Battery Materials Recycling Market Overview

The global battery materials recycling market was valued at USD 26.3 billion in 2022, and is projected to reach USD 56.9 billion by 2032, growing at a CAGR of 8.1% from 2023 to 2032.

Report Key Highlighters

- The battery materials recycling market study covers 20 countries. The research includes a segment analysis of each country in terms of both value ($million) for the projected period 2023-2032.

- The study integrated high-quality data, professional opinions and analysis, and critical independent perspectives. The research approach is intended to provide a balanced view of global markets and to assist stakeholders in making educated decisions in order to achieve their most ambitious growth objectives.

- Over 3,700 product literatures, annual reports, industry statements, and other comparable materials from major industry participants were reviewed to gain a better understanding of the market.

- The battery materials recycling market share is highly fragmented, with several players including Cirba Solutions, Eco-Bat Technologies, GEM Co., Ltd., Gopher Resource, GRAVITA INDIA LIMITED, Li-Cycle, RecycLiCo Battery Materials Inc., Redux GmbH, Redwood Materials Inc., and Umicore N.V. Also tracked key strategies such as acquisitions, product launches, mergers, expansion etc. of the players operating in the aerogel market.

Introduction

Battery materials recycling refers to the process of recovering and reusing valuable materials from used or spent batteries. Batteries contain various components and materials, including metals, electrolytes, and plastics, which may be extracted and recycled to minimize waste and environmental impact. The used batteries are collected and sorted according to their types, such as lithium-ion, nickel-metal hydride, or lead-acid batteries. Then, the batteries undergo a mechanical or chemical process to break them down into their individual components. The components are separated and treated to isolate the valuable materials. This typically involves techniques such as smelting, leaching, or chemical precipitation. Metals such as lithium, cobalt, nickel, manganese, and lead may be recovered from the battery materials and used in the production of new batteries or other applications.

The materials are refined and purified to meet the required specifications for reuse. The recycled materials may then be used in the manufacturing of new batteries or other products, reducing the need for extracting and processing raw materials from the earth. Battery materials recycling plays a crucial role in reducing the environmental impact of batteries and promoting a circular economy. It helps to conserve natural resources, reduces energy consumption, and minimizes the release of potentially hazardous substances into the environment. In addition, it is projected to contribute to the overall sustainability and long-term viability of battery technologies, which are increasingly being used in various sectors, including electric vehicles and renewable energy storage systems.

Battery recycling is essential due to the increase in demand for batteries in various industries, such as automotive, electronics, and renewable energy. Recycling helps recover valuable metals and materials, reduces reliance on mining, conserves resources, and mitigates the environmental impact of battery production and disposal. The lithium-ion batteries used in electric vehicles contain important metals such as lithium, cobalt, and nickel. Recycling these materials contributes toward meeting the increasing demand for battery production while lowering dependency on mining and minimizing environmental impacts. The rapid growth of the electric vehicle market has led to an increased demand for battery materials recycling.

Battery Energy Storage Systems (BESS) are vital for storing renewable energy and balancing grid demand. Recycling battery materials allows for the recovery of valuable metals, which may be used to produce new batteries for energy storage applications. It contributes to the sustainability of renewable energy systems and reduces the environmental footprint of energy storage technologies.

The extraction and processing of raw materials for battery production may have adverse environmental consequences, including habitat destruction, water pollution, and greenhouse gas emissions. The need for extracting and refining new raw materials is reduced by recycling battery materials, resulting in a lower environmental footprint associated with battery production.

The battery materials recycling market forecast growth is primarily driven by the increased demand for recycled battery materials in electric vehicles.

The growing demand for electric vehicles (EVs) has resulted in an increased need for recycled battery materials such as lithium, cobalt, nickel, and graphite. Lithium is a crucial component in EV batteries, and its demand has increased due to the popularity of EVs. Recycling battery materials is an important part of sustainable EV production as it may help reduce the demand for raw materials. Efforts are underway to improve recycling infrastructure and recover valuable materials from used EV batteries.

In 2022, over 10 million electric cars were sold worldwide, with sales projected to increase by 35% this year. Europe and California have set targets for EVs to make up a significant portion of new car sales by 2030. Recycling battery materials help mitigate the environmental impact of the EV industry, as battery production requires large amounts of raw materials, which may have negative environmental consequences when extracted. By 2029, electric vehicles could account for a third of the North American market and approximately 26% of global vehicle production.

Driving sustainable development, particularly in the context of battery materials recycling, requires prioritizing e-waste management and establishing circular supply chains.

The increase in battery usage in electronic devices and electric vehicles has led to a rise in electronic waste, which poses environmental and health risks if not handled properly. E-waste recycling is crucial for extracting valuable components from discarded electronics, including precious metals, plastics, and battery materials. Battery recycling is an essential part of managing e-waste, involving mechanical and chemical processes to recover metals like lithium, cobalt, nickel, and lead. These metals can be reused in the production of new batteries or other applications.

The Global Battery Alliance (GBA) is a collaborative effort aiming to establish a sustainable and responsible battery value chain. They provide trusted information and a quality seal to ensure responsible sourcing, management, recycling, and use of batteries throughout their lifecycle. Mechanical processes, such as shredding and crushing, are used to break down batteries for easier separation and metal extraction.

However, the complex and costly process of recycling battery materials is expected to hinder the growth of the battery materials recycling market during the forecast period. Battery recycling involves complex and costly processes to extract valuable materials such as lithium, cobalt, nickel, and rare metals, which are tightly bound within the battery cells. The lack of standardization in recycling processes poses challenges for facilities, increasing operational costs and complexity. Safety measures are crucial due to hazardous materials in batteries. Overcoming these challenges requires investments in research and development, standardization, government support for recycling infrastructure, and financial incentives to make recycling economically feasible.

Segment Overview

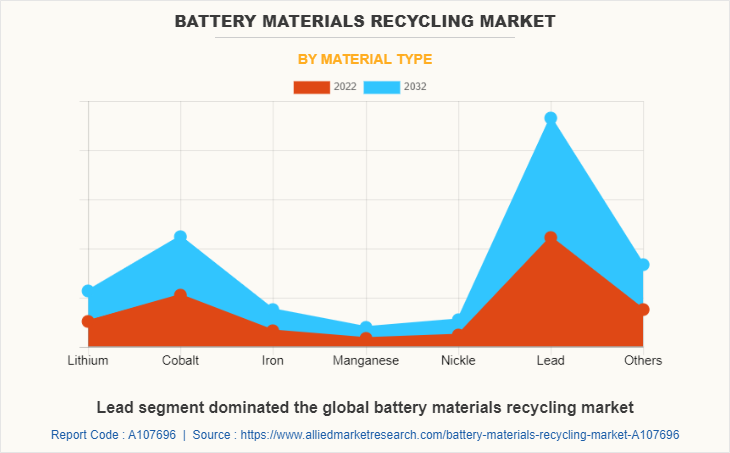

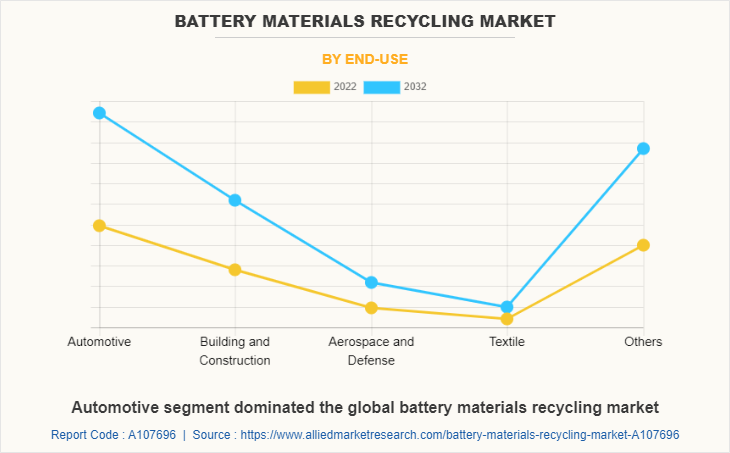

The battery materials recycling is segmented into material type, end-use industry, and regions. On the basis of material type, the market is categorized into lithium, cobalt, iron, manganese, nickel, lead, and others. On the basis of end-use industry, the market is divided into automotive, building and construction, aerospace & defense, textile, and others. Region-wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

Lead is a versatile and widely used material in various applications, including battery recycling. It is highly valued for its exceptional properties such as high density, malleability, low melting point, and resistance to corrosion. Lead batteries are one of the most common types of batteries used in numerous industries, ranging from automotive to renewable energy storage. The recycling of lead batteries plays a crucial role in sustainable resource management and reducing the environmental impact of battery waste.

Lead battery recycling offers several environmental benefits. It helps reduce the environmental impact of battery waste by preventing the improper disposal of lead-containing batteries, which can leach toxic substances into the soil and water. By recycling lead batteries, valuable resources can be conserved, reducing the need for new lead mining and extraction, which can have negative environmental consequences.

Battery recycling plays a crucial role in the sustainability and environmental impact of the automotive industry, particularly with the increasing adoption of electric vehicles (EVs). As electric vehicles (EVs) become increasingly popular, there is a rising demand for battery materials and the development of efficient recycling methods. This shift in the automotive industry toward EVs is driving a significant transformation. To meet their power storage needs, EVs heavily rely on rechargeable lithium-ion batteries. These batteries consist of valuable resources like lithium, cobalt, nickel, and manganese, which play a crucial role in the production of new batteries. Ensuring the sustainable use and recycling of these materials has become essential.

Europe is actively investing in advanced recycling technologies to enhance the efficiency and effectiveness of battery material recycling. These technologies encompass hydrometallurgical and pyrometallurgical processes, as well as innovative separation techniques, all aimed at recovering and refining metals from spent batteries. Europe is actively investing in advanced recycling technologies to enhance the efficiency and effectiveness of battery material recycling. These technologies encompass hydrometallurgical and pyrometallurgical processes, as well as innovative separation techniques, all aimed at recovering and refining metals from spent batteries.

Key Market Players

The major players operating in the battery materials recycling market growth include Cirba Solutions, Eco-Bat Technologies, GEM Co., Ltd., Gopher Resource, GRAVITA INDIA LIMITED, Li-Cycle, RecycLiCo Battery Materials Inc., Redux GmbH, Redwood Materials Inc., and Umicore N.V.

Historical Trends of Battery Materials Recycling

In (1980s-1990s) the battery materials recycling focused primarily on lead-acid batteries used in vehicles and industrial applications. The recycling process involved breaking down the batteries, recovering the lead, and reusing it in new battery production. These efforts were driven by environmental concerns and regulations regarding lead pollution.

In the 1990s, as the use of nickel-cadmium batteries grew in portable electronics, efforts were made to develop recycling processes for these batteries. Nickel and cadmium were recovered through smelting processes, and the recovered materials were used in the production of stainless steel and new batteries.

The widespread adoption of lithium-ion batteries in the 2000s prompted a focus on developing recycling solutions for this technology. Lithium-ion battery recycling processes typically involve mechanical, pyrometallurgical, and hydrometallurgical methods. Mechanical processes involve shredding the batteries to recover valuable metals such as lithium, cobalt, nickel, and copper.

In 2010 the demand for lithium-ion batteries increased significantly, driven by the growing popularity of mobile devices and the emerging electric vehicle market. Recycling efforts for lithium-ion batteries began to gain momentum. Several research initiatives focused on developing efficient and cost-effective recycling technologies for lithium-ion batteries.

In 2015, governments and regulatory bodies worldwide started recognizing the importance of battery recycling and began implementing policies to promote and regulate the industry. Battery manufacturers and electronics companies became more involved in recycling initiatives, collaborating with recycling facilities and investing in research and development.

Key Benefits For Stakeholders

This report provides a quantitative analysis of the market segments, current trends, estimations, and dynamics of the battery materials recycling market analysis from 2022 to 2032 to identify the prevailing battery materials recycling market opportunities.

The market research is offered along with information related to key drivers, restraints, and opportunities.

Porter's five forces analysis highlights the potency of buyers and suppliers to enable stakeholders make profit-oriented business decisions and strengthen their supplier-buyer network.

In-depth analysis of the battery materials recycling market size assists to determine the prevailing market opportunities.

Major countries in each region are mapped according to their revenue contribution to the global market.

Market player positioning facilitates benchmarking and provides a clear understanding of the present position of the market players.

The report includes the analysis of the regional as well as global battery materials recycling market trends, key players, market segments, application areas, and market growth strategies.

Battery Materials Recycling Market Report Highlights

| Aspects | Details |

| Market Size By 2032 | USD 56.9 billion |

| Growth Rate | CAGR of 8.1% |

| Forecast period | 2022 - 2032 |

| Report Pages | 300 |

| By Material Type |

|

| By End-Use |

|

| By Region |

|

| Key Market Players | Gopher Resource, Umicore N.V., Redwood Materials Inc., GEM Co., Ltd., Gravita India Limited, Redux GmbH, Li-Cycle, RecycLiCo Battery Materials Inc., Eco-Bat Technologies, Cirba Solutions |

Analyst Review

According to the opinions of various CXOs of leading companies, the battery recycling materials market is driven by E-waste management and circular supply chains. E-waste management and circular supply chains are crucial for sustainable development, especially regarding battery materials recycling. The accumulation of electronic waste has increased with the growing use of batteries in electronic devices and electric vehicles. E-waste recycling is essential for extracting valuable components such as precious metals, plastics, and battery materials from discarded devices.

However, the complex and costly process of recycling battery materials is expected to restrain industry expansion. Battery recycling is a complex and costly process that requires advanced technologies to extract valuable materials such as lithium, cobalt, nickel, and rare metals. These materials are tightly bound within battery cells, making extraction challenging as it requires specialized equipment. The lack of standardization among batteries complicates recycling facilities' operations, as it needs multiple systems to handle different types. Safety measures are crucial to protect workers and prevent environmental contamination, adding to the overall cost of recycling operations.

The Europe region is projected to register robust growth during the forecast period. Europe is exploring the concept of "second life" for batteries, where used batteries that no longer meet the performance requirements of EVs may be repurposed for stationary energy storage applications. This approach extends the useful life of batteries and reduces the demand for new battery production. According to calculations by Fraunhofer ISI, the number of batteries to be recycled in Europe will reach 420 kilotons by 2030 (scenario range 200-800 kt) and 2100 kilotons by 2040. In January 2023, 50 kilotons of spent batteries are recycled annually in Europe.

The battery materials recycling is segmented into material type, end-use industry, and regions. On the basis of material type, the market is categorized into lithium, cobalt, iron, manganese, nickel, lead, and others. On the basis of end-use industry, the market is divided into automotive, building and construction, aerospace & defense, textile, and others. Region-wise the market is studied across North America, Europe, Asia-Pacific, and LAMEA.

Increase in demand for recycled battery materials in electric vehicles and E-waste management and circular supply chains

Implementation of environmental protection is the upcoming trends of battery materials recycling market in the world.

Cirba Solutions, Eco-Bat Technologies, GEM Co., Ltd., Gopher Resource, GRAVITA INDIA LIMITED, Li-Cycle, RecycLiCo Battery Materials Inc., Redux GmbH, Redwood Materials Inc., and Umicore N.V. are the top companies to hold the market share in battery materials recycling market.

The leading end-use industry of battery materials recycling market is automotive, building and construction, aerospace & defense, textile, and others.

Europe is the largest regional market for battery materials recycling market.

The battery materials recycling market valued for $26.2 billion in 2022 and is estimated to reach $56.9 billion by 2032

Loading Table Of Content...

Loading Research Methodology...