure for electric equipment is not as developed or optimized as that for traditional machinery, contributing to higher initial investments.

Another significant challenge is the necessity for a robust charging infrastructure to support the widespread adoption of electric construction equipment. The transition to electric machinery heavily depends on the availability of reliable and efficient charging solutions on construction sites. The requirement for charging stations represents a notable departure from conventional equipment that can be quickly refueled with gasoline or diesel. Establishing these charging stations strategically and cost-effectively remains a considerable obstacle.

Additionally, technological advancements in battery technology, while promising, also present challenges. While lithium-ion batteries are gaining popularity due to their higher energy density and quicker charging speeds, there's an ongoing need for development in this area to enhance equipment runtimes and reduce downtime. Moreover, larger batteries face integration challenges within the confined spaces of construction equipment, calling for advancements in battery capacity and efficiency.

Complying with strict emissions and noise regulations in the construction sector is challenging due to the regulatory environment. However, these regulations drive the market toward more sustainable practices. In Europe, for instance, strict emissions requirements for construction machinery have prompted the adoption of electric and hybrid powertrains to meet Stage V emissions standards.

It's crucial to tackle these challenges for the electric construction equipment industry to keep growing. In April 2023, Volvo Construction Equipment teamed up with Portable Electric to offer mobile charging solutions. Caterpillar and Pon Equipment also launched an all-electric excavator. These innovations aim to reduce the carbon footprint on construction sites and improve the working environment by lowering noise and air pollution.

To succeed in the market's challenges and grab the opportunities of sustainable construction demand, it's important for companies to invest in R&D and collaborate across the industry.

Innovations and Advancements

The electric construction equipment industry is witnessing significant innovations and advancements, with major players like Komatsu Ltd., Caterpillar Inc., and Hitachi Construction Machinery leading the charge toward a more sustainable and efficient future. These advancements are important for the industry's move to electric power, aiming to cut carbon emissions and enhance efficiency. Komatsu Ltd. is set to launch its 20-ton electric excavators, powered by lithium-ion batteries, in Japan and Europe, marking a significant advancement in electric construction equipment. This move is part of Komatsu's broader strategy to become carbon neutral by 2050. The company's collaboration with Proterra, a known entity in high-load handling and commercial vehicles, highlights a commitment to innovation. These electric models, including the PC200LCE-11 and 210LCE-11, are designed to offer environmental friendliness and safety, with zero exhaust emissions and reduced noise, making them ideal for urban construction projects.

On a broader scale, the electric construction equipment industry is embracing battery technology advancements, particularly in Lithium Nickel Cobalt Aluminum (NCA) and solid-state batteries. These developments are expected to enhance the efficiency and longevity of electric construction machinery, thereby supporting the sector's growth. The rise of earthmoving equipment, including excavators, loaders, and motor graders, as the fastest-growing segment, highlights the industry's direction toward electrification. This trend is particularly evident in Asia, where countries like China, India, and Japan are driving demand due to extensive developmental activities and significant infrastructure projects.

Companies are developing new electric construction equipment to meet changing industry demands. These efforts support sustainability and efficiency goals, representing a significant change in construction practices. As these technologies develop further, they're expected to transform the construction industry by providing better, eco-friendly, and easier-to-use solutions for modern infrastructure projects.

Case Study: Electrifying Landscaping Operations at the Eden Project

The Eden Project, situated in Cornwall, UK, is renowned for its innovative approach to environmental sustainability and conservation. With its iconic covered Biomes replicating diverse ecosystems like tropical rainforests and the Mediterranean, the Eden Project serves as a beacon of environmental stewardship, attracting over 600,000 visitors annually. In a groundbreaking collaboration with Volvo Construction Equipment (Volvo CE), the Eden Project embarked on a three-month project to showcase the efficacy of electric construction equipment in landscaping applications, aiming to reduce emissions while maintaining high productivity.

Championing Sustainability through Collaboration

The partnership between the Eden Project and Volvo CE exemplifies a shared commitment to environmental responsibility and societal change. By harnessing the power of electromobility, the project aimed to demonstrate the feasibility and benefits of adopting electric construction solutions in the landscaping sector. This collaboration not only highlighted the potential for decarbonization but also provided a platform to inspire broader industry transformation toward sustainability.

Achieving Environmental and Operational Excellence

The main focus of the project was using Volvo CE's ECR25 Electric compact excavator and L25 Electric compact wheel loader, which produce zero emissions. These electric machines, equipped with various attachments, are seamlessly integrated into landscaping operations, including the construction of a 10,000-square-meter garden nursery and maintenance tasks within the Biomes. Despite operating in a highly sensitive environment, the electric equipment delivered the same performance as their diesel counterparts while eliminating emissions and minimizing noise pollution.

Realizing Environmental and Economic Benefits

Over the three months, the electric construction equipment facilitated a total CO2 saving of three tons and conserved nearly 2,000 kWh of energy. Operators praised the machines for their smooth operation and quick responsiveness, ensuring minimal disruption to delicate plant life and visitor experience. The Eden Project's ready availability of power outlets enabled efficient charging of the electric equipment, further streamlining operations, and showcasing the viability of electromobility in real-world scenarios.

Pioneering Sustainable Solutions for the Future

The success of the project highlights the transformative potential of electromobility in diverse sectors, including landscaping. By embracing electric construction equipment, organizations can significantly reduce their carbon footprint without compromising productivity or performance. As Volvo CE continues to lead the way with its evolving range of electric and charging solutions, the Eden Project serves as a perfect example of sustainable innovation and environmental stewardship in action. Through collaborative efforts and strategic partnerships, the path toward a greener and more sustainable future is within reach.

Summing up

The future of the electric construction equipment industry looks bright, propelled by technological advancements, regulatory support, and a growing demand for sustainable construction solutions. As companies invest more in research and teamwork, they're expected to transform construction methods, providing eco-friendly, efficient, and cost-effective options compared to usual machinery.

Allied Market Research delves into the wide industry of electric construction equipment, providing in-depth analyses of technological advancements, market dynamics, and regulatory landscapes influencing the industry. Our exhaustive reports are designed to equip stakeholders with valuable insights into the pivotal role of electric equipment in boosting construction efficiency, safety, and environmental sustainability. Businesses can take advantage of new opportunities, drive innovation, and encourage smarter, more eco-friendly building practices to improve efficiency in the sector.

For an in-depth analysis of the growth drivers and investment opportunities in the construction and manufacturing industry, feel free to contact our experts!