Wafer Backgrinding Tape Market Outlook – 2030

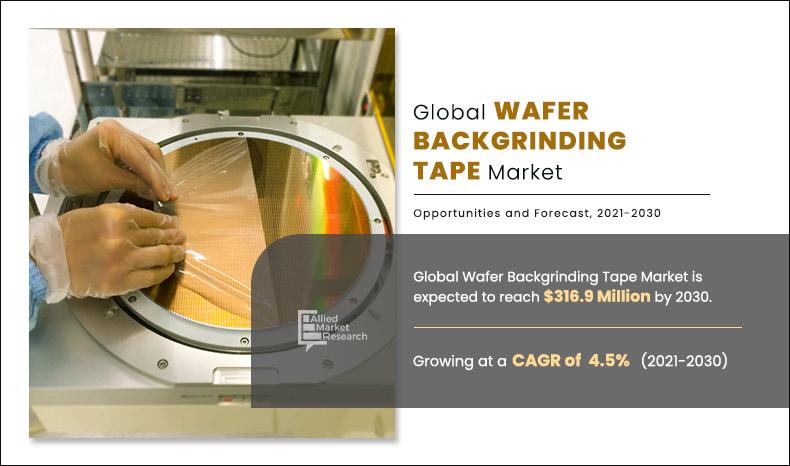

The global wafer backgrinding tape market size was valued at $201.6 million in 2020, and is projected to reach $316.9 million by 2030, registering a CAGR of 4.5%. Wafer backgrinding is a semiconductor device fabrication step during which wafer thickness is reduced to allow stacking and high-density packaging of integrated circuits. It is the process of grinding the backside of the wafer to the correct wafer thickness prior to assembly.

Rise in need for wafer fabrication, increase in focus toward wafer surface protection during grinding process and growth in the semiconductor industry primarily drive the growth of the global wafer backgrinding market. However, increase in shift from non-UV to UV curable backgrinding tapes, which increases the overall cost of wafer manufacturing, is expected to restrain the market growth.

By region, the wafer backgrinding market trends have been analyzed across North America, Europe, Asia-Pacific, and LAMEA. Asia-Pacific accounted for a significant share of the global market in 2020 and is expected to be lucrative market in terms of revenue during the forecast period. Organizations across verticals in this region are realizing the importance of enhanced semiconductor technologies to ensure efficient power management, owing to an increase in demand for high voltage operating devices. In addition, emerging countries such as India, Philippines, and others are expected to offer lucrative opportunities for wafer backgrinding tape market growth. For instance, India has a very fast-growing electronics system design manufacturing (ESDM) industry.

North America is the second largest region, in terms of revenue generation, in the global wafer backgrinding tape market share. The region is one of the key contributors to the wafer backgrinding tapes market, owing to technological advancements, innovations, and investments in the respective industry. Wide acceptance and usage of semiconductor chips and ICs across North America is due to increase in need for smart technologies and devices.

Top Impacting Factors

As per the latest wafer backgrinding tape market trends The factors that drive the growth of the market include rise in need for wafer fabrication, increase in focus toward wafer surface protection during grinding process and growth in the semiconductor industry. However, increase in shift from non-UV to UV curable backgrinding tapes, which increases the overall cost of wafer manufacturing is expected to restrain the wafer backgrinding tape market growth. Moreover, increase in investment in wafer fabrication equipment and materials especially in developing countries such as China, Taiwan, and South Korea provides lucrative market opportunities in the coming years.

By Type

Non-UV segment will dominate the market throughout the forecast period

Segment Overview

The global wafer backgrinding tape market is segmented on the basis of type, wafer size, and region. Based on type, the market is bifurcated into UV curable and non-UV. Based on wafer size, the market is divided into 6-inch, 8-inch, 12-inch, and others. Based on region, it is analyzed across North America, Europe, Asia-Pacific, and LAMEA along with their prominent countries.

By Wafer Size

12-Inch segment projected to be the most lucrative segment during 2021 - 2030

Competitive Analysis

Competitive analysis and profiles of the major wafer backgrinding tape market players such as Furukawa Electric Co. Ltd., Mitsui Chemicals Inc., Nitto Denko Corporation, Minitron Elektron GMBH, Denka Company Limited, Lintec of America Inc., AI Technology, Inc., Force-One Applied Materials Inc., AMC Co, Ltd, and Pantech Tape Co. Ltd. These market players have adopted various strategies such as product launch, collaboration & partnership, joint venture, and acquisition to expand their foothold in the wafer backgrinding tape industry.

By Region

Asia-Pacific region would exhibit the highest CAGR of 4.9% during 2021 - 2030

COVID-19 Impact Analysis

The emergence of coronavirus has become a disastrous issue worldwide. There is a halt in the production process, owing to the global lockdown scenario causing disruption in the overall supply chain of electronic components. COVID-19 outbreak has also caused lag in meeting requirements of end users as the epicenter of virus outbreak Wuhan, China accounts for the largest manufacturing items of electronic components.

The COVID-19 crisis has led to the decrease in business confidence, uncertainty in the stock market, and immense slowing of the supply chain operations. The overall impact of the pandemic is impacting the production process of several industries including Semiconductor and Electronics, and others. Trade barriers are further constraining the demand and supply outlook. The overall production process is adversely affected as the government of different countries has already announced total lockdown and temporary shutdown of industries.

Key Benefits For Stakeholders

- This study comprises analytical depiction of the global wafer backgrinding tape market size along with the current trends and future estimations to depict the imminent investment pockets.

- The overall wafer backgrinding tape market analysis is determined to understand the profitable trends to gain a stronger foothold.

- The report presents information related to key drivers, restraints, and opportunities with a detailed impact analysis.

- The current wafer backgrinding tape market forecast is quantitatively analyzed from 2020 to 2030 to benchmark the financial competency.

- Porter’s five forces analysis illustrates the potency of the buyers and the wafer backgrinding tape market share of key vendors.

- The report includes the market trends and the wafer backgrinding tape market opportunity of key vendors.

Wafer Backgrinding Tape Market Report Highlights

| Aspects | Details |

| By Type |

|

| By Wafer Size |

|

| By Region |

|

| By Key Market Players |

|

Analyst Review

According to the insights of the CXOs of leading companies, the wafer backgrinding tape market is expected to leverage considerable potential for the semiconductor industry. The current business scenario is witnessing an increase in the demand for integrated chips, microcontrollers, MCUs, particularly in the developing regions such as China, India, and others, due to an increase in government mandates related to investing in semiconductor manufacturing. Companies in this industry are adopting various innovative techniques such as mergers and acquisition activities to strengthen their business position in the competitive matrix.

Wafer backgrinding tapes are mainly used in processing semiconductor wafers made from materials such as silicon or glass. Its powerful adhesive strength keeps wafers in place when grinding and cutting. Once the wafer has been processed, exposing the tape to ultraviolet light (UV) reduces its adhesive strength, making tape peeling, or die pick up simple.

The wafer backgrinding tape market is steadily gaining traction, owing to growth in the semiconductor industry, increase in need for wafer fabrication, and rise in focus toward wafer surface production. In addition, increase in investment in wafer fabrication equipment and materials especially in countries such as South Korea, China, and Japan is expected to offer lucrative opportunities for the wafer backgrinding tape market globally. The wafer backgrinding tapes market provides numerous growth opportunities to the market players such as Furukawa Electric Co. Ltd., Mitsui Chemicals, Nitto Denko Corporation, and Denka Company Limited.

The Wafer Backgrinding Tape Market is estimated to grow at a CAGR of 4.5% from 2021 to 2030.

The Wafer Backgrinding Tape Market is projected to reach $316.9 million by 2030.

To get the latest version of sample report

Rise in need for wafer fabrication, and increase in focus toward wafer surface protection during grinding process etc. boost the market growth.

The key players profiled in the report include Furukawa Electric Co. Ltd., Mitsui Chemicals Inc., Nitto Denko Corporation, and many more.

On the basis of top growing big corporations, we select top 10 players.

The Wafer Backgrinding Tape Market is segmented on the basis of type, wafer size, and region.

The key growth strategies of Wafer Backgrinding Tape market players include product portfolio expansion, mergers & acquisitions, agreements, geographical expansion, and collaborations.

Asia-Pacific region would grow at a highest CAGR of 4.9% during the forecast period.

12-Inch segment will dominate the market during 2021 - 2030.

Loading Table Of Content...