Table Of Contents

- Automation and Robotics Revolutionizing Manufacturing

- The Expanding Influence of Additive Manufacturing (3D Printing)

- The Internet of Things (IoT) is Transforming Manufacturing

- Growing Emphasis on Sustainable Manufacturing

- The Rise of the Circular Economy Concept

- The Bottom Line: Crafting Tomorrow’s Manufacturing

Sonia Mutreja

Pooja Parvatkar

Revolutionizing the Manufacturing Landscape: Top 5 Trends for Q1 2024

The manufacturing sector is a driving force behind global economic growth, continuously evolving to meet changing consumer demands. It plays a pivotal role in various industries, from automotive and electronics to pharmaceuticals and construction. In recent years, advancements in technology have revolutionized the manufacturing landscape, paving the way for increased efficiency, productivity, and sustainability. Allied Market Research has identified five key trends expected to shape the manufacturing sector in Q1 2024. Looking ahead, the manufacturing sector is poised for further transformation.

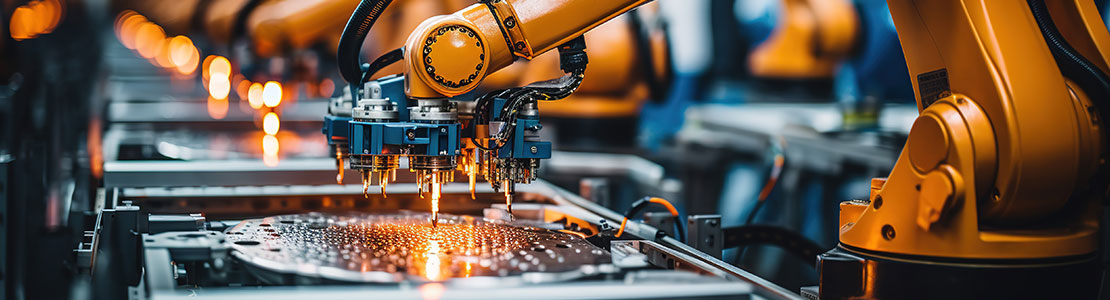

Automation and Robotics Revolutionizing Manufacturing

In an era of technological advancements, automation and robotics have emerged as game-changers in the manufacturing domain. These technologies offer numerous benefits, including increased efficiency, reduced human error, and round-the-clock operation. The relentless march of automation and robotics is not merely a trend but a revolution that heralds a new era in manufacturing. As industries embrace these advancements, the symbiosis of human ingenuity and machine precision promises unprecedented innovation and operational excellence in the manufacturing landscape. Industrial robotics is becoming more adaptable and intelligent, capable of performing complex tasks with precision. This trend is set to transform manufacturing floors by optimizing processes and enhancing overall productivity. By 2032, the global industrial robotics market is projected to reach $163 billion.

The Expanding Influence of Additive Manufacturing (3D Printing)

Additive manufacturing, commonly known as 3D printing, is poised to revolutionize the manufacturing landscape in 2024. This technology enables flexible production, customization, and reduced waste. Its applications are diverse, especially in prototyping and manufacturing complex parts that are challenging to produce using traditional methods. From crafting intricate components to prototyping products with unprecedented ease, additive manufacturing emerges as a transformative force, heralding a future where complexity meets efficiency on the manufacturing floor. Additive manufacturing empowers manufacturers to achieve greater design freedom and cost-effectiveness, opening new possibilities for innovation. The global metal additive manufacturing market is projected to grow at a CAGR of 18.1% from 2022 to 2031

The Internet of Things (IoT) is Transforming Manufacturing

The internet of things (IoT) is reshaping the manufacturing industry by connecting machines and enabling seamless communication with centralized control systems. This integration leads to the development of smart factories, where real-time monitoring and predictive maintenance optimize production processes. By leveraging IoT, manufacturers gain insights into machine performance, reducing downtime, and enhancing overall productivity. Efficient safety management on manufacturing sites is a major driving factor for implementation of IoT technologies in the manufacturing industry. This trend is set to drive efficiency and competitiveness in the manufacturing sector. The rising awareness regarding digital transformation in manufacturing sectors is driving the growth of the digital manufacturing market.

Growing Emphasis on Sustainable Manufacturing

Sustainability has become a critical focus for manufacturers worldwide. With increasing environmental concerns, companies are adopting sustainable manufacturing practices to minimize waste, optimize energy consumption, and incorporate recycled materials. They are also embracing lifecycle assessments to understand and mitigate the environmental impact of their products throughout their lifecycle. Sustainable manufacturing not only benefits the environment but also enhances brand reputation and attracts environmentally conscious consumers. Thus, the integration of eco-friendly materials, energy-efficient processes, and waste reduction strategies is gaining prominence.

The Rise of the Circular Economy Concept

The concept of a circular economy is gaining traction in the manufacturing sector. It involves designing products and processes that prioritize resource reuse and recycling. Unlike the traditional linear model, the circular economy promotes sustainability by prioritizing reuse, recycling, and reducing waste. This transformative approach encourages businesses to design products with longevity in mind, embrace eco-friendly practices, and minimize environmental impact. Manufacturers are developing sustainable supply chains, from sourcing raw materials to product end-of-life management. The tire recycling market and the metal recycling market are both witnessing significant growth as part of this trend. By embracing the circular economy, manufacturers contribute to reducing waste, conserving resources, and creating a more sustainable future. The global waste management market is expected to garner a revenue of $3,498.2 billion by 2032.

The Bottom Line: Crafting Tomorrow’s Manufacturing

As per Allied Market Research, the manufacturing sector is poised for a transformative period driven by technological advancements and sustainability imperatives in Q1 2024. Automation and robotics, additive manufacturing, IoT, sustainable manufacturing, and the circular economy are the top trends that will shape the industry. Manufacturers who embrace these trends will gain a competitive edge, enhance productivity, and contribute to a more sustainable world. It’s an exciting time for the manufacturing sector as it continues to evolve and innovate, meeting the demands of a rapidly changing global landscape. To obtain deeper insights, get in touch with our esteemed analysts.